No building material can boast of such wear resistance, strength and ...

|

|

Many different solutions are used to design the ceiling. Each option has how ... |

In any mixer, no matter how high -quality it is, sooner or later this is manifested ... |

DIY chimney: Subtleties of manufacture and installation

A country house cannot be represented without a fireplace or furnace, which means that a chimney will be on the roof. Famous for removing combustion products, a well -known since ancient times is a complex engineering structure. For the safe and successful functioning of the chimneys in the house, first of all, you need to responsibly design the pipe, correctly make a chimney with your own hands and further periodically check its work and clean it.

Table of contents:

- The design of the chimney

- Choosing material for chimney

- How to make a quality chimney

- Installation of the chimney

- Masonry of a brick chimney

- Cleaning the chimney

The design of the chimney

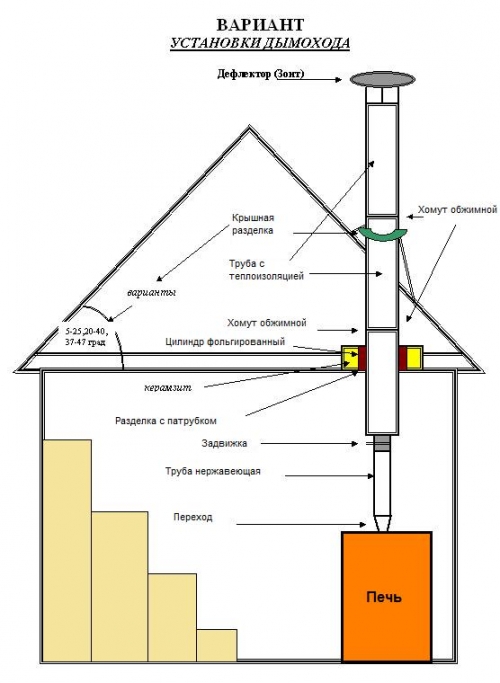

Chimmers are arranged in such a way that the combustion products from the room are effectively removed. The main part of the design is a direct vertical channel. The chimney begins directly from the boiler. After the vertical part of the pipe, the channel goes through the cutting and overlap, which leads to the attic, and then enters the lying, turning 90 degrees. It ends with the laying of another vertical pipe, which is located above the skate of the roof.

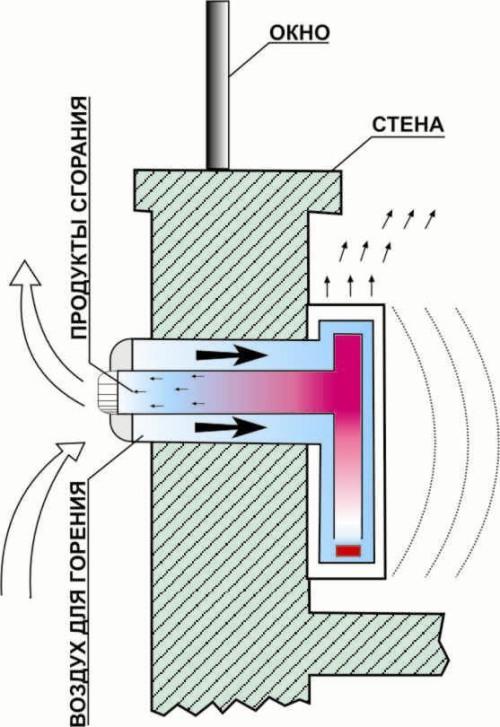

Due to the changes in temperature and pressure in the chimney, a constant movement of air is formed in the direction from the bottom up, which is called traction. The presence of traction is the main factor for the proper operation of the chimney. The chimney pipe should have good aerodynamic characteristics, so it is given an advantage to structures with a round section. In the pipes with smooth walls, smoke rises unhinderedly upward, without forming twists. To prevent condensate loss, it is customary to warm the external parts of the pipe.

Choosing material for chimney

When deciding which chimney to install, you will have to focus on the stove: you need to know the type of heating device, the temperature of the outgoing gases, location, and the coefficient of useful action. Discharging gases are very heated during the operation of devices that work on solid fuel, because the temperature of the smoke during its incomplete combustion can easily reach 600 degrees Celsius.

Since the brick can withstand such a high intensity, there were brick chimneys until recently. This type is also relevant today for house furnaces and classic varieties of masonry fireplaces. Also, temperature loads are well tolerated by ceramics, heat -resistant and enameled steel.

The new generation of heat generators with natural gas or liquid fuel has a high efficiency, which reaches 90%, due to the low temperature of the combustion product (less than 160 degrees). However, in this case, aggressive acid condensate appears on the walls of the chimney, which quickly destroys the material porous asbestos cement and brick. This process can be prevented using additional waterproofing. But it is easier to make a chimney made of chamoth, steel, polymeric materials, special varieties of glass and ceramics.

Smooth mirror surface and simple installation The main positive qualities of modern chimneys made of steel. The brilliant surface provides minimal friction of the outgoing gas against the wall of the chimney, and the collections that are included in the set of modular systems are removed outside the chimney. If the house has a brick mine, then inside it you can lay a steel channel.

High-tech style fans can install special reflective screens. The wall inside the room along which the chimney is located can be lined with patterned ceramic tiles. And the outer part of the pipe for the removal of smoke can be covered with galvanized iron, which is painted in any color you like.

How to make a quality chimney

A working, high -quality and reliable chimney is the key to the lack of smoke and good reverse traction, and also acts as an important element of the cottage comfort system. The same option for price/quality was recognized as a smoke car with a la Sandwich - a heat -insulated channel with an impressive service life, a slight indicator of soot deposits and a reduced level of condensate formation.

The calculation of the main characteristics of the diameter and traction chimney is carried out in compliance with the main requirement: the thrust should simultaneously increase with an increase in the height of the pipe. Otherwise, the effect of chimneys chopped smoke will arise in the form of a decrease in traction with an increase in the height and a large section of the pipe. Lastly, the appearance and harmonious proportions of the chimney with other elements of the roof skate, the pipe height, and ventilation ducts are considered. First of all, the effectiveness of the heating system and its functionality.

The design options for the removal of the smoke channel depend on the installation site of the boiler and the characteristics of the room. The internal chimney is customary to be installed inside the structure and carried out together with additional work: the device of support, segments and protective casing. It is not necessary to insulate the internal chimney. But no less than 60 centimeters before the ceiling, you need to arrange insulation of the sandwich type. According to construction standards, it is strictly forbidden to lay through the ceilings of non -insulated channels. Moreover, pipes that pass through non -heated attics must be insulated.

The external prefix smoke -breeding canal consists of a connecting gas sector, sections, audit and carrier wall bracket. For an external chimney, it is necessary to insulate pipes. A conventional cylinder is the most effective shape of the chimney that provides easy operation of the product. When choosing a chimney form, experts recommend choosing the simplest schemes, because intricate forms serve as the main reason for the clusters of a large number of soot. The height of the installed chimney channel should not be less than 5 meters.

When installing the chimney, it is necessary to provide that all the joints of the structures are placed below or higher than the inter -story jumpers and are open for a visual inspection. Before installing the chimney on their own, it is worth studying the fire norms and places of joints to isolate with non -combustible materials, as well as pay special attention to the place of exit to the sandwich roof.

Installation of the chimney

The process of installing chimneys is usually carried out in the direction from below -up, in other words - from the heating object. Pipe links must be collected in series: each subsequent segment is inserted into the previous link. A similar sequence of installation of the chimney with your own hands provides protection of the product from entering the insulation of moisture. In order to better protect the structure from moisture, it is recommended to use a special sealant, which has an operating temperature of about 1000 degrees.

All working joints in the heating system must be fixed using special clamps and along the lining line with a step of 1.5-2 meters of the bracket, which serve to fasten the structure to the elements of the structure. It is imperative to control the horizontally laid areas and exclude contact with various communications of gas pipes and electrical wiring, as well as limit the length of each section in one meter.

For the convenience of cleaning the chimney channel during operation, the door or the removable part should be installed in the lower part of the structure. Working channels must be installed along the internal partitions and walls, the structures should be made exclusively from non -combustible material. If it is impossible for technical reasons, installation is performed along the walls, you need to use nozzle chimneys.

High -quality insulation of the chimney is the key to the rapid heating of the premises and the formation of a small amount of condensate. Having pipes near a flammable finish, an additional fire protection is the isolation. Part of the chimney pipe overlooking the street should be protected from wind and fixed. Protection against garbage and atmospheric precipitation is provided by deflectors, weathercocks and nets. But such protection is not suitable in all cases. If a cap is a norm for a stove and a fireplace, then for gas equipment it is the strictest violation of the system safety.

Caring for the chimney made by personally made by the chimney is not too burdensome. For its organization, it is worth only several times a year (at the end and at the beginning of the heating period) to check the quality of the thrust in it, as well as the tightness of the seams and the integrity of the joints of its individual elements. When conducting such examinations, it is possible to clean the inner surface of the chimney from soot simultaneously.

Masonry of a brick chimney

The masonry of a brick chimney is considered a difficult work, so it is required to watch a video about a chimney with your own hands. But if the brick channel passes inside the wall, then special qualifications are not required for its organization. It is enough to leave an unknown shaft in a riveting brick wall, the cross -section of which is equal to the size of a lying brick.

The sides of the brick are approximately 25 by 12 centimeters. According to the construction standards, about 8 square centimeters of the section of the section of the chimney section should account for 1 kW of the power of the installed boiler. Counting the area of \u200b\u200bthe largest side of the standard brick, 300 square centimeters are obtained. You can connect boilers with a capacity of up to 38 kW to a smoke -shatting channel with a similar cross section, which are suitable for heating houses with an area of \u200b\u200bup to 350 square meters.

If you plan to separately lay out a brick structure, then you need to carefully approach its construction. The laying of the chimney in this case needs more accurate performance of the corners should be straight and the walls - even. If the chimney does not adjoin the wall, then it should be made strictly vertical. The channel that adjoins the wall should be attached to a vertical surface with anchors located every 4-5 rows. It is recommended to provide technological and revision holes in the laying, as well as arrange a hatch in the lower part of the shaft for the scoop of soot.

The walls of the chimney on the inside should be smooth. There are many recommendations for decorating the surface of the chimney of the smoke. One option offers to plaster the channel from the inside under the mittens. The channel cross section is closer to a round form, and irregularities are also smoothed out. Another option does not require coating, because with poor quality work, pieces of plaster showered into the canal and make it difficult to move the air. The outer part of the chimney is usually covered with facing bricks or decorated with roofing material.

Cleaning the chimney

The burning of any fuel is accompanied by the release of carbon compounds and carbon dioxide. When burning gas of combustion products, less, and when a large amount of solid fuel is burned. The substances that contain carbon are settled on the walls of the chimney in the form of soot, which should be periodically removed from the chimney.

They clean and repair the chimney with their own hands using chemical, mechanical and physical methods. For chemical processing, means are used, which contains substances corroding soot. The easiest way is the burning of aspen logs in the furnace or fireplace, the combustion temperature of which is about 1100 degrees Celsius. The soot burns at this temperature, but this method is dangerous, and it can be practiced if the smoke channel has no damage and is made of refractory materials.

If the chimney has not been cleaned for a long time, and on its walls the soot layer exceeds 3 millimeters, then preliminary mechanical cleaning should be done. For this purpose, a load on a rope with a ruff has long been used, which is thrown from above into a chimney. He pushes the cork down. If this manipulation did not bring results, then there is nothing else to disassemble that part of the chimney channel in which clogging formed.

Specialists produce professional cleaning using reagents and atomitors, after processing which the soot is separated from the walls of the chimney and crumbled into the furnace. The effect of such a procedure lasts for 3-4 months. You can also clean the chimney using a special vacuum cleaner, which sucks soot from the canal through the furnace. But this does not save with large deposits of ash.

Now you know what the perfect chimney should be from the standpoint of functionality, efficiency and safety. Follow carefully the instructions before making a chimney with your own hands, and the heating system of your home will work for more than a dozen years.