Building materials stores amaze with an abundance of assortment. Recently, many ...

|

|

The quality of ready -made concrete or reinforced concrete structures depends primarily on ... |

In the field of construction, one of the most famous manufacturers of insulation is considered ... |

DIY tissue decorative ceilings. Instructions for the installation of a fabric ceiling

Create a cozy and modern interior in your own house, while spending not much effort at all, using a special ceiling coating of a stretch ceiling made of fabric. Alternative material has many advantages, popular and widely used in the design of modern housing.

Table of contents:

- Which ceiling to choose?

- Fabric ceilings are fast, comfortable, beautiful

- Positive sides of fabric ceilings

- Disadvantages of tissue ceilings

- Aesthetic possibilities

- How to fix a fabric ceiling?

- Instructions for the installation of the ceiling from fabric

Which ceiling to choose?

When asked what type of material for a stretch ceiling is better: PVC film or fabric, you cannot give a definite answer. Each of these materials has its own advantages and disadvantages.

So, the polyvinyl chloride film is practical, durable, there may be a wide variety of colors and shades, with and without a pattern, glossy and matte, does not proceed. But PVC cannot be used in non -heated rooms, since at negative temperatures it loses elasticity and can burst.

When installing such a ceiling, it is necessary to use a heat gun, so it will not be possible to perform installation on your own without special equipment. Also, any random touch with a sharp object or a shot from champagne, a real threat to a stretch film ceiling.

On the other hand, caring for the appearance of PVC is very simple. It can be washed, wiped, it does not absorb odors and does not cover it with stains, quality material does not change color.

The tissue stretch ceilings have their positive and negative qualities. Their features, characteristics and installation methods will be considered in this article further.

Fabric ceilings are fast, comfortable, beautiful

The ceiling from fabric can be mounted not only in the apartment, but also in a country house where heating may not be all year round, in public premises (kindergartens, offices) and even on a veranda or loggia. It is in such difficult operational conditions that all the advantages and disadvantages of tissue ceilings will be visible practically.

Fabric ceilings are sometimes called seamless. This is the main characteristic of this material. The maximum size of the canvas is 5 meters. On average, such parameters are enough to cover most ceilings. If the room is more than this maximum, installation for the entire area will not be possible, since the canvases do not join each other. In such cases, additional plasterboard structures are used to create the necessary surface size for the fabric canvas.

Positive sides of fabric ceilings

The advantages of the fabric ceiling are as the material itself from which they are created. Usually these are synthetic fabrics impregnated with a polyurethane composition.

- Strength.

Technically, such material is stronger than polyvinyl chloride (PVC film) and more resistant to mechanical damage. A traffic jam from a bottle of champagne or a blow to a no sharp object will not damage the canvas.

- Environmental friendliness.

Some manufacturers use natural fibers to create suspended ceilings, but in the end these fabrics are still impregnated with a synthetic component, so it is still impossible to call them ecologically clean 100%. The plus is the fact that during operation the material does not distinguish substances harmful to human health.

- Tolerance to temperature changes.

The possibility of using a fabric ceiling in periodically heated rooms or in completely not heated, is due to their immunity to temperature extremes. They do not change their technical condition and appearance either in the 40-degree frost, or in the summer heat.

- Ease of operation.

Fabric ceilings are not susceptible to fire, they do not gain a charge of static electricity due to special impregnations, and do not react with chemicals. If necessary, they can be covered 3 or 4 times with acrylic paints. The canvases are mounted quite simply. Care consists in periodic wiping such a ceiling with a damp sponge or a rag, detergents can be used.

High -quality ceiling fabric coatings do not burn out, their paints remain bright for a long time.

When laying a fabric ceiling, the space under it can be effectively used to lay communication lines. Without additional allowance in height for the installation of lighting devices, the indentation from the ceiling ceiling can be limited only to the level of the difference in its plane.

Disadvantages of tissue ceilings

Any fabric, even synthetic consists of weaving of threads, but special impregnations are so tightly fused for pores that they make the canvas almost air -resistant.

The surface of the ceiling made of fabric can only be matte. Glossy can not be done on a PVC film. The most close to it is the imitation of silk, with a slight brilliance.

Manufacturers say that the ceilings from fabric are waterproof, but this is not entirely true. The fabric under the weight of water flowing through the ceiling from the neighbors will not sag as in the case of PVC, because it is less elastic. Most likely, the canvas will break out of the mount if the flooding is strong. The porous structure of the material allows the liquid to seep through it if the contact with water lasts more than 48 hours. From all this, the product is lost, its color changes.

It is difficult to wash the soot and spots of fat from the fabric ceiling, to remove the smell. Pollution and humidity will ultimately lead to the fact that the ceiling will have to be replaced completely, along with fasteners. Therefore, before installing such a coating, you need to be sure that the water from the ceiling is not afraid of you. It is also not recommended to install such a coating in the kitchen.

Aesthetic possibilities

In other cases, the fabric ceiling will become an excellent decoration, complement the image of the room, create a unique color. Types of tissue ceilings:

- Satin.

- Imitation of various textures (velvet, leather, stone, etc.).

- Translucent.

A variety of color scheme, painting and color printing, the use of crystals and various lamps, including point or installed in the interference space under the translucent canvas, allow you to create unique visual effects and unique compositions. All this can be done with your own hands if you use it correctly fabric ceilings. Video presentation of designer solutions will be interesting to everyone who decided to use this material to decorate their housing.

How to fix a fabric ceiling?

Almost anyone who knows how to use a drill and knows what the level is at least a little to use the fabric with their own hands. The mechanism of fasteners of fabric ceilings is extremely simple. High -strength plastic or aluminum is used, nailed to the wall with dowels.

It is not necessary to warm the room, as in the case of PVC stretch ceilings. Fasteners for a fabric canvas are of such types:

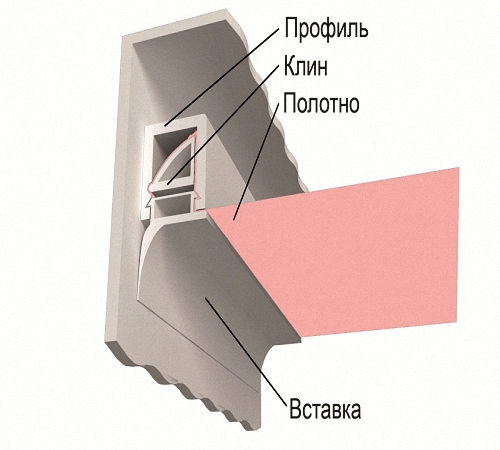

- P-shaped profile (wedge). It is mounted on the wall with the help of dowel-grooves. The canvas is clamped by a special insert and stacking with a glazing rod. At the same time, you do not need to use additional decorative elements along the edge of the ceiling.

The disadvantage of this method is the lack of a clear border between the canvas and the wall, which can cause some complications and distortions of the fabric during installation, as well as the displacement of the location of lighting devices.

Based on the features of architecture, you may need the use of special spacers

- Clips fasteners have a clamping device type of clothespin, reliably fixing the fabric ceiling cloth in place. The method is more preferable and easy to perform non -professionals, it is not so laborious, not needed a ceiling plinth, the fabric is pulled with a rounded spatula. Also, clip fastening is durable and reliable.

Important! When installing a fabric ceiling by the clip method, it is necessary to make clear miscalculations, otherwise the formation of gaps cannot be avoided.

The P-shaped profile and clip fasteners should be fixed very reliably, since the tension force of the canvas will constantly act on it.

The most optimal and convenient clip fasteners are considered. It is mounted quickly, holds the canvas reliably and looks aesthetically pleasing. With such a mount between the ceiling plate and the fabric, the minimum distance can be only 2 cm.

How to calculate the required amount of material:

The length of the baguette (fastener) is calculated correlate the perimeter of the room. In the corners, it is necessary to cut the profile for a clear docking of the elements.

In order for the fabric of the canvas to be exactly enough to cover the ceiling of the room, it is necessary to correctly measure the surface of the future ceiling and add 0.15 m to this size per reserve.

Instructions for the installation of the ceiling from fabric

To install the ceiling made of fabric, you will need a minimum set of building tools:

- punch or drill with a shock mechanism;

- roulette, level (preferably water and laser);

- recitting thread;

- construction (or wallpaper) knife.

Finish all dusty work before starting the device of a stretch fabric ceiling, otherwise fine dust can settle on its surface and spoil the appearance of the finished room.

- Baget mount

Installation of the baguette stage, which will largely determine the appearance of the entire future structure. It is very important to mount it in an ideal plane, because any defect will be visible and spoil the visual effect of a monolithic coating.

Before starting work, it is necessary to check the horizontal of the future ceiling coating. To do this, determine the lowest point and retreat from the ceiling (focusing on this height) the distance necessary for laying the communication lines and the installation of lamps, marked using a water or laser level.

After setting marks using the marking thread, you need to beat off the lines to install the fastener profile. Having cut off the baguette of the required size, attach it with the help of dowel-grooves to the wall. The mounts are installed every 10 15 cm.

Important! The strips of the baguette are cut at an angle, which is equal to half the corner of the room. Thus, it will be possible to make an aesthetically attractive angle.

The result of the correct installation of the profile will be a beautiful, even ceiling.

- Installation of the canvas

The canvas packed in a bundle must be removed from the envelope and straightened. At least two people perform installation: one will hold the fabric on weight, and refuel it in the profile.

Start straighten the canvas from the corners along a shorter wall. Fix the canvas in the middle of the profile with temporary mounts and, stretching it, continue to refuel it every. Leave a fabric supply of 4 5 cm, after the canvas is completely straightened, the excess can be cut.

If everything is done correctly and gradually, the difficulties with straightening the canvas should not arise. But even if everything did not go exactly as planned, and small waves formed on the ceiling, this defect is easy to fix. It is enough to warm up the folds of the folding with a construction or ordinary household hairdryer. Please note that the temperature should not be higher than 180 degrees, and the distance to the canvas is at least 20 cm. Warm up the fabric in a circular motion, and it will gradually straighten out.

At the end of the installation of excess, the fabric is cut off with a construction knife. In order not to damage the canvas, substitute a wide spatula under it and gently make a cut. Install a decorative plug.

The final stage of the tissue ceiling will be installed by lighting devices. Their location is thought out in advance. As in the case of PVC film, you will have to make embedded for massive chandeliers and use a special thermal ring made of heat -resistant plastic. It reliably solders the edges of the hole and holds the lamp.

At this installation is over. To clearly find out how to mount fabric ceilings, watch the video instructions.

What type of stretch ceiling you would not choose, modern technologies allow you to mount them quickly and admire beauty for a long time, minimally careing about the care of the ceiling coating.