Any repair ends with the installation of a skirting board, without which the room will have ...

|

|

When planning to engage in the lining of the balcony, many people are inclined to use for this ... |

Installing the fence on brick pillars is distinguished primarily by good ... |

Bitumen tiles: types and choice

In the modern world, the development of building technologies is so rapidly that all new materials appear annually or a significant improvement of the old ones occurs. This applies to all repair and construction activities, and products for covering roofing structures were no exception. But, despite the appearance of a wide range of new coatings, often homeowners strive for unshakable classics. An ideal option, combining the properties of new technologies and traditional products, was the invention of bitumen tiles. Such a product in appearance resembles ordinary ceramic tiles used for roofs of roofs several centuries ago (and in some parts of the world preserved and still), but at the same time, thanks to a special production technology, it has many advantages that are absent in its predecessors. The article will talk about how to choose a bitumen tile.

Content:

- History of the occurrence of bitumen tiles

- Bitumen tile device

- Modern models and size of bitumen tiles

- The main forms of gont cutting

- Bitumen tile manufacturers and prices

- Useful tips when choosing bitumen tiles

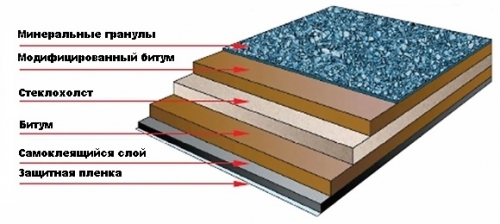

The bitumen tile has several variations of the name. Among which are the most famous, such as soft roofs, roofing tiles, tires, hin or flexible tiles. But, no matter how the material is called, this is still a reliable and strong product, mostly made of glass chuckle, saturated with modified bitumen and sprinkled with stone granulatory.

Of course, this is an too primitive concept of the structure of the product, because its production is based on rather complex processes.

History of the occurrence of bitumen tiles

- For the first time about the roofing canvas impregnated with oil production products, they spoke in America in the middle of the 19th century. Then a material was created, which is a cardboard with bitumen applied to it on both sides. But the patented tiles appeared only in 1903, thanks to the efforts of the company Grand Rapiz, and specifically one of its employees of Henry M. Reynolds, since it was he who first tried to cut rolled roofing materials into separate rains. Of course, the choice of forms at that time was small, and was rectangular even pieces or hexagons. In addition, there was no color variety, the spectrum was limited by natural shades of sprinkle, and it was either red or gray.

- Such a product began to be called tiles only in Europe, but in the USA, where it was invented, and in Canada it is still called bont. Due to its excellent properties and light installation, the coating very quickly gained popularity in many countries of the world, and today it is almost impossible to meet a single city in which homeowners would not use a soft bitumen roof, to overlapping roofs.

- The material has a rather complex structure. Initially, two types of foundations were used in production: glasshold, which was used for the first time in the 60s of the 20th century, and cardboard made of cotton, resulting from the material was called organic tiles.

- Organic tiles could be covered with two types of bitumen: soft, soaking cardboard, and hard, which had to be applied to the surface from two sides. Despite all the protection measures, this material was not so resistant to moisture and weather conditions, in contrast to the fiberglass, which in itself is better protected from water exposure, and besides, due to the bitumen coating, such a tile perfectly maintained the stability of the form. In addition, she had good fire -resistant parameters and lower weight.

- The entire model range produced at the beginning of the 20th century had a single-layer structure and only after 40-60 years they began to make laminated products, that is, glued together several hounds.

- At the same time, mineral sprinkle painted in various colors began to be used. Laminated material had high competitive advantages due to an attractive appearance, which almost perfectly imitated the roof coating with wooden shock, and also had improved technical characteristics. Among which the most significant were strength, resistance to wind loads and a long warranty service life (up to 25 years, against the usual at 15 years). By the end of the 20th century in the United States, the model range has been significantly updated and today you can find products for which the manufacturer gives a life guarantee.

- The main share of the modern market is filled with products only on the basis of fiberglass. In order to better understand due to which the tile has such excellent quality indicators, you should understand the structure of this multilayer product.

Bitumen tile device

Glasshold

- This is a synthetic canvas obtained from molten mass of inorganic glass, which consists of safe natural materials, such as quartz sand, dolomite, soda and lime. This means that the product produced from them is characterized by environmental friendliness, as well as the lack of harmful chemical elements. In addition, thanks to the composition, it is also a rather strong, wear -resistant product.

- Fiberglass is a non -woven material in which the fibers are interconnected due to special additives (resins). There are two main ways to produce the canvas:

- wet In which the rubberization of the ramp (a harness of glassons) occurs, the gradual foaming of the resulting mass and the molding of the canvas, after which a binder is applied over the resulting canvas, which is glued after drying with a special film. The result is a strong composite product with a homogeneous structure, which is characterized by high operational properties;

- dry In which the glass mass obtained by the melting method is squeezed through the filters (high -strength forms) and is pulled into fibers, intertwining with each other and settling on the conveyor tape in the form of a single canvas. The resulting canvas is impregnated with a binder and enters dry chambers.

Glassholst has a number of advantages that are transmitted and products made from it. We are talking about the following parameters: size stability, resistance to mechanical influences, excellent noise absorption, resistance to chemicals and fire, moisture insulation. It is also very difficult to deform the material, but it is distinguished by flexibility and elasticity

Bitumen

- This is a solid or resin -like natural raw material, organic origin. To improve the qualities of its substance, it is customary to combine it with various polymer additives. This procedure is called modification, and the resulting product is called modified bitumen. There are two varieties of this material:

- SBS-modified bitumen (styrene-tadien-styrol) or rubber-gun, that is, a product based on synthetic rubber. The main advantages of the tiles of this product covered with this product include excellent frost resistance, resistance to fever, long operational period and high elasticity.

- APP-modified bitumen (atactical polypropylene) tiles made using such a substance is characterized by increased resistance to ultraviolet radiation, chemical reagents (acids and alkalis), as well as resistance to high temperatures.

- In addition to modified bitumen, there is also such a variety as oxidized by it by oxidation, that is, air is passed through the molten bitumen mass, due to which the artificial aging of the material occurs. Thanks to this, the service life of the product and its heat resistance increases. The finished product is used only in regions with a relatively warm climate, since from sharp temperature differences the coating becomes unusable very quickly, external deformation can occur in the form of twisted edges.

Tip: You can distinguish a type of bitumen used in the manufacture of soft tiles visually, for this it is enough to pull the edge of the product (beyond the corner of the upper layer) and if the substance is calmly stretched, then this is modified bitumen, if it immediately broke off. Most modern tiles are made using SBS-modified bitumen.

Mineral powder

- This is a substance that is used as the upper protective layer, and also gives the roof a special appearance. The main types of granulators can be several natural minerals:

- basalt;

- silicon;

- clay.

- Basalt today is the most commonly used type of sprinkle. This is explained by the special properties of this stone and in particular by the fact that when grinding the baby is more rounded, that is, when coating tiles with this granulate, its particles are very tightly adjacent to bitumen and, accordingly, are better fixed on the surface. In addition, slate has the properties of absorbing oils contained in bitumen and change its color. As a result, over time, the shade of the roof changes significantly and not at all for the better.

- Stone powder is a very important component of soft tiles, as it is:

- provides additional protection against ultraviolet radiation;

- gives strength and durability to the product;

- prevents mechanical damage (for example, from strong gusts of wind, trees growing near the house, can tilt branches to the roof);

- confronts high temperatures, protecting the bitumen layer from melting;

- protects the roof from various natural phenomena, including from the city;

- it creates an attractive appearance thanks to various color shades.

Manufacturers supply tiles for the sale, both with basalt pouring and shale crumbs. Since, despite the shortcomings of the latter, products with it have the same attractive appearance and differ in a long service life.

The high quality of bitumen tiles depends on the properties of all components that are part of the components, and only with their excellent characteristics can the water -absorbing qualities of the finished product almost to zero, so this roofing material is not subject to corrosion and decay processes. Soft tiles have a lot of advantages and is highly valued due to the possibility of using it on the roofs of any configuration, up to domed shapes. In addition, since this is a piece product, even if some tile is damaged, it is easy to replace it with a similar model, without violating the integrity of the intact surface.

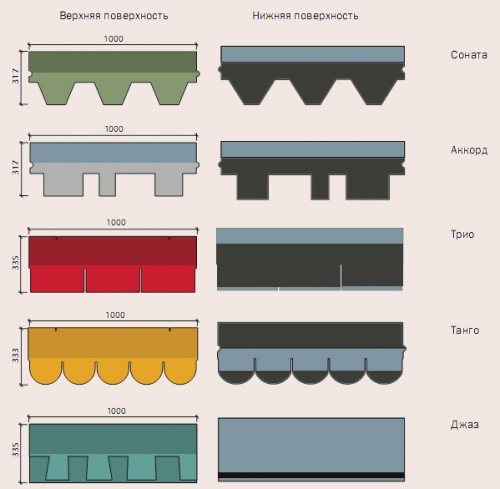

Modern models and size of bitumen tiles

Despite the wide variety of manufacturing companies, bitumen tiles have several main varieties that are distinguished in the shape of petals, material and color of the spice. The very first soft tile had a three-petal design, modern products can consist of 4-5 petals, with petals of different lengths or completely unreasonable gont. Of course, a product that does not have cuts will cost an order of magnitude cheaper, but at the same time, external attractiveness should not be expected from it.

When choosing a bitumen tile, you should know that it is divided into two classes according to fire safety. Classes are indicated by Latin letters A and C. Classification division occurs in several parameters.

- In particular, a-class tileit has a base of glassons and has a high degree of fire resistance, while the warranty service life of 20-30 years extends, which indicates its high quality.

- C-class tilesinferior in quality, it is based on a special cardboard saturated with bitumen and the manufacturer guarantees the service life of his product for no more than 15 years, but at the same time such products are a little cheaper and it can be safely selected in cases where an inexpensive reliable coating is required, but with a limited service life .

The size of the bitumen tile varies not only in every manufacturer, but also in each model.

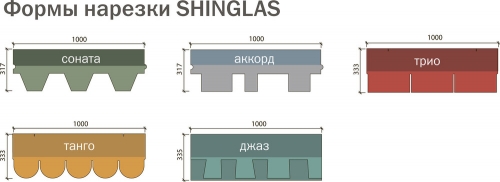

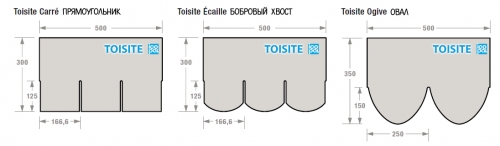

The main forms of gont cutting

It is customary to divide the tiles into an ordinary, that is, which is laid in the rows over the entire surface of the roof and the skate-cornice intended for the first roofing row walking along the cornice and for styling on the horse. To date, there are several main forms for cutting petals:

- hexagonal;

- rhomboid;

- rectangular;

- oval;

- beaver tail;

- Dragon tooth;

- brick;

- shingles.

As a rule, for tiles intended for the first row, manufacturers choose only a cut with a flat edge of the gunt. For the identification and uniqueness of their products, each manufacturer assigns various names and series manufactured products.

Bitumen tile manufacturers and prices

Before buying bitumen tiles, it is recommended to familiarize yourself with its main manufacturers and prices.

| Manufacturer / country production | Products webpage | The name of the series |

Price per m2 products

(depending on the region of sale) |

| Icopal / France, Finland |

www.icopal.ru | Antik Claro Natur Plano Claro Antik Tema Toisite Versite |

300-500 rub. |

| Bitumen tile Katepal / Finland | Katepal-russia.ru | Katepal Ambient Katepal Foxy Katepal Jazzy Katepal Katrilli Katepal KL Katepal Rocky |

340-560 rub. |

| Daflex (Holzplast) / Germany | http://holzplast.ru | Diamant Imperial Sapphire |

350 -550 rub. |

| Ruflex / Russia | www.ruflex.ru | Briss Esten Ornami Runa Sota Tab |

300-480 rub. |

| Togola's bitumen tiles/tegola Italy, Russia | www.tegola.ru | Nordland: Alpine Alaska Antik Classic Nordic Top Single |

215-540 rub. |

| Bitumen tiles of shinglas/Shinglas (Technonikol) Russia | http://shinglas.ru; http://www.tn.ru |

Shinglas Classic Shinglas Country Shinglas Jazz Shinglas Ultra Shinglas Finnish tiles |

180-500 rub. |

| Certainteed / USA | Article 20 Cariage House Shangle Grand Manor Shangle Highland Slate Independence Shangle Landmark Presidental Shake |

380-1740 rub. | |

| BP (Building Products) / Canada | http://www.firestonebpe.com | EVEREST 42 Mystique 42 |

500-540 rub. |

| Docke / Germany | www.docke.ru | Genoa Granada Koln Liege Nice Zurich Sheffield |

300-400 rub. |

| Bitumen tile IKO / Belgium, Canada | http://www.iko.be | Armourshield Cambridge Marathon Skyline |

500-1000 rubles. |

| BRAI / Italy (produces a unique flexible copper bitumen tile) |

http://www.brai.ru | Giotto Copper Leonardo Copper Leonardo Patina Leonardo Perfetto Leonardo Primo Leonardo Unico Leonardo Zinc Titanium |

1500-2500 rub. |

| Kerabit / Finland | http://www.keraabit.ru | K three-series K-Series L-Series S-series |

350-500 rub. |

| GAF ELK / USA | www.gaf.com | Camelot II Grand Canyon Grand Sequoia Grand Slate Monaco Royal Sovereign Slateline Timberline Woodland |

400-550 rub. |

| Ondulin / France, Russia |

http://www.onduline.ru | Ondubila 3D | 250-350 rub. |

| Bitumen tile aquaizol / Ukraine | http://www.aquaizol.ua | Accent Quartet Mosaic |

250-400 rub. |

It is believed that the best bitumen tile is produced in the USA, since it was in this country that this material began to produce for the first time. But many Russian and European companies are not inferior in the quality of their products to analogues from America.

In the Russian market, the most common options are the products of companies such as Tegola, Technonikol and Catepal. But not all types of bitumen tiles have positive reviews.

Technonikol

Technonikol Corporation produces bitumen tiles under the brand of Shinglass.

An economical option is the Finnish tile model, but it has the largest number of negative reviews. So its main shortcomings are considered:

- a strong and unpleasant odor in the first year of the product;

- crowning stone powder, especially after the winter period;

- mismatch of slabs in different packages;

- uneven application of the adhesive of the lower layer.

Most of the problems in the bitumen tiles of the techno-nitrate occur due to the use of modified bitumen of low quality. The same disadvantages are noticed in the models of the classic and ultra series. Products from the Jazz collection can be considered the best bitumen tile from the company, but at the same time this series is more expensive than high -quality American or European analogues.

Tegola

- The Italian company Tegola has established itself as a reliable manufacturer of high -quality products. But not so long ago, an independent department with its own production appeared in Russia. The Nordland series products are produced here and very often this type of tile had negative reviews.

- The most common problem is the appearance on the surface of the laid roofing carpet, which arise due to the use by the manufacturer of low-quality SBC modified bitumen.

- Many developers who use this product to cover the roof, come to the conclusion that this is a budget option that is not able to show high operational characteristics. Therefore, if you choose the tiles of this manufacturer, it is better to give preference to products manufactured at factories in Italy.

Katepal

- The products of the Finnish concern of Katepal have proven itself in the best way. The bitumen tiles of this manufacturer are presented on the Russian market by five main collections that are reliable and durable with proper installation.

- Nevertheless, in the reviews, you can often find a description of such a problem as the warning of the roofing, but most often poor -quality ventilation or an incorrectly laid layer of litter is guilty. If the technological processes of the installation of the tiles were not violated, then it will last the entire stated warranty period (25 years), and for a long time after its completion.

Useful tips when choosing bitumen tiles

- When choosing a specific brand and manufacturer of bitumen tiles, you should dwell on well -proven products in a particular region. Especially if you can visually see examples of objects that have stood for at least 10 years. The main criteria for choosing is the type of bitumen and the specific gravity of a square meter of coating.

- As a rule, experts recommend choosing products, coating with SBC-modified bitumen, as it better resists adverse weather. As for the weight, it should be at least 12-13 kg/m2, since it is such a mass that can reliably resist wind loads.

- The manufacturer’s guarantee can also say a lot. So, many manufacturers give a guarantee for minimal water resistance, but do not guarantee color resistance. It is not worth saving on roofing material, but it will also be unreasonable to overpay for the brand, so the most optimal to find the balance between the two parameters and adhere to it.

Bitumen tiles are quite complex in structure of multi -layer material. But it was precisely thanks to the features of its production that the product was so widespread around the world. Among the main advantages, high strength, zero water permeability, long operational period, light installation and simple care can be distinguished. Such a coating is able to withstand the most severe climatic conditions, preserving its excellent qualities and reliably protecting the house, guaranteeing comfortable conditions indoors. When making a choice in favor of a particular manufacturer, you should pay attention to the warranty period of the service, and the higher it is, the better and more durable the purchased material, and if you combine it with regular care and control over the roof state, then the coating can last 50 and 100 years, performing its purpose is in the best way.

For 3 years as installed

For 3 years now I installed a bitumen tile in the country, and I will tell you that I am quite satisfied.

The advantages of bitumen (flexible) tiles:

The slight weight of the bitumen tile;

Excellent sound insulation;

Corrosion resistance;

High impact resistance;

The life of a flexible tile is more than 30 years;

Resistant to high loads.

Disadvantages of bitumen (flexible) tiles:

Water absorption over 10% (depending on the quality of the material);

Not all bitumen tiles are equally fireproof (it is necessary to pay attention to fire safety classes: “A” - a high safety class; “C” - a cheap and less safe base);

Demanding in compliance with coating technology;

If you are interested in who I addressed http: //www.mirkrovli.com.ua/katalog-produkczii/krovelnyie-materiali/bit ...