For some reason, there is an opinion that, of course, is erroneous, which is on a stretch ...

|

|

For accommodation in a house or apartment to be comfortable at any time of the year, it is important ... |

After a certain life of a brick foundation, it needs ... |

Installation of a chimney from a sandwich pipes

The chimney is an important component and an integral part of the boiler room, fireplace and furnace equipment operating on any type of fuel. Among the large selection of materials for organizing the removal of combustion products, modular products, the so-called sandwich pipe are considered especially in demand. The article will talk about how to properly assemble a chimney from a sandwich pipes.

Content:

- Causes of popularity of chimney chimneys sandwich

- Chimney device from sandwich pipes

- Sandwich Pipes

- Preparatory work and calculations of the chimney system

- The nuances of the choice

- DIY chimney installation of a chimney from your own hands

Causes of popularity of chimney chimneys sandwich

- Installation efficiency. With the help of additional elements, you can assemble a channel of any complexity.

- Fire safety. Due to the special device, the outer body of the channel heats up to a minimum temperature.

- High operational indicators achieved by aerodynamics and a thought -out structure working to prevent condensate formation.

- The chimneine from the sandwich pipes is suitable for almost any heating equipment.

- Small weight of the entire structure allows you to do without a fundamental base.

- Work can be performed on their own by saving on the services of specialists. Ready -made sections exclude errors and miscalculations.

- Aesthetic appearance. You can choose a channel from stainless steel and painted in accordance with the RAL catalog.

- A fairly long service life. The materials used and the correct installation of each element of the system are responsible for this parameter.

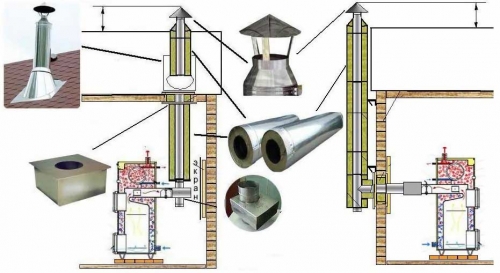

Chimney device from sandwich pipes

- Such a system is two pipes of different sections. Between them there is a thermal insulation layer more often from basalt wool, which provides rapid heating of the chimney, which, in turn, avoids the formation of condensate.

- With the help of ready -made sections, you can assemble a channel without significant labor costs. Thanks to the carefully developed design of the joints of individual elements, the strength and gas seal of the entire system is guaranteed.

- However, do not confuse concepts such as fire safety and refractiveness of the presented modular product. In this connection, it is necessary to take additional measures to strictly follow the instructions attached to each kit, as well as comply with all the norms and rules of fire safety.

Sandwich Pipes

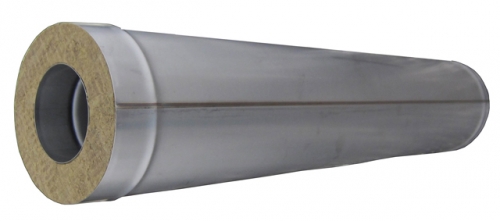

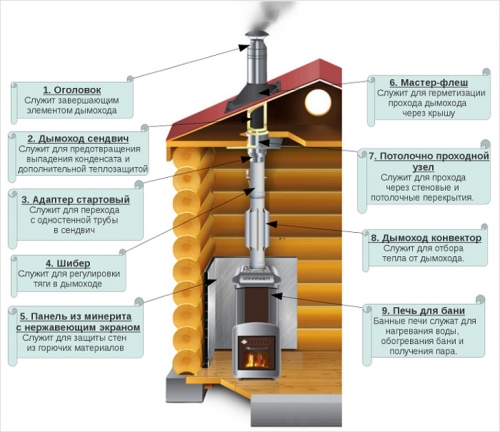

Each element of the smoke-haul system consists of 3 layers:

- for the manufacture of the internal body of the pipe, as a rule, stainless steel sheets with an absolutely tight welding seam are used;

- as a thermal insulation gasket, basalt cotton wool, less often polyurethane foam. The thickness of the layer is 30-80 mm, the filling density is at least 120 kg/cubic meter. The materials perfectly withstand the operating temperature of the chimney, sometimes reaching 700 degrees;

- the outer pipe is made of AISI 430 steel, copper or brass alloys. The connection is carried out by means of laser welding. This method does not violate the galvanic layer of the case.

In addition to direct channels, the transcontitions, a condensation device and fasteners, include the chimney. For convenient assembly, you can additionally purchase rotary modules, as well as the nodes of passage through the ceiling and roof.

Products from various manufacturers have general structural features. Differences are in the materials used, the thickness of the insulating layer and temperature conditions in working condition. On the market, channels painted with powder paint in almost any color are also presented.

Preparatory work and calculations of the chimney system

Before collecting a chimney from the pipes sandwich, heating equipment is checked for serviceability and readiness for operation. After installing the chimneine canal, the device cannot be moved or adjusted to its location. The unit must be firmly fixed and stable. In the presence of an old chimney, it is dismantled. The output of the heating device is thoroughly cleaned of soot and soot.

The calculation of important parameters when arranging a chimney channel should be carried out by specialists. Many homeowners refuse to attract them and try to solve all issues on their own. For those who first encounter such a task, the following recommendations will help:

- the diameter of the chimney sandwich is selected in accordance with the output of the heating equipment. This indicator is usually indicated in the instructions for the operation of the unit;

- the length of the channel is taken at least 5-6 m. Moreover, the calculation is carried out from the grate or burner to the upper part of the pipe;

- it is possible to reduce the resistance of the release of combustion products by using the minimum number of turns. The optimal angle of the knee is 45 degrees. The horizontally located pipe until the next insert should be no more than 1 m long.

Based on these recommendations, the scheme of the entire chimney system is drawn up. Now you can safely go to a specialized store. Acute lovers are a direct road to the market.

The nuances of the choice

Of course, the manufacturer’s brand matters. However, no one is safe from fakes. It is difficult for a simple layman to understand all the intricacies of choice. Therefore, some advice-falling words will not be superfluous.

- When heading to the store, take a small piece of a magnet with you, wrapped in a scarf or thin fabric. If the consultant claims that this is a high -quality stainless steel product, then put a magnet. The slightest attraction will be a fact for you for a reverse opinion. The fabric here is necessary to prevent the scratching of a shiny metal, thereby this will avoid conflict with the seller.

- Attention deserves the thickness of the pipe walls. This parameter should be at least 0.5 mm. The thicker steel, the more reliable and durable the design itself will be.

- Check all sections for chips, dents and other deformations or damage. The shape of each element of the system should be even, and welds without interruptions.

- It is recommended to collect several structural elements right in the store. The connection should be durable, the presence of gaps, free walking of parts is not allowed.

I undoubtedly want to save on a purchase. But the chimney system is not the case. The quality should be in the first place, not the cost.

DIY chimney installation of a chimney from your own hands

For the correct, safe and durable operation of double -walled chimneys, the following rules are observed:

- the total length of the channel should be at least 5 m. Such height provides the necessary traction;

- the pipe should be higher than the flat roof by 0.5 m. This parameter is observed when it is elevated above the skate during the pitched roofs, if the channel output from it is 1.5 m;

- when the chimney has a height of 1.5 or more meters without the possibility of reliable consolidation, clamps are used or a supporting mast is erected;

- for sealing docking joints, materials with a working temperature of at least 1000 degrees are used;

- sections of the docking of pipes with tees, bends and other elements of the chimney system are strengthened by clamps;

- every 2 m of the length of the canal is enhanced by special wall brackets. For the tee, a console or support site is mounted. walls, beams, ceilings and other structural elements of combustible materials in the places of touch with a bimming pipe are isolated or the indentation is performed;

- from the heating device, a plot should go without any isolation;

- most of the system should be located indoors. Thus, the temperature difference is reduced, which means the heating will be the most effective;

- the top of the chimney is protected by the head of the deflector.

DIY chimney sandwich video

During operation, it is prohibited:

- use plots of chimney for drying clothes, shoes, brooms and other household items;

- place a channel in a direct proximity to flammable materials;

- as fuel, construction garbage, items with paintwork, etc.

- install galvanized products in living rooms and rooms with a high level of humidity;

- mount stainless steel chimneys to coal units.

How to mount a chimney from sandwiches inside the house

There is no particular complexity in the installation of the system, it is important to observe the sequence of the connection of each section.

- The process begins with the installation of the coupling on the chimney of the heating unit.

- A tee or horizontal segment of the pipe is fixed to it. Here the module is selected depending on the pre -prepared system diagram. The lower part of the tee is closed with a plug, which is removed after a certain period of time to remove soot.

- A hole is made in the ceiling to pass the vertical pipe. At this point, a pipe-adapter is installed. A straight pipe is passed by the attic or from the street to the prepared opening.

- The remaining distance between the channel and the overlap is isolated by fireproof materials. Only then you can proceed to the next stage of installation. It should be noted that the docking of the modules in the places of their passage through the ceiling is prohibited.

- Later, this site can be plastered and painted over or other work to disguise an unsightly appearance.

- Further, work is carried out in the attic and roof. Chimney pipes are lowered on top and do a docking with lower modules. This assembly procedure will provide protection against condensate penetration into the channel.

- If the roof is flat, then you can use a simple sheet made of galvanized metal carved in the shape of a square. It starts under the coating to prevent moisture leakage during rain or melting snow. The edges are treated with hermetic materials.

- For inclined structures, you can purchase a special passing node with a non -on -class cover. This element is made of plastic under a certain angle of inclination. Some products are made of elastic materials, making them universal. Plasticity allows you to install on roofs with any slope.

- The outer part of the pipe is crowned with a headstock or the so -called umbrella. The role of this element is to ensure protection against small debris, snow, and ice ice, and also does not allow birds to take a warm place to arrange a nest.

Installation of a chimney from sandwich pipes outside the house

- Reception is relevant for the installation of a chimney from the sandwich pipes through the wall. This design allows you to save the internal space of the room. In addition, in some cases it is impossible to make holes in the inter-story ceiling or in the roof itself due to their structural features.

- The start of work is similar to the installation of the channel inside the house. A horizontal segment of the pipe is attached to the starting clutch or, if necessary, a knee with a different angle of rotation is used.

- A technical hole is made at the wall at the chimney output point. The next section of the system is passed through it. The free space of this site is also filled with thermal insulation material.

- On the street, the end of the pipe should end with a tee with a dull plug in the lower part. For reliability, a support console is installed under this element.

- Before starting the vertical assembly of the canal on the walls, it is necessary to install brackets with a step of 1.5-2 m. The installation method, as well as the choice of fasteners, depends on the material from which the house or type of skin is built.

- For high -altitude work, you will need a staircase, or maybe even a lifting crane. As the structure is extended, one should not forget to wear special rings-blocks that serve as part of the bracket.

- The sandwich chimney ends with a head of the head (umbrella). If the segment rises above the roof than 1.5 m, then it is recommended to install fasteners to enhance and stability of the structure.

In principle, work does not provide special difficulties. It is important to observe the assembly sequence. Additional tools are necessary only to make technical holes for the passage of pipes. All stages are freely performed in one. A partner may be needed to speed up the process when installing a channel at different levels.