In snow winters, no construction can do without such protective structures as ...

|

|

Finishing with tiles of walls and floor of the bathroom, toilet, kitchen requires a master of knowledge, ... |

The rafters serve as the basis of the entire roof structure, and their installation is one of ... |

Supporting the frame house: step -by -step instructions

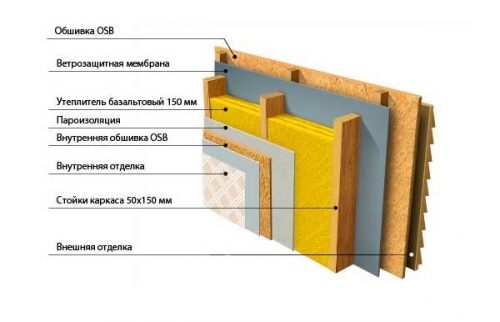

Frame houses are a wonderful option for quick and inexpensive individual development. However, despite these advantages, they have one significant defect: taking into account climatic features in most of the country, they require specific refinement in the form of large -scale insulation work. How and with the help of what can this task be implemented? There may be several options. It makes sense to dwell on the most popular ways to insulate a frame house.

Content:

- Options for insulation of the frame house

Options for insulation of the frame house

Insulation of the frame house with mineral wool

Mineral (stone) cotton wool in the role of thermal insulation material is chosen quite often.

- This is explained by its magnificent properties of sound absorption and heat preservation. It is an environmentally friendly and non -combustible material, and its five -centimeter layer can easily replace a brickwork by almost 60 cm wide (if compared according to thermal insulation characteristics).

- The main task of installing basalt wool is a competent and reliable protection of Rockwall from moisture.

- The formation of condensate on the material will nullify all its wonderful characteristics.

Therefore, if such an expensive material as mineral wool is purchased for insulation, then saving on special membranes and vapor barrier films does not make sense.

Insulation of the frame house photo

Squeezed of work during installation of stone wool

- Basalt wool slabs are placed in cells formed by the frame. It is collected in such a way that its vertical guides have a step strictly 60 cm. This is the width of the material produced in the roll. The chopped plate should enter between the racks a little with effort and stay tight, without sagging. As for the thickness of the insulation of the frame house, it is individual depending on the region of the country. In areas with a softer climate, layering of 10 cm is allowed where the winters are harsh, it will require a layer of 15-20 cm.

- To exclude the formation of cold bridges in the latter version, it is recommended to lay up as follows. The first two layers of mineral wool (each 5 cm thick) are laid in the crate cells. And the final is made so that the guide frame is blocked on top.

- Frame houses on the outside have a mandatory layer of vapor barrier, so before laying stone cotton wool, you can not duplicate it. But after all layers of insulation took their places, you need to create a protective layer from moisture and condensate on top. A single piece of material cannot be done. Therefore, the joints of a vapor barrier film are neatly and carefully glued with construction tape.

- Mineral wool is also used to warm the floor in the frame house. But its layer should be at least 20 cm. Work is performed similarly, as in the thermal insulation of the walls.

Scheme of insulation of the frame house

Insulation of the frame house video

Ecowata Alternative way of insulation of a frame house

This material belongs to the category of available insulation.

- This is possible due to the fact that it is made of two main inexpensive components: waste production waste, paper and waste paper.

- Both components form 80% of all material, a little more than 10% falls on an antiseptic to prevent the development of microorganisms.

- The remainder in this percentage is for an additive, the purpose of which is minimized by the heater of the insulation.

- The areas of the use of ecovata also include small construction, but not always owners of private houses make a choice in its favor. This is due to a number of features of the material, which for some masters are significant disadvantages.

- Good indicators of thermal insulation, which are attributed to ecovata, are reduced over time due to the fact that under the influence of natural processes, the insulation compresses and its volume is reduced. Losses can reach 1/5 of the total mass. In order to avoid such troubles, the material is laid with a similar margin. An excess of 25% will be a guarantee of maintaining the thermal conductivity of the material at the same level for the entire period of operation.

- Like everything that has the basis of paper, Ecowata can absorb a significant amount of fluid. The indicator in this parameter ranges from 9 to 15%. And with each of them the properties of the material are lost to retain heat. Therefore, it is extremely important to organize the insulated space in such a way that it is ventilated, and it was possible to withdraw moisture.

- The uniform volume of hardware slopes is able to provide only special equipment. It is believed that professional technology makes it possible to control the density of stuffing to minimize the shrinkage. Therefore, you will have to either hire professionals or gain experience yourself, risking to obtain the level of thermal insulation in quality below the expected.

- You can use a dry method of filling the voids. Its negative moment is the formation of fine dust, which is better to avoid the hollow and the respiratory system. The humid method of application requires drying the insulation layer for two to three days. Depending on the weather, the duration of waiting may increase. In conditions of limited time for the construction of a house, this is considered a big disadvantage. Although of the two ways it is the method of wet application that allows you to achieve the best results.

- Ecowan rigidity does not allow it to be used without the construction of the frame, when it comes to insulation of horizontal surfaces.

- Despite the additives that make the material less combustible, it is impossible to achieve complete protection against fire. Therefore, the use of ecowata is not recommended near the fireplace pipes, chimneys, and even more so near the sources of open flame. To exclude the possibility of smelling of insulation, a protective barrier is built between it and the heat source. As it, stone wool with foil coating or asbestos cement slabs are used as it.

- Particular attention to compliance with the norms for filling ecowide is required at the time of wall insulation or inclined structures. Ignoring the recommendations of the consumption of material at the rate of 65 kg per 1 m will lead to an ambulance and the formation of plots left without insulation.

The advantages of ecovy as a heat -saving material

It may seem that with such an extensive list of shortcomings, the use of ecowar is inappropriate. This is not true. Subject to the technology, the pluses of the material become even more obvious.

- You need to start with the fact that the material itself will not need so much. The above norm of 65 kg per m is not always required, and minimally ecowata is consumed from 28 kg per m.

- The insulation provides a decent level of sound insulation. A layer of one and a half centimeter does not miss the sound up to 9 dB volume.

- The environmental friendliness of this material does not need confirmation, if we recall what is its basis. Actually, the name speaks of this. During the fault, the ecovites during operation do not allergies at the residents of the house.

- The only thing that should be paid to when studying the composition indicated by the manufacturer what substance was used as an anti -beggarly additive. Antipyrene of the best quality is considered to be a drill (sometimes called Borax). Ammonium sulfates and boric acid can be culprits of an unpleasant persistent odor, and they do not provide prolonged protection against fire.

- Thanks to seamless laying, the material fills the space without leaving voids, therefore, there are no unprotected sites.

- The affordable price of insulation, coupled with good performance, often plays a decisive role in choosing material.

Technology of insulation of the frame house ecowide

As mentioned, there are two main ways for insulation with this material: dry and humid. The second option can be performed on water -based or using the adhesive composition. But no matter what excellent result he gives, the simplest and most popular method is the method of filling dry insulation. So, in order to perform work manually, you will need to perform the following manipulations.

- The floors are a little easier to warm. The purchased material must be loosened by a special apparatus, after which a pressed briquette weighing 15 kg will increase in a volume by three times.

- Equatus prepared in this way is covered between the lags. This must be done gradually, yielding layers. At the end, the material should form a small slide. Why is this excess already mentioned. It will be rammed under the weight of the boards.

- To carry out work on the walls, a layer of vapor barrier material is attached to the guides, or the lining of drywall or OSP is immediately made. This is not done to the end, but a gap is left through which Ecowata is falling asleep. She will gradually fill the space, compacting under her own weight. But at the final stage, it will have to be rammed.

- All actions are carried out using protective tools (glasses and mask-filter), and the filling process can be optimized if the installation that blows the material, while loosening it, is used for this. Some construction companies provide the opportunity to rent such equipment.

Foam and polystyrene foam for insulation of the walls of the frame house. What to choose

Both of these materials have a practice of application in frame houses. They insulate facades on the outer and inside of the building. With some similarity, the foam loses to its opponent in most indicators, but due to a good heat -insulating characteristic and cheapness, it is in demand. Among the obvious shortcomings can be noted:

- not very high -quality sound insulation,

- highlighting harmful substances during combustion

- and the obvious interest in him from the rodents.

Insulation of the frame house with foam from the outside

- The surface will have to be prepared with all the supporting structures. For this, nails are necessarily removed, the remains of other materials, cracks are closed. A flat surface will exclude air gaps between the wall and polystyrene. After leveling the surface, it is treated with a primer intended for work outside. The consumption of the composition is from 150 ml per m.

- The field of how the primer dries, the system of vertical suspensions with a step of 60 (70) cm is built. Due to this, it will be possible to prevent distortions when fastening the plates of the material. Foam is planted on glue, which is applied at five points in the form of small piles, and an adhesive strip is completely drawn along the perimeter of the plate. The canvas with glue tightly and with force is pressed to the base. Subsequent rows are laid in the manner of brickwork, that is, a frame. A portion of diluted composition needs to be in time to use it within an hour.

- If the laying, inconsistencies between the sheets of the material are formed or irregularities are formed, then all such defects are eliminated using a sharp and heated knife. The creeping gaps can be embedded:

- a mixture of crushed foam and glue,

- penoizol (liquid analogue of the material),

- mounting foam.

- Plastic dowels create an additional mount for insulation. They will be required in an amount of at least five pieces per plate. The following is fixed by the entire structure with fiberglass for special strength, and special profiles for the corners will create reliable stiffener ribs. The putty is best applied to two layers, and the final finish can become, for example, facade paint.

Insulation of the frame house with foam from the inside

The technology for performing indoors is similar. The stage of surface preparation differs only in the use of primer materials for internal work.

- As an adhesive composition, you can use the usual tile glue for ceramic tiles. The use of dowels is also desirable.

- As for the sizes of cells on the reinforcing grid, they can be from 3 to 6 mm. It is necessary to fasten it with a overlap and tightly pressing it to the foam.

- Often, drywall is used as the final layer. We must not forget about the mandatory sealing of the seams.

Insulation of the frame house with a foam

- Polystyrene foam in installation differs from foam with increased requirements for creating protection against moisture and sunlight. The technology of fastening on the wall has no fundamental differences.

- What specifically prefer, you will have to decide on your own. Both materials are really different, including in price. The latter is more expensive, but it is more durable and dense.

Warming with a glass -wool house with your own hands

Some do not take into account glass wool, considering it the material of the past generation, but in vain.

- Modern representatives of insulation of this category differ from their predecessors with improved characteristics. In addition, it costs less than its counterparts, and heat is able to hold well enough.

- The principle of its installation is the same as that of stone cotton wool. That is, in order to insulate, for example, floors, the material is cut from the roll so that it is a couple of centimeters wider than the distance between the lags.

- Before laying, create a waterproofing layer. It can be both only and polyethylene.

What is the result of insulated the frame house is not so important, the main thing is to proceed from their own strengths and capabilities and observe the technology in everything.