Any person dreams of living in a private house with a personal plot, and very often ...

|

|

The roof is not just the protection of the building from the weather, but also the logical ... |

The concrete screed of the floor is the most common base in apartments and private ... |

How to lay paving slabs with your own hands

Porcelain tiles are ideal for decorating garden paths, territories near the house, garage or recreation areas. The cost of laying paving slabs is quite high, having performed this process with your own hands, you will be able to save significantly. We’ll talk about how to lay paving slabs with your own hands.

Table of contents:

- Material manufacturing technology and photo stacked paving slabs

- How to lay paving slabs: advantages and disadvantages of the material

- The main varieties of paving slabs

- How to properly lay paving slabs - general information

- How to properly lay paving slabs on the sand

- How to lay paving slabs on a concrete base

Material manufacturing technology and photo stacked paving slabs

For the manufacture of paving slabs, concrete is most often used. The mixture for the production of tiles contains cement, water, plasticizers and other fillers. I exist certain requirements for the manufacture of tiles due to GOST.

In order for the tile in the end to get high -quality and served its owners for many years, it is necessary to exactly observe the technological process of its manufacture and dosage of materials. In some expensive tile options, clay, granite crumbs or polymer sand are also present.

The shape of the tile depends on the preferences of the customer, it is rectangular, triangular, square, diamond, hexagonal, etc. The color of the tile is determined by the coloring pigment that is part of it. Most often, sandy, olive, brown or beige tiles are produced.

How to lay paving slabs: advantages and disadvantages of the material

Porcelain tile is a fairly popular material for the decoration of the sidewalk. The scope of its use is quite diverse. With its help, not only alleys, parks and squares, but also private houses and cottages decorate it. This material differs not only in an attractive appearance, but also with good performance.

Among the advantages of using paving slabs we note:

- Destability to frost is an excellent quality of this material that provides long -term operation;

- Environmental safety - in the production of tiles, substances harmless to the human body are used, which in the process of heating do not secrete toxic substances;

- The duration of operation is another important advantage that ensures the popularity of this material in the process of finishing, the technology of manufacturing tiles implies the use of special pressing, which makes the tile high -strength and persistent before mechanical damage;

- The tile does not need additional care, it is easily washed and cleaned with water;

- resistance before moisture and other external environmental stimuli ensure the ability to lay tiles on the street;

- Aesthetic attractiveness is another important advantage of this material, distinguish tiles of different sizes, colors, textures, while it is used for both household and industrial purposes;

- The affordable cost is provided by cheapness of materials that are part of the tile.

However, this material is distinguished by the following shortcomings:

- The presence of seams between the tiles leads to the fact that they accumulate dirt, worsening the appearance of the coating;

- Ice, which accumulates on tiles in winter, makes it slippery;

- If you do not follow the technology of laying the material, the tiles in certain places are subsided, you have to dismantle it and lay it again;

- If tiles with high porosity are selected, then moisture accumulates in it, which later destroys the material with severe frosts.

The main varieties of paving slabs

Before laying the paving slabs on your own step by step, we recommend that you familiarize yourself with the varieties of this material, since the styling technology for each type of tile is individual.

First of all, paving slabs are whole and pressed. The scope of use of each of these tile options is diverse. Cast tiles are used in the process of arranging the territory in front of private houses, and pressed - in the process of decorating city parks, squares, paths, etc.

In the technological process of the manufacture of tiles, the processing of dry composition with vibropress or vibrating is used. We offer to familiarize yourself with these processes in more detail:

- Vibration implies the laying of the concrete composition in a special form, installing them on coating, constantly amenable to vibration. After compacting the composition in the form, it is removed from the surface and installed in the furnace for twelve hours, holding there at a temperature of 385 degrees. To improve the quality of tiles, various plasticizers are added to the concrete composition.

- The second method of processing the material implies its vibration pressing. The concrete composition is laid in the press forms that are installed on a constantly vibrating table. Initially, the matrix is \u200b\u200binfluenced by the press, then it is compacted under the influence of vibration. After giving the composition of the necessary shape, the matrix rises, and the tile remains on the table.

For the further use of tiles, it is necessary to wait for its complete solidification. The casting method of manufacturing tiles is cheaper and lightweight, it does not need additional equipment and technological processes. Therefore, cast products are distinguished by a variety of colors, shapes and colors.

Keep in mind that the tiles of overly saturated color implies the use of a large number of dyes in the process of its production. This factor negatively affects the performance of the material.

Vibro -pressed tiles are more expensive, since its production requires specialized equipment. This version of the tile is more frost -resistant, moisture resistance, it practically lacks pores, but such tiles do not differ in a variety of colors and shapes.

How to properly lay paving slabs - general information

The method of laying paving slabs depends on its purpose:

- functional - laying material on office roads, pedestrian paths, in front of private houses in places with increased operational load;

- Decorative - manufacturing from tiles of beautiful patterns, original designs, etc.

In the ratio with the base on which the tile is laid, it should be noted:

- Sandy base - needs thorough tamping, used on pedestrian paths, not suitable for moving vehicles along it;

- the use of dry - cement -sand mixture, as it solidifies, it helps to form a strong base, it is located for the decoration of parking lots;

- The use of adhesive solution on a cement basis is this method of installation of paving slabs the most expensive, but also the most reliable, the base is initially filled with concrete, then the tiles are laid on a special glue.

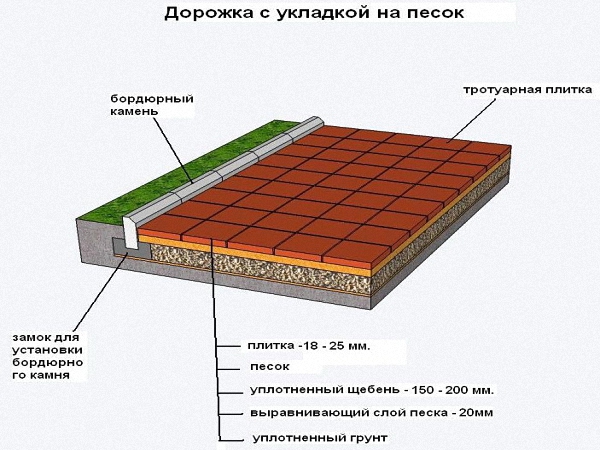

How to properly lay paving slabs on the sand

Most often, the shape of paving slabs is rectangular. There are many schemes according to which the laying of the tiles is performed - the most popular of them: Christmas tree, brick or laying in the form of columns. Porcelain tile has gained popularity due to the ease of its installation. Properly laid tiles will serve its owners for more than a dozen years.

The type of base on which the tile is laid is determined by its thickness and purpose. In any case, it is initially necessary to remove the soil 15 cm into the base, align it and arrange a slope for water drainage.

The following is the process of tamping the site using sand. For this, sand, as it falls asleep, is moistened and well trimmed. Pay special attention to the thickness of the material, if the tile is intended only for the movement of pedestrians, then a thickness of 2 cm, otherwise, this value increases to 4-6 cm.

Before laying paving slabs on the sand, prepare materials in the form:

- sand, the amount of which depends on the total area of \u200b\u200blaying;

- paving slabs;

- border elements;

- cement;

- a hammer of ordinary and rubber;

- steel pegs

- shovels;

- leveling;

- Bulgarians.

After forming the slope of the area of \u200b\u200bthe site on which the tiles are laid, the area should be divided into stripes. However, the strip should be equal to the width of the rule. In order to divide the site, use pegs and threads. Next, the site is aligned using sand.

After that, the process of direct laying of the tile follows. In order to prepare a sandy cement mixture, you should combine the sand with cement in the ratio of six to one. Keep in mind that the sand should be moisturized. It is recommended to carry out work in the autumn-spring period. The prepared composition is evenly distributed in one lane, carefully compacted. Next, under the thread, which distinguishes the site on the zones, a steel pipe is installed. After thoroughly aligning the site, the sand and cement composition is laid tiles. Install the first tile starting from the corner, thoroughly align it in the ratio with the marking. Tap it with a rubber hammer. In the same way, lay the second tile. Start work on yourself, thus, laying the tile, you will move on it.

If there are any obstacles on the site, it is bypassed by whole tiles, and then adjusted at the end of the work. After completing the work, the tile is sweeping from sand. To fill the cracks between the tiles, the same solution of sand and cement is used in the ratio of six to one. All cracks should be carefully filled.

Laying square paving slabs is easiest. To trim the tiles and fitting it, use a grinder and a disk with diamond spraying. At the edges of the tile laying, install the curbs. For their fixation, a thick concrete solution is used. In the presence of areas that are subjected to special load, for example, near the gate, it is preferable to lay the tile on the concrete base.

How to lay paving slabs on a concrete base

Sometimes there are situations when you have to lay paving slabs on a pre -flooded concrete base. This styling method provides greater strength of the material. Transport and heavy equipment can ride a tile laid on a concrete base.

Initially, the site is launched for laying. Next, the curbs should be installed initially, having previously calculated the place of their location. If the height of the curb is about 50 cm, then it is placed in a trench by 25 cm, while 10 cm of the trench should be covered with a crushed stone, 15 mm trenches are poured with concrete solution, then the curbs are mounted in such a way as to help the removal of moisture from the tile.

If the base is subjected to high operational load, then before pouring the concrete layer, it is recommended to reinforce it. Laying paving concrete tiles should be laid in compliance with all technological nuances. To reinforce the surface, a grid is used, the thickness of the cells of which is 15 cm.

For additional removal of moisture from the tiles, it is recommended to equip special openings of drainage purposes. For these purposes, an asbestos pipe cut into areas, the height of which is about 150 mm, is suitable. One piece of asbestos pipe is installed on one square meter.

This is followed by the process of preparing a concrete solution, which covers a area of \u200b\u200b15 cm, if there is no reinforcement on it and 20 cm, in the presence of reinforcement. When pouring a large section, after three meters it is necessary to leave the gaps for the temperature seam. To do this, the boards are installed, then after grasping the concrete, they are taken out.

24 hours after the filling, a wooden formwork is removed, and drainage holes are filled with a gravel. In order for the tile to hold well on the surface, it is laid on a mixture of sand and cement.

To mix them together, use a concrete mixer. The thickness of the sand layer is about 10 cm. A vibration plate or toptouch is used for the trambling of the composition. Follow the presence of a slope on the surface to provide water stack. A rubber hammer is also used to fix the tiles. Work should start from the curb, gradually moving to the top point of the site. Using the level, the surface is checked for evenness, if necessary, tiles are adjusted using a rubber hammer. To fill the joints between the tiles, the same solution of sand and cement is used. Through these seams, moisture will enter the drainage holes and E will accumulate in the tile.

How to lay paving slabs video:

Trotuar-moskow.ru

Trotuar-moskow.ru

R & k system address: Moscow

R&K Stroy

Address: Moscow region, Dolgoprudny, microdistrict Khlebnikovo, st. Gorky, 1

Phone: +7 (919) 962-58-85

Opening hours: 09: 00-22: 00

Site: http://rk-stroy.su/