In most cases, the floor structure is a screed. The most familiar and ...

|

|

Domestic construction technologies are developing a rapid pace. And it pleases... |

Laminate is quite popular finishing material. This is due primarily to him ... |

Coniferous substrate for laminate: features of choice and installation

Despite the fact that the laminate floor has long lost the status of the novelty of the construction market, its undeniable advantages still allow it to occupy a leading position in this area. Having proved his reliability and practicality to the consumer, as well as demonstrating his competitiveness in the building materials market, the laminate for a long time gained consumer trust. Not the last role in the durability and operational characteristics of the laminate is played by the correctness of its styling, which is impossible without the use of the substrate. Despite all the warnings of the manufacturer, domestic builders continue to practice laying the laminate directly on the stone base of the floor is the easiest way to small savings, but also the loss of the manufacturer’s guarantee for material. This is due to the fact that, by abandoning the arrangement of the damper substrate, which is a kind of shock absorber, you personally contribute to the fact that soon the compounds of the castle type on the dies of the laminate will begin to spin, which cannot but affect the operational characteristics of the flooring. There is a wide variety of types of substrates made of various materials, which are characterized by both advantages and disadvantages, but the desire of a modern person to choose environmentally friendly products often plays the benefits of coniferous substrate with the above advantage. How to choose a coniferous substrate, as well as how to learn its installation by reading our article.

Content

- The selection of the substrate for the laminate: what to prefer?

- The thickness of the substrate: what to focus on?

- Laminate substrate: main varieties

- Coniferous substrate for laminate: the main advantages

- Coniferous substrate for laminate: Popular manufacturers

- The laying of the coniferous substrate: the main features

The selection of the substrate for the laminate: what to prefer?

Experts argue that a huge impact on the operational characteristics of the laminate, such as its service life, physical indicators and appearance, directly depend on the method of laying it, which is impossible without the use of the substrate. This is due to its sensitivity to the quality of the surfacing surface, the deficiencies of which can be level using the substrate under the laminate. Many had to face the fact that the slightest unevenness of the surfacing surface led to cracking or pushing the lamella at the place of appearance of the defect. This would not be so critical if the slightest defect of the laminate did not require thorough dismantling measures. A properly selected substrate is able to completely solve the problem of a defect in the subject, however, choosing a substrate, it is important to take into account a number of nuances, among which the following deserve special attention:

- The material from which the basic surface is made;

- Quality characteristics of the draft floor;

- Average level of humidity in the room;

- The purpose of the premises and the possible load laid on the floor and flooring;

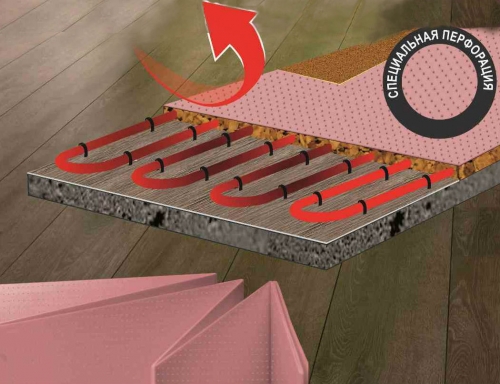

- The presence or absence of a warm floor system;

- And finally the thickness of the substrate under the laminate.

The thickness of the substrate: what to focus on?

Due to the fact that the last parameter is the most significant when choosing a substrate for the laminate, let's talk more about the necessary thickness of the substrate.

When choosing the necessary thickness of the substrate under the laminate, it is important to determine the maximum loads placed on the flooring. In addition, it is impossible to neglect the constant point loads of lower intensity, which often can be more destructive for the laminate. Until recently, it was believed that the thickness of the substrate used was directly proportional to the loaded loads. In this regard, practices preferred to use the substrate of the greatest thickness, and if such a substrate was absent, they used thin in several layers.

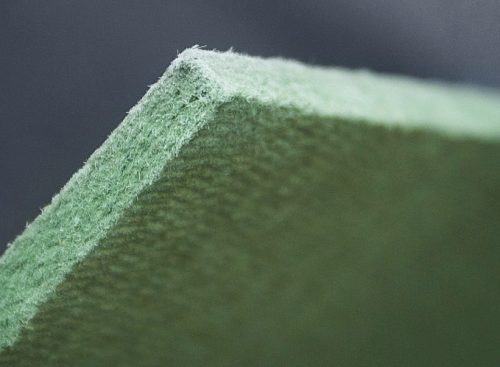

But it is not always possible to completely level the shortcomings of the floor. It was believed that the use of a thick substrate will smooth out irregularities, but these assumptions were not always justified, since an overly thick substrate can bend so much that in the end it would lead to cracking of the laminate. In this regard, it was decided to select the thickness of the substrate individually for each surface. Also, the rigidity and strength of the substrate is of no small importance. It was precisely when difficulties arose with the choice of a substrate, rationally combining all these qualities, the masters drew attention to the coniferous substrate.

Laminate substrate: main varieties

The generally accepted classification of the substrate for the laminate is based on the separation of the substrate in accordance with the material used. Despite the fact that the manufacturer offers a large number of types of substrates made of artificially synthesized materials, which is associated with the rapid development of the chemical industry, a person seeks to give preference to natural, environmentally friendly materials, which include coniferous substrate. But for the sake of interest, we list the main varieties of substrates under the laminate:

- Dampfer layer of polymer film;

- Polystyrene foam canvas;

- Bitumen-proof substrates;

- Substrate, which are a combination of polystyrene and polyethylene foam (Tuplex substrate);

- Coniferous substrate for the laminate.

Regardless of the material from which they are made, a number of standard requirements are presented to them:

- Effective sound insulation. If you neglect the substrate under the laminate, each step will be given to the concrete or wooden surface of the floor, while the presence of a soft litter is able to extinguish sounds;

- Surface leveling A parameter that has a significant impact on the operational period of the laminate. Hiding small irregularities of the base surface using the substrate, you will extend the service life of the flooring;

- Moisture insulation. Due to the fact that the main material for the manufacture of the laminate is pressed paper, experts do not recommend that even moisture -resistant models expose moisture, as they can simply swell. By laying a substrate under the laminate, especially coniferous, you will protect the laminate from moisture from the side of the concrete surface;

- Thermal conductivity. The use of a laminate substrate in the presence of a warm floor system will significantly reduce its effectiveness indicators, in connection with which, in the presence of such a system, it is necessary to use the substrates specially designed for this.

Coniferous substrate for laminate: the main advantages

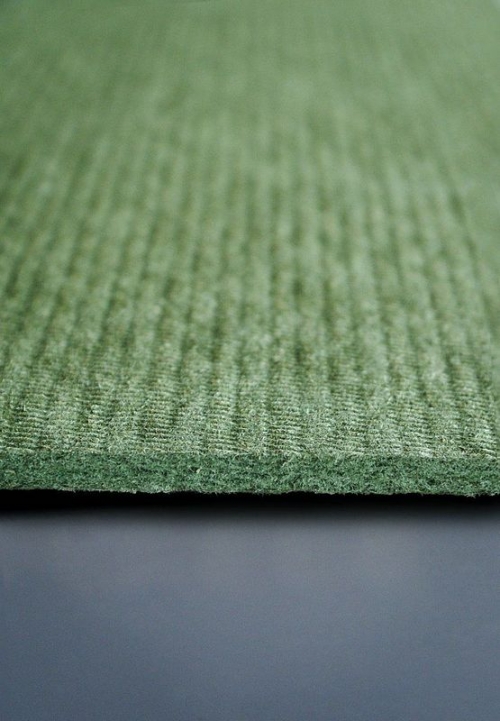

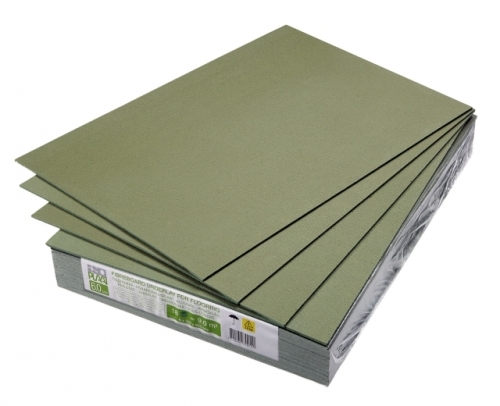

The coniferous substrate, which you can buy in any specialized store, gained the popularity of the consumer due to the optimal balance of thickness and stiffness. The manufacturer supplies the coniferous substrate to a wide network in the form of plates, which can be used both for laying new floors and for repairing old, former in operation of the bases. Initially, according to the manufacturer, the coniferous mat should have been used only as a noise insulator, however, the ability of the coniferous substrate to extinguish shock vibrations allowed to detect new advantages of the coniferous mat and use it as a flooring. In the process of wide operation of the coniferous substrate for flooring, new advantages of environmentally friendly material became noticeable.

The main advantages of the coniferous substrate:

- The first effect that consumers noted during the operation of the material was the creation of an acoustic atmosphere in the room, due to the ability of coniferous plates to destroy vibrational connections between different planes and thereby contribute to the extinguishing of rather strong sound vibrations;

- The use of the material contributes to the excellent holding of heat with floor and prevents the penetration of the cold through the floor, and therefore, the flooring, during the installation of which the coniferous substrate was used, cools very slowly. Thanks to this advantage, residents of even the northern regions can refuse to install floor heating systems;

- Coniferous slabs are characterized by the optimal level of density, due to which their use allows you to hide all the existing irregularities of the floor and present a perfectly smooth surface, devoid of even the slightest defects for the installation of the laminate;

- In the process of laying the material, the use of additional films, adhesives and other materials and devices will not be required;

- The environmental safety of the coniferous substrate is not subject to any doubt in its composition neither glue, no additional additives, nor modifiers.

Disadvantages of the coniferous substrate for the laminate:

As in the case of any other building material, in our situation it was also not without flaws. Despite all the advantages, the coniferous substrate is characterized by the only, but very significant minus. The manufacturer, advertising the coniferous substrate, claims that it is a breathing material that perfectly misses moisture, preventing its accumulation. However, despite this fact, it is prone to mold.

Important!For active reproduction of the fungus, a combination of two conditions of temperature and humidity is necessary. If the coniferous substrate will accumulate moisture, then this will be a great reason for the appearance of mold, since cellulose itself is a favorable environment for the reproduction of the fungus. To avoid this, experts advise laying the coniferous substrate on a completely dry surface.

Coniferous substrate for laminate: Popular manufacturers

Steico coniferous substrate: quality tested by time

The leader in the production of MDVP stamps is the famous European company Steico. Despite the fact that the products of this manufacturer are manufactured in Poland, it is currently available in most countries of the world. The Steico Underfloor laminate substrate is characterized by active use in order to increase the soundproofing characteristics of the room. In addition, it guarantees high -quality thermal insulation of the floor, which is especially relevant for country houses, heated only partially or characterized by insufficiently effective ceilings. As for soundproofing, the coniferous substrate of the Polish manufacturer can extinguish not only the sounds of steps, but also the air shock waves.

Speaking about the technology of production used by the company, it should be noted that it completely eliminates the use of chemicals and other connecting components that can question the environmental safety of the material. You may quite naturally ask: is it possible? - Undoubtedly! After all, the wood is first subjected to evaporation, as a result of which the resulting mass is used to form coniferous plates. The only, permissible connecting component is the resin originally contained in wood. The evaporation process involves gluing wood fibers precisely due to this resin.

Advantages of the coniferous substrate Steico:

- Increasing thermal insulation indicators of the floor;

- The absence of chemicals in the structure of chemicals eliminates the release of harmful volatile components;

- The ability to eliminate the irregularities of the base without the use of additional materials and tools;

- The porous structure eliminates the accumulation of moisture and mold;

- Proven environmental safety;

- Lack of tendency to drying out and subsidence during operation;

- The absorption coefficient of sound waves reaches 220 dB.

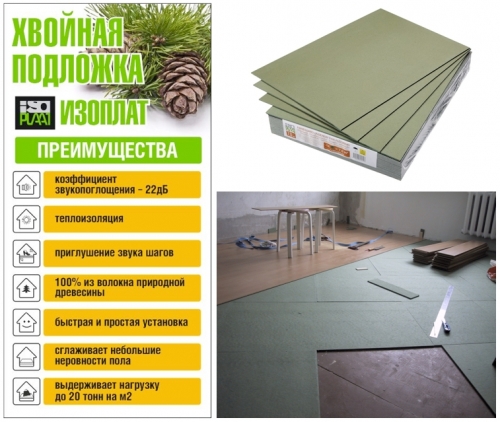

ISOPLAAT floor slabs: characteristics and advantages

The use of ISOPLAAT coniferous substrate is advisable if you need to equip a floor covering covered on a wooden floor.

The plates of this manufacturer were specially designed not only for the arrangement of a new flooring, but also for the repair of the old floor, which was in operation for a long time. Their installation is carried out only on a solid, dry base.

The main advantages of the coniferous substrate isoplaat:

- The ability to smooth out irregularities. The material is supplied in a compressed state in the form of plates, the thickness of which is optimal for aligning small defects without using self -leveling mixtures and installing plywood sheets;

- Mechanical strength. Thanks to this advantage, the material can withstand even increased mechanical effects at the junction of laminated boards;

- Environmental Safety. For the manufacture of coniferous substrate, the manufacturer uses only natural wood without inclusion in its composition of additional binding components;

- The ability to maintain shape. Even during long -term operation, the slabs are not subject to compression and retain their original shape, as well as qualitative characteristics;

- The porous structure not only prevents moisture stagnation, but also helps to drown out various sound waves and increase the floor temperature, which makes it more comfortable.

The laying of the coniferous substrate: the main features

Important! Before starting to lay the coniferous substrate, it must be unpacked and withstanding in this state at room temperature for 24 hours. Thanks to this simple event, the material will accept the level of humidity characteristic of the room. During the installation process, you do not need glue or nails everything that is necessary for work, this is a ruler, a sharp construction knife and a square.

Coniferous substrate laying technique

There are no particular difficulties in the laying process, since cutting of the material can be carried out using a knife. The substrate is laid so that the seams of the plates do not coincide with the seams of the lamellas or flooring boards. For this, the plates are laid, starting from the corner of the Christmas tree, that is, at an angle of 45 degrees the joint in the joint.

Important! The laying of the coniferous substrate should be carried out in dry rooms, which is due to the ease of absorption of moisture with porous material. If you put the substrate on the concrete base, lift the plastic film under it and glue the joints with tape. This will protect porous material from condensation.

After you cover the entire surface with a coniferous substrate, you can start laying the finish flooring.

Laminate Subway Video