The device of the domed house will give warmth and comfort in the winter season, freshness and ...

|

|

The absence of a water supply in the country causes many problems associated with ... |

A cozy and attractive balcony is a wonderful addition to any housing, in ... |

Addresses in concrete: characteristics, classification, choice

Concrete is called a special construction mixture, which most often includes several main components of cement, water and various aggregates. As a result of solidification of the solution, artificial stone is formed, which is used in many areas where strength, stability and durability are required. Very often, various drugs are added to the mixture to improve the basic characteristics of concrete. These substances are also able to accelerate the rate of construction and reduce the consumption of funds. It is especially important to use additives for the installation of coatings for airfields, the construction of berths, during the construction of roads, when laying pools or other hydraulic structures, as well as in the construction of monolithic industrial facilities and residential buildings. The article will talk about additives for concrete.

Content:

- Classification of concrete additives

- The most popular concrete additives

- Polyplast concrete supplements in the company

In Western countries, the use of concrete with special additives in the composition is considered ordinary practice. In Russia, this has not yet become the norm, but most buildings and structures are already being built using just such a solution. In addition, modern norms and rules make such high requirements that it is not possible to build from concrete without additives.

There are a huge amount of additives in concrete and each species has its own purpose. Some are used in hot climates to slow down the mass hardening process, others are necessary to increase the qualities of concrete used in the open air, others are important in construction in a humid environment, as they are able to significantly increase the waterproofness of the solution. That is why it is important to initially make the right choice for each specific situation. And for this it is necessary to understand what additives exist, and in which areas they will be most effective.

Classification of concrete additives

Additions for concrete solution are able to instantly improve the quality of the composition and at the same time do not require large cash costs. Maximum effectiveness appears only if correctly selected components are used. Added elements can easily increase strength and durability, increase frost resistance and reduce permeability.

One of the modern classifications divides the additives into six main groups.

- Modifiers They increase the strength of the mixture and frost resistance, lower permeability, extend the operational period of the finished concrete, while the solution can have significant mobility, which allows the work more efficiently.

- Plasticizing concrete additives They help to achieve a reduction in the consumption of the mixture, without reducing strength, but even, on the contrary, increasing it. The mobility of the solution and its density also increases, when the components are added to the composition, excellent water resistance of hardened concrete can be achieved.

- Solution mobility regulators It must be used in cases where it is required to maintain plasticity, for example, in hot weather, or in the process of long transportation.

- Antorozoic additives to concrete They allow construction procedures using concrete mixtures even at minus temperature, withstand frosts up to -15 degrees, and some to -25 degrees.

- Accelerated setting additives It is necessary to increase this indicator for the first time, the strength of the finished concrete is also increased.

- Self -sealing additives It is necessary to use in cases of filling thin -walled structures.

In addition to the selected six groups, there is a separate type of additives, the so -called complex. Such additives can simultaneously show the effects of several groups at once to obtain specific properties of concrete. Perhaps this option allows you to use all the necessary qualities as efficiently as possible. Indeed, when using several different additives, the result will not always be predictable. Components may simply not interact properly with each other. And in cases using high -quality complex drugs, the proportions and ingredients were calculated in the factory, which means that they were balanced properly.

- It should also be taken into account by the fact that those products that have proven themselves abroad will not always be so effective in domestic production. Indeed, in the West, only high -quality ingredients are used, even the requirements for the composition of sand and crushed stone are very high. It is not recommended to make domestic and imported additives to concrete with your own hands.

- So, for example, superplastifiers made in Sweden are poorly interacting with Russian additives that provide frost resistance to the composition. This means that the additive from one manufacturer should be used in one solution. And since the drugs produced in Europe are much more expensive than domestic counterparts, it is extremely unprofitable to use only imported agents.

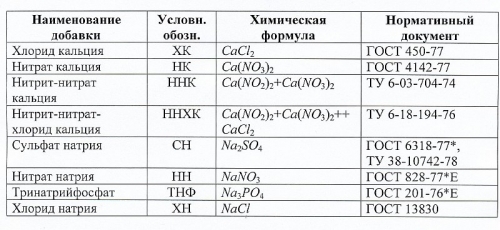

- There is another common classification of additives. They are divided into chemical and finely humble substances. As a rule, chemical additives for concrete are introduced into a small amount, they are in the form of powders, aqueous solutions and emulsions. The second species is used in the case when the saving of cement is required, while the concrete is dense and persistent. Also, this species is called mineral additives, is a small grinding powder. To obtain such a substance, industrial waste is used.

Chemical substances, added to a solution for concreting, are divided by the main effect that they have. So they happen:

- increasing mobility and plasticity of the mixture;

- reducing fluid separation from the solution;

- concrete additives for waterproofing;

- stabilizing, not allowing concrete to divine;

- accelerating mass hardening;

- slowing the process of setting the mixture;

- anti -control additives;

- foamy and gaseous drugs that increase the porosity of concrete;

- regulating deformation processes;

- protective substances;

- increasing resistance to corrosion, bacteria, aggressive environments and other factors;

- hydrophobizing.

Some types of additives can simultaneously show several properties, but only one effect will be the most noticeable.

The most popular concrete additives

Plasticizers in concrete

- The most popular and popular types of additives can be attributed funds from the group of plasticizers. They are divided into four categories of strong, weak, medium and superplastifiers. For the first time, such funds began to be used back in the 40s, but with the development of modern technologies, they reached a high level of perfection and are able to really increase the quality of the concrete mixture.

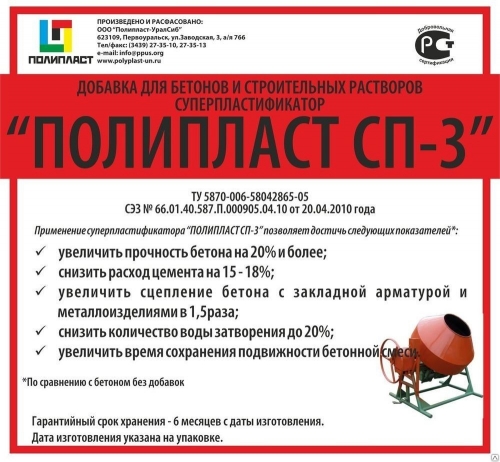

- To date, substances from the group of superplastifiers are most often used. And the most popular type of such additives is the S-3 drug, it is produced by the Russian company polyplast.

Such an additive has many advantages, among which you can highlight the following:

- economical cement consumption;

- the mobility of the mixture increases;

- the strength characteristics increase by approximately 20-25%;

- increased use;

- it is allowed to pour thin -walled structures or densely targeted;

- the resulting composition has increased density;

- high frost resistance of the mixture;

- improved crack resistance;

- the compression strength increases;

- saving energy in the production of a mixture, due to the reduced preparation time and reduced temperature in special concrete chambers.

It is worth noting that plasticizers have not only positive properties, but also negative. So, one of the disadvantages is an increased hardening time of the solution. To avoid this effect, experts recommend introducing special supplements for accelerated hardening. As a rule, the most optimal option is the use of complex additives based on two components of plasticizers and hardening accelerators.

Renewal accelerators for concrete

- As an accelerator of concrete hardening, aqueous solutions of sodium chloride, calcium chloride and other chloride salts are most often used. As a result of their impact on concrete, the hardening process occurs more actively. Such additives are used for the installation of prefabricated structures made of reinforced concrete (it is not recommended to use in the presence of a reinforcement of less than 5 mm), they are also added to the solution in the production of thin -walled or densely targeted structures.

- Very often these additives are in demand in cases of filling non -standard forms. For example, when the rapid captivity of the lower layer is required, for a more productive filling of subsequent layers. The most characteristic example for this situation is the pouring of the pool bowl. After all, it is necessary that the bottom has maximum strength during the installation of the walls.

- So that the builders did not have to wait for a long time, when the concrete gains the desired hardness, and hardening accelerators are used. They are also in demand when conducting construction work in cold weather, because the salt available in the composition does not allow the liquid to freeze at a small minus temperature.

Concrete hardening delayers

- The following important additives are the hardening delay. That is, they show the opposite effect to the previous form, prolonging the viability of the mixture. Most often they are necessary during transportation, especially over long distances. Settlers of setting are indispensable in cases where continuous concreting is required. Since in cases where a large thickness of the structure is needed, builders most often lay concrete, as a result of which working seams are formed in the structure, and this already means that the design will not have proper strength.

- Without the use of such substances, it is necessary to responsibly approach the docking of the old and new layer. With the use of special drugs, it is possible to achieve maximum reliability and avoid the formation of shrinkage cracks or minimize their appearance. The main function of the slowdown is that they are able to inhibit such processes as hydrolysis and hydration, and as a result of which the sealing of the mixture occurs less intensively. Moreover, this process can be delayed even for several hours.

Air advantage to concrete supplements

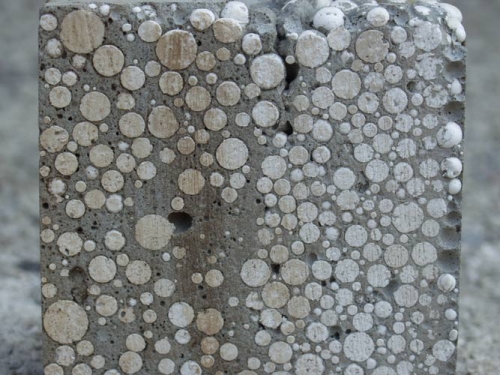

- The next important group is the aeronautic supplements. Their main purpose is to increase the operational properties of concrete mixtures and the finished product made of concrete, especially in the conditions of the northern latitudes.

- When they are added to the composition, the solution is filled with the smallest air bubbles and a microporous structure is created that can significantly increase the frost resistance indicator. Explain this phenomenon is quite simple, after the concrete structure is impregnated with water, and the water freezes, the concrete does not burst and does not crack, since the water is evenly distributed through the available pores.

- Also, such additives increase the water resistance of concrete structures and allow us quite conveniently and easily mount any required objects. Of course, it is not possible to completely protect products from destruction from destruction. That is why they are most often used when laying the upper layer of the road surface and when creating the external decoration of the buildings, that is, where the thick layer of the mixture is not required.

Frost -resistant additives in concrete

- The frost resistance of the solution is best increased by the special substances of frost -resistant additives in concrete. The principle of operation of such drugs is that they lower the temperature of the liquid solidification, and the concrete solution receives the ability to harden at minus temperature. It is these additives that make it possible to carry out construction work using concrete mixing even in cold weather.

- Various nitrates, for example, sodium or calcium, as well as sodium chloride, are used as antimoosis substances. The addition of antimoosis drugs helps reduce the consumption of the mixture and reduce the stratification of the solution. The strongest additives allow construction without additional warming up the mixture even at a temperature of -25 degrees.

Modifiers for concrete

- Another large group of additives are various modifiers for concrete. Depending on what the concrete mixture is used and the types of modifiers will differ. After all, the mixture used to build wells or pools will differ significantly from the solution used to build the facade of the building or filling the floors.

- Modifiers are able to significantly increase the performance of concrete mass, and also help improve the construction result to extend the durability of structures, achieve high strength of structures, and reduce the indicator of moisture permeability.

Of course, these are far from all groups and types of additives for concrete today, because there are a huge number of them. The largest enterprise produced by a wide range of domestic drugs to improve the properties and characteristics of concrete mixtures is the Polyplast company.

Polyplast concrete supplements in the company

To date, this Russian company is one of the largest organizations for the production of concrete additives. The holding has three plants that use only the latest equipment and the most advanced technologies. Polyplast products are sold throughout Russia, as well as in the countries of the near abroad. All products have the necessary international certificates and comply with the quality standard.

Additions significantly improve the quality of concrete mixtures, and also increase the reliability and operational period of finished structures and structures. The company Polyplast produces almost all popular groups of drugs.

SuperplastifiersSubstances that can increase the plasticity of the mixture. Each product from the assortment series of Polyplast products differs from each other in terms of influence on the properties of concrete and the main composition. The most popular products:

- C -3 - the most common type of plasticizer, increases concrete mobility and raises the strength of the finished structures, is indispensable when erecting monolithic structures with a complex configuration;

- SP -1 - a universal type of additives, most often used in the production of self -sealing concrete mixtures;

- SP -3 - a comprehensive supplement that has the effect of slow -down seizing the mixture, optimally used in the manufacture of commodity concrete and when pouring prefabricated structures;

- P -1 - a drug related to a group of strong plasticizers is used for the production of commodity concrete;

- Lux is a universal type of additives, which, with different quantities in the composition, is able to change the resulting effect;

- VIBRA - an additive used for the manufacture of structures using vibrational units and vibration presses.

Settings of graspingadditives used for continuous construction of structures from monolithic reinforced concrete, as well as in cases of long transportation of concrete mixture. The Polyplast company offers consumers several types of additives under the brand of the Line. They differ in the effect, composition and area of \u200b\u200bapplication.

- Line P120;

- Lynamix SP-180;

- Line PC;

- Line for RS.

Accelerators of concrete strength setRefers to a group of complex additives, which simultaneously have the effects of superplasticitators and hardening accelerators. Polyplast produces several types of additives from this group under the brand Relamix.

- Relamix is \u200b\u200bcarried out on the basis of organic and inorganic sodium salts, used in the construction of structures, to which requirements for maximum strength on a small date;

- Relamix-M is used for commodity concrete, as well as in such areas of construction as industrial, transport, road and civilian;

- Relamix Torkret without adding alkalis in the composition (the main element of aluminum sulfate) is used for concrete solutions that are applied by spraying.

Antorozoic supplementsIt is necessary to lower the freezing temperature of the water that is part of the construction solution. As a rule, these are universal drugs that increase such indicators as the location and strength of strength at a negative temperature. They allow you to spend the mixture economically and increase its vitality. You can buy anti -control additives in concrete of the polyplast company in the following assortment:

- Cryo-25 (type 2);

- Cryoplast 30;

- Alpha cryoplast;

- Cryoplast LN;

- Cryoplast luxury;

- Cryoplast P25-1 (type 1 and type 2);

- Cryoplast PC;

- Cryoplast premium;

- Cryoplast SP15-1, 2;

- Cryoplast SP25-2;

- Extra cryoplast;

- Polyplast Nord;

- POLIPLAST PMP.

Concrete modifiers,two main types are produced:

- PFM NLK based on naphthalain sulfate, increases frost resistance;

- BF regulates the rheological properties of rigid and sedentary mixtures.

For high -strength concreteAdditions allow you to increase the strength of solutions and finished products, reduce the time of the necessary heat treatment or completely exclude it.

- 1MB;

- 3MB.

For low -daub concrete increase the operational properties of concrete mass, provide strength, even when using a low -quality aggregate.

- NSB;

- NTB.

Air -winning additives Increase the properties of the mixture, in particular water resistance, crack resistance and landing, also significantly increases to show frost resistance.

- Airfly;

- Aero polyplast;

- Polyplast of explosives;

- Polyplast R.

Biocide additivesSuch drugs are used to prevent the development of fungal and mold formations. The polyplast company produces a bioplast additive - this is an aqueous solution based on ammonium salts and polyhexamethylene hydrochloride.

A huge variety of additives helps to find exactly the products that will help as much as possible in each case, increase the efficiency of the concrete mix, and also extend the operational quality of finished products.

http://superplast.su/

http://superplast.su/

http://poly-chem.ru/catalog/d

http://poly-chem.ru/catalog/dobavki-v-beton/

http://poly-chem.ru/

http://poly-chem.ru/