It is difficult to overestimate the significance of the deep pump in the water supply system of suburban ...

|

|

The skirting board is one of the main decorative elements of the room. He gives the floor ... |

The modern market of building materials offers a huge assortment of various kinds ... |

Albes's rack ceiling - installation, features

The rack ceiling is a suspended structure with an attractive design and is characterized by ease of installation. Such a ceiling can be erected in rooms with a variety of purpose. Due to excellent strength, good moisture resistance, a rich assortment of colors and textures, this solution will become a decoration of any interior. Recently, rack ceilings from Albes, made of the highest quality aluminum profile and having a variety of coating from simple white to exclusive mirroring, are becoming increasingly popular. In the article, we consider the advantages of the albes rack ceiling and the method of installation.

Content:

- Information about the manufacturer

- The main characteristics of the rack ceilings Albes

- Necessary components

- Installation of the rack ceiling Albes

- Prices and assortment of rack ceilings Albes

Information about the manufacturer

Albes is a Russian production group, the main activity of which is aimed at the manufacture of aluminum and steel finishing materials. The company was formed in 1997 and today unites several diverse companies responsible for the production of products, its promotion and sale.

- All products are made according to the technology of cold rolling of sheet metal, as well as the method of stamping made of thin -leaf aluminum and galvanized steel. Such products are used in buildings and structures that make increased requirements for ceiling structures.

Rack ceiling Albes photo

- Albes can be purchased at retail outlets located on the territory of the Russian Federation, in the CIS countries, as well as in neighboring countries. The products manufactured are high -tech materials that combine rich experience and intellectual knowledge of the best engineers of the company. That is why for several years now the company has been holding a leading position in the Russian market for the production of finishing materials, as well as in their quality and a wide range of assortment.

- The goods manufactured have passed the necessary certification and are recommended for use in medical, general education, sports and many other institutions. In addition, the products have repeatedly occupied prizes in various all -Russian competitions, and the organization itself was awarded with honorary diplomas and diplomas, as the best enterprise for the production of building materials in Russia.

The main characteristics of the rack ceilings Albes

Rage ceilings are narrow straight parallel panels installed on a special frame from the guides. This design can solve many functional problems and create a unique design of the room. Albes racks are made, as a rule, from thin -leaved aluminum and have a polymer coating, on which the color scheme depends, in addition, panels with the color of the imitating various textures are produced.

Application area

- Ceiling structures are used in residential buildings, in office buildings and in public structures, they also found widespread at industrial facilities, in medical and educational institutions.

Dimensions

The following sizes are considered standard:

- length 300-400 cm, aluminum rails can be made by an individual order, the length of which reaches 6 m;

- width depending on the type of product varies from 25 mm to 20 cm;

- thickness from 0.32 mm to 0.6 mm.

Competitive advantages

- Strong and durable design with an unlimited service life and practically no need for replacement;

- original design and attractive appearance, thanks to a large assortment of color solutions and the presence of many diverse models;

- resistance to mechanical damage, chemicals and anti -corrosion resistance;

- have sound -absorbing qualities due to the installation of a special substrate;

- excellent fire safety, as the rails are made of non -combustible materials;

- increase natural light due to reflective properties;

- increased moisture resistance, due to which rack ceiling systems can be used even in rooms with high humidity (in bathrooms, pools, saunas and so on). It is also allowed to wash them and clean them with any detergents (without abrasive particles in the composition). It is important to consider that using galvanized ceilings in a humid environment, all available parts should be treated with anti -corrosion compounds;

- environmental friendliness of both the ceiling racks themselves, and components attaching to them;

- hygiene, due to the fact that metal structures are not susceptible to decay, mold, propagation of bacteria and fungi, and also do not emit harmful substances into the environment;

- fast and convenient installation, which will be able to cope with it independently without involving expensive equipment and highly qualified specialists;

- it is possible to mount lighting and other devices directly into the rails;

- it is allowed to create multi -level and curved structures;

- thanks to the precisely verified size of the profile, the reliability of the fastening and the necessary rigidity of the structure are ensured, in addition, the rails are not deformed at any load;

- good frost resistance and wear resistance, rack ceilings can be installed on unheated loggias and balconies, in addition, they have excellent color resistance, that is, they are not exposed to ultraviolet radiation;

- the versatility of the application, since the design of the products fits perfectly into any interior and harmoniously complements it;

- safety, thanks to a particularly subtle rental of aluminum, the ceiling rails of Albes have a small share and you can not worry about the health of others if there is a force majeure situation in which the panels can disconnect and fall down. In principle, the mounting technology is so reliable that under any ordinary conditions and high -quality installation this simply cannot happen;

- a relatively small cost, due to the production of products at their own factories located in Russia.

Color performance options

Albes suspended rack ceilings are made of aluminum or galvanized sheets, which are painted in factory at the production stage, and are also additionally covered with polymer substance. The front side of the panels can be painted in a fairly wide color scheme. Among the most common shades can be called colors such as:

- white matte or glossy options;

- metallic matte and silver options;

- chrome, super-chrome and super-chrome luxury;

- gold and super-gold;

- beige and light beige options.

These colors belong to the standard coloring, also include color solutions such as black, blue, light gray, copper and raspberry and rifle.

- Reiki can have a surface that imitates various natural materials, for example, the texture of a tree, pearls or granite, as well as mixed color options such as: white pearls with metal stripes, a gold strip on a white background, light beige or beige-gold strokes on White background, beige-green or green stroke on a light background and so on.

- At the request of the customer, embossed panels can also be made that will have light wavyness on the surface or have patterned perforation, as well as a variety of rails made of special mesh, with square, rhomboat and round cells.

- If it seems that it will not be possible to embody the design plan from the proposed standard options, then you can choose any suitable shade of more than 200 colors available in the RAL color collection (German color standard that has become universally recognized). Any selected color can be used in a matte or metallized version, as well as give a light mirror effect. The selected paint is applied by powder staining.

Important! You should not select a shade on the image on the monitor, since due to the characteristics of color rendering, the color on the screen may differ from the real color, so before making a choice, it is necessary to see the finished sample with your own eyes.

- The reverse side of the panels is additionally covered with protective varnish or primed with a special composition.

- Thanks to the rich selection of color solutions and design textures, it became possible to create a variety of voluminous interior solutions, avoiding inexpressive flat forms.

Varieties of rack panels Albes

Aluminum ceiling rails differ in the form of the profile. Albes offers several standard options for its products.

German design

- Like everything that is produced in Germany or has a German characteristic, this type of product has a strict and laconic form. These are rectangular rails, the width of which can be 8.5 cm, 13.5 cm and 18.5 cm.

- Mount such a ceiling is allowed to be open or closed. At open type Reiki are installed at equal intervals, as a rule, 1.5 cm. The formed cracks are either left in this form or closed with contrasting inserts with decorative layouts.

- Closed ceilings Mounted closely, without intervals. The color coloring of the panels themselves can be absolutely any, also offers options with perforation (1.5 mm in diameter) or additional designer relief.

Italian design

- This type of product is a racks with round edges made of aluminum, also one of the varieties is considered mesh panels made of protruding and exhaust metal nets. The ceilings of Italian design are mounted in an open and closed type. If the choice was made in favor of mesh racks, then the ceiling is installed only in an open way with additional decorative embroiders or without them.

- The standard panel width is 8.4 cm, a height of 1.6 cm, such indicators provide the necessary rigidity and reliability of the installed structure.

- The color scheme is offered a classic, as well as the client’s individual order, in addition, a perforation (1.5 mm) or a decorative relief can be applied to the surface.

Omega design /Omega»

- The rack ceiling in this performance is mounted only by a closed type, since the produced aluminum profile does not have lateral recesses. Standard dimensions are considered a width of 5 cm, 10 cm and 15 cm. When collecting the structure, it is recommended to combine the racks different in width on one supporting comb. This solution allows you to create an exclusive individual design, it is also allowed to combine ceiling panels and various colors.

- In addition to standard species, under the Albes brand, rack ceilings of original shapes are made, which help to arrange the ceiling space stylishly and unique.

Crinnine rails

Crinoline is called the designs of ceilings that have smooth transitions and bends. Most often, such a system is installed in those rooms where there are irregularities in the height of the ceiling, and also, if necessary, go around any parts, engineering communications, etc.

In addition, this type of panels allows you to create a peculiar design. Bent rails are made on the basis of Italian design panels. The resulting wave can have two directions:

- across the rails (when special bent combs and ordinary panels are used);

- along the rails (rails are bent in a special way in the factory).

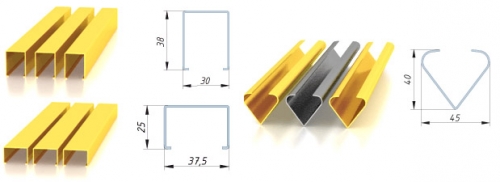

Cubo -shaped rail

- Such panels are used in open structures, both with additional layouts and without them. The aluminum profile has a rectangular cross section, and when installed, the surface of the ceiling space acquires a pronounced straight relief.

- The height of such a rail can be 25 mm or 38 mm, and the width is 30 mm and 37.5 mm.

V-shaped rail

- Such rails are also designed for open structures and the ceiling mounted from them has a pronounced relief.

- The difference from the previous type in the form of panels, which in the cross section resemble a heart -shaped object or letter V. The height of the rails is 40 mm, and the width along the protruding edge is 45 mm.

A plate -shaped rail

- Each such panel has a flat cross section. They are installed through equal gaps in an upright position. The plates are produced 90 mm high and 16.5 mm wide.

Necessary components

- Rail It is made of sheet aluminum and is the main element of the rack ceiling system. There may be two types: open (equipped with a layout) and closed (mounted close to each other). If necessary, joins in length using special connecting elements;

- layout Aluminum inserts, 16 mm wide, are designed for an open ceiling design, inserted into the intervals between open -type rails;

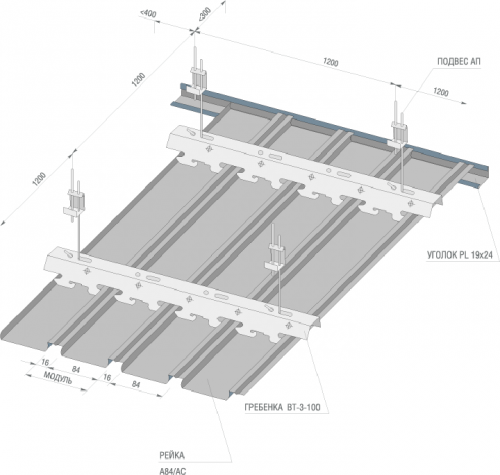

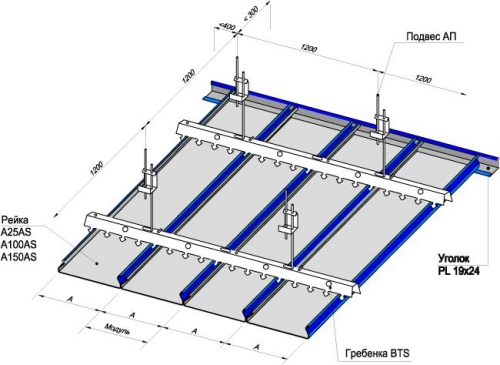

- rowman (Stringer) The element refers to the main parts of the structure, it is the panels that are inserted into this profile. It is guides made of thin -leaf galvanized steel (thickness of not more than 0.5 mm). Received its name due to the tongues that are necessary for fastening panels by snapping;

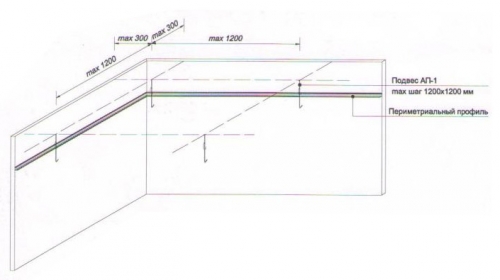

- perimeter profile This is a corner profile that is fixed around the perimeter and is designed to block the junction between the wall and the rail, it gives the design a finished look and can be several different configurations, a corner with sides of 19x24 mm is considered standard;

- suspension It is two thin knitting needles, one of which has a ring with holes for dowels, with which the element is fixed in the floor plate, the other knitting needle has a hook at the end to hold the comb. The knitting needles are fixed with a spring that serves to adjust the height. The element can be fixed with a rack ceiling at a distance from a supporting structure from 12 cm to 4 m;

- metiza These are self -tapping screws and dowels on which the entire structure takes place.

Experts recommend the use of point -built built -in lamps in the rack ceiling system, which will complete the composition and create the necessary comfort and comfort in the room.

Installation of the rack ceiling Albes

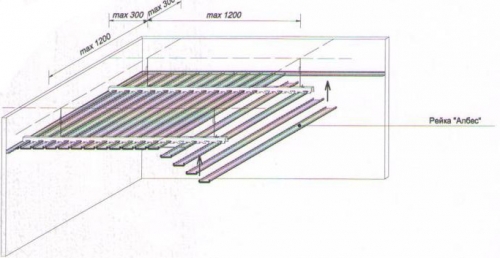

The rack ceiling involves installation on a specially installed frame. Albes ceilings can be mounted in a closed and open version, for this two varieties of panels are produced. For an open type of installation, a special layout is delivered in the kit, which differs in a smaller width than a rail and can be either in a single color scheme with panels, or contrast with them by color.

The first thing to do before starting direct installation is to purchase material in sufficient quantities, and for this, preliminary calculations should be made.

Calculation of the amount of material

- To begin with, the perimeter of the decorated space is measured. This parameter is necessary to install the required length corner profilewhich is fixed on the walls under the ceiling. You can get the required figure by measuring the length and width of the room and multiply the resulting result by two (if the room has a rectangular or square shape, if there are protrusions and complex design, then each section of the wall is calculated separately). It is worth considering that the corner is sold 3 m of length, which means that the resulting figure must be divided into 3 and thus it becomes clear how much the profile to buy for a particular room.

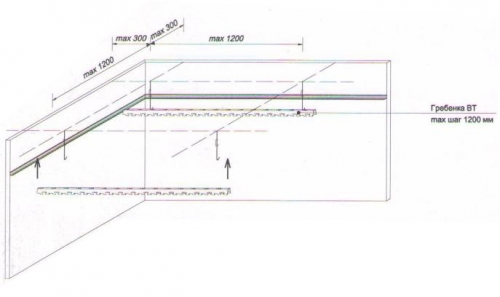

- The next thing to do is to calculate the length rowmanand their number. It is worth considering that the guide should be located from the wall no further than 30-40 cm, and between stringers the distance should not exceed 120-150 cm (it is better to make a lower distance, then the design will be more rigid).

- The combs are delivered to the sale of standard sizes of 3.8 m. Do not forget that the guides are installed perpendicular to the position of the rails, that is, if the vertical placement of panels is planned, then the guides are fixed horizontally and vice versa. We calculate the required length in meters, based on the size of the room, and then the resulting figure is divided by 3.8. Thus, you can find out how many combs are bought. When calculating, the number of connectors for guides should be taken into account.

- The most crucial moment is the calculation of the required the number of rails. Here everything will depend on the chosen width of the panel, as well as on the installation method (closed or open). For example, you can take the most common size of 8.4 cm, installed with an insert of 1.6 cm, that is, the total width will be 10 cm.

- The choice of the length of the ceiling panels will depend on the size of the destroyed space, so if the width of the room is 3 m, and the length is 5 m, then you can purchase rails of 3 m long and mount them along the width of the space. That is, for a room with sizes of 3x5 m, you need to buy 50 racks and 49 inserts (5000/100). Inserts are always required one less, since installing them on the edges is not recommended.

- This calculation is correct with the exact coincidence of one of the sides of the room and the length of the rail, if the room does not fit the standard sizes of the panels, then it turns out too many waste, for example, in the room 2.5x1.9 m (bathroom or loggia) is not rational to purchase 3M lengths , it is best to buy 4 m rails and lay them on the lower side, cutting in half.

- If necessary, connect the panels in length, buy special connecting elements. It is important, if there are opportunities to avoid such a docking, it is better to do so, since even straight rails without unnecessary connections look much more attractive.

- The last thing to calculate is the amount suspensions. For rack ceilings, there is enough suspension installation at a distance of 30-40 cm from walls and 120-150 cm from each other. In addition, you can find out the required number of dowels, since each suspension requires 2 dowel-bvys.

When all calculations are made and materials were purchased in the required quantity, you can go directly to the installation.

Stages of work

Tools and materials:

- a set of the rack ceiling Albes (panels, guides, corner and suspension);

- drill, punch, screwdriver;

- pencil or marker;

- ruler, roulette and construction level;

- pliers, knife and scissors for metal;

- dowel-gvo.

- Since the rack aluminum ceiling Albes is a suspension structure, the main ceiling plate does not require any special processing. If this type of structure is installed in a wet room, then you can treat the surface under it with special primers, which contains antibactericidal substances, while all the defects and seams available on the surface should be close up.

- It is important to fix the communications that will be located under the rack ceiling to prevent their accidental fall on the panel and damage to the installed ceiling structure.

- To begin with, marking is applied to the walls for the installation of an angular profile. If the fastening involves drilling tiles, then the marking must be done in such a way as not to get into the seams, otherwise the tile may crack or split. The marking line should be along the entire perimeter in one plane, for this you can use the construction level or laser level.

- If it is planned to place some additional elements between the suspended ceiling and the floor slab, then this should be taken into account at the stage of the markings and this is laid in advance in the indentation from the upper edge of the wall, if the space remains empty, then the minimum gap may be 5 cm.

- With the help of a perforator, holes are made in the P-shaped profile, retreating from the edge of 5 cm, at a distance from each other at 50 cm. Then, applying the corner to the wall, through these holes the wall itself is drilled. The corner is fixed with the help of dowel-grooves. After that, you can go to the marking under the guides and suspensions.

- The suspensions are installed at a distance of 30-40 cm from the walls from gaps of 1.2-1.5 m, with 2 dowels. When all the suspensions are securely fixed, you can mount a frame of stringers, in which ceiling rails will be located. The combs are suspended on the hooks available in the suspensions and hold them reliably.

- Each panel has such a shape that it is easily inserted into the grooves of the guide tire and, as it were, snaps there (to a characteristic click). If the last rail is not completely placed, then it should be cut and first inserted by the cut side into the corner profile and only then snap on the comb.

- At the last stage, the ceiling is leveled in one plane by pulling or weakening to the desired height of the suspensions.

Tips and recommendations

- When planning the installation of panels, you should rely on the direction of light from the window, so the joints should be located in the direction from the window to the opposite wall.

- If the room is narrow, then the transverse location of the rails will help visually to expand it.

- The square room will change the proportions with the diagonal installation of panels.

- To quickly perform the cut under the crashed elements (lamps, communications, decor), you can use the drill with the nozzle-box of the desired diameter.

Prices and assortment of rack ceilings Albes

| Type and dimensions | Color performance | Price for one | |

| Length 3 m | Length 4 m | ||

| Italian design (marking a), width 84 mm | White matte | from 180 rubles. | from 235 rubles. |

| Super-chrom | from 290 rubles. | from 385 rubles. | |

| gold | from 350 rubles. | from 460 rubles. | |

| Super-gold | from 480 rubles. | from 640 rubles. | |

| German design (labeling AN) width 85 mm |

White glossy | from 185 rubles. | from 245 rubles. |

| White matte | from 160 rubles. | from 215 rubles. | |

| White matte perforated | from 255 rubles. | from 340 rubles. | |

| Super-chrom | from 290 rubles. | from 385 rubles. | |

| chromium | from 230 rubles. | from 300 rubles. | |

| chrome perforated | from 430 rubles. | from 575 rubles. | |

| Super-gold | from 480 rubles. | from 640 rubles. | |

| gold | from 335 rubles. | from 450 rubles. | |

| metallic | from 180 rubles. | from 240 rubles. | |

| Metallic is perforated | from 270 rubles. | from 365 rubles. | |

| German design (labeling AN) Width 135 mm

|

White glossy | from 330 rubles. | from 435 rubles. |

| White matte | from 250 rubles. | from 330 rubles. | |

| White matte perforated | from 375 rubles. | from 500 rubles. | |

| Super-chrom | from 425 rubles. | from 570 rubles. | |

| Super-gold | from 690 rubles. | from 925 rubles. | |

| metallic | from 280 rubles. | from 375 rubles. | |

| Omega design (marking at) width 100 mm

|

White matte | from 220 rubles. | from 290 rubles. |

| Super-chrom | from 430 rubles. | from 575 rubles. | |

| metallic | from 300 rubles. | from 405 rubles. | |

| Omega design (marking at) width 150 mm |

White matte | from 290 rubles. | from 390 rubles. |

| White matte perforated | from 320 rubles. | from 425 rubles. | |

Albes creates rack ceiling systems, which consist of durable and durable metal panels, they are not afraid of sudden changes in temperature, resistant to mechanical stress, are easily mounted and convenient in operation.

Reese ceilings are distinguished by a variety of shapes and coatings, thanks to which all kinds of designer projects can be created, which can be implemented both in public buildings and in residential premises. And you can always be sure that such a design will delight its owners for many years, remaining unchanged.

i really liked the article about

i really liked the article about the rack ceilings. Everything is in detail and right. more about rack ceilings