Among the highest artistic methods of decorating metal products remains ...

|

|

Crossing structures must meet the requirements regarding strength, ... |

The flowing roof for many owners of garages becomes a real disaster, because ... |

Roofing material - pormoplast. Installation of roofs from keramoplast

Technical progress does not stand still, in the field of construction and construction technologies, a range of roofing coatings is expanding annually. Modern roofing materials are reliable and durable, they are made from various compounds and components, however, all of them are united by environmental friendliness and ease of installation. One of these materials is pormoplast. It combines excellent performance and beautiful outdoor appearance. In the article, we will consider the main characteristics of this material and the method of laying the roof from keramoplast with your own hands.

Content:

- What is a keramoplast

- The advantages of roofing roofing material for the roof

- Specifications

- Keramoplast roof price

- Consumer reviews about the roof pormoplast

- Installation of roofs from keramoplast

- Roof exploitation from keramoplast

- Keramoplast roof photo

What is a keramoplast

Keramoplast is domestic material, which relatively recently appeared on the market, but has already managed to gain trust and popularity thanks to its excellent installation and operational qualities. It was developed by a company with the same name and has been produced in Russia since 2000.

- For its manufacture, both natural minerals and technological synthetic components are used. Such a combination favorably distinguishes a peremptor from other roofing materials, since it makes it not only environmentally friendly, and therefore safe for people, but also technically perfect, with a material that can not lose their qualities for many years.

- Natural minerals are added to the strength and resistance to external damage, and synthetic additives provide a small specific mass with these high -strength characteristics. This material has good resistance to ultraviolet rays.

- Keramoplast perfectly withstands large wind and snow loads. In addition, due to low weight, the total weight of the roof and pressure on the foundation decreases.

- Installation and repair of the roof from keramoplast is carried out easily and quickly, and operation does not require much effort.

- The line of this material presents a wide selection of color shades, the buyer will be able to choose any that is most suitable for the appearance of the building and the environment. In addition, a large color palette provides scope for creativity and the ability to embody some drawing or ornament on the roof, which will make the roof unique and recognizable.

The advantages of roofing roofing material for the roof

- Made from environmentally friendly materials;

- does not contain toxic components;

- has high mechanical strength;

- multiple use is possible;

- withstands large wind and snow loads;

- it has high resistance to aggressive external factors, can be used in any climatic zone;

- not subject to decay or corrosion;

- coloring pigments are introduced at the stage of manufacturing of the material, so the keramoplast is painted over the entire thickness;

- has good thermal insulation properties;

- excellent sound insulation, does not convey external noises of atmospheric precipitation;

- does not lose its properties both at very high and low temperatures (from -60 to +80C);

- with the help of heating, a sheet of keramoplast can be given any necessary shape;

- the material is easy to cut or saw;

- small cost of installation and maintenance.

Specifications

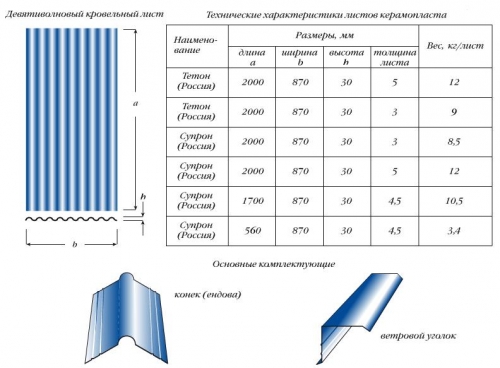

Keramoplast is made in the form of wavy sheets with a thickness of 3 and 4.5 mm. The surface can be either smooth or with the texture applied to it.

The material with a smooth surface has a size of 200 x 90 cm, and with a texture of 170 x 87 cm. In addition to sheets, the company has developed a tile with a 56 x 87 x 0.45 keramoplast size, as well as 50 x 90 x 0.4 cm.

With a low sheet of 9 kg (with a thickness of 3 mm), its specific strength is 1,500 kg/m cubic meter.

In addition, the material has 100% waterproofing properties and excellent frost-resistant qualities, withstanding up to 165 freezing cycles.

Keramoplast roof price

Thanks to the ease of use, the pormlast makes it possible to reduce the cost of laying, since almost anyone can do this work. Further roof service also does not imply any expenses, which allows us to talk about the economy of the material.

The average cost of materials for the roof of the porcelast in Russia is as follows:

Consumer reviews about the roof pormoplast

Since the material is quite new, of course, the reviews of those who have been using keramoplast for at least ten years are quite small. Most often, reviews about it are written by those who have the material used for 3-5 years. All of them are more than satisfied with their choice.

Flaws:

- changes the color, fades;

- the material can be confused with analogues released in lower quality;

- it is difficult to find installers who will be able to lay a kerapoplast on a roof according to the instructions. With improper laying, it can give cracks and shrinkage.

The main advantages for consumers:

- price and silence, does not convey the sounds of rain or hail as, for example, a metal tile;

- another important advantage of the roof from porcelast is its maintainability and the possibility of re -use. They dismantled the bath to cover a couple of arbors or garage with a pormlast from her.

Many are afraid of new materials and technologies, due to the lack of experience in use and a small number of reviews, however, this is not always true tactics. If we study the technical characteristics of the material, purchase it from the proven dealer and perform installation according to the manufacturer’s instructions by the Keramoplast by faith and truth will serve its owner for 20-30 years (as stated in technical specifications).

Installation of roofs from keramoplast

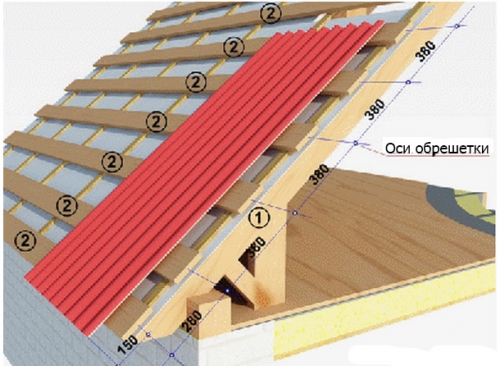

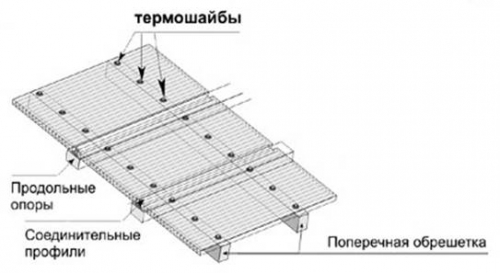

- Before starting direct laying of porcelast, they perform a crate on rafters. The rafter beams are boards with a section of 150x50 mm and a step of 600 mm. For the crate, wooden bars with a cross section of 150x25mm are selected and laid with 380 mm pitch, regardless of the angle of the slope of the roof.

- Also, before laying porcemlast, all wooden structures are treated with special antiseptic solutions and fire -resistant agents. And in order not to accumulate condensate, a layer of waterproofing is laid along the rafter system.

- The question arises of the number of sheets of keramoplast necessary to cover a particular roof. The solution is quite simple on millimeter paper to create a roof layout on a scale on which the material is calculated, including waves of waves, as well as end and ridge nodes.

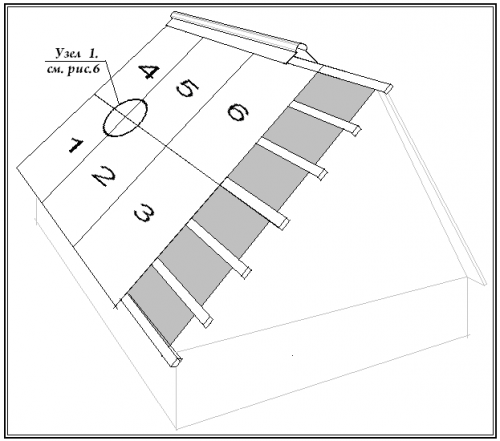

- So that the vertical seams of the compounds are not visible, the styling of the material should begin on the opposite side of the main facade of the house, then the roof looks like a single lined.

- Laying is performed horizontally, against the main direction of the wind in this region (it is necessary to clarify the wind rose before starting work).

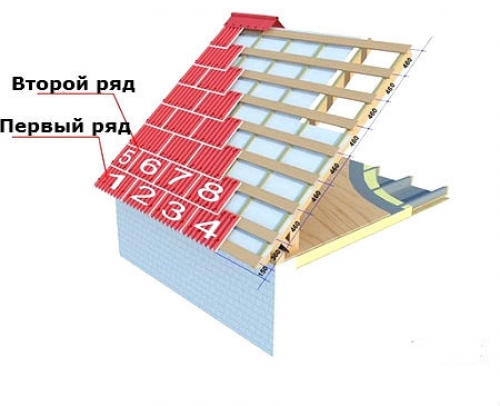

- If you need to cover a large area of \u200b\u200bthe roof, then it is first recommended to lay the lower row, then the extreme side is strictly vertically. And only then all the others with a guide on the lower and lateral rows.

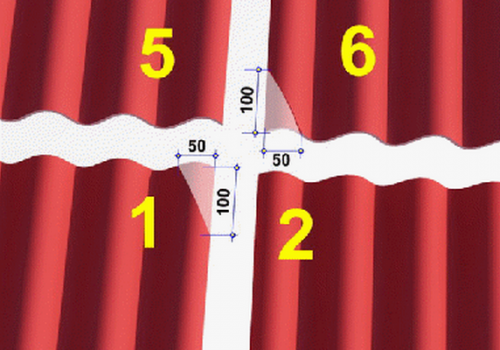

- There are two basic principles of laying sheets: standard and zigzag. In the first case, styling is done in a checkerboard pattern, the sheets are not displaced. With this method, in the places of docking, the overlap of four sheets is obtained. The manufacturer recommends cutting off the corners so that it does not turn out to be too thick and the design does not change.

- When laying a zigzag, the second row is laid with a shift of half the width of the sheet, thus, the joint of two sheets of one row is located in the middle of a sheet of the other row. This method avoids cutting sheets and the formation of excessive overlap.

Fastening of sheets

When laying keramoplast, the initial mount is carried out for one or two mounting screws. Before the final fixation, the correctness of laying all sheets, as well as lateral and end overlars, is checked. The fasteners are carried out strictly in the center of the crate board, a thread can be pulled as a guideline. The location of the fasteners on the roof from the keramoplast is shown in the diagram presented below.

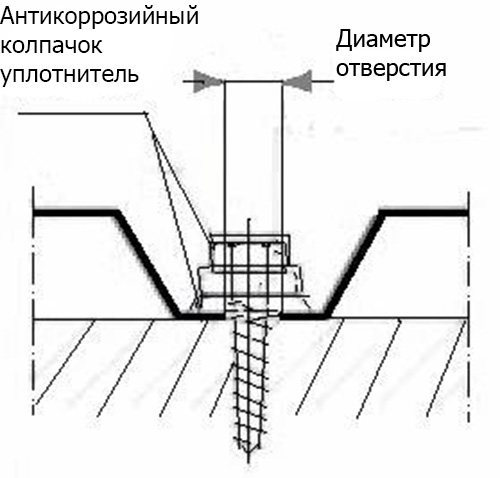

- In order to avoid deformation of the sheets, when fixing them, it is necessary to ensure that the fasteners do not pull the crest of the waves.

- On the crest of the wave, at the place of mounting, it is necessary to make a hole with a diameter of a little more than the diameter of the fastener element, this will prevent bloating at temperature changes. The first sheet will require at least 30 mounting parts, for all subsequent 20.

- At the junction of the two slopes of the roof, the roof is mounted. It is attached only after the complete completion of the laying of the material. When fixing it, it is important to follow that the wing of the part closes the first row of fixing elements on the sheets of porcelast.

- If it is necessary to change the angle of the ridge part of the roof, then it is heated from the inside using an industrial hair dryer or a soldering lamp to 50-60 degrees, then it can be bent to the required angle.

- To create a closed roof contour and its complete sealing, that is, to protect the underlying space from precipitation and dirt, as well as to hide the structural elements, wind strips are used, which are attached to the end sides.

Below is a video about laying a roof from a porcelain. It is available and clearly demonstrates all the main stages of work.

Roof exploitation from keramoplast

- In order to avoid deformation of the parts of the roof or their complete breakdown, it is recommended to move along the roof only according to pre -prepared flooring (pedestrian paths). Their width should be at least 25 cm for uniform load distribution.

- In winter, with large amounts of precipitation in the form of snow, you can remove the roof only with a wooden shovel. Rocking ice must be extremely neat, without using sharp metal objects.

Keramoplast roof photo