For a decorative and protective coating of a wooden door, there is a large ...

|

|

If you have become the owner of the land, then you can congratulate you, as you did ... |

Not so long ago, people to close the door automatically used the simplest ... |

Speaker laying: step -by -step instructions

The slate as a roofing material recently, of course, has lost its share of popularity, because there have been many new attractive analogues on the market: from metal tile to Ondulin. Against their background, he, of course, loses from a visual point of view, but regarding many technical indicators and, most importantly, it has several advantages. The article will talk about the styling of slate with your own hands.

Content:

- Types of slate

- The advantages and disadvantages of the slate over other roofing materials

- Schifer dismantling

- Laying slate on the roof

- Repairs of slate roof and caring for it

Types of slate

- The slate can be asbestos-cement and cement-fiber. These two species are not particularly different from each other in terms of technical characteristics, but due to the fact that the second does not include asbestos, it has a slightly lower strength, although it is quite enough to calmly withstand, for example, the weight of an adult.

Important: slate sheets can be made of pressed and unprotected material. The latter has lower quality indicators than pressed, namely:

- below density (and, accordingly, strength);

- inferior in resistance to temperature extremes and weather disasters.

In shape, both types of slate can be flat and wavy. The wavy sheets are characterized by a thickness of 5.8 to 7.5 mm, there is also the following gradation:

- size 1125x980 mm has 6 waves;

- size 1130x980 mm 7 waves;

- size 1750x980 mm 8 waves.

The advantages and disadvantages of the slate over other roofing materials

Advantages More than many think, namely:

- enviable strength and resistance under any weather conditions, and therefore a long operational period;

- excellent refractory;

- high resistance to various chemical influences;

- low thermal conductivity;

- a large selection of color solutions along with a democratic cost;

- easy installation.

Schifer disadvantages

- High weight. And, if a special engineering approach to the slate laying process is needed, then physical efforts will have to be made;

- for all its resistance and durability, the slate can be called a rather fragile material, which must be taken into account when installing it, transportation and storage. The sheets cannot be thrown (they can crack), and, folding into piles, take into account that their number in one should not exceed 165 pieces;

- the composition of the asbestos -cement slate, as the name implies, includes asbestos, and it is not the most useful substance for the human body. Therefore, for the roof of the house, an asbestos-cement version is suitable quite, but for objects that are in the immediate vicinity of people, it is worth using cement-fiber material;

- over time, moss can appear on any slate, although the coverage of phosphate and silicate colors solves this problem to some extent, because noticeably reduces the degree of absorption of moisture.

Schifer dismantling

If there is a need to dismantle the old before the slate laying, then the main human factor (proper distribution of roles) and a convenient tool, because The process does not create special difficulties.

- Remembering the fragility of the slate and that its sheets will always find the use of a private house in the courtyard of a private house, it must be removed and lowered from the roof with a carefully, one sheet, in a sequence opposite to the one in which he laid.

Laying slate on the roof

Work plan

Directly, the process of editing the slate consists of three main stages: preparatory work, creating a crate and laying of sheets in the chosen way.

- Preparation implies the choice of the type of coating. If, nevertheless, he fell on the slate containing asbestos, then, starting to work with him, you should protect all the people involved in the process.

- Determining between flat sheets and wavy, for residential buildings it is still worthwhile to stop at the latter, because wavy products much more contribute to draining water from the roof.

- Among the wavy views, you will also have to make a choice, depending on the desired density of the slate. It can be ordinary, unified, medium -voltage and enhanced option.

- What qualitative indicators will be required to make the choice for the cipher for slate.

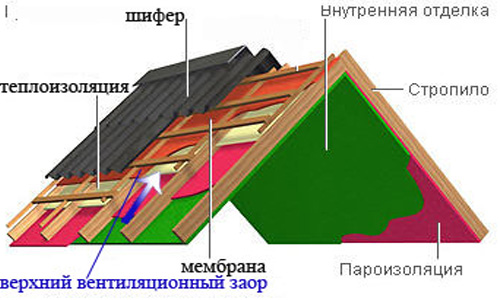

Waterproofing of the roof for slate

- There are many waterproofing materials for the roof on the market, but, if we talk about the slate roof, the most optimal option for it can be a polypropylene film.

- You need to fix the film on the rafters with the glossy side up. The pile, located on the inside, serves as an additional barrier for moisture, this is especially important if there is a layer of insulation under it. If desired, you can lay 2 layers of the film.

- The fastening is carried out using a construction stapler, for the process, you will need at least two pairs of hands (one gradually spreads a roll with a film and pulls it, the other fixes it on the rafters). The joints of the joints should be additionally strengthened with sealant or construction tape in more affordable places.

- On top of the insulation layer, the crate bars can be attached.

Chatter under the slate

- Installing a crate is a very important stage. Here the main point is the use of only dry wood. With a percentage of dampness exceeding 12%, the crate will swim and lose stability, because, drying, the bars will significantly decrease in size.

- For the frame, wood and 3 varieties are used: spruce, pine, fir, aspen. Before installing the bars, it is necessary to treat with an antiseptic, covered with olifum or resin, treated with refractory solution (antipyrene).

- You need to calculate the length of the bars of the crate, based on the size and number of slate sheets. It can be either 3.5 m or 6.5. Ideally, it should turn out so that the slate does not have to be cut along the edge of the roof, i.e. Entire sheets should fit on the slope, otherwise the roof will look sloppy.

- The size of the bars with a square section of 60x60 mm is considered universal, although the most correct solution will be their selection depending on the thickness of the slate, which is from 50 to 75 mm.

The distance between the bars also depends on the quality of the slate:

- for ordinary it is 50-55 cm;

- for unified 60-80 cm;

- for medium and reinforced 75-80 cm.

It is important that this distance is the same throughout the roof.

If the bars that are different in width are used (which is also acceptable), then the widest should be placed near the skate and in those places where the joints of the sheets occur.

- It should also be borne in mind that the beam closest to the skate should be installed by the rib and rise above the rest by 1-3.5 cm (i.e., to the thickness of the slate), for cornice bars, this indicator is from 6 to 10 mm (they should also stand by the rib of ).

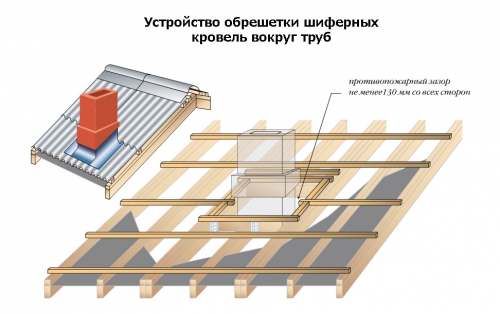

- It should begin to fix the bars to the rafters from below, given the overhang of 30-50 cm, in the course of laying certain construction subtleties must be taken into account, especially for places near the pipe and on the cornices.

Laying slate sheets

- The slate sheets are attached to the crate using galvanized nails.

- For drilling holes, the diameter of the drill is 2 mm larger than the diameter of the nails. It is necessary to score them in the crest of the wave (this will protect the roof from the flow) through the rubber gasket and the washer. This must be done carefully enough, and most importantly, not very deep, to minimal contact with slate. Otherwise, the material may crack at the slightest temperature difference.

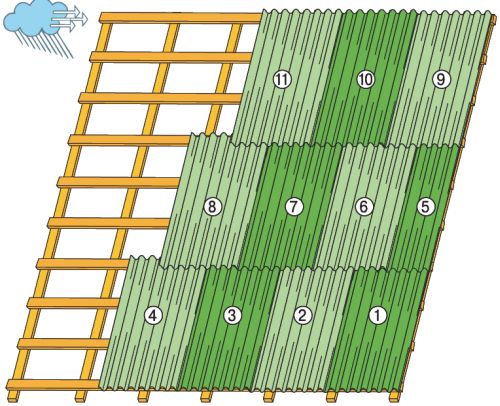

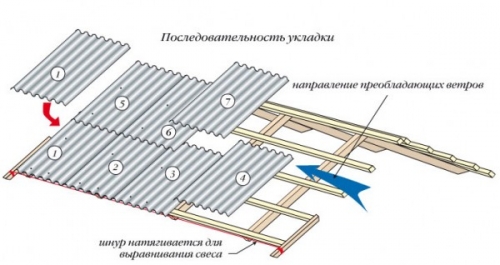

- The installation of the slate begins with the lower part and preferably on the more windy side of the roof. The first sheet is a very important element, it sets the tone for everyone else, so you need to check the evenness of its styling using a plumb line. The overlap of each subsequent row of sheets is made depending on the angle of inclination of the roof (for 20-45 degrees 10 cm is enough).

There are two main methods for installing the slate:

- with cutting angles, without displacement, when each slate of slate requires a form adjustment;

- routing, when the sheets of slate are laid according to the principle of brickwork.

The last option is most popular, because More simple to work.

Schifer laying in a way

Of course, by purchasing slate in the store you can always get both a detailed instructions of the manufacturer and a consultation of a knowledgeable manager. All of them come down to the following stages of work:

- schifer layout plan on the roof. It is also needed at the acquisition stage, because allows you to calculate the amount of material (it is better to take it with a margin, then if there is an excess check, you can return) and understand how many sheets will have to be cut;

- preparing the slate for working with him, which consists in pruning sheets using a grinder. Knowledgeable builders advise before this to wet the material a little in the estimated place of the cut. And inspection for chips and cracks (such sheets need to be rejected);

- direct installation. He, as already mentioned, needs to start from below. The sheet must be attached to the crate in one of the upper corners, joint with the edge of the roof and fixed with three more nails in different corners (necessarily in the crest of the wave);

- the next sheet in horizontal is fixed the same method, with an overlap for 1-2 waves;

- in this way, the lower row along the entire perimeter of the roof is laid, fixing each with four nails;

- the second row must start with half of the lower sheet, and move on, making overlaps both on the lower sheet and the previous one in the row. This is how the scan effect is achieved;

- thus, one roof slope is filled with slate, the latter in front of the skate should leave a gap for ventilation. Then they start the second slope. As a result, a roofing is formed, resembling a chessboard.

Angle cutting method

This method, as already mentioned, is more laborious. But the surface of the roof, laid down in this way, is very flat, without unnecessary gaps and, accordingly, its service life will be longer than that of the method created by the method. In addition, the material consumption will be noticeably less.

Stages of work

- The first, of course, is a roof plan, the construction of which must be approached no less responsibly than when laying a displacement. Indeed, not only the amount of material, but also its correct preparation depends on the correct calculation.

- It is necessary to determine which side of the ramp will begin. There is no one opinion here, someone advises on the left, someone on the right, there is no fundamental difference. Further examples will be indicated for direction from right to left.

- Preparation of slate sheets. The size of the angle, which should be cut off equal to 103 mm on top and 120-140 mm on the side. When pruning, the following points are taken into account:

- the first sheet of the lower row and the last upper is not cut (we are talking about one slope);

- sheets of the lower (first) row are processed depending on the direction. If the slate is laid from right to left, then the upper right corner is cut off for all sheets.

- The laying of the second row is performed according to the following scheme:

- first sheet of the lower left corner;

- middle sheets of the left lower and right upper;

- the last sheet is upper right.

- The final row on the same principle as the middle rows, but the last sheet is not cut at all.

The first sheet is fixed as in the extensive method. Next, the sheets are mounted with an overlap equal to the size of the cut (at least 120 mm). The upper row is exactly with the same overlap on the lower. At the same time, the places of cuts of the upper and lower row of sheets located diagonally must coincide, and the gaps between them are 3-4 mm.

Shtoper's styling video

Repairs of slate roof and caring for it

Of course, the slate roof, like any other, must be periodically cleaned. It is especially important to ensure that the moss does not appear, antiseptics help in this matter, which in most cases are part of the chief colors.

- In cases of chips and cracks, of course, a small repair may be required. If the leakage site is not very large -scale, then the processing with a special putty or installation of the patch may well be enough.

- In more serious cases, the damaged part of the roof must be replaced. The slate allows you to do this without unnecessary effort, because It is not difficult to dismantle individual sheets.

The cost of sandwich panels

The cost of sandwich panels changes depending on .... read the continuing-http://sp-panel.ru/sendvich-paneli/

you write the house you cover the outbuilding and

you write the house you cover the wing and this is the searches for the search engines