How to make repairs in the bedroom to observe the harmony of aesthetics and practicality? ...

|

|

Before starting the installation of a stretch ceiling with backlight, you must carefully ... |

Polymer -old tiles are a new building material, which is offered on ... |

Houses from a carriage: Features and construction technology

It is well known that Russia has long been famous for the power of the traditions of wooden housing construction, but this is not the only state where historically preference was given to wooden buildings. For example, the traditions of Norway, where its own technology for the construction of wooden houses from a double -circuit beam was invented are not inferior to Russian technologies, and even surpasses them in a number of parameters. This becomes particularly noticeable with a combination of a double -circuit beam, also called a carriage, and a special Norwegian castle - a special smooth angular wedge -shaped connection, which is compacted over time and preventing the penetration of wind and water. Thus, having carefully studied this technology, experts came to the conclusion that, with an increase in the shrinkage of the log house, the strength and reliability of the fastening increase. Initially, the carriage is considered not only a log, but also a special style of manual cutting, which in ancient times has developed in Scandinavia and still remains one of the most beloved in Norway, Finland and Sweden. Initially, the construction of houses from a carriage was developed as a means of reducing the cost of a log house without damage to the thickness of the log and, as a result, the warmth of the house. The solution was so simple and, at the same time, original that it was soon borrowed by neighboring countries, and then completely spread around the world. Its essence was that the pine log was cut off on both sides, and as a result of this, the cut was used to arrange the roof and floors. The purpose of this solution was to use the entire array in the process of operation and the rejection of additional materials, since the manufacture of a rafter structure and internal partitions was also carried out from the carriage. In this article, we will consider the main advantages and technology of building houses from the carriage of the most winning Norwegian alternative to traditional Russian buildings from a round log.

Content

- Houses from a carriage technology tested for centuries

- Carbon moisture levels: dry and humid carcass

- Chamber drying of the carriage: for and against

- Constructive features of boots from a carriage

- Advantages of wooden boots from a carriage

- How to build a house from a carriage: assembly features

Houses from a carriage technology tested for centuries

Everything new is well forgotten old, and the construction of wooden houses is no exception. Despite the fact that the history of this technology has more than one hundred years, this trend, forgotten for several hundred years, is on the verge of its second youth. Industrial development contributes to the fact that the construction of wooden houses uses many well -known technologies, including a profiled timber, and a gallant -based log and frame construction. However, none of them can be characterized as proven for centuries. As for technologies tested for centuries, one of them is the technology for building one -story boats from a carriage.

The carriage, also called a dual -packed beam, is a log processed by means of manual cutting so that it acquires a semi -oval shape in which two mutually parallel planes intersect. In other words, the technology for processing logs in this way involves obtaining logs cut on both sides so that it acquires two flat surfaces. For the manufacture of a carriage, cedar or pine logs are used.

Carbon moisture levels: dry and humid carcass

The technology for the construction of Norwegian houses implies the use of both wet and dry carriage, but the latter is the most optimal material. Houses erected from a dry carriage are characterized by reliability, high strength and lack of distant cracks, which allows you to build an environmentally friendly house that will maintain heat even on the coasts blown by cold winds, which was a familiar habitat for freedom -loving Vikings, choosing houses from a carriage. Despite the impressive thickness and weight of the carriage, it can easily succumb to drying in specialized drying chambers, where they acquire an optimal humidity indicator not exceeding 18-22 %.

A humid carriage, whose humidity indicator is 35-55%, can also be used for the construction of Norwegian houses from a carriage, but they should be subjected to long-term natural drying and shrinkage, which for some time pushes the timing of the commissioning. In most cases, these processes occur over one or two years. To surely convince you of the advisability of using a dry carriage, we will consider its main advantages.

Advantages of dry carriage:

- In the process of comparing the deadlines for the shrinkage of houses built from dry and wet carriages, experts came to the conclusion that the natural shrinkage of houses erected from a carriage characterized by increased humidity is carried out three times longer;

- If before the construction of the house the material used is dried in specialized drying chambers, the number of cracks appearing during operation is significantly minimized in it;

- Dry carriage wood, unlike wet material, is characterized by higher quality. This is due to the fact that in the process of heat treatment all potentially destructive microorganisms, including mold and bacteria, die. This significantly improves the quality of the material;

- To erect a carriage of a carriage of a carriage, it will take half as much time than when erecting a building from a wet carriage.

- As for the shortcomings of a dry carriage, its only minus is a high cost compared to moist material.

Houses from a carriage photo

Important!During the operation of the log house of the house from the carriage, the level of wood humidity is regulated. This parameter does not depend on weather conditions and reflects the processes of self -regulation and stabilization of humidity.

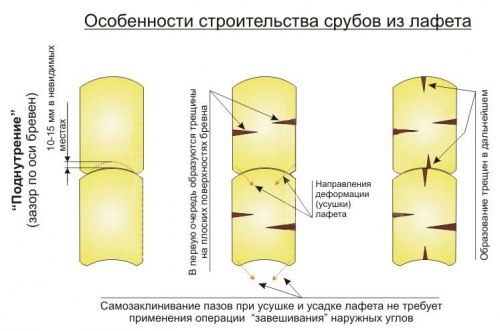

Houses made of chopped carriage are a classic version of the Scandinavian wooden construction. The carriage is a special material representing a log, which is characterized by the presence of so -called side surfaces, the so -called cheeks. Despite the fact that houses from the carriage retain all the advantages of a classic log house made of a round log, it will be almost flat on the outer and inside. This provides a more tight fit of the logs to each other and increases the thermal insulation characteristics of the building.

Chamber drying of the carriage: for and against

Forced drying is one of the main components of the woodworking industry. It is equally often used both for the board and for the beam, however, drying the round forest is much more complex (in most cases it applies to forest, the diameter of which is 28-30 cm). The most common option of chamber dryers are convection type designs, a significant drawback of which is considered deformation of the log and the appearance of cracks. Despite the fact that innovative forest drying technologies are continuously developed, such as drying drying, vacuum-pulse drying and others, it is still one of the most difficult tasks.

However, if we talk about the semibrus of a carriage used in the construction of houses using Norwegian technology, in this case the situation is different. Due to the fact that it is characterized by a smaller diameter, it is easily drying. At the same time, it is not at all necessary to dry it to furniture humidity not exceeding 8 %, as it is quite expensive and inappropriate. It will be quite enough to dry the carriage to 18-22 %. Upon reaching the specified level of moisture, the majority of connected and almost all free moisture are removed from wood. Despite the fact that the drying of the carriage is quite affordable, it is much more time -consuming than drying boards. This is due to the features of the material that do not allow the use of the hard drying mode, as this will lead to cracking of wood. When using a too soft mode, a different picture of the exit from the drying chamber will be observed by the moisture content of wood will remain at a high level. A feature of drying, which will lead to optimal humidity, is a short stay of the material in the drying chamber, which leads to drying the surface layers of wood, while the core remains wet. The use of wood of natural humidity is an integral condition for the technology of building houses from a carriage, since the drying of the material occurs directly in the log house.

Important! The ideal building material for the construction of houses using Norwegian technology is the northern forest that provides maximum thermal insulation characteristics of the structure. In Russia, Karelian and Arkhangelsk wood, as well as forest from other northern regions characterized by cold long -term winter, are considered such material. Wood from Finland is no less demand.

Projects of Norwegian houses from a carriage

Constructive features of boots from a carriage

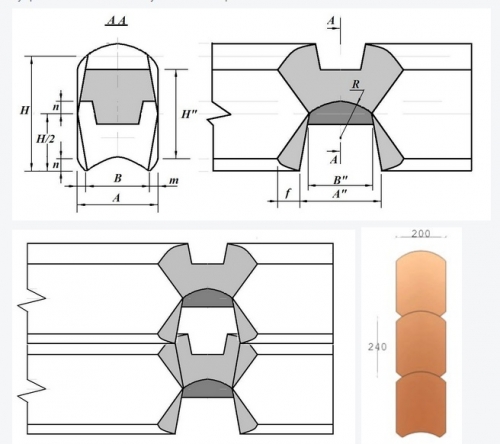

A distinctive feature of the Norwegian log house is a specific way to attach logs, which is called the Norwegian castle. The relatively small distribution of this technique is due to the fact that the technological features of this method are difficult to describe in words, as well as to learn this from books. In order for this compound to meet all the requirements for it, it is necessary to make a long and thorough fit of structural elements. What caused such a complication of cutting? According to experts, it pursues five main goals, the essence of which will be presented further.

Due to the fact that this method implies a larger number of cut angles, this indicates its high reliability;

- Between the two neighboring constructive elements, the contact area increases, and accordingly the friction force increases;

- This technique involves a beard of angle, which determines the effect of gravitational force on structural elements. This contributes to the distribution of the load inside the ligament, so it is enhanced and compacted. In this regard, we can draw conclusions about the direction of the load on the strengthening of the connection between the crowns;

- Due to the fact that this technology provides for the rejection of foreign mounting elements, there are no points of excessive voltage, which contributes to the uniform distribution of the load through a tree characterized by relative softness;

- This method of fastening is characterized by the presence of multiple conjunction and step drops contributes to blocking or at least a significant decrease in drafts.

After analyzing these data, we can conclude that such a multidisciplinary approach to the construction of houses by the Norwegian castle is quite explained by the operational characteristics of the structure, which can be built, skillfully combining the mind and technology.

Advantages of wooden boots from a carriage

High thermal insulation characteristics of the carriage determine its competitive relationship with glued beam. At the same time, despite the use of even imported material, it costs almost two times cheaper. In addition, the environmental characteristics of the structure erected from glued beams are largely inferior to Norwegian houses from the carriage. Consider the main advantages of one -story boat from the carriage, thanks to which they became popular in Russia.

- Thermal insulation characteristics One of the main advantages of Norwegian log cabins, the assembly technology of which involves reducing heat loss. This is due to the features of the material (using a round log with a diameter of 28 to 60 cm), which helps to reduce the number of crowns per unit height of the structure, the number of which does not exceed 8-12 for one floor. Moreover, in contrast to the traditional Russian log house, characterized by a decrease in the wall thickness at the joints of the logs, a uniform wall thickness is characteristic of the Norwegian log house, which is at least 20 cm.

Important! If we talk about the thermal insulation characteristics of the house with brick walls, its thermal conductivity is not able to argue with this indicator for the tree. For example, the thermal conductivity of the perforated brick is 0.63 W/ MK, while the thermal conductivity of the tree does not exceed 0.15 W/ MK. Thus, if you compare a brick house with a wall thickness equal to 1 meter, and the Norwegian log house, the wall thickness of which is 20-25 cm, they will be characterized by the same thermal conductivity;

- The presence of additional living spacewhich appears due to the covered part of logs, acquiring a flat surface. Moreover, an increase in the internal volume of the structure contributes to a small diameter of the carriage of not more than 20 cm. This favorably distinguishes the house from the carriage, the projects of which are presented in this article, from bulky log walls that steal a significant amount of living space. In this case, thermal protection, a 20-centimeter carriage is not inferior to a 30-centimeter log walls of a round log;

- Features of assembling houses from a carriage require thorough selection of building material, which undergoes multi -stage processing, combining the use of the most modern equipment and manual labor. If the side of the side surfaces of the logs is carried out on the sawmill, then it is stricted only by manually. This guarantees security maximum even and smooth wall surfaceswhich greatly simplifies and minimizes the interior decoration;

- A complex system of connecting the crowns provides the absolute inappropriateness of houses from the deformation carriage. Features of the Norwegian castle provide reliable fixation of logs in the nests, as a result of which they do not change their position. In addition, due to the uniqueness of the design of the Norwegian castle, the shrinkage of the structure and the shrink of wood contributes to the even greater self -reconnaissance of the crowbar crowns under the weight of its own weight. This system guarantees the absolute absence of cracks and 100 %thermal protection;

- Long -term operational period of the building It is provided by the design of the building. The roof and walls of the house from the carriage are a single whole, that is, the wall is a continuation of the roof, which is so dense that it allows you to reliably fasten the walls of the building;

- High aesthetic characteristics. The carriage is recognized as the ideal material for those who are a true connoisseur of the beauty and environmental friendliness of natural wood. Buildings from a carriage are characterized by an ideal appearance and are rightfully considered the pride of their owner. Due to the fact that Norwegian houses look solid and reliable, they are everywhere growing popularity among consumers. At the same time, the owner of the house from the carriage may not worry that the structure will lose its thermal insulation characteristics;

- Savings on construction and finishing materials Another advantage of the carriage houses. Unlike a log house, in order to build a reliable house from a carriage, you will need a smaller number of elements. Moreover, the design of the carriage allows you to abandon additional insulation and sound insulation, since they are obviously at a high level. The lack of the need for external and interior wall decoration with lining or block house, which also helps to reduce construction costs.

Important! One of the interesting varieties of a carriage of the carriage is the houses of a semi -laft of logs, which are stuck only on one side (the inner side of the building). The use of such material will not only facilitate the process of decoration of the house, but will also create the original interior of the dwelling. The appearance of the building from the outside will resemble a traditional log house, while the restrained inner surface of the logs will contribute to the expansion of useful living space, which makes such a structure twice as profitable.

How to build a house from a carriage: assembly features

Having familiarized yourself with the projects of Norwegian houses from the carriage and assessing the size of the construction budget, you can safely start the process of erecting a house. In the process of erecting such buildings, a northern pine is used accessible and relatively inexpensive building material. If the diameter of the barrel is 28-36 cm, then after processing the diameter of the finished material will be 21-22 cm.

Important!As for pre -processing, it includes the following stages:

- Manufacturing a carriage using specialized equipment;

- The sear of the log, followed by the application of the markings on it, which should be performed only by an experienced master, since the quality of the connection of logs and the subsequent operational characteristics of the building depends on its correctness.

Subsequent stages of work:

- After marking the log by a feature, which is performed by a carpenter using special tools, it is necessary to cut the lock of the Norwegian bowl. This stage of work is quite complex and subtle and should be carried out in the presence of a certain experience;

- Using the line, mark the longitudinal groove, which is selected using Tesla an ax characterized by a special shape;

- Next, grind the turtles, which is necessary in order to ensure the maximum density and smoothness of the joints;

- The final stage in the preparation of building material is processed by an antiseptic. For this, specialized compounds that have antiseptic characteristics are used and preventing wood and the appearance of mold spots on it.

- Having prepared the material, they begin the construction of the building. The basis of the structure is the foundation of the tape type, which is a monolithic concrete base. Before proceeding with the assembly of the house, a waterproofing layer is laid on the foundation that prevents damage to the lower crowns.

- After that, the building is assembled, which is carried out for a long time, as it requires the most strong fitting parts that guarantees the exact connection of the elements of the house. In the door and window openings, a groove is chosen, the width of which is 50 mm, which must be inserted into the guide beam, which is the basis for mounting window boxes and door blocks. This contributes to the preservation of doors and windows during the shrinkage of the log house after that they will fall into place, finally dry and will be tightly pressed to the logs, which guarantees the absence of cracks.

- In order to carry out the installation of the ceiling, wooden beams are used, characterized by the size of the section of 150x200 mm. To give the interior at home an original appearance, in most cases the ceiling is left open.

- As for the decoration of the Norwegian house from the carriage, it can be carried out using various stylistic solutions. In most cases, masters recommend giving preference to a classic version, which implies the processing of walls with translucent protective compositions, which retains their natural beauty. The use of various kits is also welcomed, since processing with various paints and varnishes will not only increase the degree of protection of the building, but also make it as attractive as possible.

In conclusion, we note that houses from the carriage are one of the most reliable construction options, which will be the best choice in regions with a cold climate. The unique technology for connecting logs allows you to build reliable buildings, the operational period of which exceeds tens and hundreds of years. The growing popularity of such houses in Norway and the northern regions of Russia once again proves this.