The car is not a luxury, but a means of transportation ...

|

|

To build a truly heat-efficient house, you need to take care of insulation not ... |

Whatever reliable operational qualities, building materials may have, ... |

How to make a crane in the kitchen

Ball valves gradually displace mixers with a linen mechanism. Given the growing popularity of the first, as well as their relatively low price and significantly greater reliability, ball valves will be an excellent solution for use in any conditions. But even despite the greater durability, they are also characterized by breakdowns. They arise primarily due to hard water and wear of mechanisms. If there is no desire to cause any leakage to cause plumbing, then you need to know how to remove the crane with your own hands.

Table of contents:

- What varieties of cranes are used

- What will be needed for work?

- How to disassemble a single -leaf mixer

- How to disassemble a mixer with two cranes

- Help in work: Useful tips

What varieties of cranes are used

Before starting work, it is necessary to study a little theory. As already noted, two types of cranes are mainly used: it is a single -leaf mixer and oilcopic mixers with two taps for cold and hot water.

In the one -seal, the intensity of the incoming water flow and its temperature is adjusted by turning and tilting the control handle. Compared to Salnikov, the one -legged has certain advantages:

- Separate temperature adjustment and water flow. For example, in a separate mixer, both taps will have to be adjusted for this. And each time again.

- The position of the handle allows you to expose and remember the ratio of hot and cold water, and at the next opening through the drain nose, water will go water.

In their classification, one -leaf mixers are divided into two types of devices:

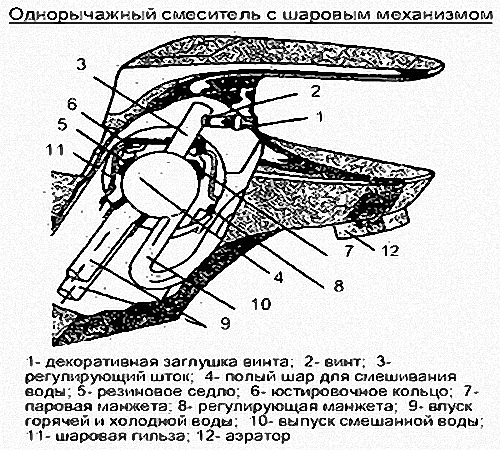

- Ball mixers have a ball with three holes in their design, with which the pressure and temperature of the incoming water is adjusted. The mechanism is quite simple and its only significant drawback is the inevitable friction of gaskets at the time of adjustment, which reduces smoothness. A similar design is characteristic of mixers of budget models.

- The ceramic mixer is equipped with a complex mechanism for adjusting the water supply. It contains several plates made of cermet. They fit tightly to each other, ensuring smoothness of the flow adjustment and general tightness. There is one danger for this design - despite the durability of ceramic plates, the ingress of solid particles with a stream of water can disrupt their tightness and the fitness of the fit to each other. To solve this problem, you need to install mechanical cleaning filters in the water supply system. For example, the manufacturer Honeywell offers available filters that allow you to protect water from the presence of particles of more than 50 microns in it, depending on the type of filter used. It is important to remember that for cold and hot water, filters different in their design use.

The mixer with two cranes is still the most popular type of plumbing equipment. Thanks to his design, he will remain a priority for a long time, despite his some of the shortcomings.

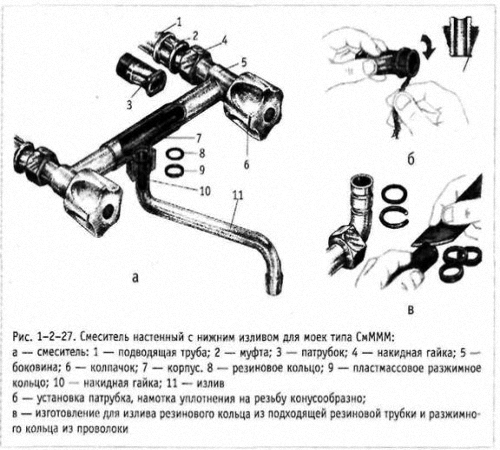

The mixer with two valves consists of the following parts:

- frame,

- pour nose,

- two taps-bokes,

- two valves.

Due to its simplicity, such mixers are easy to disassemble and replace the gaskets in the case of leaks. If more serious repairs are required, and there is no proper skills - it is better to call a specialist. Self -confidence is a useful quality, but you do not need to overestimate your strength.

What will be needed for work?

If the crane gave a leak, or it is required to remove it, then you need to know how to disassemble the mixer and what tool will be required to dismantle it.

For work you will need the following tool:

- flat screwdriver,

- steam key,

- gas key,

- lubrication for seals,

- pliers,

- fabric for wiping the elements and neat removal of parts with a chrome coating applied.

Before starting work, it is necessary to block the flow of water into the water supply in order to avoid leaks and fountain when dismantling the mixer. If the water continues to flow even on the blocked valves, then you will have to urgently call a plumbing that can eliminate the problem. In the event that there are no problems, we proceed to work.

How to disassemble a single -leaf mixer

After the flow of water was blocked using valves in the tap system, then begin to dismantle and repair the cranes.

The entire stage of work is conditionally divided into such steps:

- with the help of a mesture key, the screw is weakened, with which the control handle-knuckle is fixed,

- the handle is taken out

- using the application of a small mechanical force on the excavation of the rings with a thread, it turns off the clockwise,

- at the same time, the ball valve itself should be held firmly to avoid its turning. Otherwise, damage to the water hoses in the places of their connection to the mixer is practically inevitable,

- with the help of the tool, the dome is removed. Work must be done with due thoroughness so as not to damage or shift the position of the gear ring that is located under the dome,

- after removing the dome, it makes sense to inspect it for the presence of rust.

Tip: if it is available, it is necessary to remove it from the surface of the dome using special cleaners. Such funds are sold in plumbing stores. If you want to use folk methods, often recommend the use of warmed vinegar, which perfectly cleans the spots of rust. To avoid discomfort, you need to use an undidestive apple 6%vinegar. It must be remembered that burned sugar and other additives should not be present in its composition.

To reduce the possibility of rust due to hard water, this method is advised: the chrome surface of the dome is wiped with fish oil and left to dry for a period of 1-2 weeks. After that, the procedure is repeated, applying the second layer of fat and again leaving the structure to dry for two weeks. Next, the surface is wiped with gasoline. The radical method, given that such actions will take a month, but judging by the reviews - the expectation of it is worth it.

- a ball is removed from the tap through which the flow of incoming water is adjusted. If traces of wear are found on its surface, then it makes sense to replace it,

- springs that serve for sealing is recommended to replace immediately, since they lose their rigidity,

- using a flat screwdriver, the old seals are removed and they replace them with new ones.

The specified video will give all the answers to how the ball crane is disassembled and dismantled.

This is the question of how to disassemble the ball mixer is resolved. The mechanism is removed, the necessary components were replaced immediately. After that, the mixer is carefully inspected for the need to replace it. Work on the installation of the new is carried out with due accuracy and in the reverse order.

How to disassemble a mixer with two cranes

Two -cavalized structures are also divided into two types:

- faucets with the locking mechanism of the crane.

- ceramic mixers with a ceramic plate.

The first type is characterized by a simplicity of design, in which an elastic gasket is inserted to prevent excessive friction. It is pressed to the base of the crane-bokes, and not to the thread and therefore remains longer in operation.

In the second type, polished ceramic plates are used for the locking mechanism, which fit tightly to each other. Due to this, greater tightness is achieved.

The scheme of disassembling the mixer with two taps is noticeably easier:

- with the help of a flat small screwdriver, or a clerical knife, colored decorative caps on the valves of the mixer push,

- the locking screws hidden under them are unscrewed with a screwdriver,

- applying a slight effort, they take out the hands with pressure control,

- then the overlays are removed,

- with the help of a wrench, the core is unscrewed,

- following this, it is taken out and the mixer is disassembled.

If you need to completely dismantle the mixer, then with blocked pipes using a gas or divorce key, the connecting nuts are unscrewed at the base and the mixer is removed.

Help in work: Useful tips

There are some tips capable of helping in the matter of how to remove the crane and make minor repairs:

- If the shut -off nuts are covered with a layer of rust or scale and are not amenable, no need to make a significant effort. This can lead to deformation and destruction of the mechanism. Experts recommend using the well-known WD-40 tool, which effectively removes rust and softens the scale. Thanks to this, after some time, shut -off guilts and nuts will turn without effort.

- Before installing a new mixer with two taps, you need to wind up a new insulation on threaded joints. This will prevent the design of the mixer from the formation of premature leaks. Previously, flax was used for such purposes, but now it is much easier and more convenient to use a special FUM tone. It is wound on the thread, in the same direction in which the nut will begin to wind up. The winding must be carried out, not reaching 2 mm before the start of the thread. If the nut is twisted and effort, then you need to remove the fum tone and reduce the number of wound turns.

- When dismantling the crane bouxes, it is advisable to replace sealing gaskets. More often, especially in budget models, gaskets made of ordinary rubber are used. It begins to lose its sealing properties at a temperature of +40C and at the same time crumbles. Therefore, it makes sense to replace these gaskets with similar ones from paronite. They are made by pressing the rubber mixture and adding asbestos and powder components. A similar material is characterized by the fact that when getting wet, it increases its volume, producing effective compaction. The second advantage is the use of hot water. The operating temperature range is from -50 to +400C, so there is no need to fear the deformation of a parony lining under the influence of temperature. The last convincing argument in the direction of its choice is the price that starts from $ 0.10 per laying/

- The nuts of the connecting elements do not need to be tightened too much. Since this leads to excessive load on the gaskets and their possible deformation.

- In the event that even the WD-40 tool is not able to help remove the mounting nut, you will have to resort to the help of the power tool. Using a grinder and a circle on metal, the nut must be carefully cut across and using pliers or a gas key to remove it from the thread. Next, the thread is carefully processed with the composition for removing rust and scale, before wrapping a fum tone and winding a new nut.

- When examining the parts of the ball mixer, it is worth paying special attention to the cartridge itself. More often, the leak and the problem are found in it, and then it makes no sense to change the whole mixer - if it is enough to replace the cartridge itself. It is dismantled easily, using a small screwdriver and a mesture key.

- In order not to damage the chromely spraying of parts when they are removed, you need to cover them with a thin fabric, and then proceed to dismantle them. Such a simple action will avoid possible deformations and protect the surface of parts from scratches.

- In budgetary models of mixers, light metal is often used, which is not characterized by its strength. Therefore, when dismantling and installing new elements, there is no need to use excessive power. This will lead to the deformation of the coating and the parts of the mixer themselves.