Despite the fact that the laminate floor has long lost the status of the new building market, ...

|

|

Getting a house made of natural wood is a great choice for those who appreciate ... |

Everyone dreams of a house from a log house. Even those who do not admit this. After all... |

Medical slabs laying technology

No matter how residents of suburban villages want to dwell closer to nature, without some elements of improvement, such as paths, it will not work to do. They should be functional and convenient, as well as ennoble the entire village. On your site, you can use a natural stone pure as a path, but with this, for common streets, laying road plates that developing firms and cooperatives of citizens are more suitable for common streets.

Content:

- The purpose of road plates

- The design of road plates

- Classification of road plates

- Road plates manufacturing technology

- Creation of a path on the site

The purpose of road plates

Reinforced concrete slabs are called a unique material for the manufacture of roads, which is able to withstand huge loads. The purpose of such products is very different. This is the construction of temporary roads for construction objects and the creation of permanent access roads to enterprises, entrance to sparsely populated points in rural areas, which are removed from the main roads a short distance.

The technology for laying reinforced concrete slabs allows you to build roads in absolutely any area and actively use them. In addition, the installation of asphalt is allowed on the surface of road plates, which protects the plates and extends the useful life of the canvas. A pleasant feature of the use of these reinforced concrete products is the possibility of re -operation, if the plates have retained their characteristics, which can save significantly. From the plates that were in use, it will quite work out to build a temporary road surface.

When the temporary warehouse platform becomes unnecessary, such a coating can simply be dismantled and transferred to another place where they can be used without restrictions on the main purpose. Road slabs that were in use, from the products just made at the factory, differ exclusively by appearance. Meanwhile, the price of laying road plates that were in use is less than the installation of new ones by 40 50%.

Road slabs can be used in a wide range of temperatures, which is relevant for our country - from minus 40 to plus 55 degrees. Higher temperature resistance can be achieved using special impurities, which allowing high -quality road surface to provide even the most remote corners of the country.

The main advantage of reinforced concrete plates is the possibility of their rapid installation and a relatively simple preparation of the base for the installation of the road surface. Another advantage of using road plates in the construction of roads is the speed of spreading plates. Roads from reinforced concrete road plates are not only aesthetically attractive, but also pleasant for drivers.

However, with road slabs, everything is not simple. Installation of reinforced concrete plates has its drawbacks. In the production of the plate, the stoves are laid on the ground, as a result of which the seams occur. The road from such plates as a result of soil movements can be dispersed, so at the place of use of concrete plates you need to constantly monitor their species and condition. This contributes to the timely elimination of various negative phenomena and the prolonged use of the road surface.

The design of road plates

Road slabs are flat rectangular slabs made of reinforced concrete, which have a thickness of 14 18 centimeters close. These products are performed on the basis of tense or unstressed reinforcement. The working surface of reinforced concrete plates has a corrugation. The products along the end faces have mounting loops, however, slabs can be built under demolish captures. Installation loops are located in specially formed recesses so as to exclude the possibility of their entering the outer surface during.

Concrete acts in a binder. The reinforced concrete used in the road plate gives the resistance of the product to any atmospheric and mechanical influences. The higher the concrete brand is used, the greater the loads will withstand this design. If you are interested in how much the road stove weighs, then remember that its weight is usually at least 2,200 kilograms. Road slabs are made of concrete, which has a density of 2200 - 2500 kilograms per meter. Often, road slabs are made of concrete with frost resistance to W2 and F150.

Thanks to the presence in the design of steel rods, it will last many years and retain its technical properties. For the production of tense plates, the reinforcement of the classes AT-5, AT-4, A-5 are used. In non-straightened plates, the core reinforcement of classes A-3C, A-3 and A-1 and VR-1 wire are used. The hidden reinforcement is protected from sunlight, mechanical influences and precipitation. When installing, road slabs are returned to its original position, and the voltage that is formed in the standard mode is minimal.

The standard provides for such typical sizes of road plates:

- length 6 meters, width 1.75, 3, 1.87, 3.5 and 3.75 meters;

- length 3.5 meters and width 2.75 meters;

- length 3 and 1.75 meters;

- length 1.75 meters and a width one and a half meters.

It is customary to store road slabs in stacks, which have a height of no more than 2 meters, the lower row should be fitted on a leveled and dense base. Each plate in a stack is laid on wooden gaskets.

Classification of road plates

All road slabs are divided into two types, which determines their purpose: slabs for constant work (type 1P) and for a temporary road surface (2P). There are three types of road slabs in their shape: in the form of a trapezoid (plate of the species of PT), a rectangle and hexagon.

The slabs of a rectangular configuration are with 1 side on the long side (PB plate) and with 2 sides on the short sides (PBB marking). Plates in the form of a hexagon are diagonal orientation (PDS plates), transverse orientation (pshp brand), hexagonal shape, divided in half in diagonal (DPSH products) and hexagonal form, divided in half across (PPS plates). Despite the variety of road plates configurations, which are provided for by the standard, reinforced concrete products are mainly produced only rectangular road slabs for temporary or permanent roads.

Reinforced concrete slabs can withstand the loads of about 10 - 30 tons. The marking of the product indicates the permissible level of load. The most common road plates are PD plates (road slabs with tense reinforcement) 20-18-30. Unfortunately, they have some load restrictions with regular movement of heavy vehicles on them, but this is not relevant for styling at home.

If you can afford to put the plates of airfield smooth pag, then this will be the right solution. Judging by the name, Pag was originally used in the construction of airfields, so there is no doubt about their reliability. During their manufacture, concrete of a high brand and reinforced reinforcement are used. Another advantage of aerodrome road plates is in the corrugated surface, which also increases their operational characteristics.

Road plates manufacturing technology

The wide popularity of the installation of road plates is also explained by a simple methodology for their manufacture, for which new equipment is not required. The sequence of their manufacture is as follows:

- The preparation of the form is cleaned of the presence of old concrete, a special lubricant is applied on the bottom and side, which reduces the adhesion of concrete to metal using the form.

- The reinforcement process 2 reinforcing nets are laid in the form, fixers are installed, which guarantee the distance between the nets, and the limiters of the protective layer.

- The laying of a concrete mixture that is compacted with vibration streams.

- The departure of the form with the concreted road stove in the warm -up chamber, where its heat treatment is performed.

- The work of the slaughter of the product, checking the quality of reinforced concrete slabs and marking.

- Sending road slabs to the finished product warehouse in which they are folded with stacks.

Creation of a path on the site

The functionality of road plates allows them to be used not only in areas where a reliable and strong coating is required for heavy transport, but also at home. These products are great for these purposes, since they are strong enough, they do not have ice, because the water goes quickly into grooves from a panted surface, they simply repair them by replacing one stove without dismantling the entire track, you can drive along such a path Immediately after the creation.

Selection of paths for track

I can easily lay out the garden paths, pedestrian paths, open areas, a parking lot and a solid access road to the house. Forms of road tiles are rich in their own variety. On sale there are square, rectangular, triangular, round, rhomboid slabs, irregular products, different colors and sizes.

To create a track to the house, you can use a combination of road plates with small stone, sea pebbles, gravel, sawn paving stones. When arranging garden paths, chopped road slabs can be used. For coding products, a sledgehammer and chisel are used, it is necessary to use glasses to protect the eyes from flying fragments. The most popular plates for arranging tracks at home products with a smooth surface.

You can choose plates with a pattern or deep embossing that imitate mosaic, brick, tiles. The most natural type of track can be obtained when using plates with a stab surface for natural stone. However, it is better to give preference to slabs with a corrugated surface, which ensure safety when moving along the path in ice or wet weather.

Arrangement of the base under the slabs

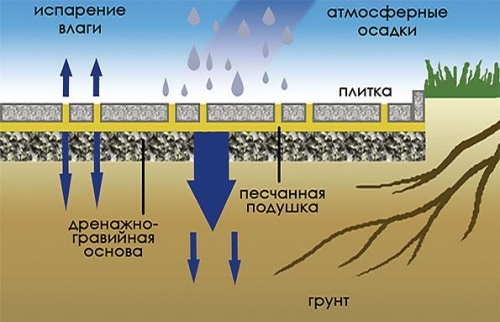

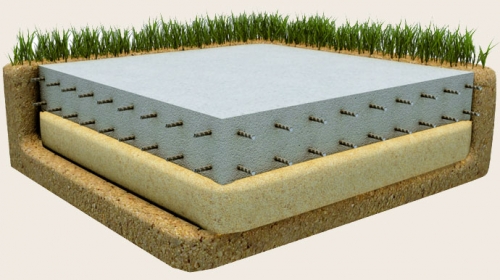

It is impossible to lay road slabs directly into the soil. First you should prepare a bed for the future path and patio. First, cut the top layer of the soil, moving the surface and removing all the irregularities. Dry the trenches in depth of 25-35 centimeters. In lowlands on loam and clay soils, the depth of the trench should be at least half a meter. The bottom must be sent to drainage non -woven material - geotextiles.

Geotextiles will prevent the germination of weeds and leaching such a sand-gravel base. Then fill in the layout of the crushed stone trench (5 centimeters for garden paths and 10 centimeters for parking lots or access roads) and sand (10 centimeters), lay the so-called sand pillow with indispensable tamping and watering with 5-7 centimeters. Sand is better to use career, because it is less crawling and dusty than river, it will be easier to compact it.

Then it is worth sealing the sand with a vibration plate. You can also use a vibration channel, but the cost of laying road plates through this technology is somewhat more expensive. Pulling and adding must necessarily be controlled by a simple rope beacon or leveling, which is stretched in level. At the end of the tamping, the surface should be perfectly flat, since the reinforced concrete coating is subsequently laid along it.

Given the relief of the land plot, equip a small slope so that rain and meltwater flowing without forming a puddle. In addition, you can create the basis for installing storm sewers. The next step will be the installation of on -board stone or the creation of a border with a groove for a docking with ordinary products.

Paving the path with slabs

The paths are transport communications on the site, and are also important elements of landscape design, which are responsible for the interaction and relationship of different objects of garden composition. Therefore, when arranging routes, it is not recommended to get involved in stained glass windows and sharp turns. Absolutely straight paths are also not an option, as they look unnatural.

The width of the tracks should obey the logic of movement around the territory and be linked to the overall dimensions of the cleaning equipment, which is planned to be used to maintain ownership. The width of road plates, which are used at home, is about one and a half meters. If you plan to lay out pedestrian paths, there will be enough width of 70-80 centimeters. When arranging paths half a meter. The recommended width of the access road 2.25 2.5 meters.

There are two methods of laying solid coating dry and wet. In the first case, the products of the correct shape are adjusted tightly with each other (the gaps between the plates are no more than 2-3 millimeters), after which the seams must be filled with sand and shed with water.

Wet technology for laying road plates involves the use of a cement-sand mortar, thanks to which the coating grabs well with a sand-gravel base. At home, the material can be practiced and the intermediate option is located on a dry cement-sand mixture. After laying, the road surface is shed with water, then the stones and the underlying layer are grasped.

We will act as follows. It is recommended to place plates sequentially. Tighten the cord along the edge of the track, on it you will lay out the first row of plates. Raise the first plate, at 5 points on the sand apply a solution to which return the plate back. Then besiege it with a sledgehammer and boards. Lay the rest of the slabs according to the same principle. Insert wooden planks between them, which have a thickness of 8 millimeters close. Control the horizontal masonry using the construction level.

They can be laid not only in v and with a small interval, which is filled with cement mortar, stone, sand. In order to avoid scratching the seams, it is better to steal the seams with a wet solution, having previously protected the road slabs with a special adhesive film. The planks are taken out at the end of the work, the solution freezes within two days. In the intervals you can also plant seeds of herbs.

You already realized that under any circumstances to lay the slabs directly on the bare ground. Remember one more point. If you equip the entrance to the house or a car parking place, the mounting loops of the slabs for reliability are connected to combine with the help of steel rods, and the voids are poured with monolithic concrete. This will allow you to equip an absolutely flat road to avoid further traveling and spreading the slabs. It is advisable to lay the asphalt-concrete mixture over such a roadbed.

And I prefer my site

And I prefer to cover my site with paving slabs. A good option. https://mirkamnia.com/dorozhnoe-blagoustroystvo/plity-moscheniya/. Granite slabs are durable and durable. It is worth considering this option.

In general, everything is right

In general, everything is written correctly. But, nevertheless, such work is better not to trust guests from South Asia. Such work should be done by experienced, professional people. If there is a need to build a road from road plates or pag plates in Moscow or Moscow Region, I recommend that http://bazagbi.ru

They built a road from the slabs in SNT. There are no problems for the fifth year.

More their group in VK

https://vk.com/public168472286