To look beautiful, fit, young and energetic, it is not at all necessary to be ...

|

|

The range of flooring suitable for the bathroom includes the most ... |

The construction of the reinforced concrete foundation in the construction of the building is evidence of its ... |

Do -it -yourself well rings

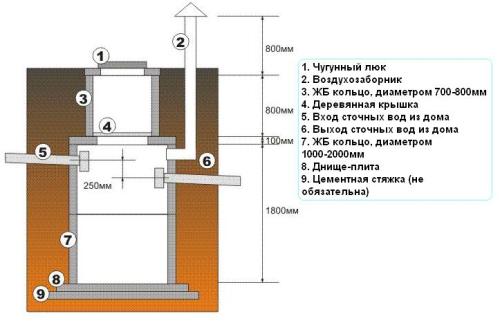

A personal water supply, a well or an equipped septic tank can not only take wastewater, but even produce gas for a kitchen slab. In such designs, the reinforced concrete ring is the main involved element. Some people get such rings, delivering immediately to the house. But not everyone can afford the purchase and delivery of this element. However, do not despair! There is an option to buy a ready -made form for making well rings with your own hands. Let's take a closer look at this technology.

Content:

- The evolution of well rings

- The purpose of well rings

- Design and production of well rings

- Do -it -yourself well rings

The evolution of well rings

If you look into history, we can say that the well rings first appeared back in 2600 BC in India. Also, similar products were used in ancient China and ancient Rome. And well rings came to Russia only in the 19th century, when the need for their operation increased, it was at this time that the first underground utilities were built. But the walls of the very first well rings were made not from concrete, they were laid out of brick.

And only in the sixties did the replacement of the material occurred, the walls of the well rings began to be made from concrete and reinforced concrete. Many problems were solved by the appearance of concrete and reinforced concrete, and with them well rings, which have more advantages than the brick that laid out the walls of the sewer. Along with this, the laborious and long process of installing engineering communications has become easier.

Along with the replacement of the material for the manufacture of underground communications, the design of the well ring changed. First of all, the differences are noticeable in the end of the ring. The most ordinary well rings had a flat end, later products with docking ends appeared, which began to be called the docking rings with a lock. It is thanks to the presence of such a reliable connection that the docking rings are characterized by high water resistance.

Of course, the well rings that have a castle became much better than traditional ones, since it was not violated when the soil shift, and thereby did not cause problems with their functioning. The movement of the rings along with the soil and provided the integrity of the structure in general. But this attachment system was not 100%reliable, therefore a new mount was developed - external and internal ledges on the well rings that curb the deaf attachment of the rings among themselves and exclude the slightest displacements.

The purpose of well rings

First of all, well rings are used to install sewer wells.

They are often used for the equipment of highways and city roads, where they are designed to remove unwanted precipitation. Today, well rings are also used to arrange bridges through channels and trenches, various types of wells, various treatment facilities, landscape design, etc. Poiled rings are involved as a fixed formwork when installing engineering structures or various foundations. In addition, rings are often used for the construction of wells at home.

There are modern options for well rings, for example plastic. They differ in small weight, which contributes to easy installation. As it turned out, in terms of strength, they are not inferior to reinforced concrete. Plastic rings do not interact with various chemical elements and are not affected by corrosion. But they still cannot provide the whole complex of properties, for example, they have very low frost resistance.

What explains this demand for these products? Firstly, they are durable and resistant to strong loads. Secondly, the material does not pass water and is environmentally friendly, this is important, since the water that enters the structure can be used for drinking and cooking. It is worth noting that well rings are very quickly mounted and have an acceptable price.

Certain requirements are imposed on the quality of acquired well rings. It is understandable that such products should have a good density, otherwise they will be not applicable. Polesy rings must be agreed with all the norms of the state standard and environmental factors. The fact is that the water that enters the structure can be used for drinking and cooking. Poiled rings should have high strength and ability to withstand heavy loads.

Design and production of well rings

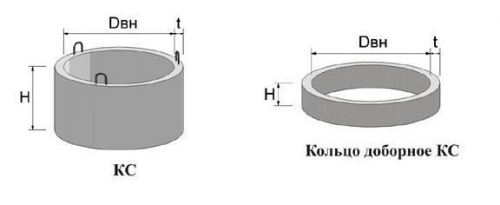

Classic rings have the shape of a cylinder, but there are rectangular options. It is worth noting that the rings can be with and without a castle. Ordinary rings are endowed with a flat end. Polodeous rings with a lock are endowed with docking ends. According to experts, the density of the lock of the lock will be able to ensure better tightness and reliability of engineering systems.

The basic rings have standard sizes and are divided into a small, middle and large group. Small rings are endowed with an internal meter diameter, the thickness of the walls of 16 centimeters, 90 centimeters high and a weight of 600 kilograms. The internal diameter of the colodeous ring of the middle group is 1.5 meters. They weigh one ton, and have the same height. Large rings weigh one and a half tons, and their inner diameter is 2 meters.

In addition to standard wall rings, wall dates are produced, which differ in height and are used to build part of the well, which protrudes above the ground. Such dates differ in a lower height, in comparison with the standard option. The mandatory element of the design of the well are covers and bottoms that are included in the set of the listed groups and have the corresponding diameter.

Each year, the production of reinforced concrete rings is improved due to the introduction of new technologies. When laying metal reinforcement, laser cutting began to be used. All innovations make it possible to produce high -quality and reliable products. In connection with the simplification of manufacturing, the final cost of well rings began to decrease.

In the manufacture of well rings, special forms are used. The dimensions of the external inner diameter are determined using formwork. A reinforcing grid frame or wire is placed into the space of these sizes and a solution is poured. To better compact shape, it is usually subjected to vibrational effects that compress concrete. As a result, the product is very strong, can withstand heavy loads and effectively fulfills its purpose.

In the manufacture of well rings, special brackets can be installed, which are called chassis. Industrial reinforced concrete rings often have special folding locks (look like ledges in the lower part of the rings and rooms for them in the upper part). Thanks to this structural feature, you can carry out reliable and dense fixation of the barrel of the well in order to avoid the displacement of its rings.

Do -it -yourself well rings

Now the time has come to consider the phased technology of the construction of well rings with your own hands. If you do everything gradually and carefully, the result will be appropriate.

Form for a well ring

There are many options for making the form, we will dwell on the proven. You need to choose two metal barrels that correspond to the size of the well ring. Squeezed fixation strips on their walls will not affect the manufacturing process. You can also use pipes or ducts of the desired diameter. You can collect formwork cylinders by connecting individual sheets with each other. A good result was noticed by the formwork made of plastic cylinders.

On the outer surface of a large barrel of the future shape, two longitudinal markings must be made. They will divide the barrel into two uniform parts vertically. Next, you need to use simple window or door awnings. At the markings, you need to place two canopies so that their wings are placed along the edges from the line, and the bending of the canopy along and over the marking. With the help of rivets or welding to the cylinder, awnings are attached. On the inside of the barrel, it is necessary to accurately copy the markings placed on the outside.

From the inside, the future form is cut in such a way as not to damage the fixed awnings from the outside. Here you can use the grinder and install the thinnest cut circle. On the one hand of the future shape, at the place of installation of the canopies, it is necessary to cut off the lower hats-fixers of the bending spindle in each canopy.

Please note that this is done only on one side. Cut spindles are pulled out, and the resulting form is revealed. When closing the form, the mobility and comparability of the parties should be developed. To ensure the closing of the shape of the shape, you can use cut spindles. You can also choose other spindles suitable in diameter, as in the photo of well rings.

Now you need to prepare the inside for the future form. To do this, use a metal barrel or a pre -prepared shape. Two springs should be applied from the inside. They should be located from each other at a distance of 1/3 of the length of the entire circumference of the barrel. Please note that the cylinder is not divided into the same parts in vertical, one part should be more wider than the other about double. On the inside, the canopies should be installed, as on the outer.

From the inside, the marking lines are copied. After that, the cylinder is neatly cut along these lines so as not to damage the internal canopies. In the canopies placed on one line, you need to cut the heads of spindles from the bend. After that, the spindles are removed, and the resulting form is developed. When closing it, the comparison of the parties is adjusted.

Please note that the assembled type of inner barrel should be about five to ten centimeters higher than the outer. The external form of the formwork is easy to close, open and fixed with spindles. The internal form should also be easily opened inside. When the ring is released, the first one should be removed.

The canopies are freed from removable spindles, a smaller part of the form is folded inward and easily pulled out of a fresh ring. The external form is also easily removed, but opening out. You can use this form more than once. Perhaps it will come in handy to your friends or relatives.

Materials for a well ring

For the standard production of well rings, you will need sand, cement, gravel, water, concrete mixer, lifting devices, a shape, a reinforced frame and a good construction site. To begin with, you must decide on the volume of the colodeless ring that you will do with your own hands. It is very important that the thickness of the ring is at least 7 centimeters.

In the manufacture of a concrete ring, the temperature should be from 8 degrees. In the heat, the evaporation of moisture should be slowed down, because with rapid drying, the product will not be able to acquire the desired strength. You can cover the product from direct sunlight and provide the necessary humidity.

As with all concrete work, the composition of the mixture is usually determined by the ratio of its components: sand, gravel and cement. The amount of cement serves as a unit of reference. It is advisable to use fresh and ripened cement, not lower than the M400 brand. The matured means cement, designed for at least thirty days after its manufacture. For the manufacture of well rings, the volume of water is very important - from 0.5 to 0.7 part of cement, sand - from 2 to 2.5, gravel - from 3 to 4. This ratio will provide concrete maximum density.

To prepare concrete, first you need to mix sand and cement, then add water and mix everything thoroughly again. After that, gravel is added to the resulting mixture, which is previously soaked in water. The finished shape should be installed on an even floor or metal pallet. Between the external and internal cylinder, the reinforcing mesh should be placed. If it is not there, you can use a wire two to six millimeters, which is gradually laid with turns with the addition of concrete composition.

The rings can be made without the use of reinforcement, but in this case their thickness should be at least fifteen centimeters. Such rings last a very long time. Between the cylinders, spacer wooden wedges are installed in a level above average in order to avoid the displacement of cylinders during the laying of the concrete composition.

Pouring the solution into a form

After prolonged mixing, the concrete is laid in a form for a well ring to a height of not more than 15-25 centimeters. After that, the solution is compacted throughout the diameter using a thick metal rod of 12-20 millimeters. This is necessary for high -quality compaction of the shape and strength of the entire product. You can use wooden tamping using a conventional shovel, tramp or a shovel handle. The space needs to be filled again, tamping the concrete mixture in a circle. When the level of complex concrete will be higher than average, wooden spacers can be removed.

You must fill the entire shape and redraw the protruding surface of the laid concrete well. It is desirable that this surface is flat, since it will be a dock. A vibration can be applied to a form -filled concrete solution, which will help to compact concrete as much as possible and fill all possible voids. If necessary, after this procedure, you can add a little more concrete mixture. But the vibration procedure is optional.

To ensure good tightness, special lids are used, which provide complete isolation and block the hit of foreign objects or liquids, as shown in the video about well rings. This approach is especially useful if the structure is in open space or not protected by a canopy.

After three or four days, the form can be disassembled. If humidity and temperature are optimal, you can free the ring from the shape the very next day. It cannot be moved and roll, since the mixture is not completely strengthened. If you want to get a sufficiently strong concrete, you should moisten the finished ring with water over the next 7 days. Poiled rings can be used after ten days of exposure, provided that the optimum temperature and good humidity.

The installation of well rings is carried out using lifting cranes, they are placed above each other according to the principle of the pyramid. So that these rings do not move relative to each other during installation, it is customary to fasten them in four places with the help of steel brackets or plates. Although to save your time, which takes the installation of a well, it is best to make well rings with a lock, but the material will be more spent more.

If you want the well to serve as long as possible, external waterproofing should be performed. For this, the rings are processed with a special solution. With impaired production technology and poor quality of the material, there is a risk of water poisoning with a well in which these products are laid.

Thus, well rings are used for installation in sewer, gas pipeline, water systems, viewing walls and wells. The scope of these products is quite extensive. If you want to make such a ring yourself, this is nothing complicated. At home, you need to have special equipment for the production of well rings and a spacious platform. It is necessary to strictly follow each stage of construction, as well as do everything neatly and slowly.