In houses made of brick, concrete or concrete blocks of ceilings are usually made of ...

|

|

Create a cozy and modern interior in your own house, while spending at all ... |

The problem of mold on the ceiling is quite relevant for many rooms, especially if in ... |

DIY I -beam

Recently, buildings erected using the method of frame technology are quite popular in the construction industry. A similar type of construction is considered relatively inexpensive and reduces the terms of construction by using individual frame elements made in the factory and delivered to the construction object already in finished form.

Being an indispensable assistant in the construction of buildings and structures for various purposes, the I-Taurus beam or double-bearer got its name for its specific profile in the form of 2 connected letters that is the T-shaped profile is called the TAVR, and the beam is considered to be impaired.

Content

- Wooden I -beams: characteristics and design features

- Classification of wooden I -beams

- Some tips for creating a floor covering using rally beams

- Metal breakfast beams: the scope of application and design features

- Classification of metallic double -barrel beams

- Manufacturing technology for an I -beam

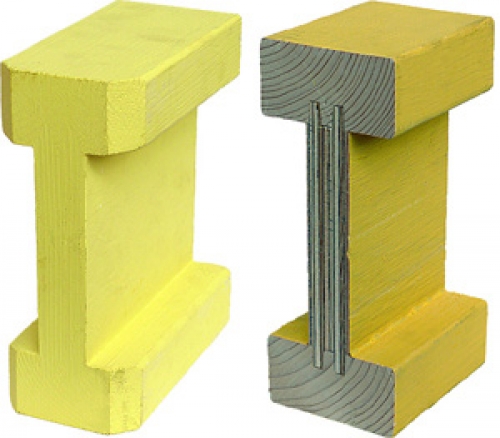

Wooden I -beams: characteristics and design features

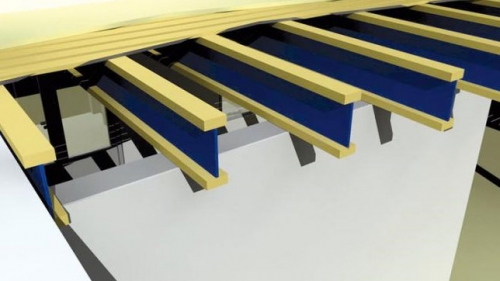

Wooden frame technology involves the use of prison beams from glued beams with increased characteristics to load -bearing loads. Thanks to the relatively low altitude of the section, you can more economically spend wood resources. The use of impaired beams, for example, for the manufacture of ceilings allows you to increase the load on the structure and significantly reduce the construction time. If you have to block spans of more than 5 m, then the best option will be the use of such double -barrel beams.

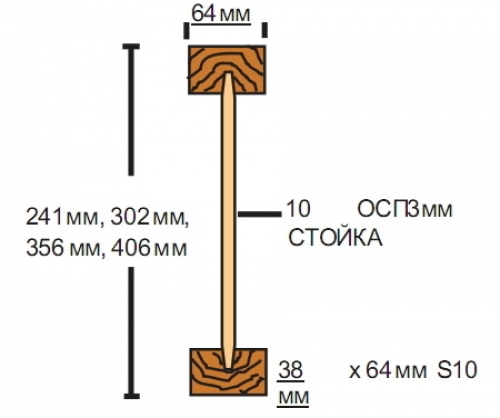

What is a double -barrel beam in the context? First of all, this is a workpiece from the OSB or plywood, acting as a stiffener, glued between the bars, in which the groove has been configured in advance. The height of the beam is determined by the value of the maximum load and can vary from 140 mm to 470 mm.

What else attracted to I -beams made of wood?

In addition to increased strength during operation, the double -barrel beams perfectly retain their original geometry and do not bend when the humidity changes, and their special structure allows installation even at conditions of negative temperatures.

Calibrated dry materials are used as the basis for the manufacture of beams. It should be noted that proper storage completely eliminates the occurrence of helicopters and sabers in the workpieces, so often found in the manufacture of floors or boards.

What is the advantage of beams from lumber?

First of all, the lack of cracking and twisting, which can be caused by the Line of Lomaterials due to the high content of moisture in them. In the future, this will lead to the appearance of irregularities and annoying violins. I-beams have an increased load capacity and can be installed on large enough areas without any possible defects: cracks, shrinkage, bends. The design of the beam allows you to easily cut holes for electrical wiring, gas and water, sewage and ventilation.

Compared to structures from traditional lumber, beams have the following advantages:

- the complete absence of bends and the exact dimensions of the I -beam;

- strength is the possibility of using beams in spans of large doors;

- noiselessness, the correct installation provides a complete absence of floating floors;

- the universality of the beam can be used in the designs of the floor, walls and ceiling;

- stability and wear resistance are not subject to shrinkage and deformation;

- the low cost of the I -beam and efficiency ensure significant savings in material resources;

- ease of production of a wooden impaired beam using ordinary carpentry tools;

- the presence of a guarantee for the entire service life;

- environmental Safety.

Classification of wooden I -beams

Experts distinguish 2 types of I -beams.

1. Grandma beams.

They act as an element of formwork ceilings and are designed to optimally distribute the load from concrete and reinforcement on racks. In this case, a laminated plywood deck is superimposed on top. The formwork beam can be made of birch plywood, lvl and coniferous wood, treated with a special waterproof composition, which protects the beam from negative influences of the external environment.

2. Balks of ceilings.

Using the impaired beams, you can facilitate the technology of manufacturing black floors, since the process of fading the skulls to the lags becomes excessive, and the correct forms greatly simplify the flooring for the further arrangement of finishing floors.

Today, the building materials market presents I -beam wooden beams up to 15 m long, while some companies provide the ability to manufacture the beams you need to order, thereby accelerating the assembly of ceilings at the construction site. When choosing a beast that is suitable in height, you will be able to lay the necessary thickness of the insulation.

So, summarizing the results, it should be noted that wooden I -beams, the price of which is very competitive, are considered modern and most effective building material, since in terms of technical and operational characteristics they largely surpass the ceilings from natural array, and in structural characteristics they can be put in one series with reinforced concrete and concrete floors.

Some tips for creating a floor covering using rally beams

To get high -quality floor covering, you should observe a large height of wooden beams with a lower deflection and higher stiffness of the floor covering. Using continuous locks in the ceilings and the ceilings, bypassing the mediating elements, you will minimize the level of vibration of the floor and improve the overall characteristics.

The following factors influence the quality of the floor when using the beams:

- the high height of the beam allows you to get high flooring and a lower deflection;

- the presence of a draft floor that is glued to the beams or nailed with nails, will provide you with a higher floor rigidity and reduce the likelihood of an unpleasant creak;

- the larger the height of the I -Toward Balka, the more optimal and at the same time economical the option of arranging the floor.

Following all the procedures: the correct calculation of the load, the correct installation, the selection of support and the rational use of fasteners, including gluing, you are guaranteed to get a high -quality half.

It should be noted that for the manufacture of I -beams with your own hands, you will have to use an ordinary carpentry tool. The relatively small weight of the I -beams and the specifics of the design allow us to conveniently and economically lay communications, and this will not affect the bearing capacity of the finished structure. Since the manufacture of beams is carried out in factory conditions on modern equipment, the quality of finished products is controlled by specialists and meets all technical standards and requirements.

YouTube video

The video clearly shows that the I -Taurus beam is an ideal option for creating a reliable and durable flooring.

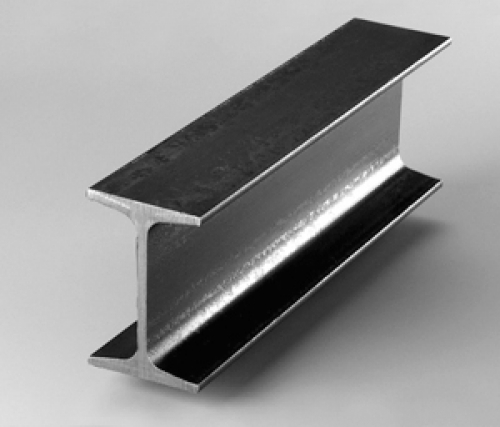

Metal breakfast beams: the scope of application and design features

The I -beam is a type of shaped rental in the form of a horizontal or inclined beam made of low -alloy or carbon steel of high quality.

The dimensions of the double -barrel beam are determined on the basis of numbers indicating the distance between the outer faces, which can be located under the slope (y) or parallel to each other (P). The values \u200b\u200bare represented in centimeters.

The scope of the metal breakfast beam is very extensive: the construction of residential buildings (for reinforcing elevators), industrial buildings and structures, the construction of bridges, columns, tunnels, mines, that is, in those places where it is necessary to resist increased loads. The widespread use of an I -beam allows you to reduce the weight of the load -bearing structures, which means to reduce the total cost of building an object. In the field of mechanical engineering, beams are used to develop and create complex and heavy equipment and machines.

From the point of view of engineering features, the beam successfully redistributes vertical and horizontal loads, working on bending, this process is successfully implemented due to the stiffness of the beam profile. Different varieties of steel and all kinds of alloys, in particular stainless ones, which are quite common in the construction of buildings in conditions favorable for corrosion, act as a material for the manufacture of a metal beam.

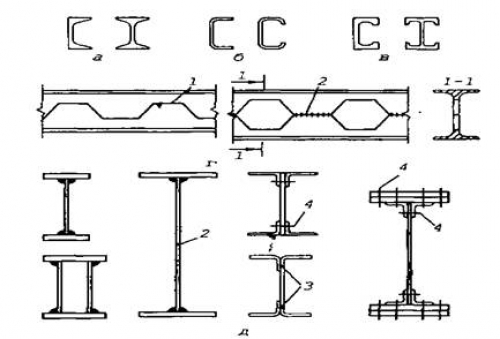

Classification of metallic double -barrel beams

The variety of I -beams represented in the metal structures market is huge: in addition to the variety of sizes, the beams are distinguished by designations and species. To recognize the beam, the following designations should be used: K1, K2, K3, K4, K5, B1, B2, B3, Sh1, Sh2, Sh3, Sh4.

The letter K indicates column beams that withstand huge loads. If the beam is intended for smaller loads, then it is better to use broad -shouldered structures marked by Litera Sh. To create supporting structures, such beams play the role of supporting guides. All products indicated above are distinguished by the presence of parallel shelves. The manufacturing technology of impaired beams is strictly regulated by GOST.

Beams with inclined shelves are divided into traditional (b) and special (M, C), which can be used to create suspended tracks and strengthen mine trunks. Marking beams B are made strictly in accordance with GOST 19425-74.

The weight of the beam can be found in a special table. For the convenience of the buyer, the weight of 1 meter of the beam is indicated.

The strength of the metal profile depends on the length of the beam, the shape of the transverse profile, the raw material base and the method of manufacturing this type of metal rolling.

The material of the manufacture of welded beams is a doped and low -alloy steel sheet. To obtain a rally beam, there may be a welded or hot -rolled manufacturing method. For high -quality welding of the beams, a flux layer is used through welding machines, which allows you to create metal structures of non -standard height and length.

Manufacturing technology for an I -beam

Structurally, the double as is consists of two belts and walls, which join each other with the help of corner and butt joints. The process of welding butt joints is a complex and responsible task, which is performed primarily when there is no consolidation in the sheets welded.

Then the design is assembled, according to the selected method of welding waist joints. Most often, it is carried out using one or two machines, when the vertical wall is located in a horizontal state. By combining all structural elements, stiffeners are attached to the beam.

To create a beam, a manual welding method can be used. This method radically changes the design sequence. For example, after installing a vertical wall on the lower belt, stiffeners should be fixed, and then install the upper weight and clamp the beam with clamps.

Conductors - canteers who will save you from the need to use the seizures, since in this case the elements are mounted using fixing equipment of quick action are greatly simplified. This assembly method allows you to organize serial and mass production of structures.

The welcome beam is most in demand, since it has undeniable advantages.

So, in comparison with the rental beam, its strength parameters are much higher, and the mass below by 30% is achieved due to the optimal calculation of the cross -section, which, however, affects the price of an I -beam - making it, of course, more expensive.

The I -beam with your own

DIY INTERABLE BALK ???

What are you smoking here?

Dear I WOULD Like to Get More

Dear

I WOULD Like to Get More Information ABOUT THE H-20 TIMBER Beam,

1. What King of Wood? (OAK, Pine, SPRUCE, Plywood).

2. What is the Maximum Load on the H-20?

3. What Finish at the end of the Timber Beam? (Plastic etc.)

4. What is the Additional Price for Plastic Cover Protection?

5. Please Reply Photo of the End and Crosscut!

6. What is the Delivery Time?

7. Please Reply Best Fob Price Quotation?

Quantity Required: 20,000 Meter,

15,000 - Meter 3.9 or 4.2 Meter.

5,000 - Meter 6.9 or 7 Meter.

Email: ksgloz@gmail.com

Best Regards

Sharon