In the process of building a house from a brick, the main issue is the type of foundation, ...

|

|

The most environmentally friendly material was and remains popular in construction -... |

The popularity of such finishing material as liquid wallpaper in the interior ... |

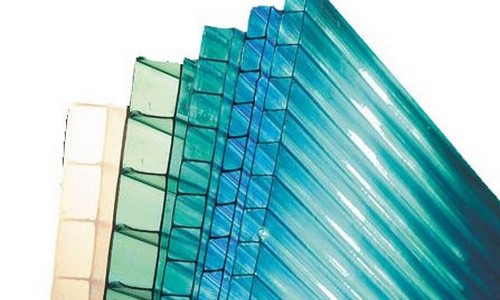

DIY polycarbonate roof

In construction, polycarbonate has been widely used recently. Its technical properties and qualities make it possible to recreate a solid roof for a residential building, verandas, arbors, garage, greenhouses and other structures that require daylight. A polycarbonate roof is being built is quite simple, allowing sunlight to be used as a natural light of a residential building.

Content:

- Technical properties of polycarbonate

- The advantages of polycarbonate

- Disadvantages of polycarbonate

- Design features of roofs

- Stages of the roof device

Technical properties of polycarbonate

Polycarbonate is a polymer material that is resistant to mechanical influences and temperature differences. The presence of small air chambers in it provides a high level of heat and sound insulation. In addition, cellular polycarbonate is characterized by high transplants.

It is simple to build a roof of a house from polycarbonate sheets, especially when you take into account all its advantages, positive properties and a low price. Polycarbonate is available in different thicknesses from 4 to 16 millimeters. At the same time, the weight of polycarbonate is 1 square meter 900-2700 grams depending on its thickness.

Polycarbonate retains its physical and mechanical properties at a temperature of minus 40 plus 120 degrees Celsius: resistance to chemical compounds and reagents, high thermal insulation indicators and impact resistance, as well as a long period of useful service of the material (up to 20 years).

The advantages of polycarbonate

Polycarbonate slabs, in addition to ensuring good natural lighting, differ near the advantages:

- Protect the space of rooms from bright rays of the sun: the light passing through the roof is diffused, and the polycarbonate canvas does not pass ultraviolet.

- The small share of the polycarbonate canvas provides the possibility of creating a particularly light roof, which affects the price of a polycarbonate roof, reducing the design in turn and allows you to expand the design number of roof modifications.

- Quite high thermal insulation properties that allow you to successfully use polycarbonate without additional insulation.

- They have good sound and thermal insulation properties, hydro- and vapor barrier properties.

- Provide excellent ventilation at home, and they guarantee quick smoke in the event of a fire.

- Proceedings are not delayed on their surface, because polycarbonate is very smooth.

- Low combustibility and a high indicator of durability at operating temperature.

- Unique physical properties: good flexibility in one direction and excellent rigidity in the opposite to withstand serious loads from precipitation.

- Easy transportation of polycarbonate, processing and installation.

- This material during installation is well lends itself to drilling, cutting, bending and gluing.

Disadvantages of polycarbonate

Polycarbonate sheets, as you already know, are very flexible, so their strong bending is unacceptable during transportation and installation of a polycarbonate roof, because a strong internal voltage may form, which leads to clouding and physical destruction of polycarbonate.

Polycarbonate in hardness and transparency is inferior to glass, so it needs neatly handling. It is also worth paying attention to the fact that long -term storage of polycarbonate sheets is permissible exclusively in ventilated rooms without direct hit by the rays of the sun in a horizontal position with a protective film. You can not cover the canvas with polymer materials.

Design features of roofs

Polycarbonate roofs in housing construction are usually arranged over cold attics, in attic, terraces and balconies. The constructed structures made of polycarbonate sheets are of the most different shape. The roof of a residential building from cellular polycarbonate can be with a slope that allows you to drain down rainwater, or relatively flat. In the photo of polycarbonate roofs, it can be seen that they may have the form of a prism, pyramid or dome, it depends solely on the imagination of the hosts.

In order for the roof to acquire the required shape, first you need to create a frame on which polycarbonate sheets are attached. For the frame, you can use aluminum or steel profiles. In addition, there are polycarbonate profiles on sale, which, together with the coating material, are completely translucent design of the roof, which has no visible compounds. At the same time, a polycarbonate roof acquires a light original, soaring a view above the building.

Polycarbonate profiles are detachable and inexpressible. The advantages of a polycarbonate profile over the metallic is that it is sealed, has small weight, has high strength indicators, it is transparent, like the polycarbonate canvas itself. The profile on the outside is protected by a special layer from the effects of ultraviolet radiation.

Stages of the roof device

Before starting the device of the roof of a polycarbonate canvas, it is necessary to have a drawing or project at hand, according to which you will assemble the roof. Previously, you need to calculate the total area of \u200b\u200bthe material used and design the roofing crate. A polycarbonate roof should be performed with a slope of at least 50%, and a large slope will provide a margin of strength from the load, which is created by precipitation.

The choice of material

For a polycarbonate roof device, it is recommended to choose the polycarbonate, which in its parameters is most suitable for your roof.

Depending on the quality of the material is highlighted:

- polycarbonate canvas premium, which is guaranteed for more than 20 years;

- polycarbonate elites with a service life of 12 years;

- optimal polycarbonate, whose use time is 10 years,

- economic polycarbonate that will last you 5-8 years.

The price of polycarbonate is different and depends on the amount of secondary raw materials used in manufacture, as well as on the indicator of thermal resistance and the size of the sheet. Therefore, before buying, you must ask these parameters to choose the right material.

If you plan to build a roof for a warm house, then preference should be given in favor of a polycarbonate of increased thickness, but it will not work to recreate the arched structure with a small radius in this case. For radius roofs, you need to select thinner sheets, depending on the displayed radii. For thicker polycarbonate, a more rare crate should be organized, because its bending significantly loads the structure.

Installation of rafters

Before covering the roof with polycarbonate and installing the rafters, it must be borne in mind that polycarbonate sheets are made 210 centimeters wide. This size guarantees the installation of the sheet without cutting, taking into account the temperature gap of 5 millimeters on each side. It should be noted that the quality of the rafters will directly affect the reliable operation of polycarbonate sheets.

For the manufacture of rafters, use a metal profile or beams that have a section of 40 by 60 millimeters. The rafter beams must be laid so that the joint of the sheets comes to the middle of the rafters.

Lay the rafters in this way that between the central lines of the bars the distance is 1.01 meters, and the distance between the edges of the material for the roof is 1.04 meters. After that, you can start installing a frame made of metal polycarbonate profiles. To strengthen the roof structure, it is customary to additionally install bars between the beams, and the transverse and longitudinal reinforcement is permissible.

Profile mount

If you plan to use metal aluminum profiles, it is necessary to glue the ends of the sheets with tape so that dust and dirt are not going to subsequently. In polycarbonate systems there is a special perforated tape, which closes reliably longitudinal grooves of polycarbonate.

When installing fasteners and connectors (detachable and inexhaustible), the sizes of the profile must correspond to the thickness of the sheet. They are attached to the indifferent profile to the beams without additional preparations, while the fastening itself with self -tapping screws and special thermal compensation washers is performed every 30 centimeters.

The collapsible profile is customary to be fixed in stages. First screw it to the lower part, and after placing polycarbonate sheets, attach the upper part of the profile. You can use self -tapping screws with a drilling function, or pre -drill plastic. Put the sheets of polycarbonate on the finished frame. The sheets are mounted using fixing profiles or a point technique with a step of 30 centimeters.

Pay attention to the fact that connecting profiles are of different modifications: corner internal and external, end, ridge and connecting. Therefore, it is necessary to use only the appropriate.

Polycarbonate cutting

Work carefully with polycarbonate sheets so that the upper protective layer is not damaged. There are hollow channels in the sheets. When making installation, follow all the rules, if you make a vertical design, then these channels should be vertical, or placed parallel to the slope of the roof and bend. The material in this case will not be deformed during operation.

Cutting polycarbonate sheets and profiles is carried out by cutting tools (circular saw, electrolobian) with a small sharp tooth, select the cutting speed experimentally. Remember that low speed leads to the formation of chips, and excessive provokes overheating and melting of the polymer. When cutting, do not allow vibration of the material, because it causes the formation of microcracks.

Drilling polycarbonate

If you plan to use ordinary self-tapping screws when installing with your own hands from polycarbonate, then before direct screwing in the polycarbonate you need to pre-drill a hole of a slightly larger diameter of 1-2 millimeters than the self-tapping screw itself. Drilling for fasteners is carried out by drill on non -ferrous metal. You can not tighten the self -tapping screw, you need to leave the opportunity to move at a temperature difference.

Carry out all the work when a polycarbonate sheet is located on a flat surface, use a sharply created tool. It is not recommended to remove the protective film from ultraviolet radiation before undergoing polycarbonate cutting or drilling, since the smallest particles of plastic can get into the hollow channels, and then you will have to shake and blow them with compressed air.

Sealing the ends

Before installing the polymer sheet, seal their ends: stick an aluminum waterproof tape on top, and glue the perforated vapor permeable tape from below that protects against dust penetration. Complete sealing of polycarbonate panels is not allowed. Also, violation of the indicators of radius bends is not allowed, which must correspond to the permissible parameters for the corresponding thickness of the polycarbonate sheet.

Installation of polycarbonate sheets

Laying polycarbonate sheets is carried out exclusively with vertically oriented stiffeners, and the orientation of the orientation of the ribs when creating rounding of the roof is carried out only according to the radius.

Polycarbonate sheets are attached using fixing profiles and pointwise in the installation situation of sheets that have a width of more than 1 meter. The point mount is customary to carry out 300 millimeters close to all the roof beams. At the same time, tightening the screws with an interference, the sheet should maintain its own mobility, because they change their dimensions from temperature.

Now you know how to make a polycarbonate roof, and what are the advantages of its use later. But using polycarbonate in household construction, it is worth remembering certain inconvenience that this material is fraught with.