Each can complete the repair in the house with an original mosaic of bat tiles, especially ...

|

|

The finish of the facade is a very important process that determines the appearance of the building and its ... |

Getting a house made of natural wood is a great choice for those who appreciate ... |

Roofing iron on the roof: characteristics, advantages, installation

Roofing iron is products made of sheet or roll steel, having a different shape, thickness and coating. Despite the fact that it is considered one of the oldest building materials used to arrange a roof, its popularity does not decrease today. Such demand is explained, first of all, by high technical characteristics, the main of which are strength, the ability to withstand external temperature changes, resistance to corrosion and fire safety.

Content:

- Roofing iron black and galvanized

- Types of roofing iron on the roof

- The advantages and disadvantages of the roofing iron

- Roofing iron methods of installation

If we take into account that when choosing a coating for the roof, the cost plays an important role, then the roofing iron is precisely the category of materials in which the price -price ratio is the most optimal. In addition, due to the slight weight, it does not provide a strong load on the construction of the building. It is quite simple to work with it, due to which it is possible to quickly and the quality of installation, and this significantly reduces the cost of construction work, not to mention the fact that the excellent appearance of this material makes it possible to choose a roof in accordance with any architectural solutions.

Roofing iron photo

Roofing iron black and galvanized

- Previously, in order to equip the roof, only black roofing iron was used. But it was short -lived and required constant staining.

- To date, thanks to the introduction of modern technologies in the production of building materials, there is the widest selection of roof products, among which the leading positions are galvanized roofing iron. From ordinary sheet steel, it differs in that it is covered on each side with a thin layer of zinc 0.2 mm thick.

- Outwardly, such sheets of roofing iron look even, smooth, without points, cracks and spots of rust. Zinc coating perfectly protects steel from corrosion and provides it with the operational period, calculated by decades.

Types of roofing iron on the roof

All roof leaf galvanized iron can be divided into several types: sheet steel (with or without polymer coating); corrugated board (profiled or corrugated sheets); metal tile.

- Leaf galvanized steel Used for the device of folding roof. It has certain advantages is a slight weight, anti -corrosion coating and a smooth surface, which makes it possible to easily remove rain water and snow. In addition, sheet steel, requiring only further coloring to give aesthetics, will last ten years.

- In addition, from smooth galvanized steel it is very convenient to perform various curly elements for the roof: cornices, drain pipes, gutter, skates and others.

- It is produced both with classical galvanizing and with a coating of a polymer film of various colors, which increases the durability and anti -corrosion properties of the material. The weight of the roofing iron depends on the thickness and size of the material, an average sheet of 2000x1000 mm and 1 mm thick weighs 15 kg.

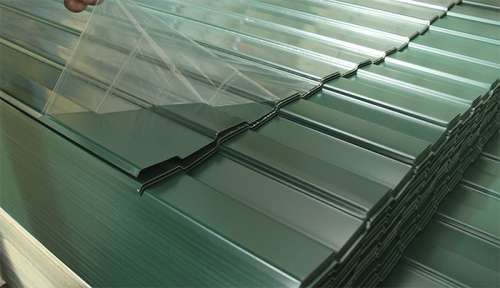

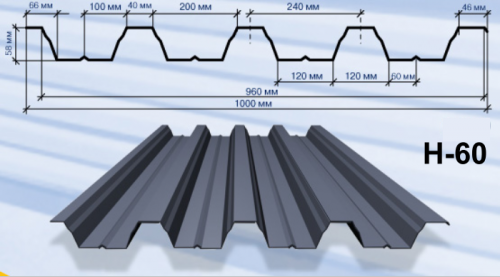

- Corrugated board It is a corrugated sheets of steel that have a cross section in the form of a rectangle, trapezoid or sinusoids. Due to such corrugations, thin steel sheets, without increasing their weight, acquire high strength, because they have stiffeners that form these profiles.

- Since the demand for corrugated board is constantly growing, now sheets with a polymer coating have a huge color scheme, which further increases the resistance of products to corrosion.

- Due to its high technical characteristics and aesthetic appearance, modern corrugated board is the most popular roofing material.

- Metal tile It is in no way inferior to profiled sheets in its technical characteristics. In fact, this is their variety, which has a polymer coating and stamping perfectly imitating natural ceramic tiles.

- It is produced in wide colors with different polymer coatings and profile geometry. The roof of metal tiles looks spectacular and is great for low -rise buildings. The average price of roofing on the roof is 300 rubles/m2.

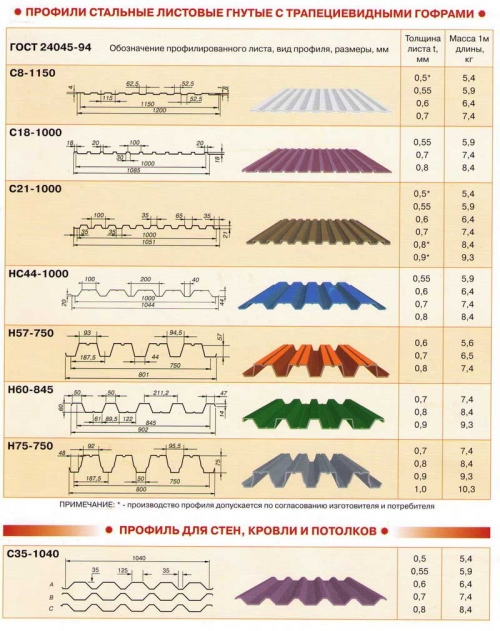

The thickness of all roofing products is in the range from 0.45 mm to 0.5 mm, which provides the optimal load on the roof. Sheets are also produced with a thickness of 0.70.8 mm, which is used for a certain type of roofs subject to special loads. But it is not appropriate to use products with more thickness than this thickness, due to the large weight, which is extremely inconvenient for lifting up and installing, as well as due to pressure on the supporting structures of the building.

The advantages and disadvantages of the roofing iron

The advantages of roofing iron are so obvious that it explains its increased demand around the world.

- Firstly, this is an affordable cost, which differs all its types, which significantly reduces the cost of construction work.

- Secondly, these are the size of the roofing iron. The width of the material is 7101800 mm, with a length of up to 2.5 m of smooth sheets, and up to 10 m profiled, which makes it possible to very quickly perform installation.

- Thirdly, these are excellent technical characteristics:

- durability, which has been calculated in decades;

- practicality, efficiency and ease of installation;

- excellent resistance to various changes in external temperatures and to the effects of ultraviolet radiation;

- high anti -corrosion properties;

- the possibility of arranging a roof of any complexity;

- a huge color scheme that allows you to choose the material in accordance with the color solutions of the facades, creating an attractive type of building;

- environmental friendliness and safety for human health;

- wide application in individual, social and industrial construction.

Against the background of all these advantages, the disadvantages seem very insignificant. These include:

- the need to periodically color to prevent the formation of corrosion. But such work should be carried out no earlier than 810 years after the installation of the roof, followed by staining every 3 years;

- overheating of the roofing iron in the summer and a significant level of noise during atmospheric precipitation. But such a disadvantage is easily eliminated by arranging a thermal insulation layer.

Roofing iron methods of installation

- Before buying roofing iron, it is necessary to carefully view its surface, it must be integral. This is due to the fact that the polymer coating can be easily scratched. For transportation, each sheet is packaged in a special protective plastic film, which must be removed immediately before the start of installation.

- When laying the roof, you have to constantly cut the sheets. It is important to know that the use of a grinder is strictly prohibited for this. There are special scissors for cutting metal, with which these works are performed. To prevent metal corrosion, it is recommended to immediately paint the seats with special polymer paint.

Installation of a roof made of sheet galvanized steel

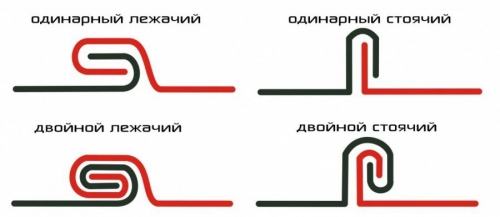

Usually, a folding roof is equipped from leaf steel, which is a coating in which the paintings are connected to each other with the help of the folds. The picture is called the metal sheets combined in advance, and the folds are the type of seam formed in the process of fastening the sheets.

Before starting installation, you need to carry out preparatory work:

- check the angle of inclination of slopes (for this roof it should be in the range from 15 to 30);

- diagnose for the strength of the crate;

- carefully examine the sheets of steel (they should not have bubbles that lagging behind the films, and be with a smooth zinc coating).

Now you should prepare the required materials:

- roofing nails for attaching sheets to a crate with special hats of 4x50 mm in size;

- ordinary nails, which will be attached to crutches and hooks, 4x100 mm in size;

- crutches designed to maintain the overhang overhang (segments 25x450 mm cut from a sheet of steel 5 mm thick);

- hooks with which a gutter will be recorded (segments of 20x420 mm, cut out of the same steel sheets);

- klyammers that ensure the fastening of paintings to the crate.

First, they mount the crate using boards and wooden beams. To exclude the deflection of the roof, the step of the bars should be at least 0.2 m. In order to further fix the cornice overhang, at the first stage of the work, the flooring is made from boards that fit with one another, at least 70 cm wide. Since steel sheets are made. Since steel sheets are made. Since steel sheets are Quite heavy, the paintings of them are first formed on the ground, and then, using the lift, transported upstairs.

Now they begin directly to the installation of a metal roof.

- First, crutches are attached to the crate along the cornice overhang. Laying is performed with an indent from the edge of at least 15 cm with a step of 50-70cm.

- The paintings are formed by bending the edge of the sheet from all sides. As a rule, for this, a falsi -capacity machine is used, and the sheets are fastened along the width with bedding, and standing in length.

- Then, ready -made paintings are attached to the crate, using Klyammers, one end of which is nailed to the beam, and the other is placed in a standing fold. Klyammers should be located at the ends of each sheet that consists of a picture.

- After the first strip is installed, the second is applied, observing the distance between the paintings of about 5 cm so that the bedridge can be diluted. Standing folds are also shifted to the same distance.

- The connection of the falses can be single or double. As a rule, with a small slope of the roof and in places where water accumulations (m landing and gutters) usually occur, a double connection is used.

- Now, the excess parts of metal sheets are cut off with scissors for metal, and the edges of the looset are connected with a lying fold, which is bent towards the m land.

- In order to increase the density of folding joints, they are carefully smeared with bitumen sealant.

Installation of roofs from corrugated board

The arrangement of the roof from profiled sheets is not particularly difficult, since this material is practical, quite easy and simple to process. The main thing is to decide which corrugated board is needed.

It is divided into three classes, each of which has its own marking:

- With walls used for wall cladding and also for arranging a light roof;

- N is used for the installation of inter -story floors and capital roofs;

- NS combined corrugated board, suitable for both wall cladding and arranging many types of roofs.

The most popular for the roof are profiled sheet with labeling n, since they are very reliable and durable, which is due to their additional stiffeners, the thickness and height of the corrugation. The corrugated board of the NS is also popular, although it is somewhat thinner and accordingly cheaper. It is used for less loaded roofs, especially those that have a large roof slope angle.

But in cases where the roof is more gentle, you should not risk and save, since the snow load on it increases significantly, and the thicker the profile and the larger the height of the corrugation, the more reliable the roof.

Having decided on the type of profiled sheets, after the purchase, the main thing is not to damage them during transportation, but to unload them so that the sheets are in a horizontal position, excluding their excesses. It is best to rise to the roof along the lags, which are installed from the roof to the ground, and only one sheet should be raised.

For the installation of corrugated board you will need:

- hacksaw with small teeth for metal or electrician;

- self-cuts-shurups;

- squad.

Before starting the installation, you should:

- calculate the amount of material;

- think through how to perform ventilation, hydro- and vapor barrier;

- set the crate.

Calculation of the number of corrugated board

- To calculate the number of sheets correctly, the area of \u200b\u200bthe roof should be calculated. To do this, measure the length of the slope, add the width of the cornice to it and 4 more, which are needed for an overhang. Then the diagonal size is calculated, measuring the length of the ridge. After that, having calculated the area and dividing it into the width of the profiled sheet, they receive the right amount.

- Also, when laying sheets, it is necessary to take into account the angle of inclination of slopes, on which it will depend on how to make a overlap:

- if it is 15, then the overlap should be 20 cm;

- slopes from 15 to 30 corresponds to an overlap 1520 cm;

- with a slope more than 30, the overlap should be 1015 cm;

- if the slope is 12 or less, then it is enough to put the sheets in the end and perform sealing all the seams.

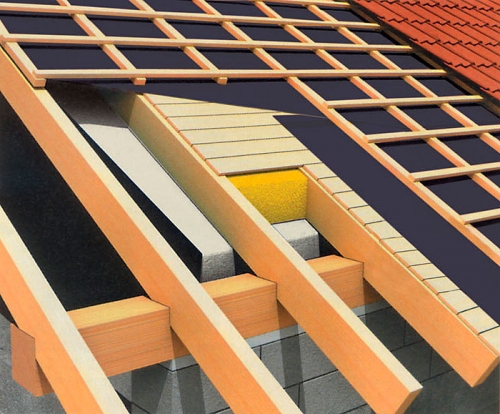

Waterproofing and ventilation device

- Installation work begins by laying waterproofing, which will serve as a barrier to penetrate moisture on the rafters, a crate and insulation. The waterproofing film is laid in the horizontal direction along the rafters, starting from the overhang to the roof to the skate. The stripes connect overlapping (15 cm), fixed with special brackets to the rafters, and fixed with counterreiks on top.

- On top of the waterproofing layer, ventilation rails are mounted, which will provide a gap between it and the corrugated board, which will not allow the air to stagnate in this space, preventing the accumulation of moisture and decaying structures.

- Thermal insulation is laid on the inside under the waterproofing, and then a vapor barrier layer, fixing them with ceiling rails.

The device of the crate

- After the waterproofing is performed and the ventilation layer is equipped, the crate is mounted on the counter -attacks.

- There are no special requirements for the crate, the only thing that you need to take into account the rails for it is better to take 32x100 mm with a cross section (no less), and the lower rail, walking along the cornice, should be slightly thicker.

- Before installation, all wooden elements are treated with special antiseptic compounds that protect against rot.

- Around all places where various roof elements will be arranged, such as ventilators, chimneys and fire hatches, the crate is enhanced with additional bars.

The laying of the corrugated board

- The installation of sheets, according to the installation technology, should be carried out from the right end (for a gable roof) or from both ends (for the tent roof), starting with the highest point of the slope.

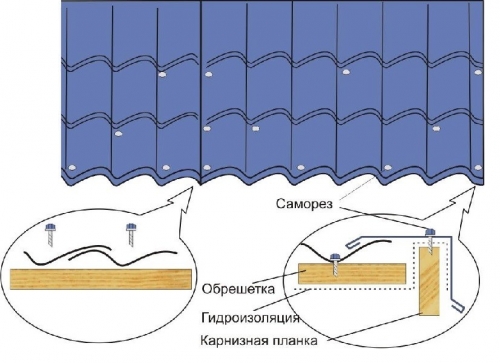

- Pre -installed a cornice bar, performing it over the edge of the overhang (4 cm), and fixed with self -tapping screws. Between the sheets of corrugated board and the bar insert a seal.

- Installation technology is as follows:

- put a sheet by shifting it 4 cm for the line of overhang, and temporarily attach it with self -tapping screws at the skate and overhang;

- then place the next sheet, aligning the edge according to the first, and fixed in the same way;

- after that, the sheets with each other fix the waves of the wave with self -tapping screws with a step of 50 cm, moving in the direction from the overhang to the skate;

- having placed several sheets in this way (34), they are once again aligned near the overhang and fixed completely. At the same time, they are attached to the crate, and in such a way that through each second wave it is to twist the bottom of the next wave;

- next occurs the extension of the sheets, with a minimum overlap 20 cm.

We must pay attention to the fact that by mounting profiled sheets, they must be very careful about them so as not to damage the coating. The best option to build a flooring from boards, which is laid on already fixed sheets, and put on soft shoes.

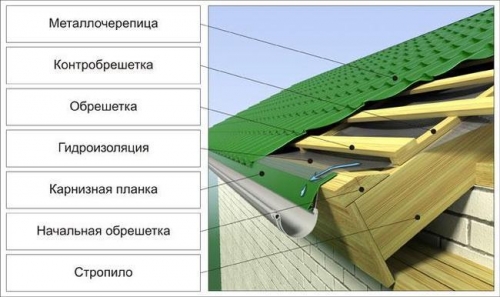

Installation of a roof of metal tiles

The roofing of a metal from a metal tile does not particularly differ from the technology of laying corrugated board. The only thing that must be taken into account by the metal tile is allowed to be mounted on the roofs, with a slope of the slopes of at least 15. We will dwell briefly at the main stages of installation.

- Calculation of sheets.Typically, metal tiles are produced and cut for the length that the customer is required. As a rule, the length of one sheet corresponds to the length of the slope of the roof. To determine the number of sheets, you should measure the length of the cornice and divide it into the width of the sheet, given that the edge of each of them will protrude for the line of the cornice by 4 cm. Moreover, this calculation must be made for each slope separately.

- Arrangement of the crate.Since the undercarbon space should be well ventilated, both a crate and the counterparty should be mounted, between which the desired air layer is formed. In addition, a waterproofing layer should be equipped between roofing sheets and rafters.

- The waterproofing film is spread parallel to the cornice, moving from overhang to the skate. On top of it, a counter -scheme is mounted, consisting of small bars (a section of 20x40 mm).

- All bars for the crate before installation should be treated with an antiseptic (protection against rot and insects).

- After laying waterproofing, a layer of insulation and vapor barrier is mounted from the inside of the building.

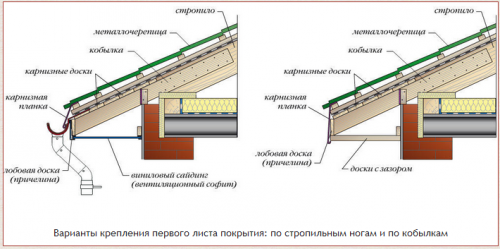

- The roof of metal tiles needs not only to protect against condensate, which can form from the inside of the sheets, but also from atmospheric precipitation. First of all, they are dangerous for the bottom of the crate, which is why it is required to install a cornice bar. To do this, they are nailed on the crate with galvanized nails (step 30 cm) a few boards.

- In the places of adjoining two slopes, Endov is required. Its lower edge is laid on a cornice bar, and so that there is no gap, a porous insulation is used. Endova gives the roof design a complete look. Its installation is made after the installation of sheets, making fastening in the upper part of each wave (step 50 cm).

After the waterproofing is performed and the crate is installed go to the installation of roofing sheets. The principle of installation is as follows:

- when the installation of the first sheet begins with the left end, the next sheet is laid under the extreme wave of the first. If the process begins with the right end, then the subsequent sheet is installed on top of the extreme wave of the previous one;

- sheets are aligned along the cornice bar;

- fasteners are carried out using self -tapping screws, and they are screwed only in the deflection of waves and strictly perpendicular to the crate;

- having installed several sheets in this way, they are tightly combined, aligned and final fastening;

- after all the roof is assembled to install the skate bar. It is attached through the upper waves, screwing self -tapping screws into them;

- it is required to carefully perform vertical adjoining, for example, to the pipe. To do this, use special strips and self -adhesive seals.

Metal tank durable material. If the roof is made taking into account all the rules of the technology, then it can stand for more than 50 years without requiring repair.

Having examined all types of roofing iron, and making sure of its advantages, you can start arranging the roof, choosing exactly the option that is more suitable in accordance with the tastes, capabilities and architectural features of the house.

And where is the phone? Hand face

And where is the phone? Hand face