Quite often, there is a need to drill holes in the walls of brick. However...

|

|

Laminate is a floor covering based on the CDF (material from ... |

Beauty and reliability are the basic requirements that consumers make ... |

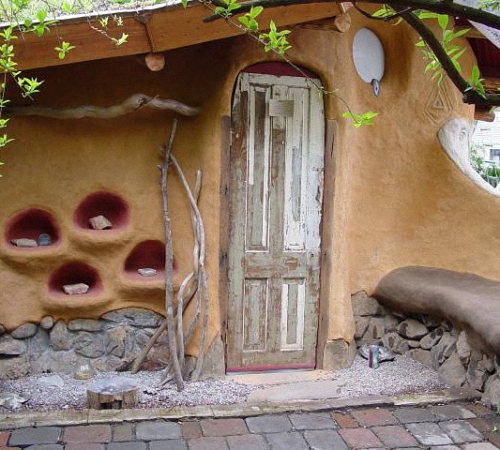

Saman with your own hands

Homemade brick Saman, made of straw and clay, the most ancient of the environmentally friendly building materials known to humanity. It is used for economical buildings of houses in heat climate, and for caman house -building it is widespread everywhere. The simplest home -made brick is based on a clay and plant raw material substrate, and the straw is most often used. Saman's technology is very simple, and you can do without any technical means and make straw bricks with your own hands.

Table of contents:

- Composition and properties of the material

- Materials for Saman

- How to choose high -quality components for Saman

- PROCOPTIONS OF THE COMMUNICAL FOR SOMAN

- Samanic brick form and drying place

- Place for kneading clay and straw and methods of mixing components

- Stages of manufacturing brick of clay and straw

- Checking the finished Saman

Composition and properties of the material

1. Saman has been known since ancient Egypt, but they did it not for the pyramids, but for the settlements of poor workers or slaves. Today, Saman is popular in rural areas around the world, especially where he does not have an alternative. The methods of its manufacture and proportions are mentioned in ancient manuscripts, and still nothing has changed, except for the varieties of straw. Although in our time, production technology has gone very far, but in many places it is known as the most affordable material of Saman photo.

2. For centuries in the Ukrainian and Kuban steppes, where there are few wood, people gathered with all the village and knead their feet a mixture for the samanas for the development of newlyweds. What could be easier than straw, water and clay are everywhere, a self -firing brick does not require firing, but kneaded it with the whole community and with the help of horses. All continents know how to make Saman, and this method of obtaining the simplest environmentally friendly building materials remains quite in demand. A qualitatively made self -made brick and the house from it serves for many years.

3. The natural components of this material are practically lying under the feet, which makes it almost free, not counting labor and wooden forms to fill the mixture of clay, water and straw. Houses made of samannt masonry are well held heat, they are quite fire resistant and quite reliable, thanks to clay, but they need to be designed outside. In the Moldovan and Ukrainian villages, the outer wall was additionally plastered with clay and whitewilled with a lime-low solution.

4. It has long noticed that buildings from Saman are most useful for the health of asthmatics, allergy sufferers and other people with a weakened immune system. Moving to the countryside for the sake of the old house of Samannaya masonry often becomes forced necessity. It is believed that the clay house breathes, regulates humidity and temperature, absorbs harmful gases.

5. There are varieties of self-saman bricks in the type of straw and proportional composition, therefore there are a heavy saam (75-80%clay), simple (40-60%) and light (10-20%), and the rest of the organic filler. A heavy saam is used for formwork and in the form of bricks for the outer wall and near the stove, light straw brick in frame -type houses or for secondary walls.

Materials for Saman

Saman with their own hands make them 4 simple components:

- clay;

- a little sand;

- straw;

- water.

The proportions can be used ready -made, they will be discussed further, but it is better to independently make several samples of different compositions to find the best option.

1. Ideal construction clay is almost not found in nature, and a certain percentage of sand makes it most suitable. River sand is added to fat clay, which is pre -sifted. Clay should also be sorted out with a shovel, remove stones and impurities, leaving it to be sophisticated to improve quality.

2. Ideal sand is coarse -grained about 1 mm, too small, with a high content of salt and dust, is not suitable. The sifted sand is dried, it is important that it does not have garbage, roots, shells, it is important to remove this so as not to get hurt when mixed.

3. Any fresh straw of barley, wheat, rye is suitable. It is important that it is not adequate, rotten or mold, as disputes can take root in the house.

4. Water is no less important component of the samannt mixture, since its chemical composition can be destructive. As you know, the microflora of the mixture and the durability of the Saman will depend on the acid-base balance. For this reason, they do not take water from swamps and stagnant ponds, but only clean, drinking or technical from the well, spring or well.

How to choose high -quality components for Saman

Clay is found everywhere, and in many villages it was chosen in places of collapse by the river. In any area, you can ask where local builders, stovers or potters are gaining clay. Clay samples can be taken in different areas when digging deep holes, pits for the foundation or wells to find the most suitable for the techno technique.

Clay may differ in the content of sand, salts, organic substances and mineral fillers in it. In different places, it has a different shade, consistency, viscosity or fat content. This property is determined by the fingers of a slightly moistened clay and knead in the hands, while the ball of 4-5 cm stops sticking to the hands, like the finished dough. A lump should dry on a smooth dry surface for 2-3 days.

Fatty clay when large cracks formed on the ball, and small grooves up to 1-2 mm show that it is a good construction, especially if the dropped ball did not fall apart. Small sand is added to the fat clay, and the proportions are verified using repeated samples with a ball.

The second way to make a larger ball, which will fit in the palm of your hand, dry it in the sun for 1-2 hours. The finished ball from the height of their height is dropped on a smooth surface, and if the ball was slightly grinned, cracked and did not fall apart, then the collapse was successful. A flattened ball without cracks requires more sand, and there are too many of it in the scattering.

The optimal choice of sand obtained by a career way. It is multifaceted and large, unlike the river, which is rounded and polished, therefore, the clutch indicator has worse. It is not recommended to take sea sand due to the large content of salts, but if there is no other opportunity, then they use any sand that is available.

The straw from the spring wheat is less than the stalking wax, so in the Samanic brick it is less durable than winter. Choosing a straw or other vegetable and fiber filler, they prefer wheat, but other plant fibers are added a little. In different regions, horsetails are mixed in straw brick, moss, rice straw, cotton, wood chips, echiped seeds, crushed corn leaves, hard hay, horse manure, etc.

PROCOPTIONS OF THE COMMUNICAL FOR SOMAN

The manufacture of self -defeated bricks with their own hands is most suitable for frozen clay, which was folded into the tower bacters and overwinter there.

It should be borne in mind that many clay will need a lot of 1000 bricks of the adult of about 6.5-7 m of clay, into which 2-3 straw chapes will be together. On the 1st cubic meter of the Samana, they cook:

- for very fat clay, 1 part of the sand and 15-18 kg of filler are mixed with 1-2 parts;

- for fat clay, 1 part of the sand and 12-15 kg of filler are mixed with 2-3 parts of fat;

- with a slight fat content of clay, 1 part of the sand and up to 10 kg of straw or other plant fibers are mixed with 3-4 parts.

These are only general recommendations, and not accurate proportions that specify straw, clay, sand, water on their local samples. The quality of the sand, the size of the grains and their roughness, also affect the percentage of sand.

Straws take 2-4 parts per 1m mixture, and the proportions of clay and sand can be:

- 3:1,

- 2:1,

- 1:1,

- 1:2,

- 1:3.

Samanic brick form and drying place

Whatever the technological technique, the proportion of a mixture or a vegetable filler, the production of any molding building materials is not complete without special forms. The only difference between this method in multi -tower or single wooden forms does not have a bottom. They are more like a small ladder with thin partitions and the same oblong holes than on the usual metal or plastic forms in the form of a box. Homemade straw brick is usually made using homemade wooden shapes as on a Saman video.

Do -it -yourself wooden shapes are made of strings no thicker than 35 mm, the width of the board determines the height of the end part of the adult. Having decided on the rest of the dimensions, for example, 20x20x40 cm, it is important to make a drawing of the shape to cut the boards connecting with self -tapping screws at the junction. The shape should be minor so that it is convenient to carry, usually the amount of melting varies within 1-5, and its edges are supplied with handles, as in the photo of the saman.

So that when the products from the mold, Saman easily falls on the smooth surface for drying, the walls of the shape should be as smooth as possible, the corners with an accurate fitting of 90. The brick platform is sprinkled with a small layer of straw or hay so clay will not stick to the surface, and the plant fibers are included Its composition. In an open area where it is possible to rain, the finished saam is covered with a film or an awning. Until the complete drying, it will be stored until 2 weeks.

Tip: Remember that when the Saman dries, the size of the briquettes will decrease by about 8-10 %, so for the exact size you can make a slightly larger shape. In order for the formed mixture to be better removed, the boards are wetted inside the cells and sprinkled with small plant substrate or sand, but this is not necessary when the excavation process goes without problems. After ramp, the excess mixture is removed with a smooth board.

Place for kneading clay and straw and methods of mixing components

The main ways of mixing a samanide mixture:

- legs,

- with the help of horses,

- concrete mixer,

- motoblock or tractor.

To choose the most convenient way to obtain a high -quality mixture, it is important to know how it was done by the old fashioned way, without technical means. In the villages they invited everyone who made kneading bare feet in a special non -deep pit, and at the end everyone was supposed to be treated with the owners of the construction site. The second method was driven by a hole for a kneading horse with a guide. At the same time, a person walked along the inner diameter, holding the horse by the reins, and the horse along the outer. At the same time, the reins had to be pulled closer to himself and go to the center so that the horse was changing the trajectory, because to simplify the move along the viscous mixture, she tries to become a ready trace. The assistants after the knighters poured new portions of straw. For large volumes, 2-3 horses were taken, which were changed in turn.

Today they use special devices, such as concrete mixers, use a motor block or tractor, but this is problematic due to the sticking of the mixture into the wheel and soil entering the mixture. The straw enters the cutters of the rotary cultivator or a walk -behind tractor, and you have to constantly clean. It is impossible to knead clay in the cold time in boots, since the shoes are grinning, sticking and decreasing.

For kneading with your feet, a shallow pit is prepared up to 40-50 cm, the width is arbitrary, but so that the bottom is covered with a tarp or film. Usually they make a circle up to 2.5 meters, and for a horse twice as much. Do not make a high layer of the mixture, otherwise not to achieve high -quality kneading. On dense heavy soils, where water is poorly absorbed, do without a film or tarpaulin, but the bottom of the pit should be perfectly smooth.

At one ancient recipe, water was first poured into the pit, then clay was covered and left for the night so that it was well wetted, then sand and all the straw for kneading were poured. There are other technologies, for example, when a mixture of sand and clay was poured with water in front of the batch, and added straw gradually.

A mixture of clay, water and sand and 3-4 rounded stone up to 10 kg weighing is laid in a concrete mixer, which help to mix clay. The straw is not added there, and mixing with the filler is done in a prepared place to continue the process of the legs.

Tip: For the preparation of small portions of the Saman, a mixture of clay with sand is kneaded in the trough on the water, you can with a shovel, checking the viscosity, the finished mass is similar to a thick sour cream that flows from the shovel. Next, the vegetable filler is mixed with viscous clay and thrown into the molds with a shovel and tamped with the hands, especially at the corners, and the top is leveled.

Stages of manufacturing brick of clay and straw

1. Prepare a plant filler, clay, sand, water, as well as a place for a batch of a mixture and drying of the adult.

2. Prepare a pit for a kneading to be a depth of up to 35-50 cm with an even bottom and steep walls.

3. The bottom of the pits is lined with whole tarpaulin, tent, film or other waterproof fabric, fixing the edges outside the recess.

4. In the prepared seizure, up to 1/3 of the depth of water is poured, pouring clay and sand in a verified proportion.

5. The process of kneading is made by legs or with the help of horses. It is convenient to hold hands so as not to slip on a tarp. In a small pit, you can raise the edges of the tarpaulin, turning the edges of the mixture.

6. Check the quality of a sandy-clay solution without lumps, a homogeneous mixture is sculpted with fingers.

7. The straw is covered gradually, after the next portion is completely immersed in wet clay. It cannot be added to the straw to the water and it swims and interferes worse.

8. The addition of straw goes to those time until the mixture resembles a plastic thick dough, where there are no puddles and dry straw.

9. They also make sure that the mixture does not dry and did not harden it so difficult to lay out in the forms and remove it for drying.

10. The finished mixture with a shovel or pitchfork is loaded on a stretcher or to a wheelbarrow and sent to molding.

11. Ready -made forms are wetted inside, sprinkled with sand or substrate, placed at the place of brick excavation. The cells with wet Saman are stuffed to the top, checking the filling of the corners, and the tops are equal to the top or a wide building spatula.

12. Remove the shape, holding the handles on both sides and tapping along the walls, removes vertically so as not to damage the shape. If the formed Saman does not fall out, you can gently push your hand.

13. Before filling the new batch, the shape is cleaned, moistened and sprinkled again, after which they put in parallel with ready -made briquettes, but not too tightly to dry better.

14. Until the end of the insan mixture, the entire molding process is repeated, make sure that the diluted solution does not dry out, losing properties. There should be so many finished solutions and the number of assistants to complete the entire process in a day. The residues of the mixture can be used for repair work in outbuildings.

Tip: Samannaya brick dries in about a week or two, it needs to be turned over and put on a rib. Then it is cleaned in a barn or under a canopy, laying with stacks until need. If there is nowhere to remove it with stacks on the shield from the boards and covered with slate or tarpaulin from the rain.

Checking the finished Saman

For samples for readiness, take a couple of ready -made bricks and break the color outside and the same inside, when it has completely dried. High -quality Saman has no cracks and defects, it does not fall apart in a bucket of water, and dry is well cut with an ax. When trying to score a nail, he should enter the samanas tightly and hold firmly. Smam Saman from the roof of a one -story building or a barn, it should be whole or split in two, but not fall apart. Sometimes a good Saman manages to make on the second attempt, changing the proportions and the time of kneading.

Saman is left in

Saman is a poison left in places of accumulation.