It should be noted right away that stretch ceiling in the bathroom will ...

|

|

One of the most popular floor coverings laminate. It is used in residential and ... |

Installation of plastic windows is an excellent solution to ensure comfort at home and ... |

Ecowan application: step -by -step instructions

Due to the inevitable deterioration of the environmental situation on the planet, both beginners and experienced masters, when choosing thermal insulation materials, began to pay attention to goods characterized not only by the high level of heat and sound insulation, as well as the simplicity of installation measures, but also the manufacture of natural ecologically clean materials. The possibility of independent installation is also appreciated by consumers, since in this case they get the possibility of full control of each stage of applying the material, which will not only save funds, but also in the event of any damage, independently eliminate them. One of these materials is Ecowata, which, despite the above characteristics, has not yet gained due popularity, which leads to the fact that often the consumer prefers the foreman and mineral cotton -tested by many builders. We are sure that having familiarized yourself with this article, you will see the undeniable advantages of Ecowan, as well as the simplicity of the technique of its application, which we will also talk about in this material.

Content

- Ecowata: structural composition and expediency of use

- The main advantages of ecowine

- Disadvantages are ecovy: What did you not know about the material?

- Ecowan application methods: manual and automated

- Equipment for an automated method of applying ecowan

- How to warm with ecowide: the main methods of application

- Recommendations of experts for applying Ecowan with their own hands

Ecowata: structural composition and expediency of use

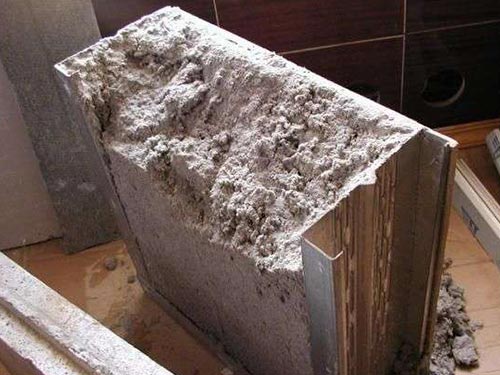

The insufficient popularity of the ecowan, associated with its recent appearance in the construction market, as well as the long lack of necessary equipment for its application, is quite fixable, since its undeniable advantages cannot go unnoticed. The thermal insulation material of the ecowata is characterized by a loose structure, 80 % of the cellulose, which has the highest thermal insulation properties and excellent mechanical characteristics, thanks to which, after its application, a homogeneous layer is formed, devoid of seams and irregularities. But, despite its characteristics, cellulose is not used in construction work in its pure form, due to its high ignorance. As part of the ecowine, these properties of cellulose do not prevent its use, since in addition to cellulose, antipyrene, in which the drill acts, and the antiseptic of boric acid, are included in its structure. The use of these components in the structure of the ecovaty makes it absolutely fireproof and allows you to use it for thermal insulation of boilers and chimneys. The use of boric acid makes it possible to prevent damage to the thermal insulation layer with rodents and insects, as well as the appearance of mold and fungus.

Important! Unlike Ecowan, boric acid is not included in mineral wool, and therefore, it is often damaged by rodents and insects.

The main advantages of ecowine

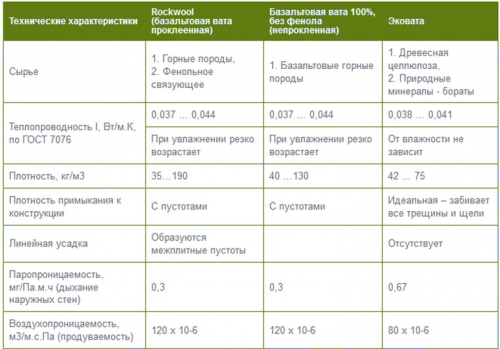

- Despite the fact that Ecowata is practically unable to pass wet steam and heat, it easily absorbs a large amount of moisture, and unlike mineral wool, this does not affect its thermal conductivity. The thermal conductivity of the previous one with an increase in humidity by at least 1 %increases by 8-9 %, respectively. In this regard, you get the opportunity to use an ecovata to insulate wooden frame houses, where it will help maintain an optimal level of humidity;

- Due to the fact that Ecowata is a homogeneous loose mass, subject to all the rules for its application, a seamless layer with high thermal insulation characteristics is formed, while the formation of voids and cold bridges that contribute to a decrease in thermal insulation characteristics is completely excluded;

- Ecowata, in comparison with mineral wool, has higher soundproofing characteristics and, unlike foam, has higher elasticity, which also allows it to more effectively extinguish any external sounds;

- There are no substances that are not harmful to human health. An absolutely safe lignin is used as an adhesive substance, while the antiseptic and antipyren, not spraying and not evaporating, also do not represent any harm, which can not be said about the everywhere used by polystyrene foam;

- Ecowata is a loose material, which in the case of industrial laying is pre -moisturized. The use of the material can be carried out without preliminary moisture, then the ecovat is pumped into the frame using the compressor. The laying of ecovites can also be carried out manually, which is the most labor -intensive and long -term application of application.

- Low chemical activity, due to which in the places of contact of the heat -insulating coating and metal parts of the fastener or frame of the building, the formation of corrosion processes does not occur;

Important! Due to the chaotic arrangement of cellulose fibers included in the structure of the ecowy, it eliminates the shrinkage of the material in case of its vertical application. This contributes to the prolonged preservation of thermal insulation properties of the coating.

Disadvantages are ecovy: What did you not know about the material?

- Despite the fact that the ecowuta is absolutely non -combustible material, when it is at high temperatures, it can be subjected to decrease. In this regard, when insulating objects subjected to heating, basalt or asbestos is additionally used;

- Application of an ecowan process, the complexity of which depends on the method of its installation. For the correct implementation of installation measures, sufficient experience and the use of specialized equipment will be required;

- In the process of insulation, an ecowide form a large number of dust microparticles of cellulose and drill;

- In the case of humid application of ecowan, subsequent installation measures can be taken no earlier than after a day;

- And, perhaps, one of the most important disadvantages is a fairly high cost of an ecowine insulation, which is several times higher than thermal insulation using traditional polystyrene foam and mineral wool.

Ecowan application methods: manual and automated

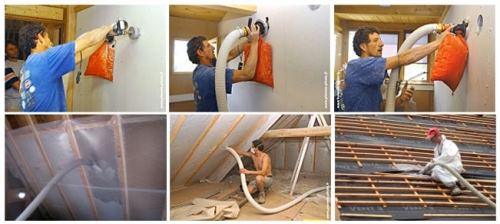

Installation of ecovata can be carried out in several ways, each of which is intended for the implementation of various goals and are characterized by their advantages and disadvantages. One of the simplest ways by which the ceilings and floor is insulated is the manual method of applying ecowan. Despite the fact that the method is characterized by a number of advantages, there is a more modern semi -automated method that implies the application of material using a sprayer.

Manual methodit implies the stages of the performance of work, the first of which is to pour the necessary mass of insulation into a container of a certain volume. In the role of this container, you can use volumetric boxes or a bucket. Given the fact that the supply of ecovites to the retail network is carried out in a compressed form, the next stage of work is to flush the material. It will require a drill or a specialized nozzle for mixing paints and varnishes. It must be remembered that after the implementation of this event, the volume of material will increase at least three times. Having carried out the above actions, experts recommend starting the direct installation of Ecowata, which implies its backfill in vertically oriented structures or floor ceilings. In the process of manual laying, it is important to know the density of laying the material in the case of each insulated element, which, first of all, is determined by the consumption of the material. So, for example, in the case of insulation of the ceilings, the optimal insulation density is 35-50 kg per cubic meter. In the case of wall insulation, the proper consumption of the material is 60 kg per cubic meter, and for insulation of the roof 50 kg per cubic meter.

Important! If you need to insulate houses characterized by a large area, or cottages, the manual method of installation of ecovy is unsuitable for this, since in this case you will have to resort to the use of specialized blowing equipment.

Equipment for an automated method of applying ecowan

To carry out the installation of ecovata, the following equipment for applying ecovata will be required:

- Automatic blowing installation equipped with a specialized as a heap, with which you can produce a more uniform supply of thermal insulation material to the place of its direct installation;

- Corrugated hoses with which the insulation will be supplied to the place of work;

- Water-cell installation of ecovati implies the use of a set of specialized PPM;

- Wet spraying is carried out using an additional kit;

- A more modern version of specialized equipment implies its additional equipment with fiery nozzles and electrical trimming rollers, which will be required to remove excess material.

How to warm with ecowide: the main methods of application

Answering the question: how to insulate with the use of ecovata?, We consider it necessary to consider all the main methods of insulation using this thermal insulation material. If we talk about applying Ecowan with the help of specialized equipment, it is necessary to consider three installation methods, such as dry, humid and wet-cell installation of ecovata, each of which will be discussed in detail later.

Dry way of applying ecowan

This method is especially relevant in the case of pulp the insulation of horizontal and inclined surfaces, as well as for the implementation of installation measures in the inter -story floors, and filling the voids representing closed spaces in the walls.

The installation of ecowan is in a dry way is as follows:

The initial stage implies the organization of holes in closed spaces limited by membrane waterproofing, which will further be filled with insulation. It is important to remember that the diameter of these holes should fully coincide with the diameter of the corrugated hose or spray nozzle, with which the automated installation of the thermal insulation layer will be carried out. In the future, the just mounted hole is connected to the hose that contributes to the entry of the ecowan, mixed with air, to its place of its installation. The presence of air in the heat insulator contributes to its more effective admission to the destination, as well as the maximum filling of free space by particles of ecowan, followed by the formation of strong pulp traffic jams. Filling free cavities is carried out until they are filled with the required insulation density.

Application of insulation on the surface located in a horizontal plane is carried out similarly, however, its only difference is that before applying the ecovy there is no need to arrange preliminary insulation.

Wet method of installation of ecowan

If you need to insulate vertical planes characterized by free access, moist application of ecowan will become the most optimal way to carry out thermal insulation measures. The fundamental difference between this method is that on open surfaces that are freely available and limited by frame structures, an ecowata is applied, previously moistened with water. Moisturization of ecowan is carried out with the aim of maximizing the free space with a heat with a heater, which, due to inclusion in the structure of the ecowine lignin, which acquire adhesiveness when contacting with water, adheres tightly to the frame. In the event that after applying the ecowan, you noticed excess material that clearly protruding over the frame, you need to resort to the use of a trim electrical video, with which you can remove excess pulp material.

Wet-cell method of applying ecowan

This method is largely similar to the previous one, however, it is characterized by one distinctive moment, the essence of which is to add an adhesive to the structure of the thermal insulation mixture, which gives it a number of undeniable advantages. The most outstanding of them are the following advantages:

- Low probability of deformations of cellulose material after its drying;

- A higher level of elasticity of thermal insulation material;

- The absence of harmful impurities in the material.

The application of the ecowata by this method is most relevant in the case when it is necessary to insulate surfaces located in a horizontal plane and characterized by the lack of free access to their lower part. A typical example of such structures is ceilings located in a suspended position, as well as other thin -walled structures.

In the process of carrying out thermal insulation by applying Ecowan with your own hands, you can solve several installation and technological problems at once:

- The implementation of high -quality soundproofing;

- At the same time, you solve the problem of the formation of condensate in a room isolated ecowide;

Recommendations of experts for applying Ecowan with their own hands

- In order to make a competent calculation of the required number of packages of ecowan, the weight of which is 15 kg, you can use online calculators on any construction site or make the necessary calculations yourself. To do this, it is necessary to multiply the area of \u200b\u200bthe insulated surface by the technological consumption of the material presented in our article;

- Experts recommend that the following parameters be guided. The recommended thickness of the floor insulation is 15-20 cm, for the pitched roof 15-20 cm, for inter-story floors this parameter is 10-15 cm, for attic floors 20-30 cm;

- In the process of acquisition, the ecowan do not forget that the consumption of thermal insulation material may exceed the calculated values \u200b\u200bby 10 %, and therefore, it is important to purchase material with a margin;

- Initially, the characteristics of the ecovy are such that it is designed to warm wood structures. In this case, it is applied directly to the surface, without the use of insulating materials. In the case of insulation of surfaces from metal, brick and concrete, before the direct application of the insulation, it is necessary to isolate the ecowata from the treated surface, using isolation material. This will prevent the formation of condensate in the room;

- In the process of installation, it is important to provide a possible shrinkage of material under pressure from their own weight. Most often, this happens in case of insulation of high vertical cavities. To prevent this, in the insulated cavities during the installation of the insulation, horizontally oriented dividing partitions are installed, which help to reduce the initial weight of the insulation;

- In the case of roof insulation, it is also necessary to take measures to prevent the formation of subcutaneous condensate.

Continuing self -love.

Continuing self -love.