If the floor of wood began to creak, there are rotten boards or some kind of ...

|

|

An integral stage in the development of a house project is the choice of a method of its outer ... |

Look with sadness at a sagging door with a jamming lock and shackled varnish? Planning ... |

TISE foundation: construction technology

Having settled the construction of your own home, one cannot ignore the characteristics of the soil at the building site. There is such a thing as the abuse of soil. It characterizes the ability of the soil to change volume at seasonal temperature changes. The indicators vary depending on the moisture content of the soil and the difference in temperatures. The construction of the usual pile-lental foundation in this situation is not entirely justified, since the risk that the supporting pillars will be pushed out. And the use of the foundation by TISE technology avoids such problems. The pillar with the expansion below is reliably strengthened in the ground, and the freezing earth will not be able to exert pressure on the necessary force on it so that it changes its position. This is far from its only advantage. The article will talk about how to make the FISE foundation with your own hands.

Content:

- The principle of choosing a foundation depending on the type of soil

- TISE foundation

- Pile foundation TISE

- The procedure for the construction of the foundation for TISE technology

The principle of choosing a foundation depending on the type of soil

The mocal -sized foundation (MZF) is the only available solution if the occurrence of groundwater passes too close, and the possibility of their discharge or construction of drainage is impossible due to various circumstances. Another problem appears with its construction: throughout the cold season, the power of frosty heaving will raise the foundation. And in the spring, after warming up the soil, the base will return to its place, but with minor shifts. This phenomenon is not considered particularly destructive for wood houses, but such displacements are strictly contraindicated in stone buildings.

- Given the above, fine -sized foundation to use well on sandy soils. And if you arrange it on soils prone to fluff, then only if the planned structure does not differ in large dimensions and weight. You can not do without reinforcing walls and the foundation itself.

- A universal foundation on TISE technology allows not to take into account the described soil features. The close occurrence of groundwater and a high degree of flowering in the winter will not affect the strength characteristics of the house erected on the foundation of this type.

TISE foundation

- Individual construction from any material requires a qualitative basis. Most existing species suggest significant cash expenses, while the budget is often completely not designed for them. Therefore, the main principles were the price (which is lower than analogues three to four times) and environmental safety. At the same time, efficiency did not affect comfort at all.

- The date of birth of the TISE strip foundation can be considered the 90s of the XX century. Then a drill was developed, which allows you to create a recess under the piles with the lower extension, and all costs during installation were minimized. The expansion at the base of the column significantly increases its bearing capacity and increases the resistance to the destructive force of freezing soil. Further development of the technology was marked by the fact that the developer proposed lifting the grillage connecting the piles at a distance of 10-15 cm from the ground. This made it possible to free him from the loads inevitably provided by swollen soil.

Its reliability allows you to build buildings on different types of soil:

- clay;

- loam;

- sandy soils;

- suite.

Only the presence of a swim in the site imposes a certain restriction in its use. It will not allow you to create a qualitative basis for laying piles.

The purpose of building does not play the role and purpose of: a house, a garage, a bath or a barn for the TISE universal foundation there are no obstacles in these parameters, as well as on the material used. You can build from brick, foam blocks, timber the same stability will be ensured in any case. This technology is ideal for low -rise private construction.

Pile foundation TISE

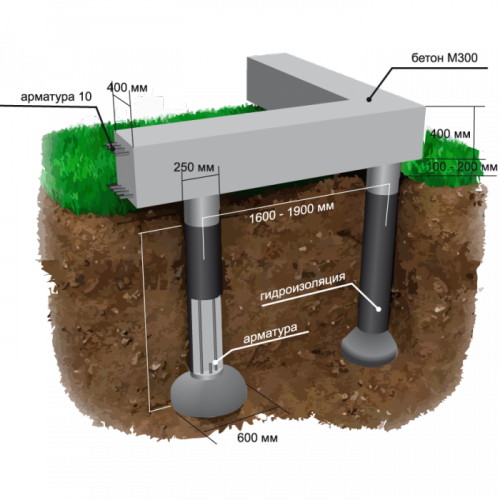

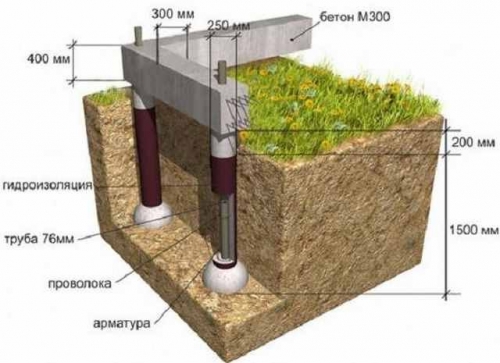

- The pile has one feature of the extension at the bottom equal to 60 cm. With the advent of a drill capable of performing the necessary deepening in the ground, the installation process has ceased to be considered complex and time -consuming. On the contrary, the speed of construction has become one of the advantages of the FISE foundation.

- It would be a mistake to call such piles in an innovative development. Pillars for the foundation, increasing along the radius in the supporting part, are known to the builders from the middle of the XXVIII century. Another thing is that the increase in the well from below was achieved not by the most convenient and safe ways from special nozzles to the use of explosive work.

Having made the necessary calculations of the FISE foundation, you can proceed to its installation.

Foundation TISE drilling technology

- The easiest way is the work in sandy soils. Clay and loam is tougher and harder to drill. But solid soil will not require significant expansion.

- Drilling occurs to the required depth, but the supporting part of the pile should be entirely located below the level of freezing. Certain difficulties can create a significant stone that came across in the way. Then the drill will not be able to pass it. In this case, you will have to eliminate the obstacle manually.

- When the level of groundwater is notable, the well done must be immediately poured with concrete to prevent collapse.

- The drill itself has a simple design, but it allows you to easily create a deepening of the necessary shape and depth. Elements of the mechanism:

- vertical stand with handles;

- folding knife with traction;

- the container for collecting soil and incisors located at the bottom for entering the soil.

- The operator begins the drilling process, which at the first stage does not differ from the usual one, and, upon reaching the desired level of depth, a knife leans back. Thanks to the thrust, he continues to choose the soil, which in turn gathers in the container and is easily extracted.

Among the common models of the drill, the TISE F300, F250 and F200 can be distinguished. The numbers after the letter designation show the diameter of the pit in mm.

How to reinforce correctly

Strengthenes will require both the columnar base itself and the grillage.

Giving durability to piles

- The appointment of this procedure to prevent the destruction of the expanded basis and the support itself in the process of freezing and swelling of the soil. For reinforcement, reinforcement with a diameter of 10 12 mm is taken, formed in the P-shaped rods. They are connected on top with wire.

- Before mounting the reinforcement, it is necessarily cleaned of pollution, manifestations of corrosion and paint (if any). This procedure is performed using a metal brush. It is needed so that the remnants of the old coating and dirt do not prevent the clutch of rods and solution.

- For reinforcement, any lengthy material of suitable diameter is suitable. The main condition is that it does not have a cavity. That is, the use of pipes is considered unacceptable, since the liquid accidentally caught in it during frost will cause cracking of the reinforcement, and then the destruction of the pillar.

- When the pile itself is strengthened, it is necessary to ensure that the reinforcing material passes in the center, and does not shift to the edges.

The principles of reinforcement of the grillage

- The diameter of the reinforcement used for this purpose is 10-14 mm. This is the case when no longer means better. The inappropriateness of using the thicker in the girth of the material is explained by the fact that it will be much worse in contact with concrete. You can calculate the number of rods depending on their diameter. The data are given in the table.

| Reinforcement diameter (mm) | Number of rods (pcs.) |

| 14 | 4 |

| 12 | 6 |

| 10 | 8 |

- The rod is cut in length so that it does not reach a couple of centimeters to the transverse sides of the formwork. When forming T-shaped compounds and when creating angles, the reinforcement elements do not require fastening. It is quite simple to build up the missing one in length: two pieces are simply overlapping.

Installation is as follows:

- waterproofing of formwork is performed;

- on an insulating layer with an interval of 1 or 1.5 meters, cakes from the solution are pounced. They should not be large, 5-6 cm will be enough;

- the lower layer of reinforcement is laid on the formed cakes;

- it is poured with concrete, a little not reaching the edge of the formwork;

- a second layer of reinforcement is laid on the solution;

- pouring ends to the very top.

Pile concreting

Some difficulties will arise if the level of groundwater is quite high. As already mentioned, such a feature will require filling the solution immediately after work on drilling. In the case when it was not possible to do this quickly, or the water managed to fill the well, it will have to be pumped out by the pump or scoop up.

The fill will take place in stages:

- expansion is reinforced;

- a wide element of the pile is poured;

- the column itself is strengthened;

- a shirt from roofing material is installed;

- final concreting pile.

Installation of TISE grillage

The final stage in creating the foundation using TISE technology is a grillage. Its installation is started after the final hardening of the piles (after about 3 days). Its height for houses made of wood or shield buildings is 20 cm, for a brick 40 cm. The width in any case is calculated according to the thickness of the walls. The need to rise the grillage has already been mentioned above. There are no constructive differences between him and the usual dug option. The difference is only in the laying level. Such a suspended state provides the advantages of the foundation in the following indicators:

- savings on materials for waterproofing. You can do all the work by going around the usual price category with five or six rolls of roofing material facilities;

- the rise above the ground level will not allow the foundation to break through on soils prone to seasonal heaving;

- such a gap creates a perfectly ventilated space. A beautiful preventive agent against mold, damp and reproduction of fungi;

- the volume of earthwork is minimized.

If the structure is located on the site with a large bias, then the element will be a stepped look, and a small rise implies a grillage with a variable height.

Stages of work

- At first, the area between the piles is filled with soil, slag or sand to a level with concrete bases. The width of the embankment should correspond to the thickness of the foundation tape with a 200 mm allowance. Everything is thoroughly compacted. Ruberoid or polyethylene is laid on top.

- The formwork is performed using stakes and a trim. The material will be required a little more than when constructing formwork using another technology, but this condition cannot be considered a significant drawback.

- It is advisable to carry out the cementing procedure in the shortest possible time, no more than two days. It is preferable to still meet the filling in the day. A smooth base can be achieved if the formwork is relaxed. You can not perform work at negative temperatures.

- The formwork is removed on the 22 day after pouring and the embankment can be removed from under the grillage. The beam can be covered with a layer of liquid waterproofing. If in the future there are plans for the construction of walls using TISE technology, then the entire surface of the grillage is covered except that which will directly contact the wall.

The procedure for the construction of the foundation for TISE technology

All actions fit in ten main stages

- It will be necessary to mark the axis of the foundation.

- Design the location of the piles.

- Broke well.

- Lay waterproofing walls.

- Install prepared frames in wells according to technology.

- Pour the columns of the foundation.

- Outline the level of future grillage.

- Mount the formwork.

- Create a waterproofing layer of formwork walls.

- Perform reinforcement and filling the grillage.

The foundation of the TISE video

Individual construction, like any other, pursues the goals of saving funds without loss in quality. The foundation on TISE technology, meeting these requirements, also allows you to carefully treat natural resources, and a home craftsman with average construction skills can cope with it. The costs have already been minimized, so it is strictly not recommended to save on the quality of concrete or reinforcing material. The decent quality of raw materials will allow the foundation to serve more than one generation of residents of the house.

We think to order the foundation

We think to order a TISE foundation on this site. How to understand whether they use high -quality concrete and reinforcing materials?