From an early age, the child needs personal space so that he can feel in ...

|

|

To protect the home from heat loss in the winter season, as well as improve the exterior ... |

Porcelain tiles - ideal for decorating garden paths, territories near ... |

The device of the polymer roof

Nowadays, the building materials market continues to improve. And if new inventions are used, then when minimizing costs, the expected results are increased. A successful example of this trend is an increasing interest in polymeric materials for the roof, since polymer roofing coatings qualitatively protect the building from the penetration of various atmospheric precipitation in the form of snow, hail, rain, etc.

Content:

The essence of the polymer roof

Polymer roofing materials very quickly gained consumer trust and the construction market due to excellent operational characteristics, such as high elasticity, greater strength, significant resistance to mechanical damage, resistance to environmental factors, and the lack of need for special equipment to care for polymer roof.

Polymer membrane roof

When, when arranging a roof, not only its durability, but also environmental friendliness is put in the first place, it is recommended to pay attention to polymer membranes. Their main feature is elasticity, which makes it possible to work with them when decorating the roofs of a complex configuration. Rolled materials have a large thickness, which reduces to a minimum the number of necessary seams. In addition, the sheets of material, as a rule, are fastened together under the influence of hot air, so such a polymer roof is a monolithic structure.

Polymer membranes are not afraid when ultraviolet radiation affects them, and are resistant to various weather conditions. Such a polymer roof makes it possible to achieve the effect of a breathing roof, since condensation does not form under it in space. The polymer roof from membranes helps to reduce the load on the rafter system due to the lightness of the material. Because of this, the membranes are quite often chosen during the construction of fast-far-fetched houses.

Liquid mastics and membranes are used as finished independent roofing coatings or as a layer inside the roof pie (as part of an inversion roof). Roofing polymer membranes are perfectly in demand due to the fact that with their help very interesting and durable roof coverings are built. And all this is complemented by a large assortment of the colors of membranes.

Our market has three main types of polymer membranes: PVC-P (PVC), EPDM (EPDM) and TPO (TPO). EPDM coating is made on the basis of synthetic rubber and has been used for a long time. The very first roofs that are covered with such material have been in operation for forty years. The EPDM membrane is very elastic and lightweight, and glue or self-adhesive tape is used for its installation.

PVC membranes are characterized by quite high quality, long -term operation and elasticity. Usually, in the manufacture, such membranes are reinforced with a polyester grid, and the connection of individual scales occurs by welding with hot air. In the upper layer of such a roof membrane, a special composition is added, which increases the stability of the material to atmospheric precipitation and the sun.

TPO membranes are based on polypropylene and rubber. Basically, when using membrane roofs, membranes with reinforcement are chosen, as they are more durable. Connecting seams are made using welding. Of the three of the above species today, TPO and PVC membranes are most popular, as they provide the speed of the roof installation and its strength. Such materials also meet the highest safety standards.

However, roofing membranes has one drawback: the price of a polymer roof is approximately 30% higher compared to polymer-bitumen material. But this fact is compensated by a long life, since manufacturers give a guarantee for 10-20 years, and some specialists are up to 50 years without repair.

Polymer bulk roof

There is another method for installing a polymer roof called a bulk. The roof covering after performing all the roofing work will be similar to continuous material that a trip to rubber. With such a coating, there are no seams, the material of the material has reinforcement (ordinary fiberglass) and waterproofing (polymer mastic). Among the advantages of the bulk roof, complete tightness, elasticity, high strength, resistance to atmospheric phenomena, ease of installation, parony permeability, and long -term operation are distinguished.

The basis for the installation of the bulk roof are reinforced concrete and concrete slabs, wood, screeds of cement-sand mortar, insulation plates, metal, flat slate, old roller coating. Reflective indicators of the bulk roof can improve due to the coating with special paints.

For the arrangement of a bulk roof, it is customary to use two types of materials: polymer and polymer-response coatings. To date, the first option is most often chosen, as it has many advantages. The installation of a bulk roof itself is quite simple. The base is preliminarily prepared and then a specially prepared composition using a roller or spatula is evenly applied to it.

Nowadays, another type of polymer roofing polyurethane bulk coating has gained popularity. Such material makes it possible to organize a holistic coating that looks like rubber. It is convenient to work, even if there are rather complex areas like pipes and ducts. Polyurethane copes with the action of atmospheric phenomena and all sorts of aggressive environments, and the polyester canvas ensures its long -term operation.

Another type of bulk material made on the basis of a polymer is called polymochevin. The origin of this roofing is associated with organic matter. If you nevertheless opted for such a coating, then you will not be mistaken with its reliability: its wear resistance is higher than that of the highest quality ceramic tiles for the floor. In addition, polymochevin is used in the process of construction work in order to organize waterproofing.

The advantages of polymochevins, which give it over other materials, are: speed of setting - within one hour, the possibility of installation with cold up to minus 15 degrees and high humidity, resistance to high temperatures and solar exposure, long -term operation, electrical insulation, environmental friendliness, complete compliance with fire safety requirements.

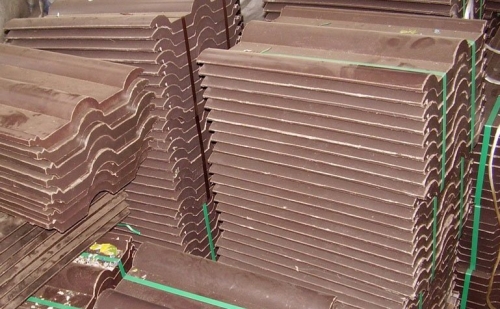

Polymer-sand tiles

The tiles of the polymer-sanded in itself combined the virtues of all roofing coatings. It acts as a high -class material that has no analogues. Polymer-sand tiles are a composite, that is, a multicomponent material that consists of a plastic base reinforced with fillers, which have rigidity and strength, and these qualities convey the final product.

Polymer-sand tile is made of molten polymers, sand and dye. Such a wonderful combination of components determines the main properties of this roofing material. In the tile, 70% of the sand determine mechanical resistance and strength to the influence of the environment. The link is 25% of the polymer. Thus, melted plastic and sand, as a whole, make up a homogeneous mass, which is pressed hot under a pressure of 130 atmospheres.

Such a frozen mass cannot be destroyed. This monolith can withstand loads up to 350 kilograms per centimeter square. The roof can resist the shock load, and this makes it invulnerable during transportation and installation, unlike natural tiles. Special additives and heat-resistant high-quality dyes that have light stabilizing properties protect the polymer-sand roof from ultraviolet radiation.

One meter square polymer-sand tile has a weight of 18 to 23 kilograms, which is 1.7 times lighter than a square meter of ceramic tile and 2 times easier than a cement-sand roof. This makes it possible to save on the device of the rafter system. The coating does not lend itself to corrosion, is resistant to aggressive media (salts, alkalis, acids), is not subject to the destructive effect of bacteria, fungi and the growth of mosses, and is also characterized by shocking properties.

Polymer-sand material under the influence of sunlight does not overheat, and this contributes to the preservation of the heat in the sub-circuit space and the absence of condensate tile coating on the inner surface. Such qualities give the material enviable durability: according to the manufacturer, the life of such a tile is at least 50 years, and some companies give a guarantee for 15 years. It must be announced that the tiles of the polymer-sand is a combustible material, but at the same time not spreading the flame and is difficult to flammable.

The house is covered with a beautiful and durable polymer-sand roof is very simple. Laying of polymer-sand tiles is performed similarly to the installation of natural tiles. The polymer-sand tiles on the crate is hung and fastened with self-tapping screws or nails. The overlap is closed with two locks and reliably protects the roof from damage.

Laying a membrane roof with your own hands

The technology of installation of membranes is quite simple, so the arrangement of a roof made of polymeric materials does not take much time and time. You can put the flooring on a tree or on concrete at any angle. Of course, the device of a membrane roof is primarily provided for flat roofs, but still in practice it is proved that such a soft roof is well laid on the roofs of houses with the attic.

Installation of a membrane on a crate

For laying the PVC membranes, the crate should be continuous. When re-overlapping the roof, if earlier there was a roofing material or some other soft roof, it is worth performing a cosmetic cleaning of the base: remove irregularities, cut off bloating so that the surface is perfectly flat. But the remains of the previous old coating is not a hindrance for the installation of a membrane roof, because the waterproofing is not disturbed.

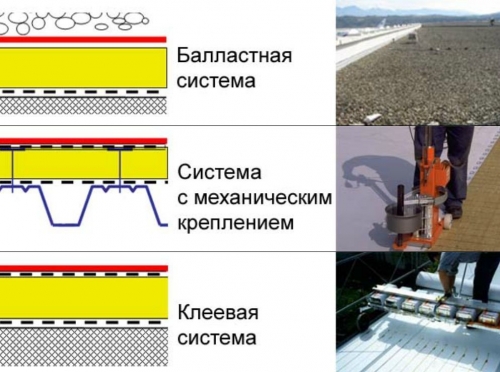

To date, three methods of installing a membrane roof are distinguished. The first method is called glued. The name speaks for itself, but still it is necessary to delve into the details. In this case, with the help of special glue, a membrane coating is fixed on the base of the roof. If your roof has many different slopes, architectural protrusions, corner slopes and similar elements, then it is necessary to choose this particular option. This method is also suitable for tent roofs. Before the application of mounting glue and fixing the coating on the roof, it is necessary to cook the sheets firmly with each other.

Holders of houses with flat roofs can use the ballast method of attaching membranes. A membrane coating is simply laid on the base, and then it is fixed along the perimeter of the roof from the end sides. In order not to move the membrane coating, it is necessary to place it under the loading ballast, which should be placed in a special way. The weight of the ballast should be about one square meter of about 50 kilograms. You can choose for ballast any material crushed stone, blocks, tiles. But it should cover the roof over the entire surface. In order for the roof to withstand this useful load, it should have a continuous crate and a strong rafter system.

Another way to install a membrane roof is mechanical. This method is used when additional loads cannot be created on the roof. In this case, we recommend that when choosing a roofing, stop on PVC or TPO membranes. In places of joints, materials are mounted using special screws. The overlap is made here at least 12 centimeters, they are attached to self -tapping screws with specialfurnitis, and the places where fasteners are produced are brewed.

The installation of a membrane roof with your own hands must be started with fixing membrane sheets along the edges of the roof. If a wooden crate was created, then the edges of the canvas are attached with a plastic sleeve with a self -tapping screw. If the membranes are laid on a concrete basis, then dowel-gvo and bushings are used. The quantity and type of fastening is affected by the design of the roof, climatic conditions of the region (wind force, the number of wind days), as well as the shape of the roof.

Membrane connection among themselves

When installing a polymer roof, the combination of membranes can be made in three ways:

- Diffusion welding using a solvent. When using diffusion welding with a solvent on a dry clean surface of the connection, a special substance for diffusion welding is applied and cargo is laid on top. Between the membranes, the floor should be at least five centimeters. In a welded joint, the minimum width is 3 centimeters. Diffusion welding is a reliable and simple way to connect roofing membranes at open -type construction facilities. In rooms of a closed type, the use of a solvent is limited.

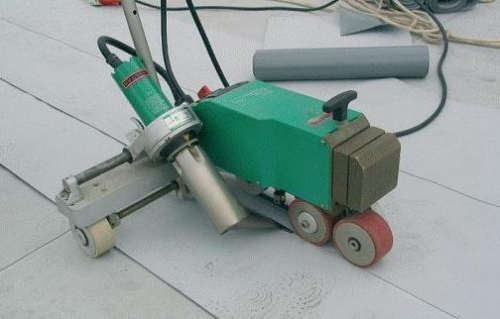

- Welding with a welding machine (using hot air). After the first sheet has been fixed mechanically, the second overlap is placed. In order to avoid wrinkling the material, it is necessary to roll the roll along its entire length and fix it in one of the corners. The material is pulled to the opposite side and the other angle is attached. This makes it possible to hold tightly during the leaf process. Next, bend the edge of the membrane, which is closest to the skiing wheel. After that, a forty -mulimeter hairdryer is installed in the gap that turned out and then turn on the electric motor.

- Welding with a welding hair dryer. Roof membranes are laid so that the overlap is five centimeters. With a manual hairdryer with a flat or round nozzle in a dot method, the membranes are boiled from their inside, and after that, the front edge is welded.

The welding connection is used for many roofing polymer coatings. To do this, use automatic or manual equipment, which makes it possible to perform hot air welding. For manual welding equipment, the optimal nozzle width is 40 millimeters. It should be without damage and clean. The device is heated to 550 degrees before use.

It is recommended to practice before starting work, take unnecessary pieces and try to connect them. When using a manual tool, it is necessary to control the correctness of the angle of inclination, the set parameters and the cleanliness of the nozzle. Make a minimum overwhelming for this, equal to six centimeters, and use a heated apparatus, grab a point of fixing a point for fixing.

When installing whole canvases, the size of the overlap should be at least 6 centimeters. It is also necessary to grab the material point of every half meters. The nozzle should be located at an angle of 45 degrees. Careless jerky movements and excessive pressure on the plane are not allowed. An indicator of the correctness of the action will be the formation of a light smoke of white color.

To connect the membranes, it is necessary to install in the correct position the heated equipment. Spend a confidently line, while acting on the surface with hot air, and immediately hand over the reverse surface with a small roller from silicone. Remember the clarity and smoothness of your movements! Now it is necessary to check the correctness of the connection. To do this, try the seam that has cooled, break. You can determine the quality of your work performed as follows:

- If it was torn at the seam of the membrane, this suggests that a high temperature was set, and therefore the canvases were not properly connected.

- If the seam did not form at the welding site, then the surface simply sticks together. Such a bad connection indicates an too low operating temperature.

- If the panel was exploding not at the seam, but near it, then you can congratulate you. You combined the layer of material correctly, so you can proceed to the continuation of the creation of a polymer roof with your own hands.

Thus, polymer roofs firmly fixed their positions in the building materials market and established themselves as durable and high -quality roofing material. The polymer roof device is very popular in the construction of large industrial and residential buildings that have flat roofs. Throughout the entire period of operation, you can not worry about the strength of the design: it is not amenable to deformations and destruction.