Aesthetic attractiveness and good performance, diversity ...

|

|

Important component of the personal plot is a well that performs a lot ... |

Today in the world of flooring, a completely new floor material has appeared ... |

Yourself

The main task of the dry mixture for leveling the floor is to eliminate the significant irregularities of the surface and the simplified formation of the main supporting layer before the finish or laying the flooring. Self -leveling compounds help to hide the engineering networks, and mixtures for screening of a warm floor - distribute heat during the installation of a heated system. Today, there are a lot of different mixtures for leveling the floor on sale, so you can choose the most suitable for your conditions.

Content:

- Choosing a mixture for the floor

- Necessary tools

- Preparation of the base

- Preparation of the solution

- Schemes of screeding

- The process of filling the mixture

- Final work

1. Choosing a mixture for the floor

The secret to the successful selection of the mixture for the floor screed is recommended that you look for the bag from the back of the bag, the composition is written in small print and the size of the mixture grain is indicated. If the size of the fraction of a dry mixture is more than 1.5 millimeters, then this screed is ordinary, which requires alignment with a spatula. The self -leveling mixture has a grain size of 0.6 - 0.8 millimeters.

The classic self -leveling mixture should provide closely 10 millimeters of the finished layer. If the manufacturer declares the mixture layer up to 30 millimeters, then you can confidently count on the effect of self -growing the mixture. If this parameter is 50 - 80 millimeters, then this is a strong composition, less fluid, thick consistency, like sour cream, which should be used according to the beacons by the usual rule.

When buying a mixture for aligning the floor, you should never forget about the deadline for manufacturing the product. Here you need to do, as with food products, to choose only fresh bags. Keep in mind that for the promotion, most often, a stale product is offered. Therefore, do not hesitate to watch the date of manufacture on each package. The shelf life of the mixture, subject to proper storage, reaches 6 - 12 months.

To calculate the mixture for screeding the floor, some calculations need to be made. With a layer thickness of one millimeter, 2.2 kilograms of dry mixing per 1 square meter leaves. Indicator 2.2 must be multiplied by the average value of the floor difference. To calculate this number, measure the hollows and surface height relative to the zero value, take it from a larger smaller and divide by 2.

Multiply the resulting value by 2.2 to get the approximate consumption of the mixture for screeding the floor by one square meter. Next, multiply this indicator by the number of square meters of your room. If you need to find out how much you need the bags of the mixture for the floor screed, then the number obtained in kilograms should be divided into a mass of 1 bag of the mixture.

2. The necessary tools

You will need you to make a floor screed:

- Measured vessel to measure the dose of water;

- A container with a flat bottom to knead the solution;

- Low -speed drill for high -quality mixing of the solution;

- Needle roller for removing air bubbles after applying to the base base;

- Rocket with height adjustment to distribute the solution;

- Needle soles for movement.

3. Preparation of the base

Before the application of this solution, it is recommended to close the windows and doors in the room. The air temperature in the room and the base should be 5 - 25 degrees above zero. Air humidity should be no more than 90%. The air indoors should not move above the floor during operation and 24 hours after its end.

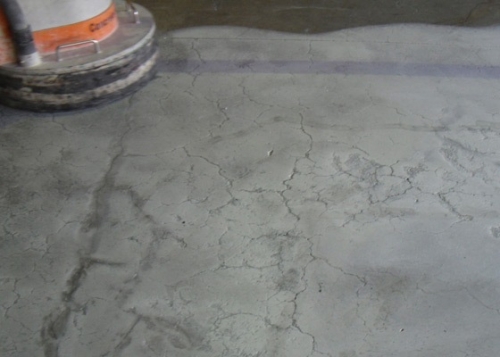

First of all, it is necessary to check the state of the base, or rather its strength using a hammer of Kashkarov or Ri-RI. Carefully clean the floor of dust and construction debris. The base should also be vacuumed. All cracks and chips that violate the integrity of the base need to be carefully disengaged, cleaned and recorded with a repair mixture.

Ideally, it is recommended to cover the surface with a layer of primer composition, which will decrease the absorption of water from the mixture and adhesion of the base base with the solution will improve. It is customary to apply the primer with a thin layer, avoiding the formation of a puddle. After drying the primer, check the waterproofness of the base floor. To do this, pour a little water to the surface of a primed screed and visually determine a change in its amount. If all the water is absorbed at the basis, it is recommended to apply the primer again.

If you are aligned with the weaker sex, then you should definitely install a reinforcing grid that will strengthen its design. When using a fiberglass mesh, the layer thickness should reach at least 1 centimeter. The grid is attached to the base pointwise. If it does not stick well enough, then it can come to the surface.

After that, you can set the installation of beach profiles. Install the slats so that their top coincides with the marks, which are indicated on the wall. By the way, experts do not use such profiles, since even without them they can withdraw a horizontal. But if you first make a screed, it is better not to refuse the lighthouses to improve the quality of the floor leveling.

4. Preparation of the solution

First, pour water into the cooked container and add the finished mixture for the floor screed, constantly mixing the mass. The water that is necessary to dilute the composition should not be too hot, otherwise the mixture will not have time to spread and an uneven surface will occur. With large areas, a large amount of solution is required, which can not be stirred manually. Therefore, mix the mass of water using a powerful drill with a special nozzle.

At this stage, it is recommended to strictly comply with the recommendations of manufacturers, because excessive amount of water provokes the stratification of the material, foaming the screed, improper hardening and loss of strength characteristics. They work at room temperature, with lower indicators some problems may appear.

5. Schemes of screed filling

Take such sketches of floor alignment using dry mixtures:

- In a dry room with a strong base, a contact floor is used. With a similar scheme, a rigid connection of the screed, made of self -leveling mixture, with a draft base, is ensured.

- If the base is sometimes exposed to moisture or it is difficult to achieve high adhesion with a leveling layer, it is worth using the floors on the separation layer. In this case, the leveling composition is customary to apply over the separation layer created from a plastic film, the thickness of which is 0.2 millimeters. Such a film is laid on and with a climbing wall.

- If it is planned to additionally equip sound or thermal insulation, the leveling surface is used on the insulating layer. First, thermal insulation mats are laid on a dry base so that they are adjacent to each other tightly, and along the walls - a strip of polystyrene foam for deformation seams. A polyethylene film with entering the walls is placed on top, and then the leveling layer.

- In the manufacture of the leveling floor in the floor heating system, the filling of the construction mixture for screeding the floor is carried out in two stages to prevent ascending to the surface of the cables and pipes. Before laying the mixture with water heating, the pipe is filled with water, then the first leveling layer is applied to the upper edge of the equipment. After grasping the first layer, the second layer is applied above the edge of the equipment by 25 millimeters. The system can be turned on 7 days after pouring the solution, gradually increasing the temperature per day by 3-5 degrees.

6. The process of filling the mixture

The finished mixture must be poured on the prepared base, starting from the far wall from the entrance and filling all the irregularities to the lighthouses. It is recommended to carry out all the filling in one appointment, working very quickly. This avoids the process of avoiding the upper edge of the previous strip and the surface to make perfectly even.

If the filling of a large surface is supposed to be poured, then the mixture is poured into the black floor with strips parallel to the wall of 30-40 centimeters, making the filling through one. The gaps are filled when the previous stripes dry. The joints of the walls of the walls and filling are filled with sealant and are brought using a wide steel spatula.

During machine filling, the solution is supplied using mixing and moving units at a speed of 6 - 120 liters per minute, depending on the type of apparatus. Before starting the procedure, it is recommended to check the mixture for spreading and pour a small amount on the base base. After stabilizing the mass, the diameter of the spot should be measured and compared with the indicators indicated by the manufacturer - the amount of the floor screed and the corresponding diameter.

Remember that in the process of applying the solution it is impossible to go beyond the thickness, which is characteristic of a specific type of mixture for the floor screed. When pouring thinner layers, it will be simply impossible to hold the water that is required to harden the solution. If the screed is exceeded in thickness, then the layer will not grab, so it is recommended to lay such layers in several visits.

7. Finishing work

After pouring the solution by the rule or spatula, it is finally aligned. With the help of a needle roller or brushes with a hard long pile, bubbles are removed that occur in the material. It is advisable for the first few days after leveling the floor to adhere to the temperature regime, which is indicated by the manufacturer, to avoid drafts and direct sunlight.

The time for which the mixture will completely dry will directly depend on the humidity and air temperature, as well as the screed thickness indicator. It is not worth accelerating a similar process without consulting specialists, since manufacturers do not provide for hardening of a dry mixture for aligning the floor in non -normative conditions. Failure to comply with technological conditions and high moisture content at the base slows down the drying process.

When it will be possible to walk on the base, deformation seams should be made on the surface, which are previously marked on the wall. To do this, cut a leveled layer using an angular grinding machine. After that, the deformation seams must be filled with special elastic material.

Before pouring the finish layer, you should pay attention to the level of moisture in the leveling layer, it should be the same as in the material used. Following all the above recommendations about the use of a quick -drying mixture for screed and competently observing technological processes, you will get a high -quality, perfectly even base for future laying of the flooring.