Today, the share of quick -collection houses in the country's country has reached about 35 ...

|

|

Choosing a water warm floor is one of the economical options for heating the room, which ... |

Each motorist simply dreams of his warm garage. He represents how in ... |

Clay plaster step -by -step instructions

The modern market for building materials offers a wide selection of finishing agents that allow the facade of the house or the internal walls of the room in an original and high -quality facade. In this article, we will consider the features of plastering walls with clay with detailed instructions for the preparation of the solution and applying it to the surface.

Table of contents:

- The advantages and disadvantages of clay plaster

- Clay plaster: composition and types of solution

- Clay plaster technology

- Step -by -step instructions of plastering clay

- Recommendations of specialists for applying clay plaster layer

The advantages and disadvantages of clay plaster

Clay plaster is considered environmentally friendly and natural material, which has been used in construction since ancient times. The use of plaster in practice will ensure a beautiful design of the room. The walls, plastered by clay, will breathe, without secreting harmful substances into the air. Moreover, this material is not harmful, unlike other putty solutions made on the basis of polymers and other synthetic substances.

Earlier, the plastering of walls in this way was the only option for finishing work. Despite the fact that modern manufacturers offer a wide selection of different solutions, yet many buyers prefer to use natural materials. Plaster in the house of clay has many advantages that will be described below:

- Ecological and natural product.

- A clay solution is able to absorb moisture, which will provide from the destruction of walls.

- The low cost of materials in comparison with other types of products.

- After applying the solution, there is practically no waste, while the remains of clay can be re -used.

- Simplicity of carrying out the preparation of the mixture.

- Clay for wall plaster will protect the surface from mechanical and other exposure.

- The material is elastic in its structure.

- Clay can be used for finishing work indoors and for the facade.

- Clay application technologies will create an original decorative pattern on the walls, and adding paint forms a certain shade.

Clay plaster has its drawbacks, which is determined by the following parameters:

1. Natural clay, which does not have different additives, is a kind of material for which experience is needed. When preparing a solution, most importantly, to correctly calculate all the components, because a certain recipe for making a mixture does not exist.

2. Plassing the facade of the house is not an easy business. It is important to consider that clay absorbs all moisture well, which is why small cracks appear around the perimeter of the building from time to time. Thus, clay walls will need to be updated every year.

3. Recently, there are not many masters who would professionally engage in plastering walls with clay, and therefore wages to workers can be expensive.

Most of the construction stores offer a wide range of goods, while on the shelves you can see decorative clay, as well as a mixture of different shades and variations. The packaging usually indicates physical and other clay characteristics, as well as manufacturers present a small instructions for use. In fact, it is not necessary to purchase clay in natural form, because it will be possible to buy a cooked mixture, which will facilitate the process of work for a beginner.

It's important to know! If you decide to choose natural clay for a summer cottage or other places, you need to remember that the use of material without special additives can cause plaster cracking under the influence of moisture or active sunlight.

Clay plaster: composition and types of solution

To maintain the properties and the original layer of clay, many advise applying a layer of plaster along the clay base of the wall. This will strengthen the finish or facade of the building, as well as protect the material from excess moisture and the like. But, most experts use only a clay solution, the preparation technology of which has this sequence:

- sand;

- clay;

- water;

- sawly sawdust or other type of material.

It is worth knowing that sawdust of various kinds, as well as different fibers are added to clay so that the solution is fastened and connected. This will make it possible to get rid of the cracking of the surface of the wall under the influence of the sun or other natural factors.

A clay solution for plaster can be divided into several types, which depends on the materials added to the mixture. So, there are such types of plaster mixture:

- solution with the addition of sand;

- a mixture with sawdust from different wood;

- combined combination with the addition of two previous components.

In certain situations, when it is important to create a high -quality mixture for decorating the facade of the building, you need to add cement or putty. These materials will fasten the solution. Before starting finishing work, it is important to calculate the climatic zone of the house. This is due to the fact that clay is a heat -insulating layer. Before starting work on plaster clay with sawdust, it is necessary to study the characteristics and features of the processed surface.

Clay plaster technology

When preparing the solution, it is necessary to know that the addition of synthetic fibers is recommended for black wall decoration or for the formation of the insulation layer. You can add cement or sand to the plaster, which will reduce the elasticity of the mixture, and also allow you to maintain heat in the thickness of the walls.

It is advised to apply a solution of clay for plaster walls when the insulation layer in the room has already been installed. The main positive property of clay is that it is great for adhesion with other materials, for example, with wood, stone, cement or concrete. To prepare a solution of clay, the following devices will be needed:

- dishes for kneading the mixture;

- bayonet shovel;

- screwdriver;

- a set of spatulas for applying and distributing clay on the surface;

- a large sieve for sifting different components that are added to the mixture;

- drill with an additional nozzle for a mixer;

- to attach a metal mesh, you need a punch.

Also, for the preparation of the solution you will need different materials that are:

- metal grid, which will be used to reinforce the surface of the wall;

- clay;

- additional fibers or sawdust, which depends on the type of work;

- dowels that will attach the grid to the surface of the wall.

After the preparation of the necessary tools, devices, as well as materials, you can proceed to the preparation of the mixture. Many are interested in the question: how to dilute clay for plaster? As a rule, the technology of work depends on the type of clay, which may differ in different parameters. In this case, there is no certain procedure for stirring clay and preparation of the solution. However, when performing work, it is necessary to adhere to the sequence, which determines the quality of the manufactured mixture:

1. First, you need to prepare all the components used in the work.

2. After that, the clay is soaked in water and left for a day.

3. After the time, the wet mixture must be mixed again and remove excess water from the container.

4. Different fibers, sawdust, as well as sand, it is important to sift through a sieve.

5. After cleansing the additional components, they are added to the clay along with the water, while all the components are thoroughly mixed.

6. The prepared mixture should have a thick and sticky consistency, and the ratio of the proportion of clay and sand for plaster should be 1: 2 or 1: 5.

After the implementation of these work, the mixture becomes ready for use. If the composition of the solution is too sticky, then a little sand must be added to remove this property. The manufactured mixture can be checked for plasticity with several methods:

- Visually, a mixture of clay should resemble a type of thick sour cream.

- You can also make a small ball. It must be pressed to a solid base, creating a plane with a thickness of 1 cm. If all the components are mixed correctly, then the crushed edges of the ball should not crack.

Another option for checking the plasticity of the solution will be the following procedure. To do this, you need to create a ball, after which it is dropped on the floor from a height of one and a half meters. The effective effect should be that the ball should not crack.

On a note! If the ball cracked in one of the methods for checking plasticity, this may indicate an excess of sand. If the ball spreads, then this is indicated by the presence of a large amount of water in the solution. All disadvantages are easy to fix, adding the necessary components to the mixture and mixing them.

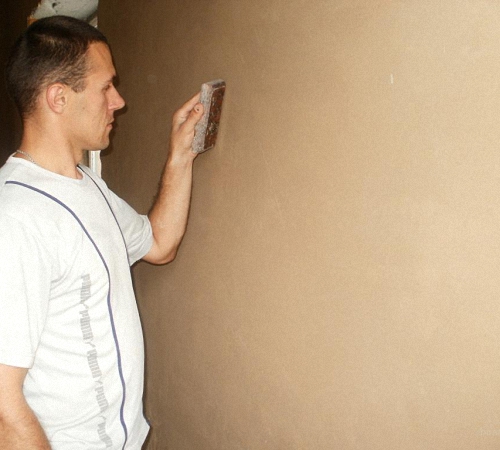

Step -by -step instructions of plastering clay

The technology of work with clay resembles a way of applying a cement mortar. For the preparation of the solution, the main components of the plaster: sand, clay, cement that can be added to fasten the mixture. When carrying out work, you should adhere to the following instructions:

1. First, attach a grid and metal to the working area using dowels. This is important for reliable application of the solution.

2. With the use of a spatula, the solution is applied to the surface of the wall. The thickness of the clay layer should be no more than 5 cm. This layer is black and does not need to be aligned.

3. After applying the first layer, you need to wait until it is completely dry, after which you can start further decoration.

4. When the black surface has dried, it is necessary to clean it and sanded using sandpaper.

5. The last and final stage of the plaster is the finish coating of the wall surface.

Plastering walls with clay is an excellent solution for insulation and finishing of a country house. This option of applying plaster is excellent for the rustic style or design of houses from a log house or wood, which will ensure the environmental friendliness of the construction. As a decoration, you can apply volumetric embossing or clay modeling technology. To protect the surface of the wall from external exposure, you can paint the clay with paint and vanicular products of different shades.

Recommendations of specialists for applying clay plaster layer

Specialists in the field of plastering houses advise adhere to some recommendations for the work. For example, starting finishing work immediately after building a house is not recommended. Otherwise, the house will still succumb to sediment, as a result of which plaster on the walls will crack. The approximate period of precipitation of the house is 1.5-2 years for wooden or brick structures. The building, erected from foam concrete or aerated concrete, has a lower load, which determines the precipitation period of 4-6 months.

After the erected house stands out, you can start plastering with clay video works that can be seen at the end of the article. At first, it is important to make the interior decoration of the room, and lastly you need to start external work. This moment is explained by thermal and physical parameters and a feature of the finish. This will avoid cracking a layer of plaster from steam exposure.

Before plastering, you need to prepare the walls. First of all, they should be even. Indeed, with an unequal surface, a layer of clay in various places will be different, which is not very good. In this case, the layer of plaster will be thicker, which is not very favorable, because the standard thickness of the layer should be up to 2 cm. With a large thickness of clay plaster, it will begin to crack and fall off. Also, a layer of plaster in 4 or 5 mm is also not recommended, otherwise, the mixture will not stay on the wall.

When applying the plaster layer, you need to remember the adhesion of the solution with the wall. To do this, the surface is pre -wetted with water, after which you can apply plaster. This will create reliable fastening of the finish and walls. At the same time, clay can not be applied to the surface not immediately, but thin layers. This will make it better to cross the building material, which will extend the life of the plaster layer of clay.

The technology of plastering walls with clay is not laborious, however, it requires certain attentiveness in the manufacture of the solution and applying it to the wall surface. All work can be done with your own hands, most importantly, adhere to the recommendations of specialists and step -by -step instructions for the expected result of work.

There are already ready -made stucco

There are already ready -made domestic production plasters. "Natural lines" http://nature-material.ru.

clay for metal

clay on a metal mesh?!

Apparently the author

Apparently the author of the article has never worked with clay. A clay solution is made with sand in a proportion of 1: 3, that is, one part of the clay and three parts of the sand. Clay is pounced on uneven walls, and not plastered. The layer can be different, but finishing, that is, the finish within 1-2 cm thick. In clay for the fortress and so that there are no cracks, they add straw and throw both on the walls and on the ceiling. They give it to dry, and then make the finish plaster.