Installation of plastic windows is an excellent solution to ensure comfort at home and ...

|

|

Today, many developers choose the construction of a columnar under their house ... |

Not so long ago in your apartment you made repairs and proudly showed guests ... |

DIY barn

You were told that the house from the beam is not necessary to be cone, they say, is it all perfectly fitted there? You can safely send such grief specialists in home and invite real professionals in the construction of wooden houses. Like any other, the technology for the construction of houses from the beam has its own stages and design features, which invariably includes the hemp of a timber house, even if you are going to make external and interior decoration with insulation in the future. Do not try to save time and money so as not to overpay in the future. If you do not want the drafts to constantly walk in your house, the curtains are fluttering even in calm weather, and over time, wet and rotten places in wood appeared, it is better to do all the workplace at the house in time.

- Do I need to brown house and why

- Than to heated a brown house

- When to heated a bar house

- DIY barn

- Brus House hemp: Video Example

Do I need to brown house and why

In some sources, you can find information that you can not brown a bar house. Yes, and builders who build a house for you can say the same thing. They explain this by the fact that, unlike barus in log houses, Osushka and the shift of wood are stronger and more intense, gaps and leaks appear, so it is necessary to pump the structure. But houses built from a profiled beam are practically not seated, since the wood is pre -processing. Let's figure out how it actually happens during the construction of a house from a beam with your own hands.

A beam of natural humidity Relatively cheap building material, for which it is popular in the construction of economy-class houses with subsequent insulation and decoration of siding. Even if you invite the best architect, he will not be able to build a house from such a bar without cracks between crowns and gaps. Moreover, when the beam begins to dry out, and this is inevitably, additional cracks will appear, wider, the beam will decrease in size, it will begin to twist it. As a result, there will be such cracks, due to which the wooden wall will lose its thermal insulation abilities. To avoid such a sad end, the walls must be pumped out at least 3 times and carefully insulated.

Profiled beam It was invented precisely in order to reduce the costs and time to build a wooden house. It undergoes special processing in production, so it practically does not dry out during operation, as well as its compounds, the spike-paz is perfectly verified with an accuracy of a millimeter. The beam adjacent to each other as tightly as possible, and a 5 mm insulation is laid between the crowns, which is located between the hooking parts. Despite the assurances of the seller, the house from the profiled beam is still seated, since the beam finally becomes in its place under the weight of the structure. In addition, the properties of wood are strongly dependent on the region of growth, climatic conditions and storage conditions. No one can guarantee that absolutely the entire beam that you have acquired equally high quality. As a result of the progress of the building, the beam can be slightly shifted, the insulation is crushed. Even if the cracks do not appear after the shrinkage, and this option is possible, all the same, those gaps that are in the intervention space outside and inside the house accumulate moisture, and since the place itself is very secluded and vulnerable, mold and rot can form in it.

The hemp of a timber house is necessary in order to isolate the wooden walls, completely filled with a natural insulation and sealing the gaps and cracks between the beam and in the corner compounds. This guarantees tightness, the lack of heat leaks through the walls, drafts and icing of the beam outside the building, which occurs when warm steam through the cracks goes outside and settles with wet hoar on the surface.

Than to heated a brown house

If you summarize, then the material that can be picked up by the house must meet the requirements below:

- Have low thermal conductivity.

- To be immune to temperature and moist fluctuations, as well as easily withstand the wind.

- So that insects and pathogenic mushrooms (mold) do not start in it.

- To be absolutely environmentally friendly material, otherwise all meaning in the construction of a wooden house is lost.

- Be relatively durable (do not lose properties for at least 20 years).

- Be breathable.

- Be hygroscopic, i.e. When you need to absorb moisture, when to give.

- And the most important thing is to be similar in their properties to wood.

Due to the fact that our ancestors for hundreds of generations in depths were heated to their homes on their own, materials that have been checked and tested by a thousand -year successful practice have survived to this day. They can be called traditional materials.

Moss The best material is even today for the hemp of wooden buildings. This is the moss sphagnum marsh plant, which can be red, white or brown. Subsequently, peat is formed from it. None of the modern materials can compare with the moss, it is so durable and environmentally friendly. You can travel around the old abandoned villages, look at the houses: the logs are almost rotten, and the moss is still in excellent condition. As an intervention seal, moss is simply indispensable: it has antiseptic, antibacterial and therapeutic properties. Closed between wood, it suppresses the development of putrefactive bacteria and molds, due to which the wood serves longer. Moss easily lets air through itself, which, passing through it, is onlyated by therapeutic pairs, so the atmosphere inside the house becomes healing. The moss is hygroscopic, which means it smoothes moisture differences. In general, the moss has no shortcomings, except for one it is not so easy for them to herself, otherwise no one would have come up with or looking for anything new.

Flax fibers It is used as a sealant and sealant everywhere, but for hemp, mainly in the regions of the growth of flax and where there are no swamps, where you can stock up with moss. Nobody produces specially pacli, these are waste from the production of ropes, ropes and canvases or elaborations and shutters after cleaning linen fibers. Packla has some antiseptic and bactericidal properties, but to less than moss. Therefore, in some cases, the dad is treated with resins to increase resistance to high humidity. These resins can be natural, i.e. Smols of trees, then this material can still be called environmentally friendly, but oil products are also used for impregnation, then Pakly has nothing to do with natural materials. Packla contains a large number of bonfires, which will shake during the first years of operation of the house, so the hemp will need to be repeated several times.

Hemp hemp It is very similar to the dad, only its fibers are rude, so they are sometimes confused. Hemp is not afraid of temperature changes and high humidity, so it can be used even in very wet regions. Such properties are due to the high content of the polymer of lignin, it is also contained in any wood for fastening cellulose fibers. Penka does not lose its properties even after getting wet, therefore resistant to decay.

Among modern materials for hemp, one can highlight the following:

Jute A foreign product, it is imported to us from China, India, Egypt and other countries with tropical climate or abundant precipitation. The plants of the juts of the Malvovov families are produced from the shoots. The jute fiber is very durable, not affected by mold, putrefactive bacteria, not interesting to insects and birds, hygroscopically, i.e. Easily accumulates and gives moisture, passes the air. Jut contains about the same number of lignin as wood, so their properties are similar and together they are an ideal couple.

Jut is produced both in fibers and in ribbons that have a different width. Ribbon jute heaters It is very convenient to use for styling between the crowns of a timber house. In addition, pure jute is evenly compacting. These advantages more than block the price of this material.

In addition to materials from fibers for hemp, felt insulation (intervention felt) are also used:

Juetry intervention insulation It consists of 90 % of jute and 10 % of flax. But it is better to trace for this ratio, since there is a jute felt, 70 % of jute and 30 % of flax, which significantly worsens its properties.

Linen felt They also call Europe or Lnovatin. It is an needle -proof material made of highly purified linen.

Floody felt consists of jute and flax in a ratio of 1: 1.

Completely jute modern heaters are considered the best, since they perfectly interact with wood and sits evenly, and other materials with the addition of flax worsen the properties of insulation. The more flax, the worse the properties.

When to heated a bar house

Work on the hemp at the house is carried out in several stages, this is due to the fact that the beam dries gradually, the house is packed under its weight. The largest shrinkage takes place in the first year and a half after the construction, and every year it is less and less. Experts say that after 5 6 years, the shrinkage is practically stopped.

First timethe brown house will be heated immediately after the construction. In the process of construction, a heater is laid between the crowns, and after the whole house is erected, the cracks between the bars are filled with material for the hemp, but not too tightly.

The second hemp It is produced a year and a half after the completion of the construction of the house. The house will already be sought out, so the hemp is necessary to tightly, without leaving cracks and hanging material.

Third time Work on the hemp will have to be done again after 5 6 years, carefully filling all the newly formed gaps and cracks and adding the material where it accidentally sprinkled or was pulled out by birds.

If the block house is planned to be sheathed outside with siding, then the third hemp is not made, but the first two must be completed. Do not rush and save on what later you will have to pay much more.

DIY barn

The hemp is a very responsible and time -consuming process, despite a certain uniformity of operations performed. Not many construction brigades agree to hemp work, they simply do not know how to do this and are afraid to spoil it, which is why they recommend not to heated at all. We have already made out why they should not be listened.

But there are brigades and entire organizations that are engaged in hemp professionally. The price depends on the floor of the workshop for the workshop and amounts to a certain amount of 1 meter of each crown. The average cost of hemp is 50,60 rubles. For 1 m. And the hemp of corner compounds can reach 200 rubles. For 1 m. At a separate tariff, a hemp will be carried out by a decorative rope (rope), which adorns the appearance of the pricked walls and does not allow birds to pull the material. By the way, it is customary to pay for the material separately. If you are offered to carry out hemp work for 25 rubles. MP, you should not agree, since the work will be done from the ordinary.

If you want to do all the work yourself, then be patient, material, tool and subsequent information.

How to pick a barbell house jute

Jut, like material for insulation of a timber house, is gaining frantic popularity. It is often used in the construction of the house itself.

Before heated a brown house, first it is necessary to correctly lay and fix the beam. A heater with a layer of at least 5 mm is always laid in the intervention space. Even if the beam is profiled, jute is necessarily laid between the spike and the groove. But its width depends on the shape of the Sip-Paz system. The easiest option is when the lower beam has a convex crescent surface, and the upper same recess (somewhat resembles the connection of logs), in which case the space between the crowns is filled with a heater completely, and its edges remain to hang 4 5 cm on each side. A more complex version of the profiled beam, when it is impossible to lay the insulation with a continuous carpet, then it is laid only in the middle, and the external and internal cracks then vibrate separately.

If the house of their timber is natural humidity, then the thickness of the intervention insulation should be 10 15 mm.

Important! The hemp is necessarily made from top to bottom. At the same time, first one crown is thug completely on the outside, then inside, and only then go to the second crown. It is better if the work will produce 4 people simultaneously on 4 walls. This is necessary so that the house does not skew. After all, after the hemp is completed, it will rise a few centimeters, from 5 to 15 cm.

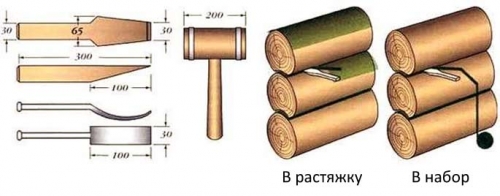

Consider the option when the insulation hangs between the bars by 4 5 cm. The hemp technology is very well shown in the video examination. Using a hemp (tool), the jute tucks under the bottom and slightly pushes into the gap. Then carefully, but already more strongly pushed in the upper part, and finally in the middle. To push the material inside the gap, a rubber or wooden hammer (kiyanka) is used, which is carefully beaten on the hemp.

If, after the work performed, the loose cracks are still observed, then an additional hemp is performed.

Consider the option when the cracks between the crowns are not filled (the insulation is somewhere in the middle of the beam). The work will be exactly the same as with additional hemp.

Typically, between the bars, the cracks are quite narrow, so this method of hemp is used: a cord with a gap with a gap with a jouple fiber and clogs with a mallet into the slit.

There is another way to stretch. Separate fibers of jute are laid by fibers across the beam and pushed inside with a spatula or hemp, until the gap is completely filled. We leave the remaining ends of the material, it should turn out about 5 6 cm. Next, a little more jute is taken, it will move into the ball (roller), which is wrapped in these hanging ends and pushed into the gap.

Important! How can you check, stop already pushing the insulation, or still need to add a little? If a 15 mm kitchen knife enters the gap between the crowns, then the hemp is successful. If the knife goes on, then the material should be added.

When forming large cracks, use the method of hemp into the set. Long strands come from jute and roll into a ball. Then loops are typed from the ball and pushed into the cracks until they are filled.

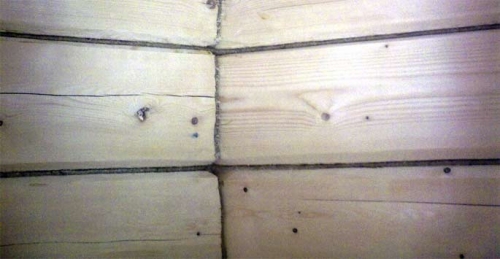

After all the hemp is completed, the house is loaded and, if possible, is operated for a whole year. In winter, it will be possible to check the presence of cracks on the so -called hares. These are the foci of hoarfrost on the outer side of the wall. If you find them, mark a place, this means that there is a heat of warm air from the house. A year and a half after the first hemp, the second is carried out, the house is carefully inspected, the insulation is added to the places where it spilled out or broke away, where the gaps increased, where the beam was distorted, as well as in places of hares.

Only after repeated hemp can be proceeded to the outer and interior decoration of the house. Even if it involves 100 mm mineral wool and a ventilated facade.

You can pick up a bar house with other materials. But there are some exceptions. For example, moss can only be heated only a house from a non-core timber, since this material is laid and fills completely the intervention space, which is absolutely impossible if the beam has a spike-paz system. The work on the hemp at home is complex and painstaking, although they seem to be painful from the side. If you are not confident in your abilities, invite a specialist.

Important! The hemp is produced

Important! The hemp is necessarily made from top to bottom. The video speaks the opposite!

it's not clear to the hemp.

it is not clear to the hemp is not clear from top to bottom or from the bottom up?