Despite the abundance of finishing materials, pasting the walls with wallpaper remains the most ...

|

|

The development of technology annually replenish the construction market with new materials with special ... |

Warming of the premises in the method of the wet facade is widely popular with ... |

How to choose the right gas concrete blocks

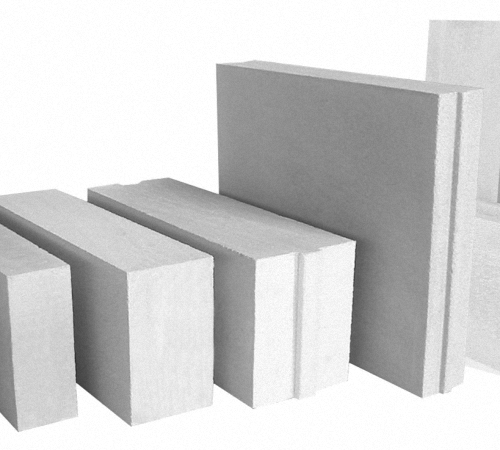

Aerated concrete blocks are quite popular, so it allows you to build buildings quickly, efficiently and without unnecessary costs. In addition, this material is easily processed, buildings from it do not create problems during the repair. At the sale points, a large assortment of these products is presented, in which it is difficult to navigate, if you do not know the main parameters of the blocks and the criteria for their choice. It demonstrates what aerated concrete blocks look like, a photo below.

Table of contents:

- What are aerated concrete blocks

- Advantages and disadvantages of aerated concrete blocks

- Types of aerated concrete blocks, technical characteristics

- The choice of aerated concrete blocks

- Ax concrete blocks, manufacturers

What are aerated concrete blocks

Gas concrete blocs are a mixture of cement, lime and sand, in fact, this is one of the varieties of cellular concrete. This is a material for buildings of artificial nature with porous inclusions, which is 85% filled with a shift or a gase. It is thanks to these parameters that the material has a low weight and low heat conductivity. In the manufacture of aerated concrete blocks, gas is formed as a result of the chemical interaction of the gas former. As such, the powder of aluminum or paste, which contains a solution of sand, water and astringent element, acts as such. Also, pores in aerated concrete blocks occur when mixed with foam or by foaming the solution that contains the foaming agent.

The cellular concrete is divided into varieties that occur when using different binders. There is concrete on Portland cement, on slag concrete, on a mixture of cement and lime, gas -mushroom concrete, foam concrete on a slag knitting, gas -sosseilite, and a foamylate for lime. There are also distinguished material for its intended purpose, there are heat-insulating blocks, structural-heat-insulating and structural blocks.

Aut -plate and non -circulative are different in the production method of production. Non -circular material is manually made. In the process of production of the material, technologies are not used, all measures are carried out manually by the mixture is made by shovels or manually made by a mechanism. For such aerated concrete blocks, the price is much lower than for autoclave, but their quality is not at the highest level. It is worth using such material in construction only if it is made independently, and not purchased from unknown manufacturers.

Autoclal foam concrete is made only in factories, using technologies and endurance of all quality standards. The autoclave name comes from the fact that during the production process the block enters the autoclave, where it is processed with steam under high temperature. The cost of such a block is higher than that of artisanal production, but it is justified, as it is high -precision material. High-precision blocks demonstrate the error in sizes of not more than 1-2 cm, in non-high-precision error it reaches 5 cm. The dimensions of not high-precision blocks are indicated conditionally, as a result, air is purchased, and saving on the price is reduced. In general, the quality of aerated concrete blocks is determined by the uniformity of the distribution, equality of volume and closed pores.

Advantages and disadvantages of aerated concrete blocks

1. The advantages of aerated concrete blocks:

- Ideal for the construction of low -rise housing in megacities, in small cities, town and villages;

- demonstrates a high indicator of the thermal protection of the structure, which allows you to reduce heating costs;

- recognized as the most modern and effective material for the construction of low -rise private buildings;

- Compared to brick and wood, it demonstrates low construction costs;

- All work with aerated concrete blocks is carried out in a short time;

- In thermal insulation, we compare with wooden materials;

- supports constant humidity in the structure;

- high fire safety indicator;

- The material endures low temperatures steadfastly, in this indicator it is equal or exceeds most of the brands of brick and heavy concrete;

- high sound insulation;

- The weight of aerated concrete blocks is less than that of complete material, which allows you to facilitate the entire structure of the house and reduce the cost of building the foundation;

- The lower wall thickness with the same thermal insulation properties, in comparison with other popular building materials.

2. The disadvantages of aerated concrete blocks:

- The material demonstrates low compression strength, this leads to the formation of cracks not by the masonry seam, but in the block itself. Cracks occur in a product with a thickness of 100 mm, this problem cannot be avoided even with the help of reinforcement;

- A high indicator of water absorption, which complicates the finishing work, when putting the putty blocks to the gas concrete blocks, it does not adhere to the surface, since all moisture absorbs the block from it. The problem is solved by applying a primer layer before finishing work;

- Aerated concrete blocks are quite fragile material, which creates problems when decorating metal columns to them;

- surfaces from aerated concrete blocks do not hold fasteners, it is necessary to use only anchor mounts and screws;

- Like all building materials, working with aerated concrete blocks requires certain skills.

Types of aerated concrete blocks, technical characteristics

1. The thermal conductivity of the material is determined by air in the pores, holds the temperature inside the structure. For cellular material, this indicator is from 0.075 W/(M*K) for brands of material with a density D350 and 0.25 BT/(M*K) for brand D700. To ensure the largest heat indicator in the structure, it is necessary to choose the lowest coefficient of thermal conductivity. The material with a high coefficient will require additional heaters. When choosing, the fact that when determining thermal conductivity, manufacturers experience material in different climate when determining thermal conductivity. Often, tests are carried out in laboratory conditions, the most close to real conditions is the calculated coefficient, which is inherent in blocks with constant indicator of high humidity.

2. The density of the material is calculated according to the standard formula, as the ratio of weight to volume. Standard density brands: D300, D350, D400, D500, D600, D700, D800, D900, D1000, D1100, D1200 kg/M3. The larger the number of the brand, the denser the material, the indicator of the insulation from the noise and conductivity of heat follows from the same. Also, a low density material is more fragile and demonstrates low resistance to damage. Of the advantages of a low density, a light cut and a small mass, even if the thickness of the aerated concrete block is large.

3. The strength of the blocks is directly dependent on the density. The strength of the block indicates the brand of compression of M with the number, which indicate the average compression of the compression in kgf/cm2. The strength class is indicated by the numbers and the letter B, the value is measured in the MPA. According to the standards of DCTU B.2.7-45-96, such classes BO, 35 (M5) are installed; BO, 5 (m7.5); BO, 75 (M10); B1 (M15); B1.5 (M25); B2 (M25); B2.5 (M35); B3.5 (m50); B5 (M75); B7.5 (M100); B10 (M150); B12.5 (M150); B15 (M200). These characteristics are a little outdated, since in the assortment of leading brands there are materials with higher indicators, for example, 350-400 kg/m3.

4. The fire resistance indicator of aerated concrete blocks is not a combustible material, according to the test results, it cannot be burned when exposed to open fire for 2 hours.

5. The ability to isolate noise is indicated by the air noise insulation index, which is measured in DB. The larger this figure, the higher the soundproofing indicator demonstrates aerated concrete blocks. The characteristics that also affect the indicator of the insulation of the noise of the partition from the blocks and their density.

6. The permeability of the steam shows the speed from which accumulated moisture and condensate from a heated structure are eliminated from the material.

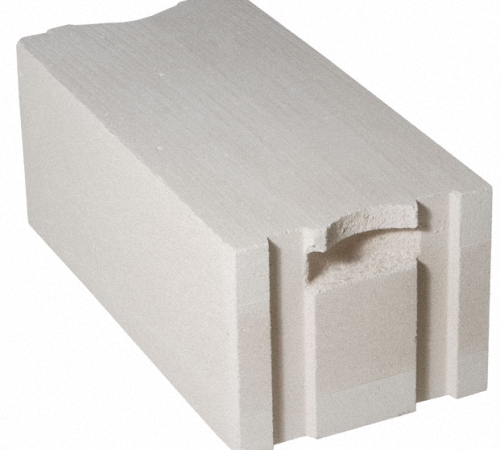

7. Another characteristic separating aerated concrete blocks sizes. Modern products are produced with a groove form of the ends, due to which the masonry is done without filling out vertical seams. Some manufacturers make captures for light carrying in blocks. Also, the masonry method and the material used for adhesion, glue or solution, are also dependent on the size.

The choice of aerated concrete blocks

1. When choosing aerated concrete blocks, it must be borne in mind that this material is not universal, a different type of material is selected to perform different works. For laying the load -bearing capital partitions, wall blocks are used, for internal partitions, regulations are used. It is not difficult to distinguish them, since the partition blocks have a thickness of not more than 200 mm.

2. The higher the density of the material, the higher its strength and the higher its indicator of thermal conductivity. That is, for blocks with the highest density indicator, it is necessary to provide additional thermal insulation. The most popular material is a brand with an average D500 density, it is rational to use the D300 brand for partitions.

3. When choosing blocks, attention is paid to their size in order to conduct accurate calculations, it is necessary their number. The presence of a groove and a ridge is everyone’s personal choice, this indicator facilitates the masonry and allows you to save glue at the end, but the cost of blocks with these additions is slightly higher.

4. As for the brands, mainly aerated concrete blocks from any manufacturer have the same indicators and quality, since the production uses approximately the same equipment. Often a slightly high price is a consequence of the cost of the brand itself. It is necessary to pay attention to the location of the plant, since the costs of logistics are also laid in the price.

5. In the calculations of the necessary materials, it should be taken into account that the glue consumption declared by the manufacturer is often underestimated and the material when performing the work will go more. Real consumption depends on the quality of the material, its size, as well as the qualifications of the masonry of a person.

6. At the GOST, no more than 5% of chips on the blocks are allowed, but this figure is acceptable only for the material of the first grade. For the second grade, this indicator is 10%, if masonry is planned with subsequent facing work, then the purchase of such material is quite acceptable. In some cases, up to 20% of the total cost is saved on such a purchase.

7. The size must be selected based on what kind of adhesive base the block will be laid. For masonry, dry material with deviations in height, length and thickness is not more than 1.5 mm is selected, deviation from a form of not more than 2 mm, the detachment of corners and ribs is not deeper than 5 mm. For masonry to glue, the deviation in the size should not exceed 2 mm, in the form of 3 mm, the depth of chips of not more than 5 mm. For the solution, these indicators are 3, 2 and 10 mm, respectively.

Ax concrete blocks, manufacturers

1. Ytong gas concrete blocks:

- Coem of warm -up 0.088 0.11 BT/MOC;

- installation on an adhesive solution with a thickness of not more than 2 mm;

- Plesses D400, D500, D600;

- Concrete class B2.5, B3.5, B5.0;

- Prochler of the Propertulation for burning 3.4, 4.8, 6.8 MPA;

- frost resistance cycles 100;

- vapor permeability 4 hours;

- Deformation and mustache when drying from 0.45 to 0.45 mm/m;

- Deviation in geometry from 0.3 to 0.8 mm, depending on the brand.

2. Blocks of aerated concrete grace:

- CEOLECTION OF NEWNLICTION 0.1 0.17 BT/MOC;

- Condition when dried 0.15 0.46 mm/m;

- CLASS B2.5 B 3.5;

- Morot resistance F50;

- Plesses D400, D500, D600;

- vapor permeability 0.16 0.24 mg/m*h*PA;

- Frost resistance is not f50.

3. Ax concrete blocks Yu-ton:

- B400, B500, B600;

- KLASS PRIPERY B1.0-B3.5;

- Morosis resistance F25-F35;

- Thermal conductivity indicator 0.08-0.14 BT/MOC;

4. Aeroc aerated concrete blocks:

- Class Pless D400, D500;

- strength class b2.5;

- frost resistance F100;

- Thermal conductivity 0.10-0.12 BT/MOC.

5. HEARTIC BOCES HETOTEN:

- Class Pless D400, D500;

- thermal conductivity 0.10-0.12 BT/MOC;

- frost resistance F35;

- strength class 25-35 kg/cm3.