The desire to save as much time and finance as possible in the construction of a suburban ...

|

|

A reliable barrier on the path of cold or uninvited guests is the front door ... |

The kitchen is the most visited place in the house. The floor in this room is usually ... |

Floor overlap on wooden beams

There are two options for arranging wooden floor ceilings: in beams and in lags. The choice of one or another way of performing work depends on the individual characteristics of the premises and the preferences of its owners. Among the advantages of the floors made in the beams should be noted a high level of their strength and the cheapness of the performance of work. We will consider how to build floors on wooden beams.

Table of contents:

- Flooring on wooden beams: calculations

- Floor overlap on wooden beams: features of the installation of beams

- Floor overlapping of wooden beams: Features of the floor device

- Wooden beams: work technology for work.

Flooring on wooden beams: calculations

The use of wooden beams, in comparison with reinforced concrete, differs primarily a more affordable cost and ease of work. In addition, the floor has almost the same strength characteristics. The use of wooden structures helps reduce the total weight of the house and its load on the foundation base.

Among the advantages of gender beams in a wooden house, we note:

- high resistance and stiffness before loads;

- low weight compared to concrete beams;

- affordable cost;

- The possibility of independent installation, without specialized technical equipment.

A specialized equipment will not require flooring for wooden beams, since a few people are enough to lay balls. The main supporting element of the structure is a wooden beam. It has the shape of a wooden beam, the height of which is from ten to thirty centimeters, and a thickness of seven to twenty centimeters. The optimal step of laying beams ranges from 65-100 cm. To determine the cross section of the beam, the individual characteristics of the room, the load and weight of the building, the length of the flight and other important factors should be taken into account. The wooden boards installed on the edge will help replace the beam. The use of a trimmed log will be the most economical option for arranging floor ceiling.

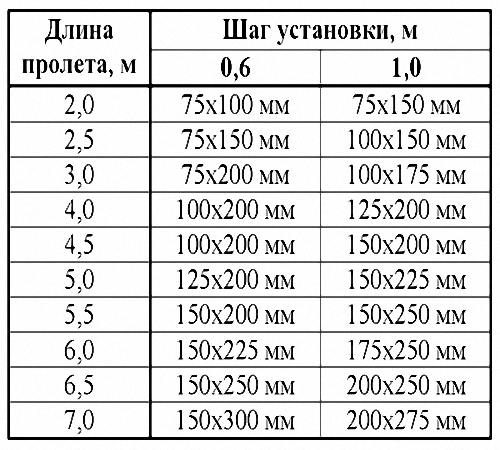

In order to determine the cross section of the beam installed in a particular house, one should first determine the level of load that affects it. To determine the overall load, the weight of the floor is taken into account, the load from people and the elements of the accessories that will be installed on it. The total value of the total load is four hundred kilograms per square meter. In the ratio with this value, the section and size of the beam is determined by the table:

If the span length is about 4 m, then with an installation step of 65 cm, you will need a beam that is 10x20 cm in size. Keep in mind that the length of the beam should be 15 cm larger from each side to ensure its installation in the wall. That is, to determine the length of the beam, you should add 30 cm to 400 cm, it turns out 4.3 m.

The correct completion of the wooden beams allows you to choose the optimal size of the materials, with which it is possible to correctly distribute the load in the building.

Laying wooden beams is performed in a direction parallel to each other. At the same time, the interval between the beams should be preserved in almost all areas, the exception will be chimney pipes and other structural elements of the floor. The interval for laying beams in a house made of wood is about one meter. If the house is made using frame technology, then this distance is reduced to 50 cm. If this value increases, in the relationship with the design features of the building, then an additional element is established between the beams that improves their bearing abilities.

If there is no place for attaching the beam close to the staircase close to the staircase, an additional structure in the form of a wooden crossbar should be equipped here. It will become a place for installing beams. At the same time, beams can be installed directly on the crossbar or in it. In order for the beams to easily withstand the loads assigned to them, these requirements should be observed:

- The optimal value of the height of the beams will be at least one twenty -fourth part of its length;

- In the width of the beam should be at least half of its height;

- If the beam is installed in the attic, then there is enough width in one third of its height.

Using this ratio, it is possible to choose the best option for beams for arranging ceilings. If the installation of the beams is carried out in the station from the fasteners, then the size of the beams should increase slightly. In order to reduce the thickness of the beam, if the ceiling is quite long, supporting pillars are installed between them.

If the installation of beams is carried out in outbuildings, garages, cabins or other non -residential premises, the average load level decreases and is from 100 to 300 kg per square meter. At the same time, the beam cross section should also be reduced.

If you could not find the specified size of the beams, then the option of their independent structure using ordinary boards is possible. At the same time, they fit in a chess order, connecting each other with the help of nails.

With the further construction of the stove and chimney in the house, it should be borne in mind that the distance between it and the beam should not be less than thirty centimeters.

Floor overlap on wooden beams: features of the installation of beams

Fixation of wooden beams is carried out directly on the wall. If the floor is equipped in the attic, then the beams are installed on the last crown of the wall made of a beam or a log.

In the wall, you should equip a hole comparable in size with a beam. Before installing, the beam should be covered with packley. In the presence of too thin beams, they are installed in the wall by 10-15 cm. In this case, a special cut method is used. It is possible to fasten the beam using a connection called a swallow tail.

This option is suitable for houses, which is also made of timber. To fix the beam in a house made of wood, a trapezoidal compound is used, and a clamp is installed for additional strength. In this case, Rigel and the beam will be at the same level. The easiest way to install floors beam beams is the installation of cranial bars and fixing the beams on them. In this case, the size of the bars will be about 5x5 cm.

If the house is made of a shield, then for laying the beam should be equipped in the wall in the form of a nest. Each end of the beams are installed inside the holes. At the same time, each nest for the beam should be at the same level. The optimal depth of the nest is about 15-20 cm, and the width between the beam and the wall of about 1 cm. Each of the ends that is installed in the nest is covered with the help of the package. The following is the process of processing the beam using an antiseptic solution. Thus, it will be possible to extend its life and protect the coating from mold and fungus.

Possible option for fixing packages using steel anchors. One end of the anchor is installed in the nest, and the second is fixed on the beam using screws, while the length of the beam is calculated so that it does not enter the wall and makes the value of different lengths of the ceiling.

If the house is made of brick, then the construction of nests will also be required to install wooden beams. They are supporting elements for holding beams. Try to build nests as much as possible in level. In order to set the beams at the same level, it will be necessary to align the bottom of the nests using a concrete solution. After the concrete solution is completely dry, roofing or only is installed on its surface, which provides the protection of the tree from moisture.

In this case, the size of the nest is 6-10 cm larger than the thickness of the beam. The gap between the wall and a beam made of wood should be about three centimeters. In this case, the depth of the nest is about 20-25 cm, while the beam is installed in the inside of only 15 cm. The areas of wooden beams, which are placed in the nest should be smeared with hot bitumen.

Next, they are wrapped with roofing material or pergamine in two layers. After that, the rest of the beam is covered with a solution with antiseptic properties. After laying the beams in the nest, they should be filled with a concrete solution, as a filler for which a gravel is used. Alignment of the beams is carried out at the same level with the wall.

Floor overlapping of wooden beams: Features of the floor device

The incident part of the ceiling is a ceiling on the rolling floor. There are several ways to lay out the flooring. Most often, cranial bars are installed on the beam, the cross section of which is 4x4 or 5x5 cm. The installation of skull bars is carried out so that they are on the same level with a beam. Next, wooden rolls are laid on the surface of the bars in the form of wooden boards, the thickness of which is from 10 to 20 cm. At the same time, there should be no gaps between the boards. A finished wooden shield or ordinary plywood will help replace the boards. In order to equip a flat ceiling on the lower floor, plasterboard sheets or plywood are installed on top of the roll.

Using another method of installation of rolling, it is possible to significantly increase the area of \u200b\u200bthe ceiling, if it is not large enough. Barks are installed on a wooden beam with a cross section of 4x4 cm. The roll is laid on them, while its installation is carried out perpendicular to the beams. This is followed by the installation of the bearing in the form of boards, the thickness of which is the same as that of previously installed bars.

In addition, a beam is also used for the manufacture of the roll, the thickness of which is from 6 cm. Sneoppan bars are installed on the beam, the cross section of which is 4x4 or 5x5 cm. The following is the process of laying the beam, while they are connected by the quarter method using a cut groove in the bead . The thickness of the beam depends on the height of the beams, they should be located at the same level. In this case, the beam performs the function of both rolling and binding. In addition, the manufacture of a fastener groove inside the beam will help replace the skull bars. In some cases, the lower part of the beams remains open and unprocessed. This method is relevant when using country style in the room.

Wooden beams: work technology for work.

The following is the process of arranging the floor on wooden beams. To begin with, bars are installed on each of the beams, in the ratio of which the surface of the flooring is formed. This stage involves the implementation of the flooring and the construction of the rough coating. Therefore, in the work it is allowed to use a non -powered board, however, it should be covered with protective materials and impregnations.

This is followed by work on the waterproofing of the flooring. The most optimal option is the use of a clay -sand mortar that has a lamp consistency. Another option for performing waterproofing work is the use of roofing material. With its help, it is possible to provide high -quality waterproofing, which does not take up much space. After that, the process of ensuring thermal insulation follows. The most popular materials for these work are the use of:

- slag filled between the bars;

- mineral wool;

- foam;

- non -polystyrene;

- sawdust or expanded clay.

The most popular floor insulation for wooden beams is mineral wool. It has high thermal insulation abilities, has a long service life, stable in front of rodents and is quite antiseptic.

Mineral wool is installed in such a way as to fit tightly to the floor surface. After that, vapor barrier is installed, since this material is unstable to the effects of moisture, which can get on it through a wooden floor.

Further actions are associated with the arrangement of the finish flooring. The option of its direct installation on the beam is possible, but it is best to first install the system from the lag. Thus, firstly, under the flooring, additional space and ventilation will be equipped, secondly, the level of noise published by a wooden floor will decrease significantly.

In addition, the option of building a wooden floor of a floating type is possible. The warm floor along wooden beams is characterized by the presence of hard fixation to the surface of the walls. In addition, he has excellent soundproofing characteristics and low creak levels. As a finish finishing material for arranging a concrete floor along wooden beams, a strict floorboard, chipboard, laminate, parquet board or linoleum are used.