Vinyl tile, the origins of the invention of which belong to the thirties of the past ...

|

|

PVC corrugated pipe is a truly indispensable material that ... |

Each of you, for sure, knows very well what the awnings are. First... |

Do -it -yourself polycarbonate roof. Tips for the installation of polycarbonate on the roof

Modern roof materials, such as polycarbonate, are gaining more and more popularity. This option is universally used to cover the verandas, individual sections of the house. This is not only original and beautiful, thus it provides reliable roof and natural lighting of the room with bright sunlight. The room becomes very cozy and attractive.

Table of contents:

- Advantages of polycarbonate roof

- Polycarbonate roof device

- Direct roof of polycarbonate

- Arched roof from polycarbonate

- Roof polycarbonate installation technology

- Types of polycarbonate for roofing

- How to choose a polycarbonate for a roof

- Polycarbonate roof fasteners

Advantages of polycarbonate roof

The material is very practical and is characterized by a large number of advantages:

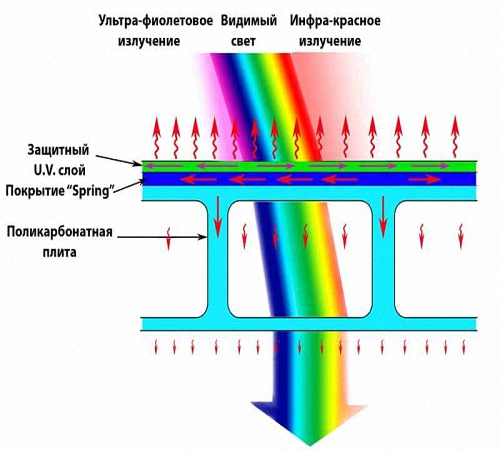

- polycarbonate panels protect the room from the exposure of the sun, passing multiple light and reliably protects against ultraviolet rays;

- relatively light weight of the structure makes it possible to make an original roof;

- high thermal insulation capabilities, as a result, there is no need to insulate the room additionally;

- polycarbonate has high soundproof capabilities;

- moisture stability;

- ability to ventilation of the room;

- resistance to high temperatures;

- well tolerates temperature changes;

- relatively flexible material, withstand the load on precipitation;

- easy to install, processing;

- it is resistant to mechanical influences, you can drill, bend and cut in size.

The material is very durable, it withstands a layer of snow weighing two hundred kilograms per square meter.

The disadvantages of the material are manifested in the fact that during transportation, large sheets of polycarbonate can bend and deform. And although the material is durable, it loses in quality of glass and requires more attentive treatment when working with it, saving and installing. It has low abrasive resistance, which manifests itself in the appearance of scratches, cracks. As a result, the integrity of the roof from polycarbonate can be broken by a strong hail.

Weighing all the pros and cons can be confidently stated that polycarbonate is recognized as one of the best materials for mounting the roofs of koridors, greenhouses, and extensions. Another plus is that the material is relatively inexpensive.

Polycarbonate roof device

Although three types of polycarbonate can be distinguished conditionally, all the same, two species are the most used and popular, it is monolithic and cellular.

Monolithic polycarbonate is used for roofs of various areas and forms with the prospect of withstand the weight of a large volume of snow and gusts of wind. The size of the monolithic material panel is two by three meters. The thickness ranges from two to twelve millimeters. Twelve millimeter polycarbonate is also called anti -vandal, because it withstands an adult strong man without damage.

Cellular polycarbonate weighs much less thanks to its porous structure with air chambers. The material has high mechanical strength with small weight. This material is ideal for the manufacture of complex elements of arches, roofs. Cell material has a diverse color scheme of shades. The thickness of the material varies from four to thirty millimeters, the length of the panel ranges from two meters to six or twelve.

There are two most common options for polycarbonate roofs:

- straight roof;

- a roof in the shape of an arch.

Direct roof of polycarbonate

A straight roof option is most often used in the construction of open verandas, arbors. When deciding to use polycarbonate, it becomes possible to create an open bright space. But since the roof insulation will lead to loss of the properties of the roof from polycarbonate, it is impractical to build this version of the roof for winter houses. Only the summer variants are suitable for arranging polycarbonate roofs.

You can make a straight roof in several solutions: holly, one or gable. Policarbonate roofs do not require powerful rafters, the material is quite light. This can be a board up to fifty millimeters pre -treated with special protective solutions. The distance between the rafters is selected taking into account the width of the panel. When the material is patted, it should be cut so that the ribs of stiffness coincide with the direction of the roof slope. It should be properly put in the sheet, taking into account the special ultraviolet coating, it should be outward.

The polycarbonate panel to a wooden base is attached by self -tapping screws with a mount. A hole is drilled in the sheet a little more than the diameter of the screw and tightly screw it into the sheet’s body. The joints are closed with detachable profiles.

All parts where there are gaps must be treated with sealant.

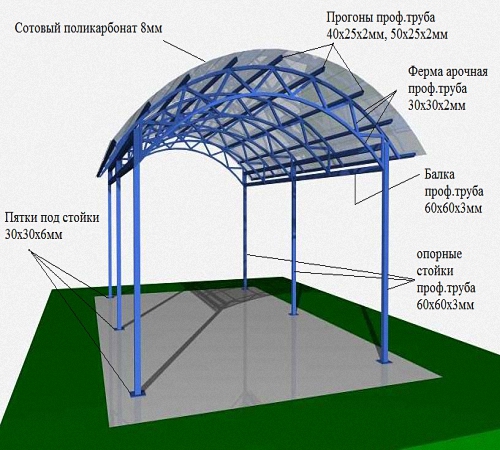

Arched roof from polycarbonate

It is not difficult to make an arched roof, the only difficulty to prepare arcs, it is necessary to bend evenly using a template, otherwise the cover can be distorted. The arcs from the profile are cut so that it is easier to bend the material for the required roof shape. But if the arcs virtually do not have the limit of the bend, then the polycarbonate behaves differently, this should not be forgotten and the material should be bent carefully. Polycarbonate is attached as well as to a wooden surface, use screws and fixed with washers. The joints and the end area are covered with sealant.

Arkal roofs are used in small areas, they make awnings, arbors.

Roof polycarbonate installation technology

The material has been used for about ten years and has shown excellent qualities in wear resistance during that time. From polycarbonate, you can make a roof of any kind, shape and size. In the private farm, cellular polycarbonate is most often used: pools, greenhouses, verandas, canopies all these structures can be covered with transparent cellular material. You can make a roof with any angle of inclination or completely flat. All this depending on the desire and imagination of the owner.

To get the roof of the required shape, it is necessary to prepare a frame in advance for attaching polycarbonate panels. For the frame, steel pipes, an aluminum profile are ideal. If there is a profile from polycarbonate, the roof dome will be perfectly transparent and this is an ideal solution from an aesthetic point of view. Carbonate profiles can be detachable and monolithic. The main advantages of the carbonate profile are:

- low weight;

- transparency;

- quality;

- tightness.

Polycarbonate is classified according to quality characteristics:

- the premium class has been operated for more than twenty years;

- an elite service life of more than twelve years;

- optimal warranty for more than ten years;

- the economical expiration date varies from five to eight years.

Polycarbonate is chosen relying on needs. If you need reliability and practicality choose the material thicker. If beautiful shapes, aesthetics and configuration are thinner, which bends well.

When the panels are arranged, the sheets should be combined so that there is a joint on the rafters.

After that, the frame is mounted. Particular attention is paid to the grooves, they are closed with a special adhesive tape or tape. Sheets are attached to the frame taking into account the requirements for fastening. There are tips that will help to carry out all the slippers correctly:

- the holes for self -tapping screws should be slightly larger than the tools themselves;

- self -cutting is not recommended to screw it to the stop, the panel should have the opportunity to shift under the influence of temperatures;

- work with polycarbonate panels must be carefully so as not to damage the upper protective spraying;

- the protective film is recommended to be removed after the work on drilling and cutting.

Polycarbonate material suitable for the construction of roofs of any shape. The choice of quality and option depends on the taste and capabilities of the owner. Installation of the material is not complicated, but requires compliance with some nuances. The cost of polycarbonate depends on the characteristics of the material and varies.

Types of polycarbonate for roofing

Roofs made of polycarbonate material are easy to install with your own hand without involving specialists. And the market can find several types of polycarbonate in order to choose the most suitable in each case, you need to get acquainted with the characteristics of each material. There are such subspecies of polycarbonate:

- this is a profiled panels with a wave or a trapezoidal profile, used to cover the outbuildings and greenhouses, the manufacture of decorative canopies;

- mobile is a material with voids inside, used in the advertising business and in a construction site, is an excellent option for creating partitions in rooms, design design, for street advertising;

- a monolithic solid smooth material, outwardly resembling glass, but much easier and more multifunctional.

Polycarbonate sheets differ in thickness, size, color, structure. There are varieties with a predominance of individual qualities: some are very reliably protected from ultraviolet radiation, others are characterized by enhanced strength or multi -layer.

Thanks to the lightness of the material from polycarbonate, you can build original complex structures that will have a low specific gravity.

How to choose a polycarbonate for a roof

Polycarbonate is widely used in various industries and gained such popularity thanks to its main qualities:

- high light outlet;

- small mass of material and as a result, light design;

- comparative cheapness of the material;

- the ability to widely use the material and work with it.

The thickness of the material ranges from four to thirty -five millimeters. The weight of the sheet also depends on this. It varies between a kilogram and two and a half. The material does not lose its qualities at a temperature difference and withstands numbers from forty degrees of frost to one hundred and twenty heat. The impact resistance, high thermal insulation abilities, resistance to contact with aggressive chemical compounds allows you to widely use material in everyday life and production.

The period of use of structures performed on the basis of polycarbonate ranges from five to twenty years.

There are seven standard polycarbonate sizes in thickness. Each of the varieties has its own purpose and is used according to technical characteristics:

- thirty -two millimeters are used to cover buildings with a large roof size, withstands significant loads;

- sixteen millimeters are also a suitable type of polycarbonate for large spans, well withstands the loads;

- ten millimeters suitable for vertical elements in public buildings;

- eight millimeters of the canopy for the yard, car, glazing of balconies;

- four millimeters of small greenhouses, awnings above the threshold;

- three millimeters of greenhouses, greenhouses.

Polycarbonate roof drawings can be found on the Internet, there are a lot of options. Very often, some option is taken as a basis and is modified in the process of covering the structure. There you can also see a photo of a polycarbonate roof and choose the one that you liked the most.

Polycarbonate roof fasteners

To carry out actions to consolidate polycarbonate sheets, you need to prepare tools. Particular attention deserves the fastening, since the strength and reliability of the design depends on them. There is a wide variety of fasteners, which is used depending on the complexity of the design and the quality of the material.

Such fasteners can be distinguished:

- polycarbonate thermo -haired;

- stainless thermal -haired;

- palpropylene washers;

- self -tapping screws;

- boltsi nuts.

Polycarbonate thermo -hayb helps to attach sheets to the frame and reliably hold them. These fastenings are more reliable and better than polypropylene washers and have a wide color palette. As for polypropylene, they are not covered with protective material and undergoing aggressive effects of ultraviolet radiation quickly burn out and lose their strength. They should be used on roofs in shaded places. The fastenings are inexpensive, but also short -lived.

Wages made of stainless steel are reliable and are not loosened, most often used on a metal profile. The washer has a rubber element in the kit, which allows you to observe the tightness rule. Application in dry rooms is recommended.

It is possible to make a roof from polycarbonate with your own hands with a properly prepared drawing and follow all the instructions. A reasonably performed polycarbonate profile attachment to the frame, the use of high -quality fasteners will make it possible to create a reliable roof with its own hands, which can protect the room and create comfort for a long period of time.

If there are questions about how to make a roof from polycarbonate in practice, if necessary, get the installation tips, watch a video in which there are answers to all often arising questions.

Looks good

Looks good

http://strport.ru

http://strport.ru

[url] http://strport.ru [/url]

[url] http://strport.ru [/url]