It is well known that Russia has long been famous for the power of the traditions of wooden house building, ...

|

|

For a long time, experts have been practicing the use of ceramic tiles as ... |

How nice to walk barefoot on a warm wooden floor! But what to do if the floor is already ... |

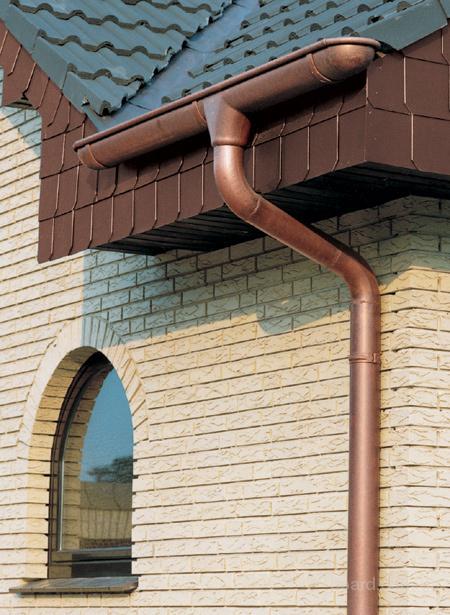

How to install a drain on the roof

The drainage system should be selected at the stage of designing the house. This will allow you to calculate all the nuances and correctly choose the desired design. Its main role is to protect the foundation of the house from the rain. Therefore, it is so important to correctly determine the material from which the drain is made. On average, the service life of the drainage system is from 5 to 100 years. But with improper installation, it can fail much faster. Consider how to properly install a drain for the roof with your own hands.

Content:

- Tasks of designing drains

- Components of the drainage system

- Materials for the drainage system

- Calculation of the required number of materials

- Installing gutters on the roof with your own hands

- Installation of a drainage system with rectangular gutters

- Homemade drain for the roof

Tasks of designing drains

In order to correctly calculate the right amount of materials for the drainage system, you should deal with the main points when designing the structure.

- First of all, the total area of \u200b\u200bthe future roof and each of its slopes separately are calculated. Thanks to the data obtained, the necessary throughput of the drain from the roof, the diameter of the drain pipes and the size of the gutter are determined.

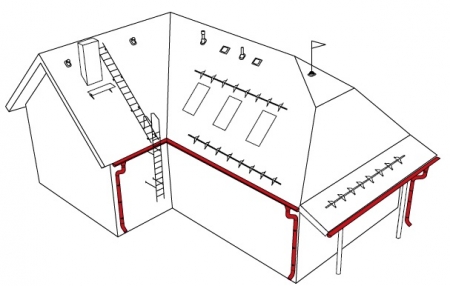

- The next step will be the preparation of the preliminary plan for the placement of the elements of the drain, which will determine the sequence of work, calculate the number of components and their approximate location. For greater convenience, this is done on a copy of the roof drawing.

- It is also important to choose the right material from which gutters for the roof are made. Due to a wide variety of options, making a choice is not so simple. To a greater extent, it depends on the general appearance of the house and the aesthetic representations of its owner. In terms of service life, inexpensive plastic drains are practically not inferior to metal. But they are unlikely to look harmonious with real tiles or copper roof.

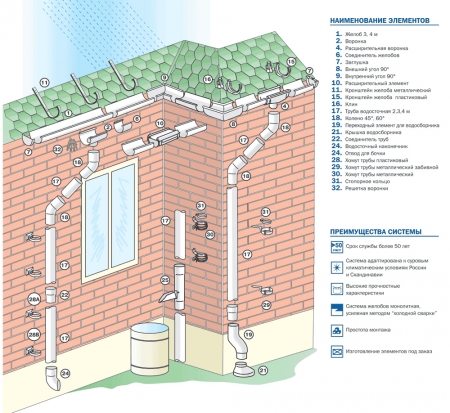

Components of the drainage system

Brackets

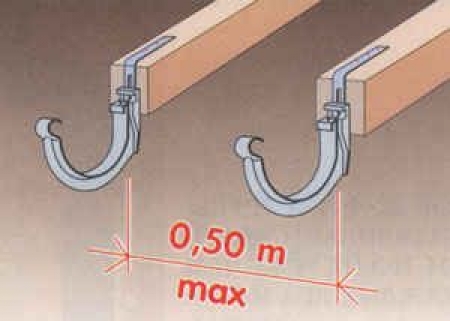

With their help, the gutter system is attached to the roof. They are produced by different forms and from different materials, but in color they completely coincide with the entire drain system.

Depending on the form, they can be attached in several ways:

- the simplest and most often used method of attaching the bracket to the winding board of the roof. Thus, the drain is easily installed on the already finished roof. Basically, such brackets are equipped with PVC systems. Thanks to a highly developed vertical ribs, they are able to withstand heavy loads. In structures made of metal brackets, for this type of fastening, are made short. In the absence of a frontal board, combined brackets are suitable. They have steel extension cords, with which they are attached directly to the rafter leg. When access to rafters is impossible, special metal crutches are mounted in the wall, and already on them, with the help of studs, the gutter is attached.

- In the second method, installation, the drain is mounted before laying roofing material. The gutter is attached to the rafter leg. This method is rational for roofs with a large area on which heavy roofing are used. For the reliability of fastening, the step between the rafters should not exceed 600 mm.

- The third option is optimal for the roof, where the distance between the rafters exceeds 600 mm. In most cases, it is a roof with a coating of metal tile or ondulin. This method involves the use of combined brackets or long hooks, which are attached to the first bar of the crate or on the lower edge of the flooring (if bitumen tiles are used). Only compliance with the rules and the procedure for installing hooks will ensure the reliability and durability of the design.

Distribution gutter

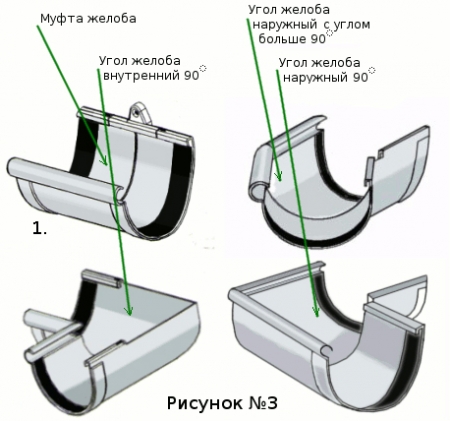

They are also produced by different forms. There is a round, semicircular, rectangular, oval or combined section. It is important that the gutter and hooks have the same shape and be from one system.

A symmetrical groove is considered universal, to which it will not be difficult to choose components of elements. This will simplify the work at the stage of design and calculation of the required number of components of the system.

In addition, they are distinguished by the method of connecting with the bracket. The most quickly assembled a system with a simple click. It is equipped with rotary latches, thanks to which it will be possible to easily dismantle a certain part of the gutter for repair or replacement.

When choosing them, one should take into account lineous vibrations of their size (especially when choosing PVC structures). For their compensation, couplings are available, on the inside of which there are notches.

Tip: a gutter made of PVC are not connected point blank - this can lead to cracks and breakdowns.

Despite the fact that the metal groove has much less thermal expansion, when installing it, the connecting coupling is also used as a compensator.

To protect the gutters from icing, they are insulated or installed a system of electric heaters.

Seals

They are made from ethylene-propylene-dive-monomer (EPDM) of rubber. This is a modern analogue of a rubber mixture for the tightness of the compounds. It has high elasticity, which allows you to restore the original form even after prolonged use.

It is moisture -resistant, not affected by environmental influences. Most often, the seals are covered with silicone lubricant, which makes the installation more simple and additionally protects the rubber.

Water collection funnels

As the name is clear, their function is collecting water flowing through the gutters, and its direction into the pipe of the drain. In PVC systems, they are made by a separate part. In addition, the funnels are divided into left, right and passing. The left and right have a wall that performs the function of the gutter plug and are installed at the end, and the passing ones are anywhere.

In the system of gutters from metal, it is permissible to put a funnel anywhere, but under it you will need to cut a round hole.

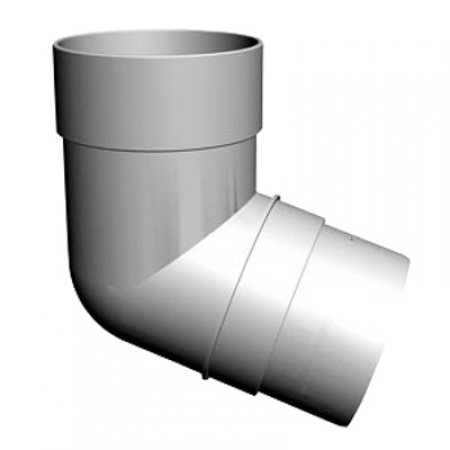

Knee

They look like a short bent pipe. They are used to combine drain pipes and funnels, as well as to drain water from the foundation. For each drain pipe, on average, three knees will be needed: two from above and one below.

Distribution pipes

They can have a rectangular or round section. This does not reflect on their functionality and depends only on the design of the facade of the house and the entire drain system. Their length varies from 1 to 4 meters. The main difference between PVC pipes and metal ones is that they have the same diameter along the entire length. So, for their attachment with each other, connecting couplings will be needed, which will lead to additional costs.

Clamps

With their help, the pipes are attached to the facade of the building. They are made from different materials and different shapes: plastic with two points of the support, metal with one long metiz, snap in the pipe or screwing elements.

Materials for the drainage system

The price of gutters for the roof depends primarily on the material from which they are made. Each of them has its own advantages and disadvantages. Consider in more detail about each form.

Plastic

This is a modern material that is distinguished by strength, lightness and ease of processing. Dyes that are used in its production remain in color saturation during the entire life of the declared by the manufacturer, and this is about 20-40 years. In addition, it has a low price.

Plastic drainage systems are made of several types of polymers:

- PVC - polyvinyl chloride;

- nPHV - non -plasticized polyhlorvinyl;

- PE polyethylene;

- PP - polypropylene.

They are resistant to mechanical damage and to ultraviolet radiation. Not subject to corrosion and will not require additional care.

Steel

Galled steel is most popular due to the low price and availability, but it has an ugly appearance and is short-lived. Much more practical drainage systems made of galvanized steel with a polymer coating. They are stronger than plastic structures, and thanks to the coating, durable. They are made of the same material as the metal tile. In most cases, they have either white or brown color, in other colors are painted only by an individual order.

Copper

The most expensive, but durable and beautiful material. The service life can reach the first centuries. To prevent the formation of electrolytic vapors that destroy copper, all components must be made of one material. Contact with titanium zinc or galvanized steel is especially dangerous for her. Over time, copper changes color to green, which does not affect its operational qualities.

Aluminum

Light and durable material that can be painted in any color. Its service life exceeds 50 years.

Zinc-Titan

This light alloy has a shiny surface. It is very durable and can be used in regions with extreme weather conditions. But in working with it you will need to observe a number of rules. Zinc-Titan should not contact PVC, vapor barrier membranes and roofing material. Work with it is prohibited at a metal temperature below +10C. This is a very expensive material, so all the work should be done by professionals.

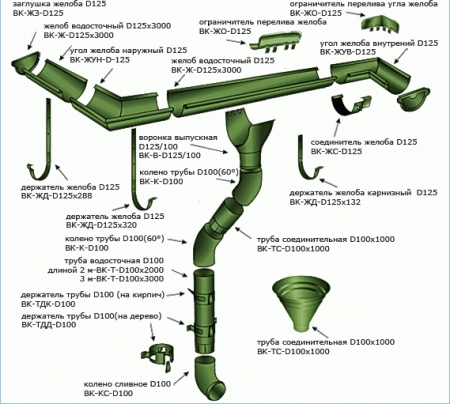

Calculation of the required number of materials

After the material has been selected, the calculation of the amount of necessary materials begins. Consultants in firms selling drainage systems or a roofing company that performs installation work can help you with this. But you can do it yourself.

First, the number of gutters is calculated. Their total length corresponds to the length of all the slopes of the roof from which water will be collected. Knowing the length of the slopes, it is easy to calculate the required number of drainage funnels. On average, one is installed for every 10 meters.

The number of gutters depends on the number of funnels. Their length is equal to the distance from the ground to the roof.

The number of turns is determined by the feature of the facade and is calculated individually. You can always buy the missing elements.

Classes and brackets are very simple to calculate. You will need one bracket for each meter of gutter. The number of clamps depends on the height of the building, the main rule each individual section of the pipe should be recorded at least one clamp.

Installing gutters on the roof with your own hands

To install metal gutters for the roof, the following tools will be needed:

- a hammer;

- marking cord;

- universal screwdriver;

- roulette from 3 meters long;

- pipe ticks;

- hooksgi;

- kryazuvka for metal.

It is not recommended to cut pipes and metal gutter. Since the polymer coating is heated during cutting, which will lead to damage to the elements of the drain.

Stages of installation:

- determination of the location of the brackets (gutters). The distance between them should be 40-50 cm;

- marks are made on brackets that determine the slope of the gutters of the drain, which is 5 mm per 1 m. It is worth noting that according to the instructions, one drain pipe can serve no more than 10 meters of gutter;

- brackets are bent at the finished marks. Do this the fastest with the help of hookhib. Then two extreme brackets are installed, and a lace is pulled between them, along which all other holders are installed;

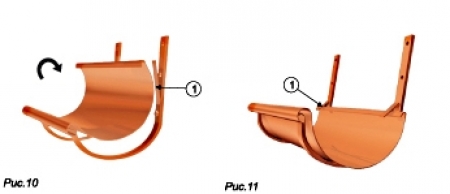

- preparation of the gutter for installation. From the component parts, the groove of the desired length is collected. It is possible that for this you will have to saw off the excess using a hacksaw for metal. But before its installation, the roof, parts are not fastened to each other. For a ruff of the drain, you need to cut a hole at a distance of 15 cm from the edge of the gutter along the shape of the letter V and a diameter of 10 cm;

- the exhaust funnel for the drain pipe is mounted. Its external edge is brought under the bent groove of the drainage system and tightly pressed. Then the flange petals of the funnel are bent;

- the gutter is installed. All components of the gutter on already finished brackets are laid alternately and attached. Further, the cornice bar is attached to the crate so that its lower edge falls into the gutter gutter. And the edge of the roofing waterproofing is started on top of the cornice of the bar. Thanks to this, all condensate, which can form in a burden, will fall into the drainage system;

- the connection of the gutters of the drain is overlapped with each other by 20-30 mm. Extra tightness of the joints is given by rubber seals;

- a protective grid for spills is installed, which protects it from garbage. It is mounted in the hole of the exhaust funnel in the gutter and is called the spider;

- installation of overflow limiter. They are necessary in the places of the gutter, which are located under fragments of roofs with adjacents;

- fasteners of connecting pipes. This design involves the connection of two knees of the drainage system with each other. The length of the connecting pipe is calculated individually;

- fastening of drainage pipes. Initially, holders (clamps) from below, from above and in places of pipe connection are mounted to the wall of the house. The distance between the drain knee and the blind area is about 30 cm.

Installation of a drainage system with rectangular gutters

Their installation is a more time -consuming process. To connect individual parts, rivets (fake) and sealant will be required.

System differences:

- the funnel of the spills is attached to the gutter with the help of rivets and sealant. The hole is cut cross -shaped or round.

- the plug, corners and gutters are also attached to rivets and sealant.

Homemade drain for the roof

For a small summer house, you can make budget spillles with your own hands. For example, making them from galvanized profiles for drywall without holes. They are of different sizes, so choosing a suitable one is quite simple. The profiles are folded by a box, and the excess is cut off for metal scissors.

Not only manufacturing, but also the mounting of the gutters to the roof will not take much time. Under the overhang of the roof, a mounted galvanized tape with a thickness of 2 mm with holes is attached. It is fixed on bolts, rivets or screws. Then, bending the fasteners, the necessary level of inclination is achieved.

As a result of a homemade germination device from the roof, it turns out to be an inconspicuous, but strong design.

Gutters for the roof photo