When decorating the bedrooms, important attention is paid to the ceiling, which should ...

|

|

Laminate coating is particularly wear -resistant. However, when exposed to ... |

It is well known that Russia has long been famous for the power of the traditions of wooden house building, ... |

Roofing iron on the roof: Installation instructions

Roofing with roofing iron is a rather complicated process. The final result of the resulting coating directly depends on compliance with the installation technology of the material. We will consider how to cover the roof with roofing roof iron with your own hands.

Table of contents:

- Varieties, features and advantages of roofing iron on the roof

- Recommendations for roofing roof iron

- How to cover the roof with roofing iron

- How to cover the roof with iron: features of installation of galvanized steel

- Iron installation technology for roof roofs

Varieties, features and advantages of roofing iron on the roof

Roofing iron is called materials for the manufacture of which metal rental is used. There are a large number of forms of roof iron release:

- rolls;

- Sheets.

Both polymer and galvanized coating are applied to the surface of the metal that protects it from the effects of external stimuli.

The popularity of the use of roofing iron is explained primarily by its low cost and excellent operational characteristics. The release of certain types of iron is controlled by special documents, so the thickness of the roofing black sheet material should not be less than 0.3 mm and more than 0.8 mm. To protect the metal from corrosion, it is processed by zinc on both sides.

In relation to the type of coating of iron zinc, it happens:

- iron, the thickness of the zinc coating in which up to eighteen microns;

- Material, with a thickness of zinc coating to forty necron.

Keep in mind that the type of coating and its thickness directly determine the quality of the product, the thicker the layer of zinc applied to the surface, the longer the iron will be protected from corrosion.

For the manufacture of roofing iron, high -quality carbon steel and cold pressing method are used. The application of galvanizing is carried out in different ways, while zinc of different categories is used. So that the coating is better kept on the surface with zinc combinated substances in the form of aluminum and lead. Thus, the coating becomes more durable, smooth and most importantly not subject to corrosion.

It is galvanizing that is the simplest and most reliable option that provides protection of metal from corrosion. To apply a layer, previously prepared metal is immersed in a pre -melted composition of zinc. Depending on the thickness of the resulting layer, the coating is first -class and second -grade. The material that belongs to the first class has a higher cost, but at the same time, its life is more than 25 years. The material of the second class is cheaper, although it will serve its owner for no more than ten years.

In addition, roofing iron is covered with a combination of zinc, cerium, lantana and aluminum, this coating is called Halfan. The iron on which this coating is applied to tolerates mechanical damage well is opposed to corrosion and is resistant to deformation.

Another option for coating iron is an alucinum layer consisting of zinc, aluminum of silicon additives. The combination of these substances helps with iron the acquisition of high anti-corrosion properties, three or four times improves the duration of its operation, since due to the presence of silicon, the coating is kept on the surface of the iron much longer.

Another common option is to apply polymers on metal coating. With its help, iron acquires any color and shade. This version of the roofing iron is the most common due to the combination of the optimal cost of the material with excellent performance and attractive appearance.

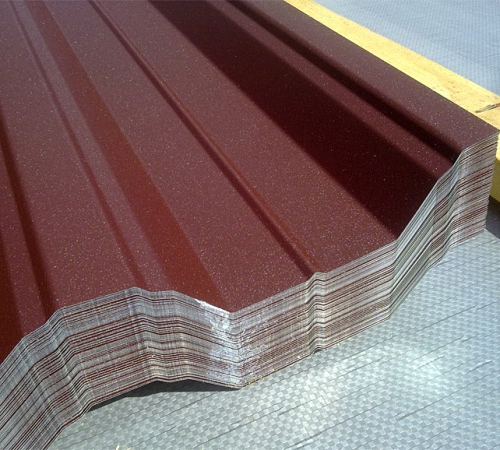

A sheet of roofing iron has the shape of a multilayer sandwich, consisting of a steel base, zinc coating, a layer of passivating purpose, soil and polymers. For the manufacture of the last layer, substances are used in the form of polyester, plastisol, a pool, glossy or matte shine giving the roof.

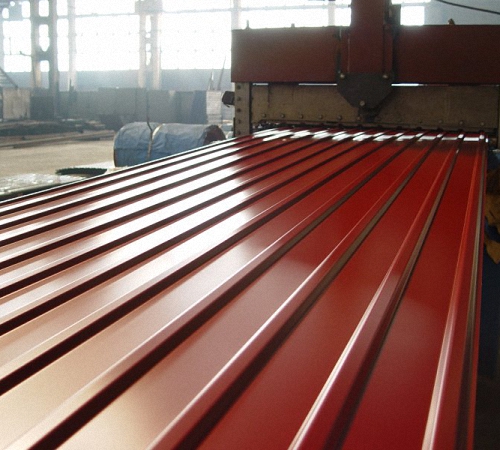

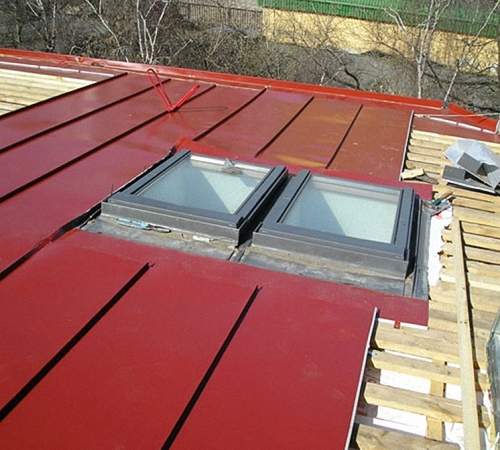

Iron on the roof photo:

To equip the roof, both a smooth and profiled type of metal is used. There are a large number of varieties and forms of roofing iron:

- metal tile;

- corrugated board;

- Steel type of slate, etc.

Among the advantages of roofing with metal are highlighted:

- excellent supporting characteristics;

- resistance before corrosion and deformation;

- stability before aggressive chemicals;

- resistance to ultraviolet;

- ease of installation;

- Preservation of a presentable appearance for a long period of operation.

Recommendations for roofing roof iron

Among the wide variety of roofing options, metal tiles and corrugated board remain the most popular. This is primarily due to the presentability of their appearance and good performance.

Installation on the roof of galvanized steel with a smooth coating is possible, however, it will make the building boring and mundane. In addition, the installation of this material requires special skills in working with the tools that connect it.

Also, aluminum, copper, zinc titanium options for finishing are installed on the roof, but their cost is very high, in addition, they need special care.

If you plan to install on the roof of profiled types of iron, then to perform this action, it is enough to study the instructions. But in order to install standard galvanized iron, you need to work very well, having previously studied the instructions on how to do it.

The most important rule of high -quality installation of a roof made of galvanized iron is to ensure its sealed connection, through which neither snow, nor rain or even wind will penetrate. This type of compound is called Faltsov, distinguish two of its types:

- lying;

- Standing compounds.

To perform the connection of iron sheets in the transverse direction, the first option is used, and in order to combine the material longitudinally - the second.

If you neglect this rule, then the water that should drain on the roof will linger on it.

In order to find out how to cover the roof with iron using folding joints, it is necessary to prepare the following materials in the form:

- a workbench, with a strong steel corner on it;

- hammer;

- kiyanka;

- Shpangelcyrkul;

- scissors for metal.

On the steel sheet, marking the bending place should be made, then the edge is bent with a wooden kiyanka. Turn the sheet over on the opposite side and make the edge the edge of the P-shaped. Take the second sheet, bend it and install it in the gap, which was formed on the first sheet. A metal hammer will help to fix the sheets with each other completely.

Keep in mind that this process requires special skills from its contractor, therefore, before the work, we recommend that you practice. An incorrect connection will lead to the fact that moisture and cold will fall through the roof on the attic.

Before making an iron roof, you should study a large amount of information from different sources.

How to cover the roof with roofing iron

Before laying the roofing iron, it is necessary to cut it into measuring sheets. In addition, in the presence of dents, they must be straightened. Start work from the bottom, gradually moving to the top. Do not forget about the allowance, which is 15-20 cm, the storm system is mounted with it.

Two methods of combining steel are distinguished:

- fake;

- The use of screws.

The second option is simpler and easier in execution than the first. However, with such installation, the iron sheets are overlapping, so the consumption of materials will be much higher than with a folding connection.

In addition, for the installation of screws, holes should be made, which will continue to pass water. The folder compound is more popular. It is with its help that the sheets are interconnected most tightly.

With a lying connection, the crest of the falsaire goes to the side on which the slope is located. With the help of standing compounds, the formation of vertical ribs of stiffness occurs. In the ratio with the number of bends, one- and two bent types of folds are distinguished.

The folding method of connecting involves the use of Klyammers that help to fix iron on the surface of the crate. These elements are metal strips, for the manufacture of which the balance of the material is used. One part of Kleammer is bent two, three centimeters, it connects to the crate, and the second part should be connected to a standing fold.

In order to bend iron, it is recommended to use a special hammer or ticks. Keep in mind that the height of all crests should be the same, in addition, they need to be well compacted and treated with sealant.

How to cover the roof with iron: features of installation of galvanized steel

1. Follow special accuracy in the process of working with this type of material, since the presence of the slightest damage to the galvanized layer will lead to the development of corrosion on the entire sheet.

2. In the process of transporting sheets, do not forget to use protective gloves. They will protect your hands from damage by sharp angles of iron.

3. If you need to cut roofing material to parts, then it is best to use scissors for metal. It is not recommended to use a grinder for these purposes, as it contributes to a strong heating of the metal and spoilage of the zinc coating.

4. In order to build the main part of the roof, use roofing material about half a centimeter thick, and to equip cornice overhangs, pediments and gutter, it is recommended to use thicker material.

5. The laying of the material is carried out on a previously prepared roof. To do this, the equipment of a wooden crate should be carried out. To build it, you will need to have a timber, the styling step of which is 200 mm. In the cornice and yndovs, the beam is laid close to each other.

6. To fix the flat material, it is necessary to have special equipment, which allows you to build folds. To install profiled iron, it is enough to use screws and special gaskets for them.

Iron installation technology for roof roofs

If possible, buy galvanized iron in the ratio with the total area of \u200b\u200bthe roof. That is, one strip should completely overlap one slope, since the connection of the strip from the parts is a painstaking and a business time.

Please note that problems often arise with transporting such a material. In order to calculate how much material is required for work, the roof area should be initially determined.

If you plan to use a double flange connection, then the total area of \u200b\u200bthe material must be increased one and a half times. In addition, 10-15% are added to compensate for waste.

In addition, for the arrangement of more loaded areas, such as overhangs and pediments, the presence of material with a little larger thickness will be required. If iron is mounted on the surface with self -tapping screws, then its number should be increased by another 15%, in addition, you will need to buy screws. For one square meter of roof area, it is necessary to purchase at least 4 self -tapping screws. Please note that under self -tapping screws, you will need the presence of elastic gaskets that will improve the tightness of the connection.

If the slope of the roof is more than twenty degrees, then sheet material without profiling is suitable for its arrangement. The process of laying iron is to check the roof for evenness with leveling.

Please note that in the presence of irregularities in the rafter system, after the installation of iron, they will appear and spoil the appearance of the roof. After checking the rafters, the crate is attached. There are two options for its implementation:

- continuous - the use of a trimmed board;

- Distributed - using the beam.

On the overhangs, cornices, the crate should only be continuous. Before installing iron, it is necessary to lay a roofing material that acts as a waterproofer.

To cut iron, use ordinary metal scissors or their electric version. The cut blanks are aligned and bent from them to create an element in the form of a gutter.

The following is the choice of the method of installation of the roofing iron - the use of a folder connection or self -tapping screws. The technology of their implementation has already been talked earlier.

How to cover the roof with iron video: