To protect the site, polycarbonate fences are increasingly used. Build such a ...

|

|

The front door is a remedy that separates the personal space inside the house from the external ... |

A lot of requirements are presented to modern flooring, among them are such ... |

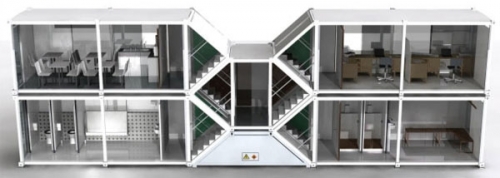

How to build a house from sea containers with your own hands

If you want to quickly and with the least costs to solve the housing issue, we recommend that you think about building a house from sea containers. A few decades ago, no one could imagine that the marine container can be used as temporary or even permanent housing, but the technology does not stand still, and today, in the light of lightning growth of housing prices, the use of a naval container for the house no longer seems unnatural . Despite the fact that in Russia, due to the insufficient distribution of container construction, you are unlikely to find ready -made projects of houses from containers, the demand for such houses abroad is not in doubt and is due to the reliability and practicality of buildings. According to experts, the low popularity of container construction in Russia is due to insufficient knowledge of the population about the advantages of buildings built using this technology, as well as the insufficient coverage of this issue on the network. To fix this, in this article, in a sense, we will try to contribute to the popularity of houses from sea containers in Russia and consider the issues of their construction and arrangement.

Content

- Residential buildings from containers: a new era in construction

- Advantages and disadvantages of houses from sea containers

- Houses from sea containers: projects, drawings, basics of construction

- Residential building from sea containers: Stages of construction

Residential buildings from containers: a new era in construction

Despite the fact that the popularity of container construction in Russia has not yet reached its peak, experts rightfully consider it the technology of the future, which will soon gain its loyal fans. Confirmation of this is the demand for container construction in Europe, where this technology has contributed to the emergence of a new independent and profitable business industry, the basis of which is the design and production of container house-houses. The semi-finished product means a base model made in a factory, the structure of which is the walls and black floors. It has already laid a heating system and electrical wiring, windows and doors are inserted. When purchasing the required number of blanks provided for by the project, they are delivered to the construction site, where they are combined into a single construction. The production of such blanks can significantly reduce the term for the construction of container houses, which is their most important advantage.

Advantages and disadvantages of houses from sea containers

Advantages of houses from sea containers:

- Houses from marine containers are recognized as one of the seismically stable buildings themselves, and therefore, they are often erected in areas where the natural cataclysms of earthquakes, hurricanes and others are not uncommon;

- Container buildings are not much different from capital houses: from the outside they can be finished with lining, from the inside with drywall;

- If you live in a house for the construction of which sea containers were used, you may not be afraid of the penetration of rodents and insects;

- Houses from sea containers can be built in any climatic conditions, but, despite such universality, it is important to remember the need for high -quality thermal insulation;

- The total cost of building from sea containers is several times lower than the cost of capital houses;

- If you decide to build a house from sea containers, remember that they are advantageously combined with various construction modules, including brick, reinforced concrete, etc.;

- The construction of residential buildings from marine containers takes no more than two to three months, and if you minimize finishing and limit yourself to simple decoration, two to three weeks will be enough to complete the construction activities;

- In view of the small load that container buildings carry, they do not need the installation of a thorough foundation and can be installed even on carefully compacted land;

- Sea containers can be used not only for the construction of residential buildings, but also of household facilities. In addition, from them you can equip a household extension to an existing structure;

- The installation of container buildings on frozen soil is widely in demand, and therefore, often from sea containers, mainly those that are designed for marine transportation, practice the construction of entire housing bases in the Far North and Antarctica;

- If the project of your construction does not imply the creation of stained glasses on the entire wall, it will protect you from extraneous invasion;

- Buildings from sea containers can be successfully erected in territories with a large bias.

Disadvantages of houses from sea containers:

- Often, special paints and high toxic compounds are used to process walls and floor of marine containers that protect them from atmospheric influences. In this regard, before using such containers to build a house, take care of removing these compositions;

- In the summer, the house from sea containers heats up greatly, while it cools into the winter. Given this, take care of organizing an effective thermal insulation layer;

- In order to avoid the appearance of rust on the surface of the building, it is necessary to organize careful observation and care for it;

- One of the disadvantages characteristic of container buildings is low ceilings (if the floor and ceiling is insulated, the height of the latter will be about 2.35 m).

Houses from sea containers: projects, drawings, basics of construction

A house from sea containers is a constructive solution, which has become popular in Europe and America thanks to the famous architect Adam Kalkin. It was he who became the author of the first in the history of the container house, which became his creative experiment. For its construction, three marine containers were used. As it turned out, the acquisition of sea containers did not cause difficulties, and the financial side of the issue only pleased the author of this know-how. Over time, buildings from marine containers began to be used not only as residential buildings, but also of hotel complexes, restaurants and retail premises, and their high seismic stability and mobility made them especially in demand in territories with frequent natural cataclysms.

For the construction of a residential building, mainly standard 40-foot freight containers are used, which are characterized by the following internal dimensions:

- height - about 2.4 m;

- length 12 m;

- width 2.35 m.

If you can build a spacious extension or utility room from one 40-a foot container, as well as equip a storehouse or workshop, then from two or three construction blocks you can build a house, the area of \u200b\u200bwhich will be 60-120 square meters. meters. For example, two 40-foot containers installed opposite each other can be connected with stained glass windows and subsequently covered with a common roof.

Important! A distinctive feature of marine containers is high strength. Initially, sea containers are made in such a way that they can subsequently be installed on the marine deck on each other in an amount of 8-10 pieces. Given this feature, it can be assumed that sea containers can be used to build two- and three-story buildings. However, to increase the reliability of the structure, the containers must be fixed with welding.

Important! For the construction of residential buildings, you can use two, three or more sea containers. If more than two containers were used for the manufacture of the house, the space between spruce containers, remaining free, must be equipped with an additional room using maximum glazing.

The construction of houses from sea containers, the price of which is on average 30 % lower than capital buildings, begins with the development of the project and the purchase of construction blocks of cargo containers. In the public domain on the network you can find a large number of projects of houses from sea containers that amaze with their diversity. The most common projects suggest the use of two containers, which are installed nearby or at an angle to each other in the form of the letter G or T. is also allowed to install containers on each other.

Having shifted containers relative to each other, you will complicate the facade of your home, while making it more original. On the contrary, extending the containers, you will create an additional free space that can be used under a spacious living room with maximum glazing.

The next project of a container house consisting of two blocks, which are combined with a pitched roof. In one of the blocks, two bedrooms are planned, in the other a bathroom and a kitchen. In the free space between the blocks, the living room is equipped, in the zone of which the height of the ceilings will be larger due to the slopes of the roof.

Masters with experience in building container houses recommend entrusting specialists to create projects of houses from sea containers, in this case there will be no problems with the drawing, since they will work everything to the slightest details.

Residential building from sea containers: Stages of construction

If you have decided to build a house from sea containers yourself, without attracting a contracting organization, take into account that the construction will take more time, and also will not do without the involvement of special equipment and skills in working with welding. Before starting construction, it is necessary to purchase containers. For the construction of a full -fledged residential building, experts recommend purchasing at least two containers, which on average (taking into account delivery) will cost about 100 thousand rubles.

Important! After the containers are delivered to the construction site, they must be checked for radiation. No matter how strange it sounds, but it is in such containers that residual radiation often accumulates. As for the norm for the radiation background, for our latitudes, it is 35 micronstgen per hour.

The arrangement of the foundation

The first and one of the most important stages of construction from containers is the arrangement of the foundation. If you put the house directly on the ground, without the foundation, then the soil under the building will sag, and the building itself freezes. The choice of foundation design for a container house is carried out taking into account its size and characteristics of the area. If you plan to build a regular change house for pastime in the warm season, several foundation blocks can be used as the foundation. However, if we are talking about a two -story residential building created according to the author’s project, he needs preliminary preparation of the foundation. In most cases, it is recommended to give preference to a reinforced belt foundation.

To do this, pull out a pit, the dimensions and depth of which meet the requirements of the project. This will require a call of specialized technology of the excavator and trucks for the export of soil. As for the most preferred foundation designs, in most cases, experts recommend preference to tape foundation, but sometimes you can not do without piles. The latter is relevant for regions with weak swampy soil.

Given the large weight of container construction (especially when it comes to a two -story house from sea containers), often there is a need to prepare a reliable base, the function of which can only be performed by a monolithic foundation. To fill it, you will need cement of the brand 400, sand and water. To increase its service life, special hardeners and other additives are often added to the solution.

Concrete work, which is an integral stage in the construction of the foundation, can be simplified by ordering a ready -made concrete mixture. In this case, the preparation of the foundation will consist of the installation of the reinforcing frame in accordance with the drawings, the installation of formwork and fill the solution. Do not forget to compact concrete using special deep vibration tools.

Constructive stage installation of containers

You can start it only after the final maturation of concrete, which will take at least 22 days from the date of filling the foundation.

Important! During the ripening of concrete, perform anti -corrosion processing of containers. To do this, paint them with an iron and then lead suck. Only after that, cover them with paint, resistant to high temperatures.

After the final ripening of concrete and anti -corrosion processing of containers, proceed to the next stage of installing containers on the foundation. If we are talking about the construction of a house from a sea container of 40 feet, you can not do without involving special equipment, namely an autocrane. After you installed the modules, they must be tied and collapsed, fastening with the foundation and among yourself. Next, internal interior partitions are installed. The easiest way to install partitions from the drywall sheet, the installation of which is easy to carry out with your own hand. However, in practice, they are more often used by another technique. It implies the removal and circumcision of the profiled sheet from which the walls of the container are made, which will be inside the construction and are not provided for by the project. This is done immediately before installing them on the foundation. At this stage, it is also necessary to cut the doors and windows.

Important! If for the construction of a residential building, in addition to 40 feet, 20 foot containers are used, it is necessary to take into account the difference in their size. Combining containers with different sizes allows you to create a building with an unusual, author's design.

Roof installation: main stages

Stage 1. For the manufacture of the frame of the attic, a beam with a cross section of 10x10 cm can be used to attach the bars to the container, use screws, and to fasten them together plumbing bolts.

Stage 2.Having prepared the frame of the attic, install the rafters for the roof. The sizes of the rafters are selected in accordance with the project, so that later they do not have to be shuffled by each other. The connection of the rafters is carried out using self -tapping screws.

Stage 3. By installing the rafters, take up the installation of the crate, on top of which it is necessary to lay the sheets of galvanized steel. At the same time, it is important not to forget about the arrangement of vapor barrier, what can be carried out, guided by two options:

- Between steel sheets and a crate, you can lay a vapor barrier film;

- On the two side sides of the house, under the very roof, you can install three 40 centimeters with a diameter of 10 cm, which will ensure effective ventilation of the undercarbon space. The holes for installing pipes must be done in advance. Considering the fact that the operation of the attic occurs mainly in the summer, for the winter these pipes will not be closed.

Obviously, the first method is the simplest.

Important! When giving a steel roof, remember that during strong wind and rain it will be very noisy. In this regard, despite the fact that the steel roof is an economy option, experts recommend that it refuse and make a choice in favor of soft materials, for example, ondulin.

Warming a house from sea containers

Thermal insulation is an integral stage in the construction of any dwelling. During the construction of a house from sea containers, this is especially important, and since the metal from which the containers are made is a good conductor of sounds, it is important to provide not only heat, but also sound insulation. For insulation of a house from sea containers, the following materials can be used:

- Mineral wool;

- Polyurethane foam;

- Styrofoam.

The life of mineral wool does not exceed 10 years, after which it loses its original characteristics. Foam and polyurethane foam, unlike the previous material, are mounted very quickly due to its dense structure, and their operational period is an order of magnitude higher and amounts to about 20 years. They have not only heat, but also soundproofing functions, which is not characteristic of mineral wool. The fastening of any of the listed materials is carried out using special glue or plastic pins. If you prefer the pins, they must be screwed in advance into the walls of the container. A plastic film is laid on the materials from above.

Internal and external decoration of the house from sea containers

After you have done the insulation, on the surface of the building, make the installation of a crate of wood or metal, on which plywood or OSB sheets for subsequent decoration will subsequently be mounted.

For the exterior decoration of the structure, the following materials can be used:

- Siding;

- Block house;

- Decorative plaster;

- Natural or artificial stone;

- Plastic.

Plastic, block house and siding are attached to a wooden crate, previously protected by varnish. Decorative and natural stone on a primed surface using concrete or special adhesive substances. The plaster is applied to a flat surface with spatulas of various sizes.

The interior decoration practically does not differ from the external to the bars of the crate is mounted insulation, which is covered with sheets of plywood or OSB. In this case, the space between the sheets of plywood should be at least 1.5 cm. Subsequently, they are filled with mounting foam, which will prevent dust from entering the house.

Further, double -glazed windows are mounted in window openings, preferably two -chamber.

When producing interior decoration, plywood and OSB can be replaced with drywall, which can subsequently be lined with paint, plaster, wallpaper and other available materials.

When finishing the ceiling, it must be remembered that its height does not exceed 2, 4 meters, and, as a result, abandon multi -level ceiling structures. Experts recommend stopping on an ordinary ceiling finished with drywall, or install suspended ceilings.