The hall plays a particularly important role for us, since there we spend a lot of time ...

|

|

Nowadays, the sphere of building materials develops very quickly and gives the world everything ... |

Sound insulation problems are more puzzled by residents of apartment buildings. Someone from... |

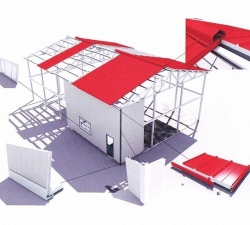

Installation of wall sandwich panels

When arranging rapidly vegetable buildings, an indispensable building material is a sandwich panel. Thanks to their universal composition, they do not load the foundation, are easily transported and have affordable cost. We will consider further about the features of installation and use of wall sandwich panels.

Table of contents:

- The general concept of wall sandwich panels and their advantages

- Sandwich Panel Wall: Scope and varieties

- Mounting and mounting wall panels

The general concept of wall sandwich panels and their advantages

The sandwich panel is a building material, which consists of three main layers, the outer layers are hard material in the form of metal, polyvinyl chloride, fiberboard, etc., the inner layer - in the form of insulation. Gluing all components occurs in two ways:

- hot pressing,

- cold pressing.

There are two types of sandwich panels:

- walls,

- roofing.

Their difference is in the method of fastening. Using wall sandwich panels, inclined areas of a horizontal, vertical or inclined nature are created, and the roofing sandwich panels are used in the construction of buildings of any type. Also, the sandwich panels are distinguished by the type of plextering, on which their cost depends. The higher the thermal pipeline properties of the panels, the more expensive they are.

We offer to get acquainted with the advantages of using wall sandwich panels:

1. This material allows you to quickly build or repair the building, regardless of weather conditions or season.

2. Sandwich panels have high thermal insulation properties, since the inner layer consists of insulation.

3. Another advantage of using sandwich panels is their environmental safety, health harmlessness and hygiene.

4. Due to the low weight, the sandwich panels practically do not give any load on the fundamental parts of the building, and, therefore, increase the duration of its operation.

5. Light weight allows you to easily transport the material to the construction site and simplifies its installation.

6. Thanks to the color diversity, the sandwich panel does not need additional care and decoration.

7. High soundproofing characteristics make a stay in a building built from sandwich panels more comfortable.

8. Sandwich panels are characterized by a wide scope of use, and even recommended for use in the buildings of resort, spa, children's and medical purposes.

9. Sandwich panels do not react with chemicals, and also do not form mold or fungi.

10. If you compare the cost of sandwich panels with similar building materials such as brick, concrete or wood, then they are much cheaper.

Among the large number of advantages of sandwich panels, there are several of their shortcomings, among which:

- lack of ability to withstand large loads;

- a tendency to the appearance of cosmetic scratches and mechanical damage;

- At the junction of two sandwich panels, cracks form that require processing using mounting foam;

- Since there is no insulation in the places of connection of sandwich panels, there is freezing, as a result of this, condensation is formed that reduces the quality characteristics of the material;

- Some sandwich panels are faced with formaldehyde, which is very toxic, with the effect of high temperatures.

Sandwich Panel Wall: Scope and varieties

Sandwich panels are a special building material, which is used both in design and in the decoration. Thanks to the universal structure, the sandwich panels have a wide sphere of application.

They are used in the construction of temporary buildings in the form of kiosks, pavilions, everyday life, cinemas, and are also used to maintain the energy efficiency of already erected buildings or storage facilities. Also, the sandwich panels are used as an excellent sound insulator or as a partition in the structure of the enclosing purpose.

The use of sandwich panels is widespread in the construction of shopping centers, supermarkets, agricultural premises, as well as during the construction of cottages and any one- or two-story houses. Another aspect of the use of sandwich panels is the scope of the construction of window and door systems. They help improve the soundproofing characteristics and energy efficiency of windows and doors.

As a heater in sandwich panels, it is possible to use:

- mineral wool;

- polyurethane foam;

- fiberglass;

- polystyrene foam;

- Combinations of several insulation materials.

The main features of the wall panels of three -layer sandwich, as a heater for which mineral wool is used:

- fire safety;

- high level of sound and thermal insulation;

- stability before chemical and biological influence;

- heat resistance;

- health harmlessness;

- easy installation;

- Lack of shrinkage.

Among the disadvantages of this type of panels, the need to use the respirator during operation, high vapor permeability and weight weight is distinguished.

Sandwich panels based on polyurethane foam or polystyrene foam have high sound and thermal insulation characteristics, stability before deformation, environmental safety and duration of operation. The main difference between these sandwich panels from the previous ones is the lightness of their weight, the simplicity of their installation is most ensured. With the help of such sandwich panels, the construction of a house in the winter season is not a problem. Among the disadvantages are low fireproof characteristics and high cost.

The sandwich panel, as the central layer of which is used fiberglass, have high stability before vibration, non -combustibility, resistance before the influence of chemicals, light weight. They combine all the positive characteristics of previous species, but at the same time have their own shortcomings, including:

- instability in front of sharp temperature changes;

- The possibility of deformation and shrinkage.

The sandwich panels with the presence of combined insulation combine mineral wool and polystyrene foam. Such material is non -combustible, but at the same time durable and sound -resistant.

As a facing layer, plasterboard, metal, wooden slabs, polyvinyl chloride or paper are used.

Another option for sandwich panels are the phased structures panels that differ from ordinary sandwich panels with assembly and installation precisely on the construction site where they will be installed. The main components of such panels are:

- a self -supporting cassette profile;

- insulation;

- The outer layer in the form of corrugated board.

The cost of panels of this type is much lower, but the installation technology is more complicated.

The basis of the outer layer of the sandwich panel is a galvanized metal, which is covered with additional materials. There is a coating of alucinka, plastisol, polydictorionad, pool, polyester.

The main advantage in the use of galvanized steel is the protection of the panel from the formation of corrosion. The duration of operation of the panel is completely dependent on the thickness of the zinc coating.

The outer layer of the sandwich panel from alucinka, in addition to the above advantage, is stable over ultraviolet. Such panels are made exclusively by the American company Steel.

If the sandwich panel is planned to be used as a decoration of housing premises, it is recommended to use the material whose upper layer is covered with drywall. Such panels are light and ease of installation.

The substance of the plastisol, which also covers the outer part of the sandwich panel, is modified by polyvinyl chloride having a high density. Such panels are recommended for use in severe adverse conditions, in addition, they are very stable before mechanical influences.

The sandwich panels are based on polystyrene or polypropylene are used for the production of windows and their slopes.

A layer of polydiftorionad, which is covered with a sandwich panel contains eighty percent of plastic and twenty percent of acrylic. Such material is well opposed by ultraviolet, temperature difference and rust formation.

The fibrous structure of polyester, which also cover the outer part of the sandwich panels allows them to tolerate the constant effect of high temperature, do not lose color and are stable before mechanical damage.

The purple coating has anti -corrosion properties, stable before the exposure of ultraviolet radiation and temperature difference. It is recommended for use both inside and outside the room.

The color of the sandwich panel depends on the preferences and individual characteristics of the building. There is an international palette of shades, which includes about 250 various colors. When choosing the color of the sandwich panel, it is necessary to proceed from their ability before the lightning and burnout, since it is this factor that affects the duration of the erected building.

The thickness of the wall panels of the walls is 5-6 mm of the outer layer and 5-25 cm of the internal insulation.

Mounting and mounting wall panels

Before starting the installation of wall sandwich panels, you should check the correct assembly of steel frame structure and basement. The preparatory stage of installation consists of:

1. Checks the presence of the required number of sandwich panels, materials, tools for work in the construction site.

2. When the basement is already erected and waterproofing is supplied to it, it is necessary to determine the exact procedure for fastening the wall sandwich panels.

3. Installation of panels always begins from below and gradually moves up. To reduce the vibration of wall sandwich panels with columns, a special self -adhesive tape should be used.

4. Before starting installation work, it is necessary to install a shaped or supporting component.

5. It is possible to install sandwich panels on facade wooden, concrete, metal structures.

6. Sandwich panels that are used when arranging a basement must have the highest thermal insulation characteristics. The option of building a base of concrete or brick is possible.

7. Make sure that the panels are located in such a way that the water drains easily on them.

The dimensions of the sandwich wall panels depend on the individual characteristics of the building being built.

To fix the wall sandwich panels on the frame, it is necessary to have special screws of self -extinguishing type, for the manufacture of which carbon or stainless steel is used. Squiru seals make materials at the basis of which lies synthetic rubber. The horizontal fixation of the sandwich panels involves their fixation on the column areas or fachwerk racks, and vertical fixation is carried out on the metal element of the basement or refrigerates of the eater.

To strengthen the gaps between the panels and the end or basement areas, mineral wool in polyethylene and the closure of metal sheets are used, on which the polymer coating is applied.

Wall sandwich panels of the support type are characterized by the presence of a minimum width of 600 mm. If the buyer desired, a special film is applied to the inner and outer sides of the panels, which protects the panel from damage during transportation and installation work.

The film outside needs to be removed at the final stage of installation of each of the panels, and the film indoor is removed after installing all panels, but no later than 90 days, from the date of manufacture of the panel.

To cut the sandwich panels, use tools that do not allow them to heat up, such as electrician, electrolobsics. Stick removal occurs using a brush.

Features of cutting sandwich panels:

1. All work should only be carried out on the horizontal surface of the earth. In no case do not cut the panels in the air.

2. The mounting gap between the wall sandwich panel and the window or door block is from one to three millimeters.

3. Using the construction level, control the evenness of the previously applied marking on both sides.

4. First, cut one, and then the second side, delete the unnecessary piece of the panel.

The end axis of each facade is the initial accurate installation of the sandwich panel. The panels that are added to the windows, the door or other openings should be carefully measured and cut in accordance with the previously applied markup.

The option of using doors and windows made of both plastic and metal or wood is possible. The best thermal insulation properties when installed in a building from a sandwich panels have doors made of plastic.

Installation of partitions is carried out according to the same principle as fastening sandwich panels on the walls. In the process of fixing the sandwich panels that are attached to the supporting walls, monitor the correct distribution of the load.

Attention should be paid to the efforts attached during tightening fasteners. In this matter, you need to find something average, between strong and weak delaying. Too tightened screws will significantly reduce the duration of the operation of the sandwich panels, and poorly tightened fasteners will lead to their destruction, as a result of an incorrectly distributed load.

In order to correctly determine the required number of screws that will be required to install sandwich panels, keep in mind:

- wind load, which is affected by the total height and conditions of placement of the structure;

- View of the object: closed or open;

- The conditional facade zone on which the panel is placed, the panels that are located in the extreme areas are needed in the additional mount;

- Fasteners and their load -bearing load.

To determine the number of screws, to fix the sandwich panels, it is better to contact the designers who calculate this parameter in relation to the climatic conditions of the region.

In the process of installation, you should focus on the longitudinal connections of the sandwich panels. In no case do not allow the appearance of cracks in these areas, since they will significantly affect the operational characteristics of the building, contributing to the formation of condensate masses and cold bridges.

If the climatic operating conditions are good, then the additional seal of the sandwich panels is not required. In harsh conditions, a sealant on both sides of the longitudinal connection should be used.

The use of the sealing tape allows you to eliminate the problem of air circulation and compacts fasteners. Before proceeding with the installation of elements of a shaped type, you should fill all the cracks with a heater or mounting foam. The shaped components are mounted with a minimum overwhelming 5 cm and a step of fastening of 50 cm. Pay attention to the cracks between the shaped material and the sandwich panel, they should be absent, otherwise, the moisture will come to the surface of the sandwich panel and reduce its qualitative characteristics, and, and, and, and, it, and, and, Accordingly, the service life.

Good afternoon! How much will

Good afternoon!

How much will it cost to post a link in the article on our site

http://strport.ru/stroitelstvo-domov/montazh-stenovykh-sendvich-panelei

Please answer the mail proinseo@yandex.ru

Buy wall Sandvich

You can buy walls of the panels here: http://sp-panel.ru/catalog/sendvich-paneli-stenovye/ High quality, the price of the walls of the panel is quite adequate. In general, I can recommend this supplier, as I know about his reliability.

Application area

The scope of structures designed when using this type of product is practically not limited. With the help of metal structures, warehouse premises, retail rooms, residential premises, industrial structures, narrow orientation, etc. are erected. Read http://sp-panel.ru/sendvich-paneli/