Installation of aluminum windows is not very different from the installation of windows from other materials ...

|

|

It is probably no secret to anyone that wooden windows are during the operation of wooden windows ... |

The heat -insulating layer of foam is needed reliable protection against destructive ... |

Concrete cesspool: Installation instructions

In the system of life support, sewage plays an important role. But if in the city line the houses are connected to the central system, then the residents of the suburbs have to solve the issue with the disposal of drains on their own. The arrangement of the cesspool on the site is considered the simplest and most inexpensive exit. However, a dug pits with reinforced walls cannot at all be considered a full -fledged cellar for wastewater. There are many rules, norms and nuances, following which we can talk about a full -fledged system for waste disposal. The article will talk about how to make a concrete cesspool.

Content:

- The design of the concrete cesspool

- Types of cesspools

- Do -it -yourself concrete cesspool

- Construction of a cesspool of concrete rings

The design of the concrete cesspool

Reinforced concrete walls, whether it is a poured structure using formwork or factory rings, are characterized by the following advantages:

- a long service life, such a pit can be operated within a century;

- this building material is characterized by high chemical resistance, which easily tolerates the ongoing processes of fermentation and decay;

- water resistance allows you to guarantee the absence of soil pollution and groundwater;

- such a pit is equipped, regardless of the geological characteristics of the soil and the level of location of the aquifer;

- the device of the cesspool of concrete rings involves the use of special equipment.

Cesspool of concrete rings

If an independent filling of walls is supposed to be concrete mixture, then mud and labor intensity can be considered negative points in the works.

Types of cesspools

The recess in the ground often has a rectangular shape, since the excavation of soil is performed manually. Such a configuration is relevant when there is no way to attract special equipment. However, the recommended option is a round drive, because the load on the walls is distributed evenly.

There are 2 types of drives.

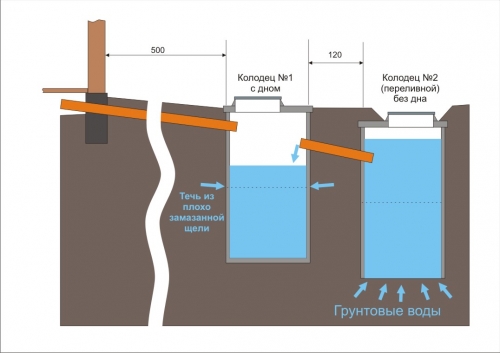

Cesspool of concrete rings without a bottom

- This type of crooked is popular in areas with seasonal or periodic living. In these cases, water consumption will presumably be about one cubic meter per day. Pollution will simply go into the ground, processing with natural bacteria. Sometimes you may need help in the form of specialized tools that accelerate the processes.

- The distance between such a drive and the nearest structure should be more than 8 meters. This will prevent a wash of the base.

- The location of the pit to the well or well must also be observed:

- with clay soil at least 20 m;

- with loamy soil at least 30 m;

- with sandy soil at least 50 m.

- Failure to comply with norms and rules can lead to water pollution in water intake structures and will make it unsuitable for use. In cases where the fault of a particular developer will be proved - a fine is imposed, and in especially difficult situations of the offender there is a criminal punishment.

Of the shortcomings, it can be noted: an unpleasant odor, low resource and environmental danger.

A pit with a bottom

A sealed drive is planned for installation in the territory with permanent residence. If there are obvious height changes in the square, then it is recommended to be placed in the lowland.

When device, they adhere to a number of fundamentally important points:

- the depth of the tank should not exceed 3 m, this is the length of the hose of special equipment;

- the distance from the fencing structures (own or neighboring) to the pit is 2 meters, and to the main building 5 m;

- the ventilation pipe with a diameter of 100 mm at a height of at least half a meter from the ground level is mandatory. Gas will pass through it, which inevitably occurs in the process of fermentation, rotting and decomposition of drains.

Do not forget to think over the drive road for the assigned car. In an effort to highlight the site under the drive as far as possible from housing, one should not forget that too long the pipeline can complicate its maintenance.

Do -it -yourself concrete cesspool

Calculation of volume

Calculations are based on the following data:

- about 0.15-0.18 m of water per day per day. Thus, a family of 4 people consumes 20 m monthly. So, the crooked should accommodate at least 25-28 cubic meters of runoff;

- if a hole is built without a bottom, then the type of soil is also taken into account. The rocks that pass water easily allow you to save on volumes, but if clay lies on the site, then monthly costs should be increased by 10-15%.

When arranging it, it must be borne in mind that at least 1 m should remain to the upper edge of the cake. Otherwise, under force majeure circumstances, contaminated waters can go beyond the tank. In addition, the low level of effluents minimizes the appearance of unpleasant odors.

Pit for the installation of a cesspool of concrete rings

When taking out the soil from the pit, remember that the volume of the finished drive should be at least 3 cubic meters. The explanation here is a simple, minimum volume of the tank of the Assencing machine is a little more than this indicator, so it is unprofitable to call the technique for the export of drains of a smaller volume.

Pile under the cuping without a bottom

- The excavation of soil can be produced in a standard way - a shovel or using a mini -excavator. The depth and diameter of the pit should be a little larger than the real size of the future cesspool.

- Remember, the finished design is done a little buried. Here you should take into account the height of the lid, which will be closed with the pit and the thickness of the backfill to prevent freezing of drains.

- The bottom is maximally leveled and the formwork for the strip foundation is equipped. It can be a square or round shape, the selection of the width of the tape is carried out in accordance with future walls.

- The resulting seizure, after the base dries, is filled with gravel, which contributes to the free passage of wastewater.

Jack of foundation jacket with a bottom

- To dig a hole, a manual or mechanized method is used. The depth and width (diameter) are determined depending on the type of sewage system, where real indicators increase by 15-20%.

- The calculations take into account the thickness of the concrete site, as well as the height from which the structure should protrude above the ground (as a rule, it is 20 cm).

- The bottom of the pit is aligned and trim. A sand-gravel pillow is falling asleep, the thickness of each layer is 15 cm. At first there is a sand that is moistened and compacted, then the turn of gravel comes.

- If the insulation of the cover is not provided for the seizure by 30-40 cm. Then, after installing the floor slab, it is covered with soil, which will prevent freezing of wastewater, thereby preventing impairment of the sewer pit.

Concrete solution

- Fill the strip foundation or site is performed in one reception. For the tape, formwork from the boards is collected, standard strengthening is performed. The design is mandatory reinforced. Metal rods are binded by wire.

- Their laying is carried out on broken pieces of brick or small stones. The reinforcement in no case is laid on the ground, it should be completely immersed in a sand and cement mixture.

- For a batch of a solution per 1 part of the cement, 2 parts of sand and 3 parts of crushed stone are taken. There should be so many water so that the output is not a very thick mass, the thrown pebble should completely immerse yourself in the mass.

- During the pouring, the solution is bay up, this technique will allow you to get rid of the formed air bubbles. After all, voids negatively affect the strength of the finished monolith. The site is aligned and left until completely dry, and this process will take at least one week.

- When working in hot weather, the concrete surface is periodically moistened, this will help to avoid cracking, as well as gain the declared strength characteristics. Then you can proceed to the next stages of work.

- If ready -made reinforced concrete rings with a bottom are used for installation, then there is no need to equip the site.

Pipe laying

- Simultaneously with the excavation of the soil for the pit, a pipe is made for the removal of sewage. If the bookmark is planned shallow, that is, higher than GPG, it is recommended to conduct its insulation: wrap with glass wool, mineral wool, foam, etc.

- An important point when laying the pipe is its slope, thus, drains will enter the cesspool of a gravity. If the D160 cm pipe is used, then the slope should be approximately 10 mm per meter of its passage, at 100 cm, a slope of 20 mm is observed, at 50 cm - 30 mm.

The walls of the cesspool

- If it was decided to fill the walls with your own hands, then a square or rectangle is the optimal shape for the cake. The formwork is made of boards or thick sheets with moisture -resistant plywood.

- The design itself should be removable, so screws and screws are used. To strengthen the corners, I use metal plates. The distance between the two walls of the formwork is 60-80 mm.

- Round -shaped crooked differs in one advantage, it occupies a small area of \u200b\u200bthe house site. Of course, a perfectly round formwork will not work, but this fact is not fundamental for such a design. An ideal material for the construction is a profiled sheet.

- Much attention is paid to supports and spacers. The concrete solution has a large mass, and therefore, the formwork should be fixed as firmly as possible.

- The reinforcement of the walls plays an important role. A metal bunch can be performed in advance and already finished in the finished form in the structure or to eliminate the rods as the frame fills with concrete.

- People's craftsmen have an amazing discovery - use a metal grid from old beds as a reinforcing material.

- In any case, pouring is carried out once, avoiding large breaks. Be sure to bay up the solution. It is carried out with caution, it is impossible to allow the displacement of the reinforcement inside the future walls.

- The drying time of the structure depends on its thickness. The elements of the formwork are neatly dismantled. Next, internal and external waterproofing walls is carried out.

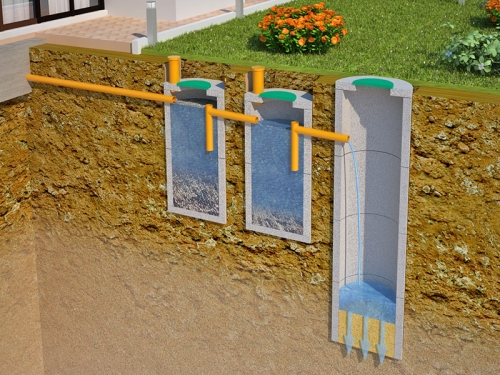

Construction of a cesspool of concrete rings

- Factory products greatly simplify and accelerate the process of arranging a cesspool. Unfortunately, impressive weight does not allow you to perform installation manually. For work you will need a car crane. Many manufacturers of reinforced concrete rings offer such services for an additional fee.

- When buying, pay attention to the inner diameter of the elements, it should be the same on all products. This will allow you to collect the tank with maximum tightness.

- The range of rings makes it possible to build a container according to the project. The inner diameter is in the range from 700 to 2500 cm, and the height is fixed 900 cm.

- The design of the products involves the presence of special metal ears. Crane hooks are attached to them. Ring of the ring is carried out with caution, observing safety precautions.

- The product is installed in level, if necessary, the ring is dismantled for maximum leveling. To avoid unjustified delay during installation, it is recommended to perform the surface leveling at the stage of preparing the bottom of the pit.

- After installing the lower ring, the joint of the wall is treated with waterproofing material. The use of rubber gaskets, cement mortar is suitable here. The best option will be a liquid glass mixed with Portland cement.

- Next, proceed to the installation of the following rings, taking into account the above rules and nuances. Simple rings are fastened with each other through metal brackets. You can purchase reinforced concrete products equipped with special grooves that provide more solid and reliable fixation.

- In the last ring, using a perforator, a hole is made for the input of the pipe. At the junction of these elements, waterproofing of the cesspool of concrete rings is carried out.

Cesspool of concrete rings scheme

- The final stage is the installation of a slab of the floor with a hole under the hatch. Next, a trial launch of water is performed, the functionality of the entire system is checked. With a positive result, the soil of the void between the cable and the walls of the trench is paced.

Video how to make a cesspool of concrete rings

Installation of a septic tank, cesspool

Installation of a septic tank, a cesspool, a drainage well, a plum from a bath, saunas from the spell of the rings along Perm! 79519444948