The windows are a kind of adapter between the outside world and your house. Hearing ...

|

|

In the light of a bad environmental situation in big cities and our welfare growth ... |

From the sport of centuries, people equipped their house so that it was comfortable and warm ... |

Playing Plasterboard ceiling options

Did you have to pay attention to what a person entered into the room rushes to the room? Of course, on the ceiling. The ceiling surface is the most important part of the interior, an extensive space for the implementation of any design and color fantasies. And the use of drywall will be the best option for their implementation. The possibility of creating any architectural solutions and fantastic configurations, environmental safety and excellent soundproofing and fire resistant properties combined with amazing decorative illumination determine the incomparable success of drywall among other construction and finishing materials.

Table of contents:

- Preparation of the surface of drywall before staining

- Tools for painting the ceiling

- Accurate observance of technology - a guarantee of an excellent result

- Some tips on staining

Choose paint for the ceiling

There are many solutions for the design of the ceiling surface made of drywall. The most reliable and most common option today is painting the ceiling. The technology of painting the ceiling made of drywall has its own specific features: for example, directly applying the paint to the surface of the drywall is preceded by a whole complex of preparatory work: primer, putty, as well as grinding of the surface. All these procedures pursue a common goal to identify minor defects and irregularities and subsequently eliminate them. Having successfully coped with preliminary work, the question arises: which paint is most suitable for drywall ceiling? Thoughts about an oil -based paint can be raised at once.

According to experts of painting, the most suitable paints for staining drywall ceilings are water-based and water-dispersion compositions. At the same time, the dispersion paint significantly exceeds emulsion in the ability to maintain its original appearance and moisture resistance for a long time, but inferior in the issue of choosing a color scheme, since it is produced mainly in shades of white. Manufacturers of emulsion paint offer consumers a variety of color palette bright, saturated tones to create any trendy and classic interior.

Water-based paincrapers are distinguished by a high drying rate and the lack of persistent, unpleasant odor, they are not toxic and, finally, form a strong homogeneous film, which can be periodically updated without any labor-intensive liquidation of the previous coating.

Today, the building materials market is oversaturated with a huge number of water -based coloring compounds. These are silicone, acrylic, acrylic with latex, silicate paints, with mineral composition, various shades and manufacturers with their advantages and restrictions on use.

Latex paintit is considered the most expensive, since it has a number of advantages, for example, it is used to create a non -vapor -permeable, resistant to various pollution of even, beautiful coating and provides for the possibility of humid maintenance based on detergents.

Applying 2 layers of acrylic latex paint to the surface of drywall will help you block visible cracks that have a thickness of up to 1 millimeter.

Acrylic water -based paintsdue to increased abrasion resistance during washing, the most in demand and are intended for use in almost any rooms.

For painting surfaces regularly exposed to moisture, the best solution will be the use of silicate paintIt reliably protects against the appearance and reproduction of microorganisms and does not imply additional use of antiseptic agents.

The best properties of silicate and acrylic compositions are combined by silicone paint. Her high elasticity will allow you to block cracks with a thickness of more than 2 mm. After applying and drying, silicone paint forms a waterproof film that will reliably protect the ceiling surface in rooms with weak waterproofing kitchen rooms and bathrooms. The surface painted with silicone paint is resistant to pollution and eliminates the additional use of antiseptic additives.

Coloring the plasterboard surface involves applying several layers of paint with strict observance of the instructions on the coloring label and withstanding the necessary periods of drying of each layer. The paint of foreign production is applied with a special roller usually in 2 layers, domestic in 3 layers.

In addition, when buying water -based paint, you have to decide on the degree of its brilliance: manufacturers offer glossy and semi -glossy, matte and semi -water compositions. Their main difference is that matte paint visually increases the height of the room, makes a significant contribution to the creation of a harmonious and finished design of the room, copes well with the removal of minor defects of the drywall ceiling, but very laborious in leaving.

The glossy paint is resistant to abrasion, the painted surface is easier to wash, however, all the flaws and defects of the ceiling surface, which were allowed by the master during staining process, are noticeable on it. Professionals advise choosing a semi -glossy or half -machine paint.

It should be noted that in foreign countries to stain the drywall ceiling is increasingly used enamel This is a better product that dries quickly, resistant to damp and has white. At the same time, high quality, of course, is reflected in the price of the enamel cost and this determines its low popularity in the domestic market.

When buying paint, do not forget to read the label in which the manufacturer informs about the purpose, expenses on a square meter and resistance to abrasion during wet cleaning.

Hypsum -plated ceiling technology

Let's try to deal with the technology and features of painting the ceiling. It is the quality and durability of the painted ceiling surface that directly depends on how much the painting technology was observed at each stage, including when performing preparatory work.

Preparation of a plasterboard surface for staining

1. The primer of the seams.

The gypsum core of the drywall sheet is a regular gypsum with various polymer additives. Try to grind a piece of gypsum, and before your eyes it will turn into dust. Any builder will tell you that it is inappropriate to carry out masking work on a dusty surface. Such a surface, first of all, needs a primer. You will have to pay special attention to the quality of the primer of the joints and those areas where the gypsum plasterboard core is exposed.

2. Switch sealing.

Often there is an opinion that cracks on painted drywall are formed due to poor-quality installation. However, this is not quite true. The cause of cracking of the drywall sheet may be poor -quality or impaired seaming technology. It should be noted here that the quality of sealing of the seams is determined by the quality of raw materials and the experience of a specialist performing the work.

Following the manufacturer's instructions, knead the material for sealing the joints. To do this, add the mixture to the clean water at room temperature and stir with a mixer until a thick sour cream is formed. After preparing putty, you can proceed to the seaming of the seams.

3. The reinforcement of the seams.

The putty of the seams of the drywall surface requires the use of additional materials, for example, Serpyanka. Serpyanka is a special tape for reinforcing joints. It can be glued before putting putty or after applying the first layer.

When gluing a sickle, pay attention to the following points:

- glue sickle it is necessary exactly in the middle of the seam;

- if you have to work not with a solid sickle, then gluing is overlapping with a mandatory entrance to each other;

- press the sickle into the seam with force;

- in the case of forming a gypsum plastic on the surface of the excess putty when gluing the Serpi, be sure to remove them;

- do not use the finish -type putty instead of Serpi. The finish putty is not intended to perform such work and can lead to cracking of the seam;

- after applying the first layer of putty with a sickle, wait for drying and apply another layer. This will allow you to get even, neatly sutured seams;

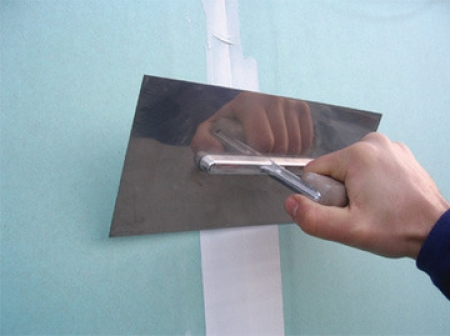

- for seaming the joints, it is better to arm yourself with a spatula, the length of which exceeds the width of the seam. In the process, the spatula must be carried out in such a way that it is located on its edges on a drywall sheet.

4. Putting drywall before painting.

After putting the seams and the overcoming of the Serpyanka, you can safely move on to putty drywall. The specialists distinguish several decoration options. The most economical way involves applying one layer of putty, grout and final application of the finish coating. As a result, we get an even and beautiful surface. A similar technology has been used by masters for many years and was the most affordable in terms of execution and financial costs.

However, today a putty in 3 layers is increasingly found. At the end of the starting processing, the drywall sheet is emphasized, the second layer and a new grout are applied, then glass chuckle is glued, which provides the best adhesion of the finishing materials and prevents the sparks of putty material from stretching and the possible crowning of the putty material, and finally, the surface putty is performed.

The finish putty, in the form of special ready -made mixtures in banks, will allow you to get a perfectly smooth surface smoothness. It should be applied with a large spatula, and in the case of small irregularities, it is recommended to pass with fine sandpaper. At the end of the finish processing of the drywall ceiling, primed the surface and proceed to the finish.

Since the final result depends on your skill and to a lesser extent on the chosen work technology, be extremely careful and in no hurry, use only high -quality materials of proven brands.

Tools for painting the ceiling

For painting the ceiling made of drywall you will need the following materials and tools:

- acrylic soil of deep penetration;

- water -based paint;

- cauler for water -based composition. A colorful palette of shades will allow you to paint the ceiling in any color and make the interior original and unique;

- a furry roller with a short pile. The presence of a long handle makes the tool more convenient. Do not use a foam roller because it forms air bubbles on the painted surface;

- masking brush for staining inaccessible places of the ceiling;

- plastic bath for staining;

- take care of your clothes. Since painting the ceiling can hardly be called clean work, then put on clothes that you do not mind spoiling. Do not forget about the headdress.

Accurate observance of technology - a guarantee of an excellent result

Having uncorked a jar of water -based paint, you have to first thoroughly mix its contents. To do this, you can use a drill with a special nozzle. If the paint is too thick in consistency, then add a little water to it.

Staining the drywall ceiling begins with painting inaccessible places and areas of adjustment of the ceiling structure to the walls and angles. Use a brush for this. The movements of the brush should be pumpkins, and not back and forth. The pinching method will not leave strips and divorces in the future.

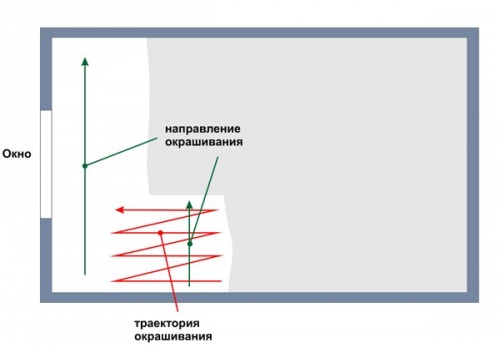

Then we dip a roller in a bath with paint and roll out along a ribbed surface. By this you remove excess paint from the roller. According to the technology of staining the ceiling surfaces, the first layer of the paintwork is applied in parallel to the windows. Remember: when applying the first layer of paint, it is necessary to do the entry of each next strip of the coloring composition to the previous one by 10-15 cm.

After drying, proceed to staining with a second layer. This time, staining should be carried out perpendicular to the first layer, i.e. in the direction of window openings to the opposite door structure. Such cross -application will allow you to get a perfectly even and homogeneous coating.

Attention: staining the surface with a roller standing with your head raised, you may not see the areas unexplored or painted. Periodically step aside and inspect the ceiling from a different angle or attract an assistant who, immediately noticing non -color, will tell you for timely elimination.

You can familiarize yourself with the technique of staining the ceiling from drywall using a spray gun by watching a YouTube video clip.

You can find many options for painting a ceiling made of drywall on the Internet. The variety of designer and color solutions, the high quality of painting and the durability of the painted surface determine the success of this method of designing the ceiling. Here are a few photos of successful painting the ceiling made of drywall:

Some tips on staining

1. If you started staining the ceiling from drywall, then do not interrupt the process, but apply the first layer of paint to the entire surface until the end. Do not change the roller that you already paint, because it leaves its own unique, decorative layer.

2. Do not paint certain zones of the ceiling surface that began to dry out, with the good purpose of improving the applied layer of paint. If this rule is not observed, you can get a ceiling with ugly stains or spots.

3. Coloring always begins with the angles of the ceiling. A small brush will come in handy for this purpose, which you will carefully manipulate so as not to stain the wall with paint. Having painted the corners around the perimeter, you need to make a small digression and walk along the ceiling with a roller with paint. This technology will protect you from falling on the wall.

4. When stained with a roller, it should be completely immersed in a bath with paint, and then remove surplus on the ribbed surface. Often inexperienced performers are afraid to immerse completely a roller in the paint in order to avoid its excess. Instead, they try to carefully focus on the paint roller on one side. This is a wrong approach. In this case, the paint is not distributed evenly on the roller, and the staining quality may suffer from this.

5. Coloring the ceiling excludes chaotic movements with a roller. Move in one direction. One layer of paint is one direction. The subsequent layer is applied perpendicular to the previous one. If you plan to paint the ceiling in 2 layers, then the first layer will be horizontal, and the second - vertical. Coloring in 3 layers suggests the following scheme: the first layer is vertical, the second horizontal, the third is again vertical. Compliance with this sequence will allow you to achieve the best result when decorating the ceiling from drywall. Success!