Often, the builder is the task of building an arched floor, ...

|

|

They start choosing a plinth when the flooring is ready, because these products ... |

Sliding partitions are widely used to decorate the interiors of residential buildings. It... |

Composite reinforcement for the foundation: advantages, disadvantages, application

Until recently, reinforcement from metal rods was considered not only the most reliable, but also the only acceptable option for creating a strong skeleton of the foundations of buildings of any purpose. The material that will be discussed did not appear yesterday (there are references to the experience of its application since the late 70s). But the composite reinforcement was not popular, so they forgot about it in our country for a while. But in foreign countries it was used actively. Therefore, it is possible to talk about the successful use of composite rods for reinforcing concrete structures. And to judge the strength and stability of such structures is not unfounded, but on the basis of facts.

Content:

- A little myths from unscrupulous manufacturers and sellers

- The use of composite reinforcement

- Composite reinforcement for the foundation

- The diameter of composite reinforcement

- Methods of combining composite reinforcement

- Foundation with composite reinforcement and construction in seismic areas

A little myths from unscrupulous manufacturers and sellers

Fiberglass reinforcement, albeit unennated (as it turned out) material, but most consumers are unfamiliar. The fact that advertising positions it as an innovation has nothing to worry about. Worse, when, taking advantage of the ignorance of potential customers, the manufacturer is trying in every possible way to increase the selling price for the product, indicating the supposedly unique properties of his composite reinforcement.

Composite reinforcement photo

So far, a regular private developer by bit collects information about it, getting acquainted with the properties and features of the use, and large construction companies are involved in the miscalculation of the revenue and expenditure part of the budget when switching to a composite instead of metal, rumors grow and multiply. And they need to give a reasonable and honest answer to them.

One of the most common myths can be debunk right now.

- Outwardly, this building material is light rods with various shades of yellow color (if they are made of fiberglass) or pronounced black (provided that the basalt was used). However, an attempt to make the goods more attractive outwardly, namely, adding a coloring pigment of various shade, allowed to bring color reinforcement to the market. And immediately a myth appeared: these additives are not easy to stain rods, and are special components that improve the characteristics of the material. Serious manufacturers give a definite answer: color does not affect the quality of composite reinforcement.

- In addition to improving the commodity species, a very noble impulse is also worth the color of such experiments with color: to highlight rods of various diameters.

Reading regulatory documentation for building materials will help not to succumb to tricks of dishonest sellers.

The use of composite reinforcement

Composite reinforcement gradually conquers space from a metal fellow in the field of laying the foundations of low -rise houses. Glass, carbon, basalt or army fibers are taken as the basis for its production. They are binded by the addition of polymers.

Fiberglass reinforcement can also be produced in the form of smooth rods, but in the case when it is supplemented with a spiral wrapping of a glass thread, a more reliable adhesion with a poured solution is provided. So give preference to better the second option.

Experts call a number of advantages of composite reinforcement:

- the convenience of transportation and use due to small weight. In addition, welding work is not used during installation;

- resistance to various aggressive environments;

- stability to corrosion;

- gap strength.

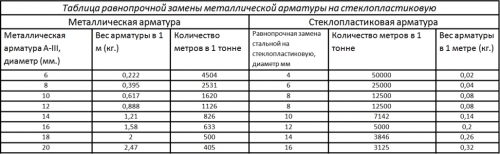

To create the foundation, composite reinforcement of a certain diameter is required. The calculation of the cross section takes place individually for each object. It depends on the number of storeys, complexity of the project and a number of other reasons. It is important that, not inferior in strength to metal rods of a similar diameter, composite reinforcement will differ in less weight.

Composite reinforcement for the foundation

- Composite rods when laying the foundation are used similarly by steel. The frame is assembled from them according to the recommendations for a certain type of base with the desired step, and in places of intersection the reinforcement elements are fastened with screeds or knitting wire.

- Developers and manufacturers do not give recommendations prohibiting the use of composite reinforcement for the construction of any type of foundation. That is, if desired, the developer, any reason for low -rise buildings can be made using fiberglass reinforcement.

- But you can exactly determine in which foundations composite rods have established themselves from the best side. We are talking about tape or columnar methods for buildings with a height of no more than three floors. Those who want to build: a private house, a cottage, a bathhouse, a garage, a thorough construction of an economic purpose.

- The service life of elements of non -metallic origin is quite large for 80 years according to minimal calculations. Their cost may only differ slightly from the price of the usual steel rods, but it is quite possible to save on transportation. The reinforcement packaged in the bay will easily fit into the trunk of a car.

- The conditions of construction and technology are different. Where reinforced concrete structures will be operated in the presence of an aggressive medium for metal, it makes sense to use non -metallic reinforcement.

- Composite reinforcement, selected with an equal strength of the reinforced concrete frame, will create a reliable base. And it will last much longer (due to the confrontation to the destructive effect of the environment and the complete indifference to the corrosion process).

For massive buildings from concrete, the following types of reinforcement with fiberglass are used:

- External. It is justified in cases where concrete structures are exposed to destructive effects, being in an unfavorable environment.

- The characteristics of composite reinforcement, produced specifically for these purposes, allows you to create a protective barrier around the structure. It is impenetrable for air or water. This method is called continuous. Sometimes, using it, they act the opposite. First, the frame is made, and then it is poured with concrete.

- A discrete method means that composite nets or strips from reinforcement strengthen the base from the outside.

- Internal. It is also divided into two ways.

- Discrete reinforcement It suggests that composite nets, individual rods or even volumetric frames created from many elements will be laid inside the design.

- The dispersed methoda little simpler - crushed fiberglasses are added to the total mass for filling. The resulting material was called glass -fiber concrete.

- A joint. The combined method got its name not only because of the simultaneous use of two types of reinforcement, but also because it allows a combination of rods from fiberglass and metal. It is used when significant weight loads are assumed on the foundation.

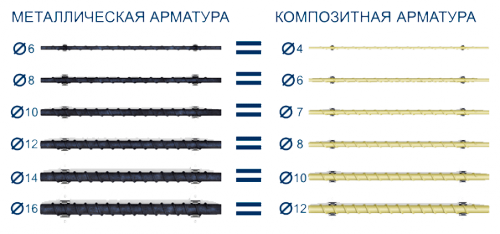

The diameter of composite reinforcement

If to date, there was no such task, then the following information may be useful.

- Due to its constructive features, metal reinforcement has several indicators characterizing the diameter:

- the external is measured according to the ribs protruding in the profile;

- the internal belongs to the rod itself;

- the nominal, which is expressed by the whole number, is the profile number.

- They do not coincide, the diameter measured on the outer side exceeds the nominal indicator. You should be extremely careful so that you can’t buy a smaller diameter reinforcement on these sizes than required.

- The determination of the above sizes in the reinforcement of fiberglass has nuances. The external diameter is determined in it in the same way as in steel. When trying to get internal size, some difficulties arise.

- The fact is that composite reinforcement does not have a perfectly round rod shape. This is due to the fact that numerous lines that produce this building material, due to certain features, cannot observe such accuracy. So the fiberglass rods on the cut have a shape striving for oval. And the larger the diameter has, the more clearly the oval is visible. By measuring such a product for the first time, the consumer will get one result. By deploying the rod by 90, repeating the procedure, he will see other numbers. The indicators should be summarized and divided into 2. The result can be considered an average indicator of the internal diameter of the composite reinforcement.

- In order to carry out work on calculation and when purchasing material, you need to know the nominal diameter. In the conditions that a simple home master has, this indicator cannot be obtained. For those to whom the solution to such a problem is vital, there is one trick.

- The nominal diameter is essentially the average number between the size of the external and internal caliber. Further, the less often the ribs are located on the rod, the greater the inner diameter approaches the value of the nominal.

That is, to catch an unscrupulous seller trying to give out the numbers of the external diameter for its nominal size as follows:

- it is necessary to measure the external diameter;

- measure internal diane of cross -country;

- compare the number called the seller with both indicators.

If the external diameter coincides with the nominal number according to the seller’s version to buy reinforcement in another place.

The weight of composite reinforcement

Methods of combining composite reinforcement

Among the above advantages of composite reinforcement, one of the points indicated that its use does not imply welding. The rods are collected in the frame by connecting among themselves.

Plastic screeds are used less often, but knitting wire, builders value more. This material is more traditional and so far not eradicated by new trends. It is carried out in the following ways:

- using an automatic gun;

- using a knitting hook for construction (simple configuration);

- using a screw (mechanized) construction knitting hook.

The popularity of the last two options is explained by the availability of the tool. Rarely, anyone can afford to purchase an expensive gun for the construction of one foundation. Some large companies, however, practice renting an expensive but very simplifying work inventory. And if such an opportunity falls out, then you should use it.

Among the arguments for automation of the knitting process, the following can be listed:

- it is quite obvious that mechanized labor is more effective and productive;

- having such an assistant, you can not overpay a hired worker. With its use, one person will cope with the strapping on his own;

- the gun performs equally even and strong nodes on the entire frame;

- the tool is functional at any temperature;

- a powerful battery makes it possible to work uninterruptedly all day.

Particularly advanced models of this tool are equipped with a device that allows you to connect the rods without leaning close to them.

Foundation with composite reinforcement and construction in seismic areas

- Another evidence of the magnificent strength characteristics of composite reinforcement can also be considered its application in other areas of construction that requires confrontation with significant loads: walls and floors of buildings, roadbed, coastal structures, bridges.

- But rarely where you can meet the mention that composite reinforcement can withstand impressive underground shocks. The Research Institute of Construction Structures named after Kucherenko about five years ago dealt with the behavior of this material with large dynamic loads. The reinforcement with a diameter of 8 mm was tested by an earthquake of 5 to 10 points. With its help, prototypes of panels were reinforced, which were subjected to appropriate loads, put on vibration platforms. The material remained intact up to nine -point seismactivity!

Composite reinforcement video

Fiberglass reinforcement is durable and convenient to use the material. Today it is a worthy replacement for metal rods, and its use for filling foundations for low -rise construction can be considered not only justified, but also an extremely desirable action from the developer. That is why there are so many positive reviews about composite reinforcement among private developers.

Dear portal, super

Dear portal, super article, and the video was posted out of the topic - read reviews for the video of specialists.

The bronze age could not resist steel, and steel could not resist the composites - the aerospace industry is an indisputable fact.

Continue to spend money on metal (.