The tradition of covering the living room with carpets seems to have gone the past, because it appeared ...

|

|

Bitum surfacing the most affordable and effective way ... |

The construction of your own home is always accompanied by numerous chores and ... |

Antorozoic supplement in concrete: description and properties

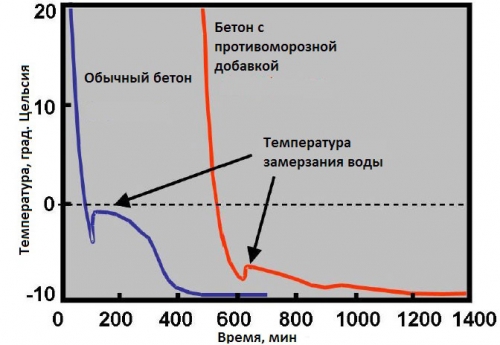

The construction of prefabricated concrete and reinforced concrete structures, as well as the construction of monolithic structures, does not stop increasing their pace, but often the masters have to face a rush caused by the approaching end of the construction season. This is due to the operational characteristics of the cement mortar, one of which is the presence of a liquid phase that contributes to the continuous process of hydration and ripening of the composition. If the temperature drops below 5 degrees, the concrete ripening phases is inhibition, and in the case of negative values, it stops, due to the crystallization of the water that is part of the cement mortar. This leads to the destruction of the structure of concrete, which becomes unsuitable for use. Despite this, most masters with experience in the field of monolithic construction are faced with the need to continue the cycle of concrete work in the winter, and therefore, the question faces: how to extend the liquid phase of concrete, and, consequently, its vital activity. To solve this problem, experts suggest using antimortoid additives in concrete, the technical characteristics and the main varieties of which will be considered in this article.

Content

- Anti -control additives in concrete: main varieties

- The advantages and disadvantages of anti -gun additives in a solution of concrete

- Recommendations for the use of antimorological additives in concrete

- Dosage and consumption of antimoosis additives in concrete

- Antorozoic additive in concrete with your own hands

- Precautions when working with anti -gun additives

Anti -control additives in concrete: main varieties

Antimorosis additives in concrete are a chemical in the form of a dry mixture or solution, which, by involving the maximum amount of water in the crystallization process of concrete, accelerate the process of hydration of concrete mixture, helping to harden concrete in conditions of negative temperatures. However, the main purpose of the antimoorous supplement is to maintain a liquid state of the concrete solution and the subsequent acceleration of its hydration, which significantly decelers at negative temperatures.

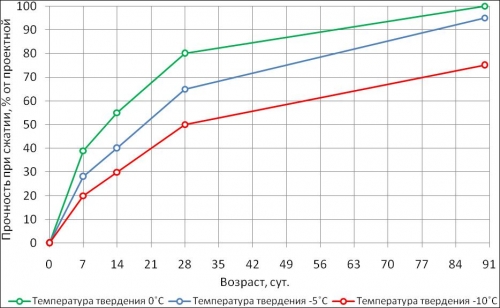

Important! Using anti -control additives in concrete, it is important to remember that concrete strength with anti -gun additives at negative temperatures does not exceed 30 % of the maximum possible design strength, the remaining 70 % of the strength is gaining in the process of thawing. In this regard, the structures, the concreting of which occurred in the winter period, should not be subjected to high loads.

In accordance with the chemical basis, the following types of anti -control additives in concrete are distinguished:

- Antifreeze;

- Sulfates;

- Antorozoic additives-accelerators.

Let us consider in more detail the characteristics of each presented variety.

- Antifreeze It is an anti -gun supplement in concrete, which helps to reduce the temperature of crystallization of the fluid that is part of the solution, and also increases or slightly reduces the speed of setting the solution. Moreover, it has no effect on the speed of the formation of structures.

- Sulfate -based concrete supplements They are another popular anti -gun component that provides the maximum rate of formation of a dense solution. A characteristic feature of the antimoorous additives based on sulfates is the active release of heat, which begins after they are added to the solution and accompanied by the interaction of a concrete solution with hydration products. Due to the fact that sulfates -based additives are characterized by strong binding with difficult to solve compounds, they cannot be used to lower the freezing temperature of the working mixture.

- The basis of action anti-controlled additives-accelerators There is an increase in the degree of solubility of silicate components of cement, which, reacting with the products of its hydration, form double and main salts that reduce the freezing temperature of the liquid component of concrete solution.

Important! Modern complex anti -control additives for concrete not only regulate the kinetics of a set of its strength, but also corrects its rheological properties. Reducing the temperature of crystallization of the liquid component of the solution, they reduce the timing of its primary setting, affecting the hardening of cement stone and increasing its stroke strength.

There are several varieties of adolescence additives, each of which has a certain set of chemical and operational properties. Consider them in more detail.

Potashor calcium carbonate, which is a crystalline substance, is a strong anti -control component, which significantly accelerates the process of grasping and subsequent hardening of concrete. Like any anti-gun supplement, calcium carbonate reduces the strength of the concrete structure, and in order to maximize this negative impact on the construction, experts recommend combining sodium or sulfine-gathering tetrabera, the concentration of which should not exceed 30 %. Due to the fact that calcium carbonate is a potentially dangerous substance, certain security measures must be observed in the process of its operation;

Sodium tetraberate, also called brown or sulfate-throat mash, is a mixture of sodium salts, calcium, ammonium or lignosulfonic acids. Experts recommend adding this substance as an impurity when using calcium carbonate, which helps to prevent the loss of the strength characteristics of concrete structures after thawing. Otherwise, it is possible to observe not only the appearance of cracks in the structures, but also a decrease in their water resistance and frost resistance. Thus, the use of Potash as an antimorosis additive without the addition of sodium tetrable will reduce the strength characteristics of the structure by 20-30 %;

Nitrite sodiumCrystalline powder used as an antimoosis additive to a concrete solution. Considering that sodium nitrite is a fire hazardous poisonous substance, in the process of its operation it is important to observe the ultimately permissible concentration of a substance, which is determined by the experimental way and usually does not go beyond 0.1 0.42 l/kg of cement mortar, provided that the temperature is the temperature The environment will be from 0 to -25 degrees. At the enterprise, in the process of working with sodium nitrite, the maximum permissible concentration of a substance at the workplace should not exceed 0.005 mg/l. In accordance with the requirements of the Research Institute of concrete and reinforced concrete, the container, which was used for transportation, storage and manufacture of sodium nitrite, should be equipped with a mark of poison. The joint use of sodium nitrite and lignosulfonic acids is prohibited, since their interaction is accompanied by the formation of poisonous gases;

Format sodium White crystalline powder, also performing the function of an antimolate accelerator. In most cases, it is used in conjunction with the folk abathalin ligon sulfate to increase hydropower and plasticizing characteristics. Sodium format is an anti-depth addition to concrete, the consumption of which does not exceed 2-6 % of the total mass of cement.

Important! In addition to the above substances, the format of sodium on alcohol, calcium chloride, ammonia water and urea can be used as antimoosis additives in conditions of negative temperatures.

The advantages and disadvantages of anti -gun additives in a solution of concrete

Advantages of anti -control additives in concrete

- Using anti -control additives in concrete, you can carry out concrete work on the construction site even in the winter period;

- Due to the fact that the antimoosis additives increase the degree of adhesion of the components of the solution, they significantly increase the strength of the monolith;

- Due to the high strength of products made using anti -control additives in concrete, they can be used for industrial purposes;

- Have a positive effect on the durability of the mixture, extending the life of the building;

- Increases the plasticizing and stabilizing characteristics of the cement mixture. The use of concrete with increased plasticity allows you to make structures that do not crack after the workplace is solidified;

- Increases the frost resistance of concrete mixture. This indicator is especially important for concrete intended for the construction of responsible structures, for example, bridge supports. In most cases, it is directly dependent on concrete density. More dense concrete brands are characterized by a large number of possible freezing and thawing cycles;

- Unlike alternative methods of increasing the frost resistance of concrete, the use of antimoosis additives is characterized by a relatively low cost;

- Using anti -control additives, you will significantly reduce the risk of shrinkage deformations of a concrete monolithic structure;

- Increasing the moisture resistance of concrete structures by filling the pores with plasticizing substances that prevent the penetration of water;

- Acceleration of the process of solidifying concrete solution, the main point, due to which the solution may not be afraid of the cold;

- Having preferred an anti-to-depth to concrete, you will reliably protect the reinforcement used from corrosion processes that have places due to water that is part of the concrete solution.

Disadvantages of antimoor additives in concrete

- The desire to increase the reliability of the strength characteristics of concrete, it is necessary to increase cement consumption;

- The individual components that make up the additives are poisonous;

- In some cases, the claimed power of concrete is reduced;

- In the case of the use of anti -sea additives in concrete, the speed of set of the strength characteristics of the concrete structure is reduced.

Recommendations for the use of antimorological additives in concrete

Experts advise introducing an anti -monitor additive into a solution of concrete along with water. It is important to note that it is advisable to do this with the last third liquid. It is not recommended to add additives to a dry mixture. By adding an anti -gun additive to the solution, you will take a certain period of time during which there will be an uniform distribution of the components.

When conducting installation measures in conditions of negative temperatures, follow the instructions presented below:

- If you work in a snowfall, take care of the organization of appropriate shelters;

- The temperature of the solution that has emerged from the mixer should not go beyond the recommended range from +15 to +25 degrees;

- To prepare a working mixture, experts recommend using heated water;

- As for the heating of the aggregates, it is recommended to be carried out before direct use.

Important!Specialists in the construction sector recommend paying attention to SNiP 3.03.01, in accordance with which, to achieve the necessary strength characteristics of a concrete solution, it is necessary to observe the requirements for concrete care in the winter. In the process of performing these measures, at the time of reaching the temperature at which the additive dosage was performed, it is not recommended to reach the strength of the structure exceeding 20 % of the declared design strength.

Dosage and consumption of antimoosis additives in concrete

The dosage of the anti -gun additive in concrete, the consumption of which is an extremely variable parameter, is selected taking into account each specific situation through testing in the conditions of production and laboratory.

The consumption of the anti -gun supplement depends on the following factors:

- Ambient temperature, in the conditions of which installation measures will be taken;

- The declared brand strength of the cement used;

- Chemical-mineralogical and material composition of cement used in the process of work, as well as its estimated speed of strength;

- The temperature of the solution, which it reaches at the exit from the mixer;

- Conditions for concrete structures.

Important!In the case of prolonged use or storage of the solution in which additives were introduced, it is necessary to check its homogenization, periodically mixing it. The calculation of the required amount of anti -control additives is made taking into account the error of 2 %.

Antorozoic additive in concrete with your own hands

If the warm days have already passed, but you unexpectedly faced the need to fill a monolithic structure, you can not do without the use of an anti -control additive to concrete. The most preferred option, in this case, will be the acquisition of an anti -gun additive in a specialized store, which is explained by their relative cheapness, a small flow and ability to significantly increase the properties of a concrete solution, provided that minimal negative consequences. If the proposed front of the work is small, and you plan to carry out the implementation of installation measures at a temperature of at least -10 degrees, this option is the most optimal.

However, if you do not have the opportunity to purchase a ready -made anti -gun supplement in concrete, you can easily make it yourself, since the only material that you need in the process of work is chlorides (salt). Chloride salts reduce the temperature of freezing of the solution, reduce the timing of its primary setting and reduce cement consumption. However, experts are confident that the anti -depth -based anti -gun supplement made independently can be used only for non -reinforced structures, which is due to corrosion processes developing under the influence of chlorides.

Advantages of antimoosis additives based on chloride

- Low cost;

- Lack of influence on the speed of solidification of concrete, due to which the preparation of the solution can be carried out in advance;

- Lack of influence on the structure of cement mortar;

- An increase in particle mobility, thanks to which, you can give the desired shape to the cement solution.

Disadvantages of antimoosis additives based on chlorides

- A high level of corrosive activity, as a result of which, an anti -control additive based on chlorides cannot be used for the manufacture of structures, in the structure of which there is metal and reinforcement. The latter are oxidized under the influence of chlorides and remove from the concrete structure, violating its integrity.

How does the ambient temperature affect the consumption of chlorides?

- The calculation of the share of chlorides in the finished solution is made according to the following scheme:

- If installation measures are carried out at an average acceptance temperature not lower than 5 degrees, the optimal share of chlorides in the finished solution should not exceed 2 %;

- If the work is carried out at lower temperatures (-6 to -15 degrees), the optimal share of chlorides should be 4 % of the total mass of the solution.

Important!In this case, the set of the expected strength of the design when dried in conditions of negative temperatures will look as follows:

For the first option, where the concentration of salt is 2 %:

- 30 % after a week;

- 80 % after a month;

- The design will reach 100 %strength only after 3 months.

For the second option (salt concentration is 4%), these figures will be 15%, 35%, 50%, respectively.

Important! Despite the fact that salt is an independent anti -control additive, experts recommend using it together with calcium chloride, the mass fraction of which when used at temperatures up to 5 degrees is 0.5 % of the mass of the solution, and 2 % - in case of temperature from -6 to -15 degrees.

Precautions when working with anti -gun additives

- In the process of working with anti -gun additives, it is necessary to use protective gloves;

- If you enter open areas of the skin, rinse it with soap water. Exclude the ingress of antimoosis additives into your eyes, if this could not be avoided, rinse your eyes with a lot of water and immediately consult a doctor.

- Disposal is carried out in accordance with local rules, which is explained by the presence of harmful components in the anti -gun additives. As a result, it is forbidden to pour the mixture into the soil, ponds or sewage.

Potash is potassium chloride, and

Potash is potassium chloride, not calcium!

Potash is not chloride and not

Potash is not chloride and calcium, but potassium carbonate. People, do not disgrace, open the chemistry textbook for grade 9. My eyes just bleed ...