I immediately want to draw your attention to the fact that installation of multi -level ...

|

|

The glazing of the facade is a rather complicated process, but the result is worth ... |

Gas generating and pyrolysis boilers have gained popularity when heating residential and ... |

Cement grouts: characteristics, advantages, application

The use of cement grouts is associated with the processing of joints between the tiles and giving them aesthetically attractive appearance. The final result of the work directly depends on the correct choice of grout. We will talk about the varieties of grouts on a cement basis and their advantages.

Table of contents:

- Features of cement grouts

- Recommendations for choosing a cement -based grout color

- Epoxy cement grout: comparing the grout on the cement and epoxy basics

- Preparation for grouting cement mortar

- Cement -sand grout - cooking technology

- Cement grout for tiles: Features of breeding

- Grout technology cement

- Grout cement -sand mixture: how to form a beautiful seam

Features of cement grouts

The main component of cement grout is cement. There is an option to use it in combination with or without sand. In order for the grout to acquire certain properties of moisture resistance, frost resistance, etc. Various components are added to the composition.

When buying a product, on its packaging, the characteristics that determine its composition, the sphere of application, the thickness of the seam, which the grout can wipe, should indicate.

In the process of working with grouting, certain safety rules should be observed. First of all, it is necessary to protect the respiratory tract from the evaporation of the fumes that are formed as a result of contact of air grout. To protect your hands, rubber gloves are used.

Among the features and advantages of cement grouting for seams should be highlighted:

- the ability to fill exclusively narrow seams, size up to five millimeters;

- If it is necessary to fill out wide seams, you should use a special fugue, which contains sand additives;

- This type of grout is easy to use, it is well bred and when it gets on the tiles it has no effect on it;

- has high properties before abrasion;

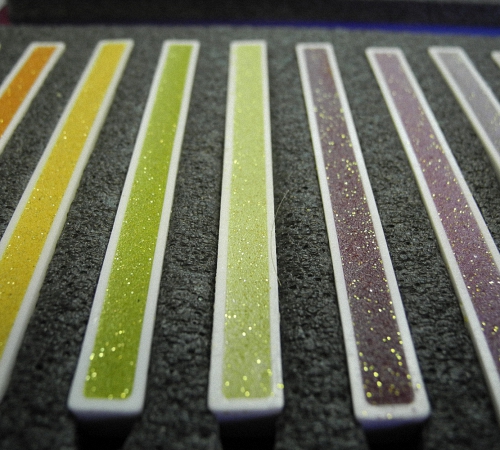

- has a wide color scheme;

- they are unstable before moisture, and therefore need to be treated with additional antiseptic solutions;

- A great option for domestic use.

Recommendations for choosing a cement -based grout color

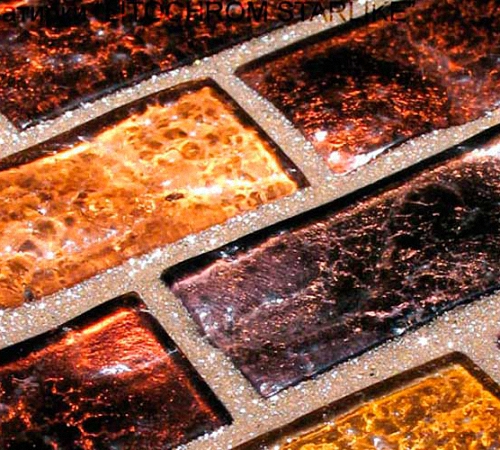

The choice of the color of cement grout is an individual business. The color of the grout is capable of both emphasizing the seams between the tiles and hide them. When using plain plate with tiles, the illusion of a flat wall is obtained. If you choose a grout of a contrasting color, a drawing and shape of each of the tiles will be released.

The latter option is more suitable for highlighting tiles that has a small size or for emphasizing mosaics.

In order for the color of the grout to harmonize with tiles, some recommendations should be followed, namely:

- To buy grout, contact a store that has a large selection of these materials, choose not only based on the color, but also from the characteristics of the material;

- For the correct assessment of color combinations, it is recommended to buy grout at the stage of purchasing tiles, otherwise, you should take one tile to the store to compare it with the color of the grout;

- If possible, apply grout to a small surface of the tile;

- A great option is a fugue, the color of which is the lightest or darkest, in a ratio with a tone of tiles;

- Try to choose a grout and tiles made in one color;

- Keep in mind that the color of the grout after its drying changes slightly;

- Using the use of light tones, it is possible to significantly expand the space of the room, so if work is carried out in the room, small area, you should stop on this option;

- The use of dark grout makes tiles more expressive;

- If it is planned to highlight other interior elements, but not tiles, then it is better to use a grout that coincides with the color of the tiles with maximum accuracy;

- For the bathroom, grout is selected in a ratio with the color of plumbing devices;

- The white color of the grout is suitable in almost any situations, except for the grout of the seams between the tiles that is installed on the floor;

- If difficulties arise with the choice of grout color, stop on gray or beige, they are considered neutral and are suitable for almost any type of tile;

- If you plan to grout a photo tile, then in this case, it is better to dwell on a sealant that has a silicone base or on a grout, the color of which is as close as possible to the pattern of tiles.

Epoxy cement grout: comparing the grout on the cement and epoxy basics

All types of grouts are usually divided into two categories:

- cement;

- epoxy.

The first option is classic, popular among professional builders, has a high quality of the final result. The composition of such a grout contains components in the form of plasticizers, various kinds of additives and pigments, but the most important component of this grout is cement, and small fraction. The mixture has a dry shape, water is used to breed it. The result is a mass, comparable in composition with putty. In addition, the option of breeding the mixture using latex, which has a water base, is possible.

With the help of a latex mixture, the grout will acquire moisture resistance, strength, and its shell will become elastic before compression.

There are two options for cement grouts:

- standard;

- Sandy.

The first option is used if the width of the seams between the tiles does not exceed five millimeters. Otherwise, it is recommended to use grout at the basis of which lies not only cement, but also sand. With its help, the grout does not spread, holds its shape well and shows resistance before abrasion. The sand fraction, which is part of the grout, depends on the width of the seam.

There are two options for cement grouts in the ratio with the form of their packaging:

- dry compositions;

- Ready -made mixtures.

For the use of dry composition, its breeding is required, and the finished mixture immediately after opening is ready for use. Keep in mind that dry undamosed grouting is distinguished by a longer period of use than the finished composition.

In the presence of a large amount of work, it is more practical to purchase a grout that has a dry base. Thus, a small amount of composition is taken from the bag, diluted with water and used for its intended purpose, then the procedure is repeated again.

With the rest of the grout, it is enough to choose a dry dark place for its storage. Despite the large number of advantages, grouts on a cement basis have the following shortcomings:

- destruction due to the effects of abrasive chemicals and various kinds of pollution;

- The severity of leaving.

The second version of the grout is an epoxy mixture. This option is used in the presence of strict operating conditions of tiles. This grout is more stable before various kinds of influences. Its use is associated with the floor surface in pools, various laboratory instances, on a kitchen apron or countertop.

Despite the high strength and reliability of this type of grout, it requires special attentiveness when working. The process of applying a grout on an epoxy basis is particularly difficult.

The epoxy grout contains epoxy resin, additives in the form of quartz sand or hardener. Before starting work, the hardener with quartz sand is made, a rather dense and elastic solution is obtained, which, due to its viscosity, leads to difficulties for its application.

But then, such a grout does not change its appearance for ten, or even more years. It is possible to add shine to this grout that improve the attractiveness of its appearance.

Epoxy grinding is durable and durable. It is resistant to household chemicals, fungus and mold. Among the shortcomings of this kind of grout, the difficulty in applying it and high cost, compared to grouting on a cement basis.

Preparation for grouting cement mortar

First of all, the width of the seam should be determined, which determines the appearance of the tile. Keep in mind that the larger the size of the seam, the brighter it stands out against the general background of tiles. Most often, the seam width between the tiles is from 3 to 6 mm.

When using tiles with an irregular shape that imitates materials such as pebbles or stone, install the elements so that the distance between the tiles does not exceed one centimeter. If this is not done, then the appearance of the surface will be completely inaccurate.

In addition, consider the fact that if there are too large seams, there is a risk of cracking in them by grouting after filling. In order to avoid this situation, the sand of a large fraction should be present in the grout.

If there is a seam between the tiles, less than three millimeters, there will be difficulties with its filling. The seam will not be completely filled with grout, which means that when moisture hits the surface, it will penetrate under the tile. This will lead to its gradual destruction.

The option of making a more liquid solution is possible, which will fill all cracks, however, in this case, the risk of cracks increases significantly.

Cement -sand grout - cooking technology

Most often, water or latex -based additives are used to prepare grout solution. To breed polymer mixtures, exclusively water is used. The laundering procedure should be completed by obtaining a homogeneous plastic solution, which easily falls on the surface.

A special kind of spatula is used to apply grout. Preparation of grout and the amount of water for its breeding should be indicated by the manufacturer in the instructions. In the presence of a large amount of water in the grout, it will lose strength and begin to crack on the surface.

Prepare the dishes in which the grout will be bred, it should be clean. When using water, also take care of its high quality. First, water is poured into the dishes, and then a dry mixture is gradually added to it.

Pour first a third of the water necessary for breeding the solution, add a little dry mixture, mix the composition until smooth, then add the rest of the water.

Please note that the consistency of the material depends not only on the amount of water, but also on factors such as temperature and humidity, adding a coloring pigment to the composition, etc.

Therefore, if the grout, when adding the required amount of water, is dry and difficult to apply, then the water must be added. If there is a dry polymer as part of a dry polymer, it should be based exclusively from the recommendations of the manufacturer.

During the portion of the grout, you need to ensure that each composition has the same consistency. When using a grout of several bags, it is recommended to type some material from each of them at the same time to exclude the possibility of the difference in color between the seams.

Cement grout for tiles: Features of breeding

If the grout is prepared to perform a small amount of work, then the use of a mixer or drill is inappropriate. In addition, the use of an electrical tool for combining can adversely affect the properties of the material. If mixing is carried out too actively, the composition contains excess air, which makes the seams less durable. When using a mixer, you should choose the mode of its work, providing minimal rotation of the blades. Although the easiest way to prepare the composition to use an ordinary fork. After mixing the grout until smooth and disappeared in it, you should leave it in the room for 12-15 minutes so that it swells. Next, another mixing of the composition is performed.

To carry out the grout of the seams between the tiles, the presence of:

- protective mask or respirator, especially important when using grout on a cement basis;

- dense rubber gloves;

- glasses, to protect the eyes from caustic substances;

- wooden rails, with the help of which the seams are ruleed;

- kelms;

- rubber spatula for applying grout;

- sponges for washing tiles from the solution;

- napkins.

Grout technology cement

If you plan to fill the seams of the tiles laid on the floor, then for this it is enough to put the solution on the surface and level it with a rubber spatula. If the work is carried out on a vertical surface, then the use of the cell will be required.

Apply grout to the surface diagonally, holding the cell at an angle with respect to the wall. Try to simultaneously process small areas with an area of \u200b\u200bno more than two square meters. When working in large areas, a rapid setting of the solution occurs, until it is aligned. The seams in this case are inaccurate.

All unnecessary parts of the grout require immediate removal. Since a lot of effort will be made to tease a dried mixture. After the mixture has been applied to the wall, a rubber grater is used to level it. The solution is not just distributed on the surface, it must be well absorbed into it, for this, certain physical efforts must be made. Make sure that there is also a solution in the corners or the slightest voids.

When working with tiles on which the author’s expensive drawing is applied, it is best to use a grout bag, which is filled with a mixture and fills exclusively the seam space. The width of the tip dressed on the bag should be such as to easily penetrate the seam into the seam.

First, the horizontal seams should be filled, and then vertical. Regardless of the tool for working with grouting, a lot should be applied, after the material dries, it must be tamped with a wooden rail.

Grout cement -sand mixture: how to form a beautiful seam

After completing the main work on working with the seams, the process of removing excess solution should be removed. For these purposes, a rubber grater is most often used. It must be kept in relation to the surface at right angles. The direction of movements should be diagonal. In case of non -compliance with this rule, there is a risk of grater in the seam and violation of its integrity.

After the grout dries completely, the process of removing the material from the surface of the tile begins. For these purposes, it is recommended to use a wet sponge, after the surface is cleaned of the solution, it is recommended to wipe it again with a damp cloth again.