During the operation of window sills, there is a need to restore them ...

|

|

Personal water supply, a well or an equipped septic tank can not only take sewage ... |

If your house like a palace has spacious large rooms with ceilings a meter high ... |

Masonry of brick chimneys

Poster laying is made of different materials. Some are able to successfully withstand corrosion, condensation and soot deposits. Others make it possible to make a chimney of complex configuration. Nevertheless, as before, traditional brick chimneys that have proven their reliability and efficiency in hundreds of years of operation are highly popular.

- Features of brick chimneys

- Structural elements of a brick chimney

- Choosing material for laying a brick chimney

- Requirements for the installation of brick chimneys

- How to make a chimney from a brick from a stove: step -by -step instructions

- What to consider when laying a chimney made of brick for a boiler

- Typical errors when getting a chimney

Features of brick chimneys

Along with the mass construction of country houses, interest in fireplaces, stoves and boilers increased. To organize the outflow of combustion products, a brick chimney is most often erected. The diverting structure from this material is usually used for single heating and heating devices.

Bricks of differentotypic chimneys have gained wide popularity thanks to a number of advantages:

- Resistance to high temperatures. Shamot brick can withstand up to +1000C (the combustion temperature from the fireplace/furnace reaches +750C).

- High level of efficiency. During heating, the brick perfectly accumulates heat.

- Available cost cost.

- A brick chimney is suitable for different styles of the interior.

The negative qualities of a brick chimney include:

- The angularity of the structure leads to the formation of vortex flows that worsen the outflow of combustion products.

- The internal walls of the chimney have roughness, this contributes to the settlement of soot. In a contaminated chimney, the workspace decreases and the thrust weakens.

- Brick constructions are bulky and weigh a lot. For the construction of such a chimney, laying the foundation is necessary.

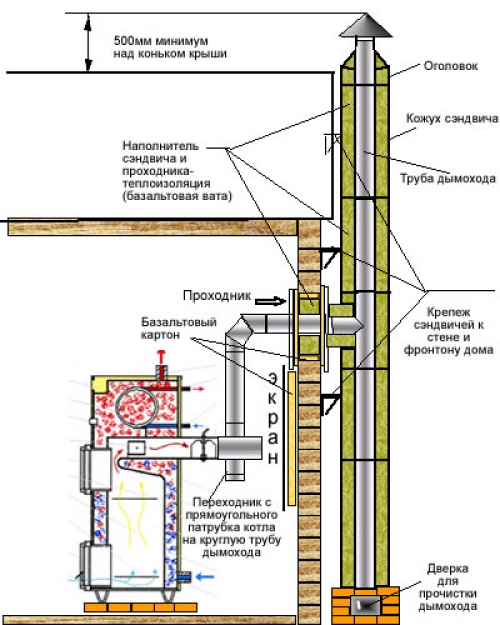

Structural elements of a brick chimney

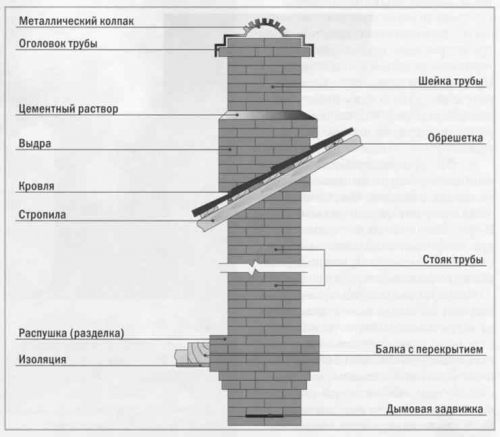

Consider the typical design of a brick chimney this will help to understand the main stages of construction.

Brick chimney: device diagram

- The neck of the furnace is part of the chimney going directly from the furnace to cutting. Here they install a smoke valve necessary for regulating traction, combustion intensity and fuel.

- The flush (pipe cutting) is equipped at the aisle of each ceiling. The purpose of this element of the chimney is protecting combustible floors from high temperature. The walls of the thrust is thicker compared to other elements of the chimneine canal. The thickness of this part is about 35-40 cm.

- The riser is an even part of the chimney located in the attic and reaching the roof.

- The otter is located on the roof and protects the design of the chimney from atmospheric precipitation and condensate.

- The neck of the pipe is right above the otter. By laying, this part of the chimney resembles a riser.

- The head of the pipe expansion above the neck. An umbrella or cap is installed on top of the protruding cap, which prevent the penetration inside of the smoke channel of pollution and precipitation. In addition, the installed flock increases the chimney's thrust.

Choosing material for laying a brick chimney

An important point in the construction of the chimney is the choice of brick. At different stages of the construction of a smoke -sized canal, different types of brick can be used:

- Red, full -bodied shmatic or ceramic brick well burned. The material has even edges and a clear rectangular shape. When tapping red brick, a characteristic metal sound is heard. This type of brick is recommended for laying any section of the chimney. The minimum brand indicator 200.

- Pink brick is unfinished. During a knock on such a brick, a dull sound is heard. Usually it is used for laying less important areas.

- Dark brown brick (burnt) optimal option for laying the chimney foundation.

- The size of the brick for the arrangement of the chimney is 25*12*6.5 cm.

Important! Porous, lightweight and hollow brick is prohibited for use in the construction of the chimney

The laying of different parts of the structure is marked by the use of a working solution excellent in composition:

- the chimney above the roof is laid out on a cement-sand mixture;

- the masonry under the roof is carried out by lime or cement-license solution.

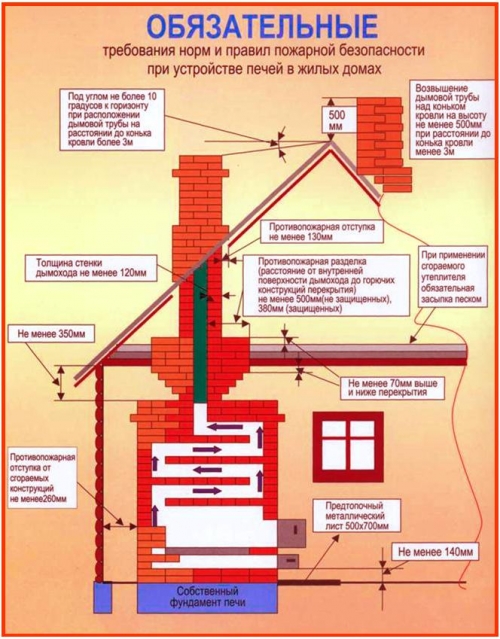

Requirements for the installation of brick chimneys

Safety in the house, comfort, fuel consumption and air purity largely depend on the accuracy of calculations of the chimney. The design of the chimney of the boiler, fireplace or furnace must meet the designated criteria:

- When laying the chimney channel, there should be no horizontal sections of the aisle of the exhaust gases. When it is impossible to avoid their formation of channels, provided that their total length does not exceed 100 cm.

- For a flat roof, the chimney above the roof should rise by at least 100 cm.

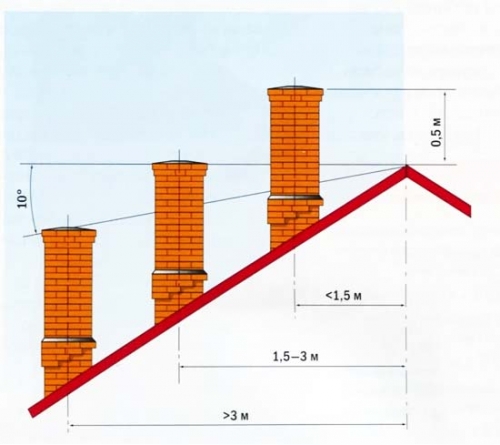

- The following standards apply to arrange a chimney on the pitched roof:

- if the distance from the ridge line to the pipe exit is less than 150 cm, then the height of the chimney should exceed the ridge structure by at least 50 cm;

- if the indicated distance is about 300 cm, then the chimney is installed at the same level with the skate;

- when the skate is removed from the pipe by at least 300 cm, the upper cut of the chimney should correspond to the line, conventionally drawn at an angle of 10 to the horizon of the ridge.

Additional requirements for chimneys in a brick house:

- The product must comply with fire safety requirements. Walls covered with flammable material should be from the outside of the masonry at a distance of at least 380 mm. In the floors between the floors, thickenings, the so -called edges should be equipped.

- The height of the pipe affects the traction. It is believed that the chimney should be at least 5 m.

- For residential premises, the thickness of the walls of the chimney is at least 100 mm.

- The area of \u200b\u200bthe internal section of the chimney should be constant along the entire length of the pipe.

- In one chimney, the introduction of more than two furnaces is unacceptable.

- It is permissible to arrange chimneys inside the external walls if they are made of non -alcohol materials. Additional condition for insulation of the wall from the side of the street. Such a measure will protect the chimney from the formation of condensate.

- For stoves on pellets, wood, briquettes, coals, etc. Details with a hole of 1.5*1.5 cm are installed.

Important! If the roof of the house is covered with combustible material (flexible tiles), then the mouth of the pipe is additionally equipped with a sparkle with a mesh cell of not more than 0.5*0.5 cm

How to make a chimney from a brick from a stove: step -by -step instructions

Determination of the shape and size of the chimney

In the stove/fireplace labor, the smoke moves spirally. Therefore, it is optimal if the internal section of the chimney is made in the form of a circle. But it is impossible to lay out a pipe of this form out of a brick. Therefore, the masonry of the chimney made of brick is performed in a rectangular shape.

It is advisable to treat the internal corners with the aligning mixture. For such work, it is better not to use plaster due to frequent temperature differences, the material can be quickly crumbled.

The size of the chimney is determined by the dimensions of the entire extension. On a small, compact house, too high and a wide chimney will look comical. For Russian furnaces, chimneys are erected with dimensions of 260*260 mm.

Advice. The economical consumption of brick is achieved when laying a pipe 260*130 mm. This design is possible when laying each row of five bricks

Necessary tools and materials

The following tools will be needed for work:

- chick hammer;

- a hammer with a rubber nozzle;

- roulette;

- level;

- bulgarian;

- trowel;

- buckets for water and working solution;

- electric drill with a mixer nozzle;

- sieve.

From the materials you need to prepare in advance: brick, clay and sand.

Breaking of a working solution

For a solution, clean clay, which was mined from a depth of 1.5 m, and river sand, is suitable for a solution. Before work, sift the clay and sand through a sieve with holes of not more than 5 mm. Two days before laying, clay must be soaked in water (about 48 hours) and mixed.

The procedure for preparing the solution:

- Combine the sand with clay in a ratio of 2: 1.

- Pour the resulting mixture with water in a ratio of 1: 4.

- Leave the solution for 12 hours.

- Mix thoroughly the mixture until a homogeneous consistency is unacceptable for the presence of lumps.

Bringing the lower part of the chimney

Before laying out a chimney from a brick, a nozzle pipe is equipped. It is built with mandatory compliance with brick dressings. The nozzle pipe is laid out directly above the fireplace or on the stove in the shape of a rectangle in size about 4-6 bricks. A smoke well is left inside the structure. The nozzle pipe ends, not reaching five to six rows to the ceiling.

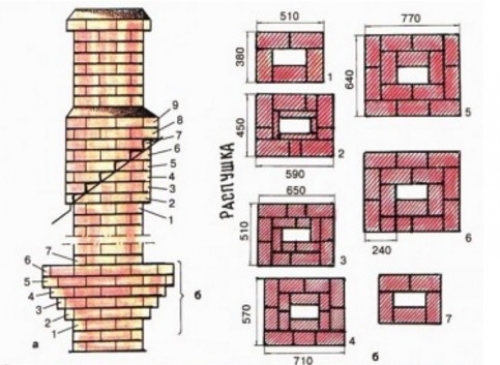

Arrangement of a fluff and chimney trunk

Subsequent masonry of a brick chimney with your own hands arranging the neck of a chopper. The height of the neck is five bricks, the smoke channel size is 140x270 mm.

The flush is laid out in compliance with a number of rules:

- The outer dimensions of this part of the chimney are 590x450 mm. When laying, halves and quarters of bricks are used.

- In inside, the smoke channel installed brick plates, they hold the shape of the chimney.

- The third row of a thrust increases, the plates are inserted in the thickness of 60 mm inward. Its dimensions are 650x510 mm.

- The dimensions of the next two rows are 710x570 mm. For the strength of the pipe, bricks 90-100 mm thick are inserted inside.

- The fifth row is laid out two whole bricks nearby.

- The sixth row repeats the masonry of the fifth, but in compliance with the dressing.

Previously, in the roof, you need to make a hole to output the chimney out. The riser is built in the attic and removed to the roof, observing the dressing of brickwork. The height of the riser on the roof is 1-2 bricks.

The output of the chimney over the roof

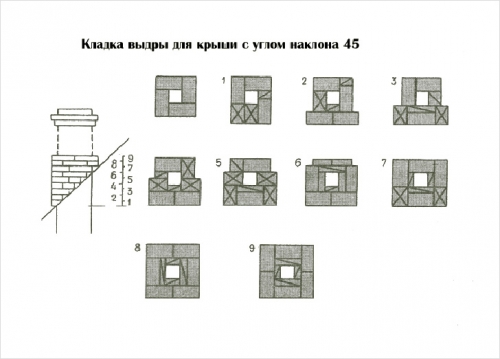

The next stage after masonry is the arrangement of otter. This pipe segment consists of nine rows, while the outer size of each subsequent should exceed the previous one in brick.

Important! At this stage of work, special attention must be paid to the internal size of the channel, he should neither narrow nor expand

In the third row, the width of the otter increases due to the bricks put forward by the front ledge on the sides. In the fourth sixth row there is an extension of the side protrusions. In the seventh row, the formation of lateral protrusions ends. The eighth and ninth rows complete the design and form all the protrusions of the pipes.

Next, the chimney neck is formed. The height of this element on average is five to eight rows. After masonry, the neck is equipped with a head of the same technology as a rally.

The finish stage of the chimney is installed a flouratic or cap.

Brick chimney: video

What to consider when laying a chimney made of brick for a boiler

When installing a chimney for the boiler, it is important to understand the features of the combustion process and the specifics of breeding products. It is necessary to take into account all the nuances of the chimney construction technology, so it is better to entrust this work to specialists. Errors in the design of the pipe and the use of the chimney valve can lead to carbon monoxide poisoning.

Basic moments:

- The best option is to arrange a separate room for placing a boiler. If there is no boiler room, then you can use a small corridor to bring the entrance to the house or basement.

- The room where the chimney is planned for a gas boiler should be able to ventilate and sufficient traction.

- The chimney and ventilation holes are made on one wall, this is necessary in order to avoid pressure drops and reverse traction arising due to gusts of wind.

- A slight leak of gas is possible when loading fuel, a cauldron of the boiler and the completion of the combustion process.

How to lay out a chimney for a brick boiler: video

Typical errors when getting a chimney

In the operation of the heating device, there may be malfunctions associated with the defects that were allowed when laying the chimney:

- The insufficient pipe height relative to the roof of the house affects the reduction of traction.

- The poor -quality solution used in laying is destroyed under the influence of various temperatures, the strength and tightness of the chimney worsen.

- The unevenness of the internal channel provokes the appearance of twisting on the walls of the soot/soot.

- The permissible deviation in vertical 30C on a piece of 2 m.