Powder painting doors is a technological process, as a result of which ...

|

|

It is probably no secret to anyone that wooden windows are during the operation of wooden windows ... |

Paths leading from home to other buildings or arbors, a blind area around the house, ... |

Calculation of siding for home skin

The prototype of modern piece material for lining of buildings of any purpose was invented by the inhabitants of North America. Initially, boards were used to protect houses from rains and winds that were nailed horizontally. Of course, wood is available and easy to process, but this material is subject to combustion, deformation changes under the adverse effects of nature. That is why manufacturers are working on the improvement of siding panels, giving the consumer the opportunity to choose. The article will talk about how to calculate the casing of the house with siding and the installation technology.

Content:

- Types of siding for home skin

- Contabbed elements for lining the house with siding

- Calculation of siding and components for lining the house

- DIY siding tooling tool

- House sheathing technology siding

- Facing panels care

- Important nuances when lining the house with siding

Types of siding for home skin

In the modern market, facing panels are presented with higher operational characteristics. Manufacturers produce panels of wood, metal, vinyl and cement, where each type of product has both advantages and disadvantages.

Vinyl (PVC) siding

- Vinyl siding gained the most popular due to its practicality and unpretentiousness. The main difference between such a skin is a wide range of colors and textures (it has about 100 varieties of panels). High decorative characteristics allow you to finish the walls of the building according to the architectural project.

Siding for lining at home photo

- In addition to the aesthetic attractiveness of the PVC panel, they differ in fire safety, a long service life, perfectly tolerate seasonal temperature changes, are resistant to the formation of corrosion processes and have lightweight.

- The disadvantages of the house of the house with vinyl siding include the fragility and non -combination of products. High thermal conductivity of the material requires a layer of insulation, but this condition is relevant for residential buildings. It should be noted that cheap vinyl siding from unscrupulous manufacturers is subject to burnout in the sun.

Metal siding

- For the production of piece elements, aluminum or galvanized steel is used. The decorativeness of the metal gives a polymer layer with a plain shade or imitating stone, wood, skin, etc. Mostly siding is used for facing industrial facilities or administrative buildings.

- Metal panels are not susceptible to burning, thanks to special coatings, they are resistant to corrosion. They are characterized by high strength properties, steadily tolerate mechanical damage. Qualitatively manufactured products will last at least 50 years.

- Among the negative points of the house of the house with metal siding, a higher cost, low indicators for heat and sound insulation can be noted. The high cost of the skin is determined not only by the cost of the panels themselves, but also by the invested costs of strengthening the structure due to the impressive weight of metal panels.

Cement siding

- As the main components in the production of such piece elements, Portland cement and cellulose fiber are used. Thanks to the components, the product is completely non -combustible, which is especially important for lining buildings with high fire safety requirements.

- Cement -based panels are durable, resistant to weather conditions. They are not susceptible to the development of mold, rust and insects. Decorative qualities are at a high level. The panels perfectly imitate the texture and texture of natural stone.

- Due to the high cost of the material, its large weight and complexity in processing cement siding are used when arranging the basement and design of individual architectural elements.

Wooden siding

- This material in environmental purity holds a leading position among all siding varieties. Thanks to the breathing abilities of wood, moisture does not accumulate under the skin, but evaporates freely. The panels are frost -resistant, have good indicators for thermal insulation, in addition, they are easy to process and installation.

- Wooden products are divided into subspecies depending on the method of their primary processing: drying, impregnation and heat treatment.

- Of the shortcomings, one can note the high cost, flammability and low resistance to insects and the development of the fungus. Low quality panels can be deformed under wet conditions and seasonal temperature fluctuations.

- Siding, made of pressed chips with the addition of polymers, is endowed with more impressive operational characteristics. Adding resins makes the structure of products strong and moisture resistant.

- A peculiar facade lining does not require tinting and regular treatment with anti -pirens and antiseptic agents, unlike natural wood. However, there can be no question of the environmental purity of the material, although the external resemblance to natural material is impeccable.

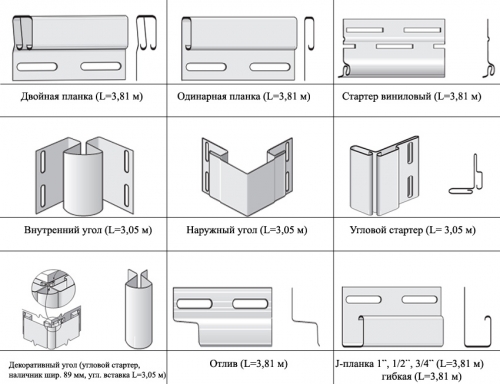

Contabbed elements for lining the house with siding

The components to the facade panels not only help to give the object a finished look, effectively hiding the joints, but also ensures their dense adjustment to each other. Conductive elements are selected the same color as siding for lining at home.

- Starting profile It is used as an initial bar during the installation of the lower row of the one coming from the base. Often it is used in places of rupture of panels, for example, when lining the building of complex architectural forms.

- Corner profiles allow you to hide the unaesthetic connection of the piece elements on both external and internal corners. Such a bar prevents moisture and snow in the places of docking the planks.

- The finish profile serves as the final element, closing the last (upper) series of siding. It is used under window openings, balconies and other protruding details of the building.

- N-profile It is installed vertically and allows you to combine horizontally located panels. Thus, a peculiar increase is made, since the length of one element is often not enough to cover the wall.

Calculation of siding and components for lining the house

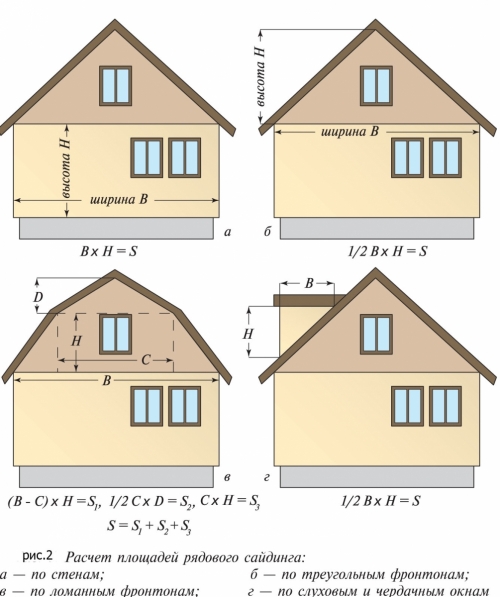

The correct calculation of the panels and additional elements of the exterior of the structure necessary for facing the exterior will help determine the amount of material, and therefore find out the estimated amount for the purchase.

- The calculation begins with calculating square meters of the surface, which is designed for facing. That is, it is necessary to determine the area of \u200b\u200ball walls. If the number of windows and doorways is minimal, then it is not necessary to subtract them from the total area.

- Next, square meters of pediments are calculated (if any). As a rule, the pediment is a correct triangle, so no difficulties should arise when calculating.

- All values \u200b\u200bare summarized, and the result is divided into the area of \u200b\u200bone panel. As a result, we get the required number of piece elements. 7-10% of the total waste for waste is added to the data.

- It is worth noting that if the building has complex architectural forms, then the surface is visually divided into geometric shapes of simple forms, the area of \u200b\u200bwhich is much easier to calculate.

- In addition to the panels themselves, additional elements will be needed. The calculation of the profile and corners is simply performed. There are measurements of the length and width of the walls, external and internal corners, as well as window and doorways. The total length for a specific profile is divided into a similar indicator of one element.

Despite all the efforts to calculate the exact amount of material, an unprepared person will be difficult. If the owner of the building experiences difficulties with calculations, you can use special calculated forms presented on the Internet. By substituting all the necessary parameters in the table, the program will give out the final result.

Unfortunately, this method is not devoid of certain errors. The exact calculations will be provided only by a professional who has a clear understanding of the sheathing technology, he knows firsthand about the purpose of a particular profile and will certainly take into account all the accompanying nuances.

DIY siding tooling tool

- Devices for measuring and applying scorch (roulette, square, level or laser, plumb line and marker).

- Material for leveling the surface and the corresponding tool. The list will depend on the quality of the walls, the degree of damage (putty for wood or brick, trowel, spatula).

- Tool for cutting panels and profiles. The choice is based on the materials from which they are made (electrolobian, canvases for wood or metal).

- Related tools, such as: scissors, screwdriver, hammer, ladder, construction knife.

- Electric devices or manual devices for attaching profiles, slats and siding panels themselves (drill, punch, screwdriver).

- Consumables (screws, screws, drills, dowels).

The listed list is very conditional, in the process of work, other equipment may be needed. Unfortunately, unfortunately, unfortunately, it will not be possible to foresee each trifle with independent installation. Therefore, it is necessary to carefully study the technology of installing panels and, if possible, prepare the entire tool.

House sheathing technology siding

Preparation before lining the house with siding

- The surface intended for the skin is freed from all protruding elements. They remove pipes, window sills, ebbs, lanterns, an external air conditioner block. The area adjacent to the structure is also cleaned of construction waste, furniture. It is recommended to cut branches of trees resting against the walls.

- Next, surfaces are examined, the old sheathing, exfoliated or poorly holding elements are removed. If necessary, the walls and the pediment are repaired. Before performing siding the wooden house, all walls are required to be treated with antiseptic drugs and anti -pires. And large gaps of brickwork are closed with putty.

- Upon completion of the stage of preparation of surfaces, marking under the crate is performed. First, the racks are located at the corners of the building and near the door and window openings, then the rest are exhibited. The step between the slats or profiles is about 40 cm.

- The material for the crate should correspond to the weight and type of siding. It will not be superfluous to recall that the panels can have a rather impressive weight. If wooden rails are used, then they are processed in advance with protective compounds.

- The profile is mounted vertically, with a horizontal arrangement of facing elements, and vice versa. When choosing racks, the thickness of the insulation should be taken into account.

There is an important nuance if the wooden structure is new and there are no irregularities or any other defects on the surfaces, then it is quite possible to do without the installation of the rails. In this case, the panels are attached directly to the walls.

Insulation and wind protection

For thermal insulation protection, for the most part of the house, built of brick, foam, gas blocks and the like, need the most part. Mineral wool or polystyrene foam can be used here. High -quality insulation will help reduce energy consumption to 35%.

When choosing the material, you should pay attention to the following factors:

- the effect of a sharp change in temperature and atmospheric pressure on the insulation is minimal;

- the heat transfer coefficient should be in the range from 0.03 to 0.42;

- the dense texture of the material provides high saving thermal energy;

- non -combustibility;

- resistance to the development of mold and insects.

A windproof film is spread over the laid insulation. It will preserve the thermo -insulating layer not only from gusts of wind, but also of atmospheric precipitation. The membrane with diffuse properties will increase the service life of thermal insulation and will not allow the formation of dampness in the insulation itself and indoors.

Installation work

- After the installation of the racks between them, the insulation is laid. Next, the membrane is spread. It should be stretched tightly, without the formation of sailing and jamming. Strips of hydraulic and windproof film are overlapping at least 10 cm. The places of their connection are glued with tape to ensure sealing.

- It was the turn to mark the initial bar. For this, the lowest level for facing is located, retreats up 4 cm and this point must be marked. Using a laser device or a long level, a line is drawn in all installed racks.

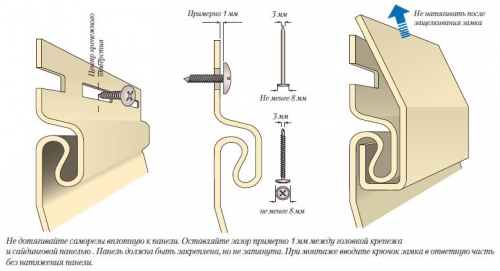

- The lower line drawn around the perimeter of the house is the starting point for the installation of the starting profile. Between horizontally located segments (as well as any other elements of siding), a gap of an equal 5-6 mm for temperature expansion is left.

- Fixation is carried out by means of nails, screws or screws into the factory holes of elements. The mounting element should be in the center of the oval hole, the head (hat) is not screwed to the stop, here the technological gap of 1-1.5 mm is also observed.

- Next, corner (external and internal) profiles are installed, their edges should be located 5-6 mm below the starting bar. The extension of the corners is overlapped with 20-30 mm. Window and doorways are edged with a J-profile. To do this, at the ends of the segments, sections are performed at an angle of 45.

- Installation of the lining panels begins from the doors to the corners and from the bottom up. The edges of the first element are simultaneously inserted into the starting and corner strip. When the optimal location of the panel is reached, it is fixed to the racks, not forgetting about the technological clearance. The set of subsequent elements continues in the same way.

- As soon as the first row is fully completed, they proceed to the second. When the panel is less than the length of the wall, N-profile is used. If the distance from the corner of the structure to the window is small, the siding is cut according to this indicator. In this case, the size is taken from the center of the corner to the center of the window profile.

- The strips between the window and the angle are usually simply typed in a vertical way. The panel above the window is cut to the corresponding dimensions. Further, the installation of siding is carried out in the usual order. The final nearby is the finish bar, which is attached directly to the cornice of the roof.

Facing panels care

- To maintain an impeccable appearance, siding does not require special care, special cleaning products. Vinyl panels are practical, it is enough to wash them with water from a garden hose. If there are strong pollution, then you can use a weak soap solution and a rag.

- As for metal panels, they are covered with anti -corrosion compounds. When installing siding, all sections are processed with special paint, which blocks access to water that promotes corrosion.

- Film elements made of natural wood are recommended to be covered once a year with antiseptic drugs and antipyrens.

- Cement panels are characterized by resistance to aggressive environmental effects. They, like vinyl planks, are freely cleaned with ordinary water.

Important nuances when lining the house with siding

In order for the final result to delight the owner of the building with his appearance and operational characteristics as a whole, it is necessary to follow simple rules.

- The choice of panels is based on a common architectural solution. The skin of the house should also be in harmony with the surrounding landscape.

- The warranty life is of great importance. When buying, check the operating conditions depending on the climatic region. So for the northern regions, the panel should endure low temperatures.

- Miser pays twice. It is better to purchase a more expensive siding from a well -known manufacturer, which will last many years without loss of initial qualities.

- It will not be superfluous to check the existing certificates and hygienic conclusion.

- Facing should be carried out in compliance with all technological stages. When purchasing expensive siding, you should not save on consumables. Otherwise, eminent panels are deformed after a poor -quality crate.

House sheathing with siding video