The basement insulation is of great importance. This allows you to reduce heat loss at home ...

|

|

Owners of private sections are increasingly interested in the system of surface drainage ... |

In the system of life support, sewage plays an important role. But if in the city line ... |

Overlapping a house from a beam: step -by -step instructions

Wooden houses have long established themselves as environmentally friendly and with a high life of housing. The proof of which is the buildings that have been about 100 years old. For construction, a beam is more often selected, it can be non -core, profiled and glued.

Content:

- Overlapping a house from a beam

- Choosing beams for overlapping a house

- The section of the beam beams

- Overlapping a house from a beam

Overlapping a house from a beam

The same wood that was used in construction is selected for ceilings, a metal channel is less often used. Each material has both advantages and disadvantages. Long -term operation of the house depends on the quality and method of laying ceilings. The following information will help to understand the specifics and nuances.

Crossings are called a design that separates:

- residential floors, including an attic;

- basement or base from living rooms;

- unheated attic from living space.

Thus, the upper part of the ceiling serves as the basis for the floor, and the lower ceiling. For houses from the beam, a beam structure is used, since the weight of whole reinforced concrete plates will not withstand a single wooden structure.

The overlap should meet certain requirements for strength, that is, to withstand the loads in the role of which are people, furniture and other interior items. In addition, the design should also have stiffness, preventing the deflection of beam elements.

- The value of the permissible load on the beam structures is set based on the purpose of the room. So, for almost empty attics, this indicator is no more than 100 kg/m, for inter -story, basement or basements up to 210 kg/m.

- The rigidity of the material on the maximum deflection for unexplosable floors of the ceilings is 1/200 from its length, for interactor to 1/250, for example, a beam of 4 m long bend at 16-20 mm.

- During design work, it is necessary to provide for the laying of material with soundproofing and heat -protective properties.

- Fire resistance is an important characteristic of the material. Wooden floors have low resistance to open flame, so it is extremely important to treat all elements with antipyrens.

Choosing beams for overlapping a house

Metal beams of ceilings

Metal beams have reliability and durability. Thanks to increased strength and, accordingly, less thickness, they can save space. I -beam structures, channel or corners can be used here.

Advantages:

- resistance to biological exposure (not subject to the formation of rot, the development of fungi, unattractive for insects);

- non -combustible material, is able to withstand high temperatures;

- metal beams can be covered with a large width of up to 9 m.

Flaws:

- impressive weight, which means that a large load on the entire structure is created, therefore, on the foundation;

- at points of high humidity, corrosion is subjected to;

- the floors do not differ in high indicators in sound and thermal insulation;

- price.

For the installation of metal beams, special equipment is used, which is not advisable in the construction of low -rise individual buildings.

Wooden beams of ceilings

In most cases, during the construction of houses from various materials, beams from the beam are used. More often they are harvested from conifers of trees, less often there is a beam from a deciduous array.

Advantages:

- naturalness;

- insignificant weight that allows you to do without lifting special equipment;

- ease of processing;

- simplicity and convenience in installation;

- available cost.

Flaws:

- a limited width of the span for inter -story up to 5 m, for unprofitable attic up to 6 m;

- increased fire hazard;

- exercise to rot and infection with a beetle.

However, processing with special preparations increases resistance to fire and biological influences.

For the installation of attic structures, logs are often used, which, depending on the diameter, differ in high bending strength.

Separately, it is worth noting glued beam beamswhich, due to its special structure, significantly increases the restriction on the width of the span. Such elements can withstand increased load. The beam is distinguished by a beautiful appearance, which makes it possible to leave them open, creating an emphasis when creating an interior in country style.

The section of the beam beams

The flight is blocked by beams along the short wall. First, the final bars are laid, then evenly distribute the distance between them. The step directly depends on the cross section of the beams used, usually the thickness of the crossbar should be 1/25 of its length. So, for example, if you need a bar of overlapping 4 m long, then its width should be at least 160 mm.

For inter -story floors

| Ground section, mm | Span width, mm | ||||

| 3 000 | 3 500 | 4 000 | 4 500 | 5 000 | |

| 50x160 | 800 | 600 | 450 | ----- | ----- |

| 60x200 | 1 250 | 800 | 700 | 550 | 450 |

| 100x100 | 600 | 450 | 350 | ----- | ----- |

For attic floors:

| Ground section, mm | Span width, mm | ||||

| 3 000 | 3 500 | 4 000 | 4 500 | 5 000 | |

| 50x160 | 1 200 | 900 | 650 | 500 | 400 |

| 60x200 | 1 850 | 1 350 | 1 050 | 800 | 650 |

| 100x100 | 900 | 700 | 500 | 400 | ----- |

If it is not possible to purchase a beam of overlapping the desired size, then it is allowed to replace it with two boards, where the total thickness is equal to the cross section. The lumber is necessarily fastened to each other with nails or screws with a step of 20 cm in a checkerboard pattern, this design will withstand double load.

| Log diameter, mm | Span width, mm | |||||||||

| 3000 | 3 500 | 4 000 | 4 500 | 5 000 | 5 500 | 6 000 | 6 500 | 7 000 | 7 500 | |

| 170 | 1 000 | 800 | 600 | --- | --- | --- | --- | --- | --- | --- |

| 210 | --- | --- | 1 000 | 800 | 600 | --- | --- | --- | --- | --- |

| 250 | --- | --- | --- | --- | 1 000 | 800 | 800 | 600 | --- | --- |

| 290 | --- | --- | --- | --- | --- | --- | --- | 1 000 | 800 | 800 |

| 310 | --- | --- | --- | --- | --- | --- | --- | --- | 1 000 | 800 |

| 330 | --- | --- | --- | --- | --- | --- | --- | --- | --- | 1000 |

The moisture content of lumber should not exceed 14%.

Overlapping a house from a beam

General rules for laying overlap beams:

- Before starting work, all wooden structural elements are processed with protective equipment. In the process of adjusting the material (cutting, clipping), the grooves or ends are also processed.

- It should be remembered that the location of the beams relative to chimney pipe should not be less than 40 cm.

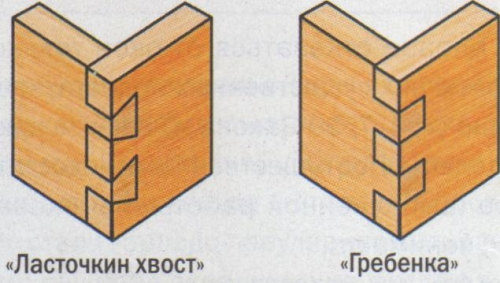

- The most reliable compound is Lastochkin's tail. Of course, the process is quite laborious, but reliable. Typically, the beam does not need additional fixation to the supporting walls by means of nails or screws. There is enough connection of the type of spike-paz, which allows you to walk the structural elements during the shrinkage of the house.

- To achieve the horizontal level, at the end of the beam, planks from the boards are placed. You can not rot quickly to use the chips and the ceiling design will skew.

- If wooden beams are intended for installation on the walls of brick, concrete blocks and other stone materials, then the ends of the beam are wrapped in roofing material. Thus, protecting the wood from condensate, and hence from premature decay.

- The voids in the nests on the outside are filled with pacle, jute fiber, mounting foam or sand-cement mortar.

Brus -hardening device

- In the lower crown of the house, grooves are cut down, the end of the beam is adjusted to the corresponding dimensions. Prepared elements are laid in nests. The ribs formed by beams are checked for horizontal via level. All supports should be in one plane, otherwise the load on the ceiling will be distributed unevenly.

- After shrinkage of the structure, all structural elements are checked. If there are changes, then they are eliminated by tightening or placing wedges. After that, the beams can be securely fixed with bolts, screws, brackets or metal corners.

- After that, the floors are insulated using polystyrene, mineral wool or other thermal insulation materials. A vapor barrier membrane is spread over them and preparations are underway for the flooring of the final floor.

Brus basement device

- The installation of beams is carried out in the same way as for the basement. The difference lies in the thickness of the stone or fiberglass wool used. And also in the additional layer of vapor barrier, here the membrane is laid on both sides of the ceiling.

- A special role is given to ventilation of the basement, it is it that prevents the appearance of dampness, and as a result of an unpleasant odor in living rooms.

Brus -free flooring device

- After inserting the beams into the nests of the capital walls, the bottom of the ceiling is filled with moisture -resistant plywood. Light bulk materials (expanded clay, sawdust, well -dried sand) are poured into the educated space, you can lay the mats of mineral wool or sheets of foam.

- Next, the filler is covered with a vapor barrier and covered with panels of the fiberboard or chipboard, on which flooring is covered.

Attic

- The fasteners of the beams can be both external and internal. In the first case, various cuts of wood are used. Using such compounds, it must be remembered that the heching is allowed no more than the thickness of the beam. The fasteners of half -term is unacceptable, at the point of the drink, longitudinal cracks can form, which significantly reduce the rigidity of the beam.

- With the internal connection, the end of the beam is cut at an angle of 45-60 and is laid in the grooves of the load-bearing walls. The depth of the bookmark should be at least 10 cm. The recesses in the wooden walls are slightly larger than the cross -section of the laid beam. This enables wooden elements not to deform with changes in temperature.

- A deaf seal in the stone walls in the nest should be relatively free air exchange. You can reduce heat loss through these points by filling the space with mineral wool, jute or packley. Thus, cold bridges will be eliminated, but there are no obstacles to passing air.

- Here you can use glued beam as beams and leave it for public display. You can reduce heat loss by making a false floor from the attic. A heater is laid in the obtained cells, which is covered with a vapor barrier film.

Insulation and sound insulation of the overlap from the beam

- When forming the floors between the floors, it is necessary to use soundproofing materials that are able to drown out 2 types of air noise (voices of people, the sound of a TV, etc.) and a shock (a knock of falling objects, running around the children).

- A hard mineral ward plate on a basalt -based density of at least 45 kg/m will cope with these tasks. This material in this context also acts as thermal insulation. The membrane in such cases is laid from the side of a warmer room.

- It is also possible to reduce heat loss through the basement, basement or attic space by laying stone cotton wool, the thickness of which depends on the climatic features of the region. The higher the coefficient of thermal conductivity of the material used, the greater the thickness of the insulation.

- The attic ceiling is equipped as follows: a vapor barrier membrane is spread out from the side of the living room and is fixed with a construction stapler directly on the beams.

- If foil material is used, then the shiny surface should look down. Thermal insulation is laid in the space between the bars, which should be covered with windproof material.

- The scheme of the heat -insulation device for ceilings separating the basement or basement from living rooms is as follows: the insulation is laid on the black floor, then vapor barrier material is spread and the plank floor is mounted.

Correctly calculating the technical characteristics of the beams, and observing the simple rules, the construction of individual elements of the house, in particular floors, will not create any difficulties.