Not every owner boasts perfectly even relief, hence the conclusion ...

|

|

In multi -storey and private construction, it is impossible to do without floor slabs, ... |

Sooner or later, each of us is faced with the need to build or repair ... |

Varieties of modern facade systems and their characteristic. Design features of the installation of the facade system with your own hands

The modern facade system must meet certain requirements, namely, an increase in the thermal insulation characteristics of the building, a decrease in thermal losses and an attractive appearance. Several options for the decoration and arrangement of the facade are distinguished. We will talk about their features, advantages and installation technologies further.

Table of contents:

- Characteristics and types of facade systems

- Ventilated facade systems: device, advantages, installation technology

- The device of the facade system of wet type

- Characterization of facade aluminum systems

Characteristics and types of facade systems

To obtain the maximum functional facade system, you need to choose the option of the facade that is suitable for a specific building. Materials for its manufacture should be certified and high -quality.

Facade decoration is the final stage of the construction of a new house or the reconstruction of the old. Several types of modern facade systems are distinguished depending on the design and manufacturing material. The use of aluminum, systems based on aluminum, plastic, steel, plaster is determined by the specific conditions of their installation and type of building.

In relation to installation technology, such facade systems are distinguished:

- Sandwich panel - thermal insulation material with already ready double -sided protection;

- The wet facade - the insulation is installed on the pre -treated surface and is additionally covered with a layer of plaster, which is applied to the reinforced coating;

- The ventilated facade system is the presence of an air gap between the internal and external wall in the structural characteristics of the facade.

Each of the options for the facade system is based on the use of purely individual materials for its installation. Sandwich panels are mounted directly on the facing material. A wet facade system is based on the installation of insulation from the outside. For the manufacture of panels, use vinyl -based plastic or galvanized steel. However, the most reliable and durable in operation are aluminum facade systems. They are not amenable to corrosion, tolerate any mechanical damage well and do not burn. The powder coloring coating of aluminum panels perfectly protects against atmospheric effects. In addition, a rich color palette allows you to choose the best option for the decoration of the facade.

The designs of the wet facade are based on the use of modern materials of thermal insulation adhesive and reinforcing purposes. They provide the building with high thermal insulation characteristics, prevent the development of dampness, improve fire safety and differ in environmental harmlessness.

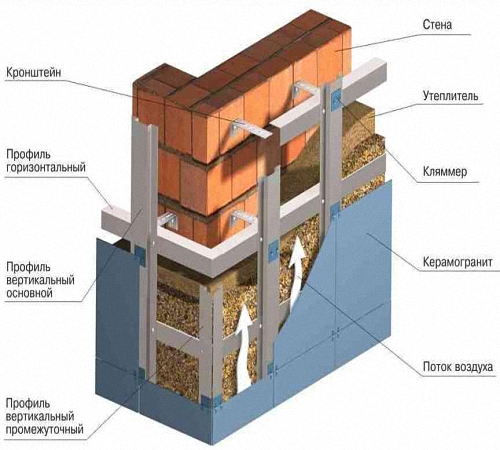

Ventilated facade systems: device, advantages, installation technology

Ventilated facade systems differ in a mass of advantages, among which we note:

- the duration of operation without additional repair for 45-50 years;

- protection before aggressive factors, prevention of corrosion;

- Excellent thermal insulation properties - in the summer in the building in the building coolly, and in winter - heat;

- improvement of energy efficiency by 30%, saving on heating;

- protection against various environmental factors, such as moisture, meltwater, condensate masses, protection against waterlogging of the carrier wall;

- improved soundproofing indicators;

- high level of fire safety, since the design consists of materials that are not amenable to burning;

- highly effective lightning protection;

- complete environmental safety and certification of materials for the installation of the facade system;

- reduced operational characteristics;

- the possibility of installation both in summer and in winter;

- ease of dismantling and re -use of materials for the ventilated facade;

- A variety of facing materials, namely: panels made of aluminum, natural stone, porcelain tile;

- A variety of design solutions, various texture components, textured inclusions;

- The ability to use dark cladding in the color of the building in the summer in the summer.

To obtain a high -quality ventilated facade, we will analyze the phased technology of its installation. Before starting work, the creation of a project is made in which the type of cladding, layout, size of the structure is clearly indicated, the calculations of the ventilated facade are made. Thus, it is possible to minimize the costs of the structure of the facade system.

Installation technology of a hinged facade system:

1. Preparatory stage.

Before starting the construction of a ventilated facade, prepare the building and the site for work. Designate the boundaries of the zone dangerous for the stay of people, make markings and place for the location of building materials.

2. Marking points of mounting fasteners.

Before starting the main installation work, mark the walls of the wall, install the main stubborn brackets. Mark the marking with previously created drawings.

At the initial stage, determine the lines of the lighthouse location, mark with indelible paint. Using a plumb line, determine the vertical lines of the installation of structures.

3. Installation of brackets.

Run the holes for the fasteners using a perforator. Remove the sludge and install anchor fasteners. Before starting the fixation of the bracket, install a paronite gasket for it. Using the anchor dowel, install the supporting brackets using a screwdriver.

4. Installation of heat -insulating materials and wind protection.

Initially, the plate version of the insulation is installed, then the installation of a windproof membrane follows, while the overlap of the paintings is about 10 cm. The thickness of the plates is determined individually, in the ratio with the parameters of the walls of the building. The interval between dowels and the extreme part of the insulation is 50 cm.

The insulation is installed from the lower row, the start profile is pre -mounted. Plates are hung in compliance with a chess sequence, in a horizontal attitude to each other. The cracks between the insulation plates are unacceptable.

5. Installation of guides, window slopes and castings.

Vertical guides are installed on adjustable brackets, and the profiles are fixed with special rivets. To check the evenness of the base, use the level. In places of docking of vertical sites, it is recommended to equip a gap of 0.8-1 cm.

6. Finishing the ventilated facade.

As finishing the facade, porcelain tiles, metal cassettes, natural stone, and siding are used.

The installation of a particular material is determined by individual technical characteristics.

The device of the facade system of wet type

There are three options for mounting a wet facade:

1. Organic - implies the use of polystyrene foam for wall insulation, organic mass is used as a reinforcing coating, and plaster on a silicone or organic basis is used as a finish layer.

2. Mineral - the heat -insulating component of this system is mineral wool. A special mass is used as a reinforcing layer, and the finished component is a mineral or silicone type plaster.

3. Combined - connection of the two previous options, at various stages of work.

Advantages of wet -type facade systems:

- affordable cost;

- saving the useful space indoors, since the insulation is installed outside;

- additional soundproofing effect;

- attractive appearance of the walls after finishing;

- the possibility of updating and reconstruction;

- long service life;

- Various execution options.

In addition, a wet facade system does not need additional space, insulation is lightweight and does not load the structure. The life of such a system is about 30 years without additional repair. External thermal insulation leads to reduce heat loss compared to other options for facade systems.

Despite this, this facade system is distinguished by the following shortcomings:

- The time of repair work is limited by the temperature regime, which should not be below 5 degrees of heat;

- The wet facade does not tolerate high humidity, frost, atmospheric precipitation, in addition, it is not recommended to work on the decoration of the facade during the day, under direct sunlight;

- Be sure to provide the surface protection from wind, dust and dirt.

Several ways to fix the wet facade are distinguished. According to the first, dowels are used to fix the insulation. This method is relevant, with a small thickness of the plaster layer. The second option is the use of movable hinges as fasteners. It is used for wall thickness of about thirty centimeters. The combination of the adhesive method with dowels is the most popular and reliable mounting method. Initially, the insulation is fixed on the wall with glue, and is additionally fixed with dowels.

The installation technology of the facade system implies the mandatory location of the insulation in a checkerboard pattern, the installation of dowels after the adhesive composition completely dry.

Characterization of facade aluminum systems

Among the advantages of a facade system based on aluminum, we note:

- easy and quick installation;

- modern and attractive appearance;

- ensuring the protection of the structure from atmospheric precipitation;

- affordable cost;

- Light weight does not load the structure;

- a variety of color solutions;

- universal use;

- corrosion inappropriateness;

- A variety of options.

Facade aluminum systems differ not only in modern appearance, but also have high mechanical strength. A successful combination of the aesthetic component with functional features makes it possible to get a strong coating, which will last at least half a century.

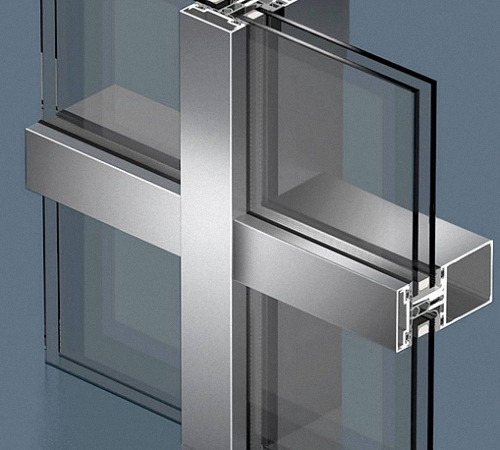

In the ratio with the form, several options for aluminum profiles are distinguished. Additionally, they are equipped with double -glazed windows or ordinary glasses. Aluminum facades with stained glass systems give the structure weightlessness, but at the same time they do not lose strength.

The possibility of installing translucent elements is possible with aluminum structures of not only walls, but also the roof. These systems have an unlimited scope of use, however, most often are used for decoration of multi -storey public buildings: shops, office and shopping centers, gyms and trading houses. The reliability and aesthetic characteristics of the facade favorably distinguish it against the background of other buildings, while filling the premises with daylight.

Several varieties of aluminum facade systems are distinguished:

1. The facade of the construction -trigel type is one of the highest resistance options. The appearance of this structure is rather concise glasses are fixed on the facade exclusively in the shape of a rectangle.

2. Half -structural facade systems - differ in a number of design differences. Contain internal supporting racks that are fixed by the external clamping mechanism. The cost of this design is slightly higher than the previous option. However, such a system is characterized by a large number of execution options.

3. Structural facade aluminum systems - have similar characteristics with semi -structural facades. The main difference is in the method of fixing double -glazed windows. Glasses are installed on special steel elements with a sealant. The strength characteristics are the same as in the semi -structural facade.

In the ratio with installation technology, aluminum facade systems are:

1. Warm - the aluminum system is installed on the already finished wall of the house. Such double -glazed windows reliably hold the heat in the room, preventing additional thermal losses.

2. Cold - do not need to be attached, installed as independent supporting structures. On the aluminum frame, a high-strength tempered glass is installed with a thickness of 1-2 mm.

3. Combined - semi -structural and structural systems involve the use of horizontal and vertical structures.

At the initial stage of work, the design of the facade system with your own hands is performed. Calculation of materials for work and relieving measures is carried out. In the ratio with the standards, the type of facade system is determined. Next, the various designs should be dismantled, interfering with the facade, the level of location of the structural parts is determined.

Installation work should be carried out by highly qualified specialists who install the system, seal all connections and seams.

Installation of the facade system of video:

Good afternoon, I saw the gross

Good afternoon, I saw a gross mistake, please fix it, but I would not have been misleading readers. Sandwich panel is not a facade system! The sandwich panel is designed for enclosing structures, see GOST 32603-2012. Accordingly, more scarce decisive document. And compare the sandwich panels and facade systems, or attribute them as a facade system, is extremely not left.