External slopes are an important detail of the window structure. They are mounted not only ...

|

|

Laminated doors fit perfectly into the interior of any room, thanks to ... |

The rhythm of the modern city, high concentration of the population, technological progress ... |

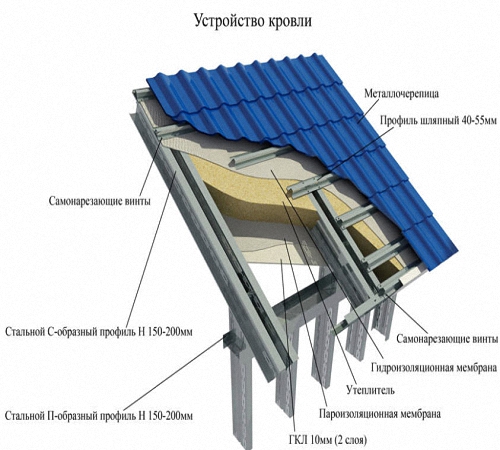

The device of a metal roof

Thanks to the presentability of the appearance, the metal roof is quite popular roofing material among the owners of country and private houses. There are several of its varieties that differ in forms and installation technology. We will talk about how to equip a metal roof and about its features.

Table of contents:

- Characteristic and advantages of a metal roof

- Varieties and construction of a metal roof

- Installation and device of a metal roof

Characteristic and advantages of a metal roof

The metal roof is made of various kinds of elements, the role of which are polymers, pools, polyesterers, plastizols, polyvinyl chlorides. The type of coating is determined by the functional load on the surface and the features of the use of roofing material.

For example, a panel -based roof is stable in front of ultraviolet, and the plastisol is before mechanical influences.

The scope of the metal roof is diverse. It is installed at residential and industrial facilities. For installation of this kind of roofing, it is not required to use special efforts or use special equipment. But before installing it, without fail, the requirements and its operational load are clarified. For example, the metal tile should in no case contact with the bitumen surface or with a profiled sheet. Since corrosion appears on the inner parts of the material, leading to premature damage.

There is an opinion that it is precisely because of the metal roof that lightning will easily get into the house and lead to its destruction. But, subject to the technology of installation of a metal roof, this statement is incorrect.

Another material from which the metal roof is made is galvanized steel of a cold -roll type. The procedure for its manufacture includes several complex procedures, at the end of which the material acquires certain positive properties.

Although the price of a metal roof is high, it is still quite justified by its advantages, namely, the durability of operation and the practical lack of need for care. When choosing a roof, which is based on high -quality galvanized steel, it will serve its owner for more than fifty years. Also, the metal roof is environmentally friendly, harmless to the environment.

Among the huge assortment of color and textured products, the consumer will be able to choose the option that will fully satisfy all his preferences. The roof made of metal is quite light, so it does not load the design of the building, is easily transported to the destination object and is installed on the roof.

The arrangement of this type of roof does not require the construction of a certain flooring, just remove the old coating and install the roof on wooden beams.

Another important advantage of this type of roof is its fire safety and fire resistance. Despite the fact that the metal is a good conductor of electricity, with the proper organization of the lightning system, such a roof is not able to pull the zipper into a thunderstorm.

A roofing slip of the slippery surface practically does not accumulate dirt, leaves in the autumn or snow in winter, so it does not need special care.

The metal roof is installed on any types of surfaces and roofs, even with a very low level of slope.

Although, among the huge number of advantages of a metal roof, one should mention its shortcomings. So, for example, a too steep roof, because of a high level of slippery, snow does not accumulate, and it falls to the surface located next to it. At the same time, there is a risk of wounding people who are nearby. Therefore, for such types of roofs it is required to install special pegs that will help to crush snow or ice into small particles, which are non -hazardous to human health.

High noise production is another disadvantage of this type of roof. During the rain, snow or hail, the sounds of their touch with a metal surface are clearly heard, although when arranging high -quality soundproofing, this moment will easily settled.

In addition, this type of roof needs to equip additional thermal insulation.

Varieties and construction of a metal roof

There are several varieties of a metal roof, among which we will highlight:

- flat metal roof in a roll or leaf version - for their implementation, compliance with folding technology is required;

- metal tile - in appearance resembles ordinary tiles of tiles, for the manufacture of which a profiled metal sheet is used;

- coatings are based on non -ferrous metals;

- Name roofing metal - used to arrange one- or gable types of roofs.

For the correct choice of a certain type of roof, their composition, characteristics, technical features and in the ratio with operating conditions are clarified, the most optimal option is selected. In addition, you should find out about the presence or absence of polymer coatings applied to the metal roof in the process of its manufacture, it is they who give it the properties of anti -corrosion, stability before ultravioletus, etc.

Among the market assortment of products, there is a wide variety of shapes, profile geometry, color palette and varieties of polymers located on a metal roof.

In relation to the type of basic substance that is part of the metal roof, it is divided into:

- copper;

- aluminum;

- galvanized;

- from stainless steel.

The first option, although it is distinguished by its original brightness, but soon fades, and even turns green. Copper is great for covering monuments and sculptures. The service life of the copper roof is more than two hundred years.

In addition, aluminum roof is highly popular. This is justified by its slight weight, stability before corrosion and ease of installation work. Aluminum is not inclined to change color during operation. In addition, it is highly plastic and allows you to make a roof of various shapes. The aluminum roof will serve its owner for more than a hundred years.

A metal roof made of galvanized steel has high anti -corrosion stability. Its life ranges from 25 to 45 years. The technology for installing this material implies a careful attitude to the zinc layer applied to the surface, since when it is damaged, there is a risk of corrosion. To extend the service life of such a coating, special paints are used, which are processed once every four years.

Another option for a metal coating is galvanized steel, on which polymer spraying is applied. They are able to better protect the roof from the influence of the external environment. Pural application helps to protect the roof from ultraviolet exposure, and also improves its stability before mechanical influence. Puralum roof has a variety of textures and flowers, it is matte and glossy. The polyester coating is very vulnerable to mechanical damage, therefore, in the process of installing such a roof, special caution is required.

The most optimal option is to cover stainless steel, characterized by excellent resistance to external influences, but at the same time with a rather high cost.

The choice of metal roof depends on the thickness of the material, which is from 2.6-2.9 cm.

One of the most modern roofing materials of metallic origin is a titanium-tohy coating. Although zinc is stable before corrosion, its main drawback is its brittle properties. Therefore, the use of this material, when constructing a roof of a complex form, is not possible. The material of the titanium-tohy composition contains 99 percent of zinc and a mixture of aluminum and copper alloys that make it strong. This type of roof will last its owner for more than 75 years. Titano-toy coating is unstable before mechanical damage and neighborhood in the form of large trees. But with its help it is possible to build a roof of almost any complexity, including it perfectly equips the nodes of a metal roof.

Installation and device of a metal roof

The hardest in the arrangement is the roof of a metal folder, since for its installation it is necessary to correctly and efficiently connect the edges of the sheets bent under the phats. There is special equipment that produces this process directly on the surface of the roof. In addition, the option of buying already bent sheets and their direct connection is possible.

A roof of metal sheets is a simpler and preferred option. Sheets of the desired size are cut off at the construction object, with the help of a special camp, the edges are wrapped with which they are interconnected.

The installation procedure of a metal roof is divided into several stages, which we propose to consider:

1. Carrying out work on arranging a rafter system and crate.

This procedure is the same as when installing any other type of roof, for example, tiles. The installation of rafters is characterized by an average step, because the material is quite light and does not load the structure. For the manufacture of the crate, a beam of 5x5 or 5x10 cm is used, installed with a step of 2-2.5 cm. It is this technology that minimizes the deformation of the metal roof during its operation. When arranging a flat roof, the crate is continuous. For the manufacture of the ridge, two boards are used, connected to one point at the edges. The cornice is continuous, for its construction it is necessary to knock down several boards together.

2. Waterproofing work on the preparation of the roof.

To minimize the appearance of condensate masses on the surface of the roof and inter -winged space, it is necessary to carry out a number of works aimed at waterproofing the back of the roof. In the case of working with a previously insulated roof, a crate must be attached to the rafter system, and a waterproofing superdiffusal membrane is already on it. It has excellent moisture -repellent properties, but at the same time allows the roof to breathe. The mounting of the waterproofing begins below with the gradual transition to the top. With the help of construction tape, the sheets are fixed on the surface, if there are joints, they are overlapped by 10-15 cm. The option of fixing the membrane and dowel-grooves is possible.

Tip: When fastening the film, leave its small space in the form of a sag, which in severe frosts will protect it from narrowing, excessive tension and damage.

Next, the control metal frame of the roof occurs. As a result of this, two ventilation gaps are formed in the space between the waterproofing and the layer of insulation, waterproofing and roofing finishing material.

3. Installation and fixation of a metal roof.

The installation of a metal roof should begin with the installation of crutches. They are nailed to areas on the cornice with a step of 700 mm. Their main function is the retention of metal sheets on the roof during installation work.

It is possible to replace crutches made of wood, using steel corners in size 5-6 cm.

Next, up the first picture of metal is raised upstairs, on which the edges are already bent. It is laid near the pediment in such a way as to form an overhang of 4-6 cm. Lease the sheet and leave the edge 3 cm to ensure the transition to the other side of the roof.

Installation of the Kleimers is carried out from the side of the second sheet. It is fixed on the metal crate of the roof using screws of 0.4x5 cm. The side of the clamp fixation is about half a meter. After installing the second picture, they are connected with the first. This is done in such a way that the edge of the second canvas is tightly put on the first. When arranging a roof with even edges of the paintings, make sure that they are in the immediate vicinity of each other, and a Klaimer is clamped between them. Roofing frames will help make a fold and complete the installation.

Due to the fact that Kleimer is inside the fold, the connection acquires an additional fortress.

Tip: PR operating buildings in conditions of high humidity, worry about the conduct of additional sealing of the butt sections of the roof. This can be done using the sealant of titanium, which is applied to pre -installed fiberglass.

Kleimers are also nailed from the other end of the canvas and the third is installed. With the help of a lateral windbreak, the picture is fixed on the surface of the pediment. It is fixed using self -tapping screws. After the laying of all the paintings is completed, the skate is performed, which is of two types:

- ventilated;

- non -premised.

Next, the arrangement of cornice overhangs and the installation of the drainage system occurs.

4. Metal fencing of the roof and additional work.

Without fail, snow retainers are installed on the metal roof, which prevent an avalanche -like convergence of snow from the surface of the roof. The fastening of these elements occurs on the surface of standing folds using screw or self -cutting joints. For the manufacture of fences, profile pipes are used.

Another important final moment is the arrangement of lightning protection. First of all, you should install a lightning receiver, which is located at the highest point of the roof. In its quality, it is possible to use:

- metal pin;

- metal cable;

- Lightning net.

The most optimal option is to install a steel pin from 20 to 150 cm in size. The installation of the pin is carried out in a strict vertical position, and copper, aluminum or duralumin is the material for its manufacture. In no case do not stain the pin. Use a steel wire welded to the lightning recreation as current -wires.

The next process is the installation of grounding. For its construction, several steel pins should be purchased, which are driven into the ground. They are connected in one circuit.

Tip: Make sure that the earth is always driven into the pins, so in the summer it must be watered.