There are two options for arranging woody floor ceilings: on beams and in lags ...

|

|

The quantity and quality of the laid reinforcement factor that directly determines ... |

The irresistible desire of the inhabitants of megacities at least one step closer to nature ... |

DIY FASALE FASE. Sandwich panel installation technology

Sandwich panel, clinker, plaster - all these materials are used in the decoration of the facade. The choice of one or another option should be based on a harmonious connection with the overall style of the exterior, functional purpose and financial preferences. Check out the main types of facade decoration, their features and installation technology.

Table of contents:

- Recommendations for the choice of materials for the decoration of the facade

- Varieties of sandwich panels for the facade

- Preparation for the decoration of the facade of a private house sandwich panels

- Do -it -yourself facade decoration with your own hands

Recommendations for the choice of materials for the decoration of the facade

The most popular facade decoration options are:

- plaster with decorative characteristics;

- clinker tiles or brick;

- porcelain materials;

- Siding or sandwich panels;

- artificial or natural types of stone;

- cassettes for the facade;

- Wallpaper for the facade.

Each option is characterized by both advantages and disadvantages. First of all, choosing one or another option for finishing the determinant with the facade area, requirements for the material, appearance.

The most ancient and popular option is to plaster the facade with your own hands. This method is the cheapest and simplest. Both textured and smooth plaster are distinguished. Among the main advantages of facade plaster, we note:

- the aesthetic attractiveness of the material - using plaster it is possible to create various textures, colors, combinations of shades for the facade;

- high level of moisture resistance - facade plasters perfectly resist moisture, protect thermal insulation from destruction;

- Frost resistance - technologically correctly plastered wall, perfectly opposes temperature changes;

- To apply plaster, it does not require specialized equipment, all work can be done by one person.

The easiest option is a mineral -based plaster. It differs in the lowest cost and wide color palette. The plaster does not give in to combustion, but it has low elasticity, therefore, when the building is shrink, it cracks.

The plaster composition on an acrylic basis is characterized by high plastic characteristics. Among the characteristics of the plaster, we note:

- long -term operation;

- resistance before frost;

- moisture resistance;

- fire safety;

- Higher cost compared to the mineral composition.

The walls for acrylic plaster should be perfectly even, only in this case, a coating with a high level of adhesion is obtained.

One of the longest in the operation of finishing materials for the facade is plaster on a silicate basis. It differs resistance to temperature changes, shrinkage, dirt, moisture. To apply the composition, you must have experience working with plaster mixtures. The work is carried out quickly, as the plaster quickly freezes. Under this option of plaster, it is necessary to purchase a special primer. Also, the composition does not differ in a variety of colors.

The silicone version of the plaster is the perfect finishing material for the facade. The only disadvantage is the high price, which is justified by excellent operational characteristics. Among the advantages of silicone plaster, we note:

- high level of wear resistance;

- universality of application;

- the duration of operation, without changing the original appearance of the appearance;

- the ability to self -clean from dirt;

- Easily applied to the walls.

Another option for finishing the facade is clinker brick or tile. The material has a variety of color texture and excellent performance characteristics. Clay with the addition of plasticizers and dyes is used for the manufacture of clinker bricks. The front surface of the tile is different:

- glazed;

- matte;

- corrugated;

- Glovyntseva.

Among the advantages of the clinker, we note:

- strength;

- low moisture absorption;

- ease of washing;

- resistance to temperature difference;

- Duration of operation.

It is more difficult to set these materials than to perform the plastering of the facade.

Quite often, porcelain tile is used to decorate the facade. Among the physical properties of the material, we note:

- high level of strength and durability;

- resistance to increased moisture;

- thermal resistance;

- Does not change color during operation.

Porcelain tile is characterized by specific installation conditions. To install it, it is necessary to build a frame from a metal profile or use a special adhesive composition.

Facade wallpaper is a relatively new way of wall decoration. The system contains components in the form:

- rolled wallpaper;

- adhesive composition;

- profiles with a net for reinforcement;

- Paints for finishing.

The appearance of the walls, after decoration with wallpaper, resembles plaster. However, the wallpaper, unlike the plaster composition, do not crack. Polymer components prevent the cracking of the material. For the installation of wallpaper, special equipment or skills of work.

Advantages of facade wallpaper:

- moisture resistance;

- long -term operation;

- ease of installation;

- Lack of cracks.

The finish of the facade with a stone is an expensive process. However, in the end, it turns out outwardly attractive, durable, durable, reliable, stable before any effect. The cost of artificial stone is lower than natural. It is possible to finish the facade with stone panels - a cheaper, but the same high -quality alternative.

Metal cassettes - excellent material for the ventilated facade. For installation use rivets or screws. Cassettes are distinguished by a wide color and textured range. Among the advantages of the material we note:

- reliability;

- duration of operation;

- environmental safety;

- moisture resistance.

The facade lining with siding and sandwich with panels allows you to get an inexpensive, but aesthetically attractive coating. Siding is characterized by ease of installation, protecting the facade from external stimuli. Several types of siding are drawn:

1. Vinyl siding - is an imitation of wood, stone or brick. It differs in the ease of installation, resistance before temperature and mechanical influences.

2. Siding from wood - preliminary panels are dried and treated with antiseptic compounds. The material is distinguished by environmental safety, great for the decoration of wooden houses.

3. Steel siding - aluminum or metal is used for manufacture. Unstable before mechanical damage, in the presence of scratches on the upper layer, is prone to corrosion.

4. Cement siding - requires the arrangement of the foundation, as it has a lot of weight. Great replacement of finishing stone.

The choice of one or another option depends on the individual preferences of the owner and the features of the building in which the finish is performed.

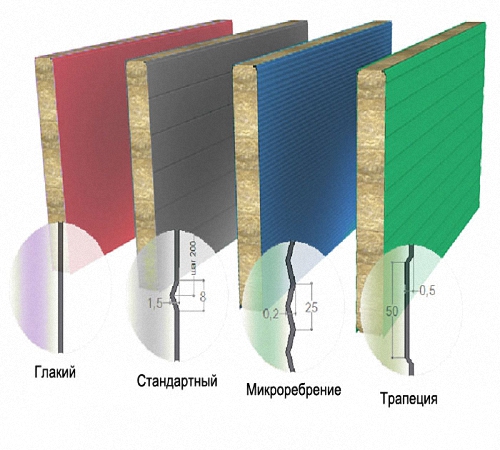

Varieties of sandwich panels for the facade

Sandwich panels - a finishing material consisting of two dense layer, the inside of which is filled with insulation. Depending on the type of insulation used for the manufacture of sandwich panels, they are:

- on mineral wool;

- in polyurethane foam;

- on polystyrene foam;

- on fiberglass;

- combined with several insulation.

Depending on the material of the external cladding, the panels are:

1. From galvanized steel - differ in affordable cost, ease of installation. They are short -lived in operation, burn out in the sun.

2. Alucing sandwich panels - are highly resistant to mechanical damage, are not prone to corrosion.

3. Plasterboard sandwich panels - contain gypsum and cardboard. For decoration, the facade is not suitable, as they are unstable to moisture.

4. Plastic sandwich panels are stable before mechanical damage and corrosion. Contain polyvinyl chloride and additional plasticizers.

5. Puralum panels are plastic, easily installed on the surface, stable before burnout and temperature changes.

6. Polyester -based panels are the best option for decoration of the facade. Easily tolerate temperature changes and persistent before mechanical damage.

Among the advantages of installing facade sandwich panels with your own hands, we note:

- speed of installation work;

- environmental friendliness of the material;

- good thermal insulation properties;

- Lightness of weight, so an additional foundation is not equipped under the panel;

- attractive appearance, variety of colors and shapes;

- resistance before moisture, fungi, mold;

- Available cost.

Preparation for the decoration of the facade of a private house sandwich panels

Before starting the decoration of the facade of any of the materials, it is necessary to prepare it for work. First of all, all detachment is removed from the walls, if any. Squirrels, hinged parts, climbing plants, and fasteners are removed from the facade part of the building.

If there is a finish on the surface, make sure of its strength, otherwise, delete the material. The walls, before the installation of sandwich panels, should be perfectly even. Window and doorways should be located on the same level with the wall.

The sandwich panels are installed on a special crate made of wood, metal or reinforced concrete. Installation of panels up to six meters long is performed using horizontal profiles. Thus, the stiffness of the wall increases.

The wall sandwich panels are installed on the wall in a horizontal position. Fixation of the first row is performed by the lower groove. Tags are installed on the panel, allowing you to hang the panel. Further work on the facade depends on the correct installation of the first row of panels.

The sandwich panels are fixed on the wall with self -tapping screws and rubber. Install the first panel in the coal of the wall. To close the basement, end and butt elements, use special overlays. The three -layer sandwich panel is fixed on the wall with screws. In the gaps between the panels, a previously selected version of the insulation is installed. To process castle joints, use a silicone -based sealant.

Installation of waterproofing for a sandwich panel is necessary for additional protection of the wall from moisture. In addition, waterproofing prevents the contact of the insulation with water. With your own hands, insulation of the facade for a sandwich panel is not required. Since the material is distinguished by good thermal insulation characteristics.

Do -it -yourself facade decoration with your own hands

Before installing siding, the walls are prepared for decoration. Ideal coating for work are even walls on which there are no cracks, irregularities and other deformations.

Siding is set in two ways:

- with a crate;

- Directly on the walls.

Having chosen the second option, make sure that the walls for the installation of siding are absolutely even. Experts recommend still installing siding on a crate. Thus, a ventilated facade is formed, which passes the air on one side, does not allow the formation of condensate, fungus and mold, on the other.

To make a crate for siding, use metal or wood. Two options for fixing siding are distinguished:

- vertical;

- horizontal.

Depending on the selected method, the method of fixing the crate is determined. To install the crate on the walls, use nails, with an interval of mounting 35 cm. The crate is installed on the corner areas of the building, around the openings and boundaries of fasteners.

In order to insulate the building, a previously selected insulation is installed under the siding. Some thermal insulation materials require additional waterproofing. After preparing the base, the installation of hydro- and thermal insulation materials, the installation process of siding follows.

First, the starting strip is installed. Its upper part is located on the lower part of the building. Vinyl fasteners allow to hide the joints between the panels in the corners. To fix the corners, use nails with an interval of 8-10 cm.

Siding is installed on the crate in two ways:

- using rails;

- Without rails.

The first option is based on the installation of siding in a special N-Rika. Thus, the quality and appearance of the coating improves. Reiki are selected in a ratio with the color of the panels themselves.

If the rails are not used, then the siding is installed with an overlap. Thus, the joints between the panels are installed in the run. Leave a gap of 0.8-1 cm between the panels. If the work is carried out in the winter season, then increase the gap by several millimeters.

To fix siding on window openings, a special profile is used. Two panels are interconnected by a groove-grown way.

Facade Video decoration: