The modern building materials market offers a wide selection of finishing funds ...

|

|

Pipes are an obligatory element of the bathroom, from the location of which is directly ... |

The process of building a log house is preceded by the laying of the foundation that should be ... |

TISE technology: construction features

The construction of a house using TISE technology attracts a huge number of advantages, among which the most important are the costs of work. Although there are opponents of this technology that give arguments about its shortcomings. We will talk about the features of TISE technology and the feasibility of its application.

Table of contents:

- TISE technology - general information and origin

- TISE foundation construction technology

- New Methods of construction technology TISE

- DIY TISE technology - wall construction

TISE technology - general information and origin

The process of building your own dwelling is best entrusted to professionals, because in this case, the duration of operation of the home will be increased, and the quality of work will be high. However, a lot of money should be spent to hire a specialized brigade, so if this side of the issue is quite important for you, then read TISE technology.

An indisputable advantage of this technology for building houses is the fact that it suits almost everyone: both experienced specialists and people who do not have skills in building construction.

The abbreviation TISE is deciphered as the technology of individual construction and ecology. She was invented by Rashid Nikolayevich Yakovlev. It was with his help that people who did not have great prosperity were able to build their home, for little money.

The efficiency of using TISE technology requires a large amount of time and physical effort from its applianist. According to this technology, not only buildings are being built, but also the foundations are equipped with various kinds of buildings in the form of garages, cattle, outbuildings.

When arranging the foundation, the presence of such equipment as a drill, with which wells for piles installed in the ground are made. The foundation made according to TISE technology requires only a drill, piles and cement mortar.

We recommend, before using this technology, to study the two books of Yakovlev, in which he describes in detail all the stages and subtleties of construction. The first book is devoted to the arrangement of the foundation - a universal foundation - TISE technology. And the second book tells about the latest methods for construction using this technology.

Among the advantages of using this technology, it should be noted:

- The arrangement of the foundation is possible on almost any type of soil;

- The total cost of all construction work is affordable, and the design is durable;

- lack of need for electricity at the facility;

- lack of need for certain skills in working with special tools or materials;

- the possibility of construction work even if there is a small money;

- the possibility of changing the terms of work, termination of construction and its layout for your mode;

- construction with the help of their strengths;

- the use of the simplest equipment, which differs in the reliability of the work;

- lack of need for the purchase, storage and transportation of a large number of building materials;

- The ability to combine houses with other technologies.

Among the shortcomings of the application of this technology note:

- the need to invest a large number of temporary and physical efforts in the construction;

- the presence of cavities in the walls of the house, they require filling them using mounting foam;

- A high level of water loss in the house, during operation, requires large investments on its heating.

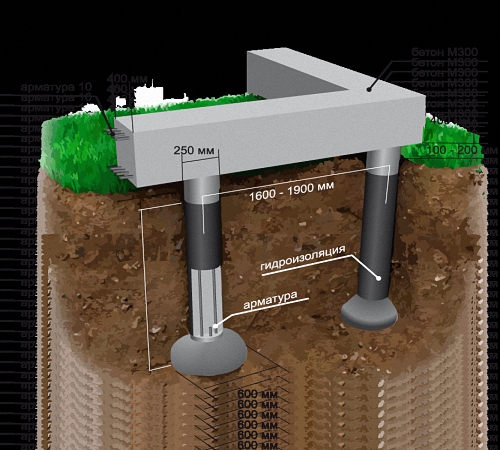

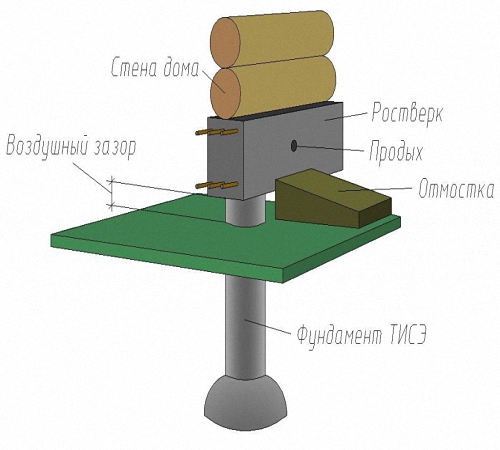

TISE foundation construction technology

This type of foundation is considered universal, as it is suitable for almost all, without exception, soil types. With it, it is possible to build any building on all foundations, except for rocky bases. The FISE foundation is an excellent zero level, which is located on soils with high guns.

The FISE foundation is indispensable in the territory located near the located railway or a heavily loaded highway. Even strong vibrations are not able to destroy this type of foundation.

In addition, the arrangement of the FISE foundation will be released several times cheaper than usual. Since its construction does not need to carry out long -term earthwork, for filling which a lot of concrete is required.

Among the main stages of erecting the foundation using TISE technology, it should be noted:

1. Preparation of the site for work.

2. The procedure for building cast -wings.

3. The arrangement of wells.

4. Their expansion.

5. Strengthening.

6. Installation of nets and filling.

7. Rostierk.

At the initial stage of construction, the top layer is removed from the ground, and sand is brought to the object. Next, the casting and marking of the future location of the foundation is installed.

The process of removing fertile soil from the soil should not be neglected, since in this way it is possible to prevent the contact of the floor with the soil. Further, based on the features of the site, the option of leveling the entire surface or installation of a grillage that has an alternating section is chosen.

One of the most critical points of construction is the calculation of the foundation and marking. In the absence of a professional water level, use a hose with water.

Mark the zero level, which should be at a distance of about 40 cm from the ground. When the zero level is marked, drink pegs, forget the nails with ropes stretched on them. You can replace the rope with fishing line, its use is more practical, since it is not capable of sagging.

After installing the corner coloshki, you should mark the location of all internal walls and partitions that are supportive.

TISE photo:

First, the frame is installed, the presence of circle and drill is required for this. The embroidery should be half -tight, this option is practical and cheapness. With the help of thick boards, the formwork is mounted, and she already notes the border of the zero level.

Next, bars with a smooth section are nailed to the surface of the boards. They, the upper part and form a zero level. On the surface of the bars, a position is established in which a cord will be located, indicating the external and inner perimeters of the walls, future pillars of the foundation base.

Follow the control of not only the perimeter, but also the diagonals. To calculate their size, use the Pythagoras theorem. Next, nails are driven, and a fishing line or cord is pulled on them. This cloak is control and subsequently removed.

In places of intersection of cords with pillars, pillars will be located. To make a plumb line, there is enough to use a pan that does not have a bottom on which there is a load in the form of a stone. A hole is dug up with this circle, and drilling begins.

To build this type of foundation, large physical efforts should be invested in it, since you need to use manual drilling drilling of wells. For its manufacture, you should have only the initial experience with welding.

At first, about four wells are drilled, and then extensions are made in them. In the presence of a small amount of sand in the ground, the complexity of the drilling increases. In order to facilitate the work, water is poured into the well in the process of drilling. This is necessary in the evening, on the eve of the work. The minimum amount of water is 50 liters. The number of wells for the construction of a small bath is at least 40 pieces, so you will have to work for fame.

A rather complicated process is the drilling of expansion, they require tremendous efforts, since during the day, it is possible to build no more than four extensions. With a design diameter of 25 cm, and an extension of 50 cm, about 25 kg of cement will require the filling of each pillar. The density of concrete should be optimal not so thick as to take it with a shovel, but not liquid, in order to avoid spreading.

The next step of the work is the strengthening of the walls of the foundation. It is a procedure for bending the reinforcement. In order to avoid wounds during work, in some areas, pieces of metal pipes are allowed. To calculate the length of one bar should proceed from the total length of the foundation, to which about 16 cm is added, for the air clearance. For the equipment of one pillar, two rods are required, each length is about 150 cm.

The reinforcement should rise slightly above the pillar. Subsequently, it is used as a concrete mixture.

To conduct waterproofing of this type of foundation, the use of roofing material is best suited. It differs in the ease of installation and is cut directly near the pillar, turns shirt and mounted on the surface. For fixing pieces of roofing material, a stapler is suitable. After filling out the expansion in the installation of reinforcement, waterproofing is installed.

After that, the concrete process should be carried out, which should be carried out immediately after the installation of waterproofing. It is better to concrete several pillars, after pouring the pillars and their backfill, the grillage is arranged.

Next, the pillars are achieved. For concrete kneading, a shovel is used, all work is carried out near the wells. A concrete mixer is able to speed up the process several times.

The final stage in the construction of piles by TISE technology is the construction of a grillage. For this, they put up shields and their boil using a dense plastic film. To strengthen the formwork, the stilettos are used. The reinforcement is laid on them, which is fixed using plastic screeds.

Tip: The arrangement of the foundation process is quite expensive in time and in physical efforts. However, with the aim of saving, it is not recommended to buy a drill, from companies engaged in the construction of TISE technology. The manufacture of a drilling installation of a house will cost much cheaper and more practical. In addition, you should take care of the presence of two drills that will make not only the well, but also the expansion in it.

New Methods of construction technology TISE

The essence of TISE methodology is simplicity, but at the same time originality. For the construction of walls, a special formwork is required, which is rearranged from one place to another. In addition, the presence of an underlying layer of concrete mixture is necessary. Thus, ready -made concrete blocks form the frame structure of the walls.

The wall blocks contain walls and air sinuses, with the help of which thermal insulation occurs. The wall thickness is correlated with an air gap of about one to four.

Perennial experience of builders has proved that it is the accumulation of air that provides maximum thermal insulation, so the use of this TISE construction technology allows organizing high -quality heat transfer. The walls of the building are one of its most costly and important parts. For their construction, a large amount of solution is needed, which is laid according to a special technology.

Advantages of wall construction using TISE:

- obtaining a monolithic structure, the blocks of which are created directly at the construction object;

- ease and simplicity of installation work;

- Since the wall has three sinuses, for the filling of which expanded clay or foam is used, its thermal insulation is at the proper level;

- the use of materials of various composition;

- The lack of the need for professional skills in working with certain equipment.

DIY TISE technology - wall construction

The development of forms for the construction of blocks was invented to increase the speed of work and simplify the process of erecting walls. Since the formation, installation and hardening of the block occurs in one position, time is saved three times more.

For the manufacture of the form, the simplest details such as metal corners and plates will be required. It is regulated in accordance with the individual parameters of each building being built.

It is possible to purchase this formwork from firms engaged in the construction of TISE, although the process of its manufacture is quite simple, and if desired is quite feasible. This process does not need a vibration engine, so electricity for the construction of walls is not required.

With the help of this formwork, separate cinder blocks are made for private construction from materials in the form:

- sawdust with concrete;

- slag compositions;

- concrete with gravel;

- cement mortar;

- Clay with cement mortar.

The walls of the block are not binded by a transverse edge, therefore, in the inside of the room there are no cold bridges, and heat loss is minimized.

For the manufacture of a house using TISE technology, any of the previously listed types of solutions is used. We offer to get acquainted with the instructions that will help to do this:

1. Delay the surface of the formwork with water.

2. Set the formwork to the location of the block.

3. Set the transverse direction rods.

4. Install limiters in the form of cubes.

5. Install the longitudinal rods.

6. Take care of laying the solution in several stages, while each of the layers requires a thorough tamping.

7. Install the damper or cover that additionally compact the composition.

8. Take care of taking out the rod.

9. Special lever remove the limiters.

11. Next, remove the walls of the formwork.

12. Each four row laying is installed by a plastic track of the mesh.

Some types of formwork involve reinforcement using basalt rods. The manufacturing procedure of one block takes from five to eight minutes. For grouting vertical seams, a raw solution is used between blocks.

TISE video foundation: