Wide wallpaper for a novice builder is a real curiosity. Our...

|

|

The use of a warm floor system for heating the premises has already stopped ... |

Quite often, in the process of gluing wallpaper, problems arise with the appearance of overlap ... |

DIY roofing

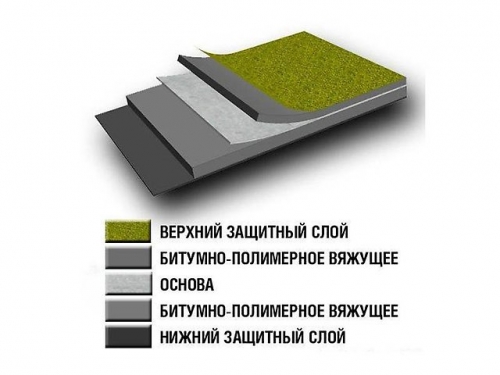

The choice of roofing for flat roofs is not as large as for the pitched ones. This is either a cheaper, but outdated roofing material or bitumen mastic, or more expensive, but high -tech rolled melting material. The installation of such a roof involves several waterproofing layers with high strength, which are directed over each other, which ensures the integrity and moisture resistance of the finished coating. The article will talk about the device of roofs from the melted materials.

Content:

- What is a melting roof

- Types of melted materials for the roof of Technonikol

- Installation of a swimming roof using a burner

- Frown roofing technology of cold styling method

- Repair of a swimming roof

What is a melting roof

The swimming roof is considered universal and is suitable for small buildings, for example, garages or sheds, and for civilian facilities, such as schools, shops or kindergartens.

- The width of the rolls is usually standard and is 1 m, but the length can be from 7 to 20 meters. The thickness of the material can also vary the same.

- Until recently, the only such roofing material was roofing material. It is the cheapest, but less durable, since it is based on cardboard. To date, in the construction market you can find high -tech floating roofs based on very durable, not rotten materials. The most popular fiberglass, which on both sides has a bitumen coating. He already managed to establish as the most durable and durable. This became possible for another reason, so it is known that bitumen is subject to aging and loss of its waterproofing qualities. In modern materials, this was avoided by adding special polymer additives to the Bituma itself, extending its operational period.

- Another modern type of swimming roof is polymeric materials called membrane. Their main advantage lies in excellent waterproofing of a flat roof, despite the fact that the thickness of such a layer can easily be adjusted. Add to this the fact that the price of such material is quite affordable, and the resulting quality of the roof meets the most stringent requirements, it becomes clear why it has gained such popularity today. The only drawback, the membrane roof is the presence of a large number of seams, which means that the process of work is quite laborious.

Types of melted materials for the roof of Technonikol

Rolled swimming roof linker

It is designed for flat roofs or roofs with a small slope. It is based on a strong organic canvas (fiberglass), which is unperestent in decay. On both sides, it is covered with high quality bitumen, on top of which a polymer film is applied on the bottom, which is easily melted, and from the upper protective film or mineral sprinkle. The roofing roof with a linker is designed to lay on a concrete base treated with a primer, or on a concrete screed. For work, the burners working on propane for this is used.

On sale it can be found in two brands, the choice will depend on the ultimate goal and selection of the desired characteristics:

- Linker K.This rolled material has a polymer film that melts easily, and coarsely sprinkled on the front side. Use it for the finish layer of a flat roof pie.

- Linker P.A more universal material that is suitable for the main layers of the roof, or for independent waterproofing of building structures. Like the previous analogue, it has a polymer coating on the bottom, but fine -grained sprinkling, or just a protective film, is made from the upper.

Rolled swimming roof ecoflex

It is suitable for any type of roof with a small slope or for partial waterproofing of individual structures. It is made by applying bitumen binding composition to high -strength fiberglass with the addition of special high -tech additives that extend its service life. Sometimes, instead of fiberglass, polyester materials are based on the basis. Like most of these materials, I use either coarse -grained shale or fine -grained river sand for the protective layer. A polymer film acts as a melted layer.

It is divided into two types, depending on the area of \u200b\u200bapplication:

- Ecoflex K.Designed for the upper layer of the roof, has a strong coarse -grained mineral coating;

- Ecoflex P.It is produced for the lower layers of the roof pie, on both sides it has a polymer film coating without sprinkling.

Rolled swimmer

Like all previous rolled materials, it is available on the basis of fiberglass, bitumen with various fillers and protective coatings of both sides. As a coarse -grained sprinkle, exclusively the ASBAGAL breed mineral is used. It is quite popular, thanks to a good combination, price quality. Stamps have a standard abbreviation:

- Glassesol to Used as the upper layer (suitable for operated roofs);

- Glassesol p. Having a polymer coating on both sides is suitable for creating the base of the roofing carpet.

Rolled melted roof bikrost

For its base, not only fiberglass or polyester fabric is used, but also cardboard, which is previously impregnated with bitumen. On both sides, it is processed with a bitumen composition with additives. Despite the visible similarity of one of the brands with a classic roofing material, the installation process is much simpler and safer, which allows saving funds in installation work. The main difference is that the technology of laying a bikost implies foam, and not gluing the material, therefore, the number of necessary layers decreases.

Its installation is carried out using a burner on propane, which can be rented in specialized companies.

- Bicrost K.. Mineral sprinkling from shale or asbagald on the front side and a light -melted film on the other;

- Bicrost p. It can be like with fine -grained sprinkling of both sides.

Rolled swimming roof uniflex

These are high -quality roller materials suitable for use in regions with extreme climatic conditions. In the bitumen composition, which is applied to fiberglass, add polymer additives, thermoplast and a number of other fillers. For protective coating, depending on the brand, they use coarse -grained and fine -grained mineral sprinkling. Mount it hot with a propane burner.

- Uniflex K. On the front side can have not only mineral stones, but also foil coating;

- Uniflex p It has to be sprinkled on both sides.

There is also such a type of product as on sale as Uniflex Vent. It happens that bloating is formed on the roofing carpet. The reason for this may be a fresh concrete screed, which has not yet had time to dry, or too old roof or wet insulating layer. To avoid this, it is worth using the breathable roof of uniflex.

- It is convenient to work with it, since even for repairs it is not necessary to dismantle the old coating.

- It simultaneously protects the roof from moisture and helps to remove extra vapors from under the roof out. This became possible due to the channels that have roofing uniflex material. It has strip gluing from the back, which helps to facilitate and accelerate the laying process, and the tightness of the resulting fastening completely solves the problem of possible swelling formations.

- For the production of this material, polyester fabric is used, with the application on both sides of the composition of bitumen, thermoelastoplast and fillers. Sprinking from shale or sand is done on top, and a ventilated surface is provided from below. It is a separate strips of bitumen composition, the distance between which is filled with fine -grained filler. On top of it, everything is covered with a polymer film.

- Uniflex EPV It is intended for the device of the lower layers, on top it has sand sprinkling, and a ventilated base from below. Suitable for repair work directly over old roofs.

- Uniflex EXV It has a large sprinkle. It is also suitable for repairing a roof that has bloating or cracks.

Rolled melted roof bikolast

This is a soft swimming roof based on modified bitumen with high waterproofing qualities. It is great for all types of roofs with a small slope. It is also used for waterproofing reinforced concrete structures. Bicroelast is a unique material that has no analogues in Russia. This is due to the fact that only it has a bitumen coating of an inorganic basis with a special modification technology, which allows it to maintain his elasticity even at a temperature of 10 C. Another feature is the fact that it withstands heating to +85 C without melting.

- Bikroelast k or tropic to. On the upper side it has a sprinkle of large shale granules, and the floating side has a protective film. Both of these species are used for the finish layer of the roofing carpet;

- Bikroelast n or tropic p. It is released in different variations: sprinkling on one or both sides, as well as a film on both one and both sides. Apply for the main roofing layers.

It is also worth mentioning the rolled swimming roof of Bipol. The main advantages of this roof is the use of SBS-Bitum, which provides high adhesive characteristics, which allows you to glue it on almost all horizontal and vertical coatings.

Installation of a swimming roof using a burner

In order for the roofing to be reliable for many years, it is important not only to make installation correctly, but also to carry out preparatory work. The swimming roof can be mounted on any continuous coating, whether it be concrete, metal, flat slate or OSP or plywood.

- The preparation of the base begins with harvesting.

- First, all possible protruding structural elements, for example, reinforcement, bulges or large cracks are removed.

- It is necessary to carefully remove all the garbage and dust from the surface of the entire roof. If there is such an opportunity, it is better to wash it with water from a hose or buckets.

Tip: To remove oil spots from the prepared base, they need to be burned. Stains of cement milk are removed using jet-abrasive cleaning. To close up large cracks, you will need a cement-sand mortar, and small is enough to cover with bitumen mastic.

Tip: it is impossible to use power tools to align the surface, since furrows can form from them.

- If the roof is not allowed to dry until the soft roof is laying, then swelling may form in the future. To check how dried the base is, it is enough to put 1m2 film on it and see if condensate is formed under it during the day.

- When everything is prepared and dried, the first waterproofing layer is made to the primer. The composition is simply applied coldly with a brush and left to dry. It takes at least a day.

- Instead, it is allowed to use bitumen diluted with kerosene, adhering to the established consumption rate of 300-400 g/m2.

- The next layer is laid by vapor barrier, which is designed to protect thermal insulation material from getting wet. Until recently, Permamin was the only material, now the choice of such products is very large - from films to technological wind protection membranes. Regardless of what exactly the material is chosen, it is laid for 10-15 cm. The joints are necessarily glued with tape. Along vertical structures, vapor barrier is placed with such a margin that it is higher than the thickness of the layer of future insulation.

- As a thermal insulation layer for a soft swimming roof, mineral wool or foam (or extruded polystyrene foam of any brand) is used. Here we must take into account the advantages and disadvantages of each of them. So, the mineral wool of the fire resistance, but it can get wet, the foam, on the contrary, has excellent moisture -resistant qualities, but when contacting the fire, it immediately melts.

- The insulation is placed in 2 layers of 5 cm each. The mats are placed in a checkerboard pattern to eliminate the coincidence of their edges, thereby excluding the bridges of the cold. If Minvat is chosen, it is glued together by bitumen, the foam is attached directly to the concrete base on the dowel-grooves with fungi.

- Now there is a turn of laying the most fused roof. If the roof has a slope, work begins with the lowest of its section. They roll out a roll along the entire length and, making sure of the integrity of the material, cut off the desired length and again turn into a roll. Now it is necessary to fix its narrow edge, for this he is heated by the roof section or the material itself and tightly pressed to the base in this place.

- Further, heating the lower side of the roll roofing material with a propane burner, it is gradually unwound and pressed to the base. Thanks to the bitumen coating, it is firmly adversely with any coating. Thus they pass to the end of the roll and fix the second narrow edge. Now we need to check whether all places are well glued, in the event of a material in any place, it is heated again and pressed again.

- The next row is mounted with a longitudinal overlap of 8-10 cm and end over 10-15 cm by end. Its direction should correspond to the previous one, crossing is unacceptable.

Tip: The three are more convenient to perform work. One person holds the burner and heats the roofing material and the base, the second gradually promotes the roll, making sure that it lay down correctly, and the third examines the possible appearance of irregularities or bubbles and eliminates them by leaving a roller.

- Even if the quality of the melted strip of material is completely satisfied with, it must be flattened with a roller. This is done diagonally, from the center to the edges.

- The movement of work on the roofing from the bottom up ensures the correct overlap in which the water will drain from it without linger.

- For high -quality waterproofing of corners, you need to prepare 2 cut -off pieces of bitumen roof and glue them into overlap.

- Despite the coarse -grained sprinkling of the upper layer, walking on freshly laid material is not recommended. Under the weight of it, recesses from traces, in which moisture will then accumulate, can remain on it.

- As a rule, such a roof fits in several layers. Each subsequent should be located with a displacement, so that the difference between the joints is at least 30 cm.

- Particular attention should be paid to the places of attachment of the roll roof to the vertical elements of the structure, corners and all joints. This guarantees long operation without the need for repair.

- At the junction with vertical walls on a flat roof, a piece of roll roof intended for the lower layers (with fine-grained sprinkling or without it) is set 25-30 cm higher and melted using a burner. Its upper edge is attached with self-tapping screws or dowel-bvs. A fabric with a coarse -grained sprinkle with an even larger margin is glued on top. Its edge is similarly fixed with fasteners for greater reliability. All joints are processed with bitumen mastic.

The device of the melted roof on the pitched roof

- Sometimes there is a need to arrange a soft roll roof on the pitched roofs. It should be remembered that the maximum permissible inclination goal is 50 degrees.

- In this case, OSB 12 mm slabs or moisture -resistant plywood with a thickness of at least 10 mm are used as the base.

- They are also processed by a primer for waterproofing. Either divorced bitumen (not only kerosene, but also gasoline or diesel fuel).

- On the pitched roofs, it is better to arrange a roll vertically, starting its fasteners from top to bottom. The crossing of layers is permissible.

Frown roofing technology of cold styling method

- Its difference is that instead of heating the bitumen binder burner, solvent is used. It is applied to the bottom of the material and on the base in an amount of 50 g/m2.

- Thus, missing the entire length of the segment of the soft roof, wait about 10 15 minutes, after which it is rolled out with pressure with pressure, thereby gluing to the base.

- If a professional pressing rink is used (the weight of the order of 100 kg), then one person is enough for work. But often the masters use the device called the fishing rod. It is a skating rink and a sprayer for uniform application of a solvent. In this case, for the convenience of work, 2 workers will be required.

- The number of clamping passages, with this method of installation, should be at least 3 per strip. It is the rolling in this case that affects the quality of the finished roof and the lack of air bubbles.

- If the roofing carpet itself is allowed to be placed in 1 layer, then complex places (ventilation shafts, corners, pipes and, tunnels of the drain, etc.) must be protected by a double layer.

Tip: Work with a roof in the most difficult places can be performed in another way. They heat the bitumen mastic and pour in an even layer in the right place and left for a while so that it hardens. Then, gravel is poured right on top, leveled it and thoroughly spray with the solvent, which was used to lay the main roof. Now it remains only to firmly roll the sprinkle with a rink, thereby it turns out a strong coating. If the roof is actively operated, then a dry mixture of sand and cement, asphalt is used as protective sprinkling.

Repair of a swimming roof

If, during a visual examination, cracks, chips, signs of decay or the beginning of vegetation, as well as various swelling, stratification or softening of bitumen are found on the roof, it means that it needs repair. Processing can lead to decay of the roof frame, in this case the repair will be much more expensive.

- Cosmetic repair is permissible if the total area of \u200b\u200bdamage does not exceed 30-40%. Problem areas are cleaned of dirt and right on top of them, without any other preparatory work, patches from the same material are melted. The size of the patches should be slightly larger than the damaged area.

- Overhaul will be required if 50% of the roof and more unusable. In each case, it may differ, but on average the stage of work is as follows:

- full or partial removal of the old roller roof;

- re -primer with a primer or arranging a new concrete screed;

- creation of steam and thermal insulation layers;

- laying of the floating roof over the entire area of \u200b\u200b1 layer, and a double layer is mounted around the parapets of other vertical elements;

- as an additional option, you can cover the finished roof with a fiery retail composition.

Relax with technology

You can familiarize yourself with the roof repair and order a contractor at http://alpansk.ru/krovelnye-raboty/kapitalnyj-remont-kryshi-montazh-krovli