Private housing construction has not been complete for several years without arranging a transparent roof ...

|

|

If you want to equip an attractive, durable and inexpensive floor in your house ... |

The quality and duration of the operation of any building determines primarily it ... |

Roofing membrane: characteristics and installation

In order for the modern home to be as comfortable as possible, new technologies are being developed that contribute to this. Any detail is important in the house: from the foundation to the roof. The latter is of particular importance- protecting the residents from atmospheric precipitation, it is a crown of the entire structure. No wonder the saying was invented about how important it is to have a roof over your head. The roof membrane, which gains more and more popularity, helps to make it really reliable and safe. The article will talk about roofing membrane material.

Content:

- What is a roofing PVC membrane

- EPDM membrane for the roof. Characteristics of the material

- Polymer roof membranes

- Roofing membrane laying technology

What is a roofing PVC membrane

- Polyvinyl chloride is truly universal material in terms of application. For a roof membrane, it also serves as the basis, giving it such basic qualities as strength and elasticity. Companies manufacturers do not stop on one proven composition of this material. The formula is constantly being improved, all new characteristics are added so that the membrane ultimately corresponds to its purpose as much as possible.

The roofing membrane of the technonic

- And you can use it in the following areas of construction:

- actually, when building roofs in buildings under construction from scratch and for the repair of the roof in the buildings already commissioned;

- as a waterproofing layer at the time of insulation of walls, ceilings, bases; When conducting various communications, when it is required to create protection for them; When laying tunnels or arranging cellars.

- Since polyvinyl chloride has practically no restrictions on use, the membrane made from it can be used in the construction of objects of any purpose: domestic, engineering, technical. It has excellent waterproofing indicators, and is also able to resist critical temperatures in both directions of the mercury in the thermometer. It is recommended to be used even under the conditions of intense ice or in places where water often stagnates.

- The service life of this material (according to the assumptions of manufacturers) for at least half a century, and new developments in the field of manufacturing technology made it possible to reduce the cost of the process. Thanks to this, the price of a roofing membrane began to decline. And economic benefit is always one of the most important priorities in construction. Moreover, this condition does not go against the quality of building materials.

- Such a membrane is very light, which means that its use will minimize the load on the structure. And it also includes stabilizing components to reduce the degree of combustibility. Welding work is performed by a stream of hot air or adhesive method, that is, the threat of fire is minimized.

- High operational characteristics are achieved due to the special structure of sheets of material. It allows you to effectively and quickly remove moisture vapors, while remaining stable and to negative effects on their part. And any atmospheric effects do not reduce the service life of the membrane, like UV rays.

- Durability, in comparison, for example, with the same bitumen, the polymer material is much higher, and there is a difference in price. The membrane will cost 30 percent more expensive, but as a result, such an overpayment will become an excellent investment in the future of the roof.

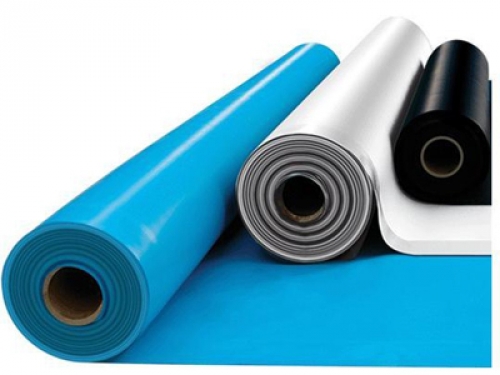

- An important feature is the convenient width of the rolls of the material. With the help of them, it is easy to ensure the installation of polymer roof on the surfaces of any configuration, and on straight roofs, this form of release gives an advantage in the speed of work. And one more important factor: laying can be done year -round without making changes to the technology.

- If you use warm welding of the roofing membrane, then the waterproofing properties of the material will be enough, that is, an additional layer that prevents moisture from hitting the hit.

- The roof membrane is covered with one layer. This gives her an advantage in the installation time. If you carry out a parallel with bitumen coating, then the timing of the roof using polymers is halved. With a thickness of 0.8 to 2 mm, the coating has small weight. For 1 m, this indicator is approximately 1.3 kg.

As a result, the PVC membrane for the roof has the following characteristics:

- flexibility

- waterproofing properties,

- the strength for a puncture (due to the use of a polyester grid acting as a reinforcing layer),

- simplicity of installation,

- the possibility of operation at extreme temperature conditions (from -40C to +125C).

In addition to PVC, the material for the roof is released by EPDM and TPO varieties of membranes

EPDM membrane for the roof. Characteristics of the material

Ethylene-Propylene rubber in the international designation is marked as an EPDM, it became the basis for one of the types of roofing materials.

Certain additives and modern technologies give this waterproofing product the following characteristics:

- elasticity. The material indicator for elastic stretching is 400%;

- the weight. A square meter of EPDM membranes weighs less than 1.4 kg;

- the speed of styling. It is connected not only with ease of installation, but also a convenient form of release. The roll in width can be up to 15 m, and the length of the canvas up to 60 m. This format will also provide a minimum amount of welds;

- resistance to influences. If we talk about the air temperature, then the membrane of this type without losses of its properties will transfer both the sixty -degree frost and the heat of 100 C. It is not afraid of the effects of ultraviolet rays;

- the service life of the EPDM of the material is defined as 50 years.

A membrane of this type is also widely used in the construction of objects of any kind. Some manufacturers have established the production of EPDM material for the roof under the welded method of formation of the seam, but such options are quite expensive compared to analogues in their class of products.

Polymer roof membranes

- The abbreviation of the TPO material is deciphered as a thermoplastic polyolefin reinforced reinforced roof membrane. It belongs to the category of polymer roofing materials and combines some advantages from the roof products described above. So, for example, it has the strength of PVC membranes and elasticity of the EPDM.

- Accordingly, its manufacture is ethylenepropylene rubber and polypropylene (approximately 30% of the total). Special additives reduce the level of combustibility of the material and increase its operational characteristics. Manufacturers say that the installation of this building material has practically no restrictions on the level of inclination of the roof.

- This species, like the previous ones, is quite suitable for buildings located in the Arctic, and in the area, where the temperature in the shade is far from the ideal of coolness. The TPO membrane is resistant to gaps, ultraviolet and is considered durable material (service life of 25 years). It does not contain chlorine, that is, we can talk about the environmental friendliness of this coating. It is vapor permeable, and it can be operated both in new buildings and for the repair of emergency roof.

- Among the physical and technical indicators, the low sailing of the roofing system created using the TPO membrane should also be noted.

- It is produced in various variations of gray color, with rolls with a width of 1.5 and a length of 10 and 25 m. The thickness of the product can be 1.2; 1.5; 1.8; 2.0 mm.

- Installation is possible in all ways available to membranes and is performed in one layer.

Roofing membrane laying technology

No even the best material can resist illiterate use. Therefore, acquaintance with the technology of styling should not be superficial.

For roof installation, several methods are used. The choice of a particular of them is due to various factors. So, you can fix the membrane in four ways:

- adhesive,

- mechanical,

- ballast,

- teplial.

- First option EPDM membranes is only appropriate. On surfaces with a large slope and an abundance of complex architectural forms. It is also suitable during the repair of the roof already in operation. The method will make the roof resistant to strong winds.

- Polymer material fixed using mechanical installation method, well -established on sloping roofs. PVC lists of the membrane are attached to metizes, and sealed seams of the seams provide the use of special equipment or adhesive tapes.

- The ballast methodit can only be used if the slope of the roof does not exceed 11% (according to some data, 15%). This restriction is valid because the roof membrane is closed with ballast to ensure additional clamping force. In his role, the layer of gravel most often acts.

- The last option It is considered more difficult to perform, as it will require special equipment and skills in working with it. The remaining methods are more accessible to most home masters, but the seams glued with tape are less sealed and less.

Laying roofing PVC membranes

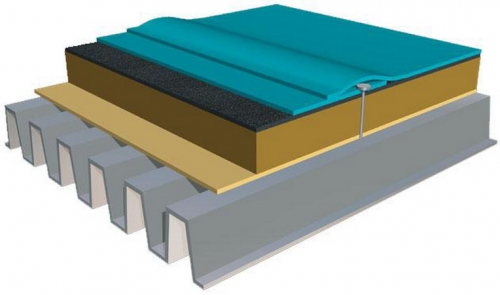

The PVC membrane has a puff pie. It can be performed on various grounds (concrete slabs, profile).

- The 1st layer is the base itself.

- The 2nd laying vapor barrier.

- The 3rd layer is made of materials with good heat retention.

- The 4th layer is laid from geotextiles, it plays the role of the divider.

- Then the fasteners go.

- 5th layer roof membrane.

The installation rate provides for the styling of the material up to 600 m per day.

Membrane roofing video

Installation of a roof membrane with your hands

- The main point during installation work is high -quality sealing of the seams. It is performed either Using an automatic machine, or on a self -adhesive tape from the EPDM polymer.

- Special equipment works from a conventional network with a voltage of 220 V, the temperature regime can be adjusted in the range from +20C to 650C. The tape thanks to the applications of advanced technologies allows you to get a monolithic seam without welding. With certain skills, the team of builders can cover up to 1000 m of the roof per day in this way.

- After such a reliable connection, the roof will not require additional protection.

- Adhesive type of connection. Special tapes are complete with other materials for the installation of the EPDM roof. The technology involves the use of such a membrane in the most complex areas with an abundance of angles, pipes. There are sealants and fasteners for this. In favor of this method, the lack of need to acquire special equipment is indicated. But, as mentioned above, the welded seam is more durable, and the repair technology performed by adhesive will require repair time.

- Welding method. The heat -welded method is available to PVC and TPO membranes. The canvases are overlapped and rafting each other under the influence of a directed hot air flow (400-600C). The exact temperature regime depends on the weather conditions at the time of installation. It is calculated, making a trial adhesion. In addition to absolute tightness, the seam acquires excellent indicators of resistance to break. They exceed the data of the membrane itself, so the material itself will be torn rather than the joint will be dispersed.

- The width of the weld varies depending on the necessity and is from 2 to 10 cm. On an industrial scale, devices that have automatic mode of operation are used. The temperature, welding rate is regulated by electronics. Inaccessible places are processed by hand apparatuses and special rollers to provide clamping force.

To make the seam really high -quality, you need to comply with the following requirements:

- do not create tension of the material during styling;

- follow the width of the overlap. The minimum this indicator is 0.5 cm. In this case, the welded seam will be 20 mm;

- monitor the quality of each seam immediately after performing actions for its seal.

- do not allow dust and any garbage on the material during welding.

- If in the process of verification a non -cell area has been found, then a patch of relevant material is placed in this place. It is made with rounded edges, and the size exceeds the parameters of the repaired area by at least 0.5 cm from all sides.

- The ballast option of fastening. As mentioned above, this method is permissible only when arranging a flat roof. The technology is simple and economical. The base must be cleaned of pollution and garbage. The canvas is spread and attached either with a welded or adhesive method not only with each other, but also in places of contact with the sides of the roof and vertical elements (for example, pipes). After the membrane is covered with a layer of gravel. The amount of ballast is calculated so that 1 m has 50 kg of cargo. The gravel layer is thoroughly leveled and slightly compacted.

- You can use not only gravel or gravel by fractions from 20 to 40 mm, but also large pebbles. The technology does not prohibit laying even paving slabs, concrete blocks. If it is supposed to use ballast that can damage the flooring, it is recommended to use a layer of non -woven canvas. Due to the use of heavy pressing materials, this method is suitable only for those roofs that can withstand such an additional load.

- Mechanical method It would be more correct to call mixed, as it also involves an adhesive connection of pieces of a membrane with the base. It should be used on the roofs with a complex configuration, when additional fasteners are useful. The adhesive composition can be applied to concrete bases, wooden floors, a profiled sheet. Between themselves, the canvases of the membranes are welded or glued. For a better fit on the protruding elements of the roof, clamping rails are used, which have a sealing layer. As mechanical fasteners, steel galvanized screws are used. They are attached to the seam.

- The main perimeter of the membrane roof holds telescopic fasteners. Its upper part is made of plastic and has a wide hat, and the bottom is a steel anchor. It is recommended to observe a distance of 20 cm when installing anchors. In places where the material adjoins the inner corners, the technology requires the second row of fasteners. This type of installation does not imply intensive operation of the roof.

Thus, even a novice builder will be able to perform the installation of the roof using the membrane, choosing the most acceptable option for himself. Buying a roofing membrane will not be difficult, and having excellent characteristics, this material is not only available, but also many times the previously used roof arrangements used in terms of indicators.