Houses erected from a log house are primarily distinguished by their environmental friendliness. To be in...

|

|

Porcelain tiles - excellent material for decorating the personal part of the house. It... |

Until recently, a chandelier was used to light the room, proudly ... |

How to glue linoleum with cold welding

The aesthetic attractiveness and good performance, the variety of design and color solutions, the safety and durability of use distinguish linoleum into a separate group of modern flooring, and the ideal ratio of high quality and affordable price makes its use almost universal.

Content:

2. Cold welding linoleum with glue: varieties

3. Technological features of cold welding

Linoleum connection methods

Being a universal flooring, linoleum is successfully used in premises of residential and office type, warehouse and production areas. In order to perform high -quality linoleum flooring, the performer must have extensive experience and knowledge of the foundations of styling technology, a professional approach and accuracy. When arranging the floor by linoleum, non -standard situations may occur that require the adoption of operational, and most importantly, correct decisions. So, for example, in the process of working at the joints of the canvases, rather noticeable gaps can form, which to hide which is to make the canvas in a single one, it is possible only using hot or cold welding for linoleum. To get high -quality seam, you must follow certain rules and recommendations.

The main methods of welding linoleum with your own hands are 2 ways:

- hot method

- cold way,

each of which has its own undeniable advantages. At the same time, we immediately note that the most simple and less time -consuming method that does not require special skills is the cold welding of linoleum with glue, while hot welding is very painstaking work, the performance of which will master only an experienced professional using special tools.

Hot welding

Hot welding is applicable for the location of the seams of commercial linoleums, in those rooms where there is a significant intensity of mechanical influences on the floor surface, for example, in public buildings. Such a coating is characterized by increased strength and high cost, which means that professional skills and a special tools welding (soldering iron) and filler rods made of a rounded or triangular profile, made of plasticized polyvinyl chloride, will be required. Note that high -quality welding is possible only after gluing the coating to the floor surface, so the best time to perform welding measures for the next day after gluing.

Linoleum welding technology is as follows:

Before starting work on adjacent panels, the edges are pre-cut specially under the shape of the bar, thereby forming the V-shaped grooves. A welding heating pad is used to form hot air flows. Moving through heating elements, the temperature of compressed air increases and reaches 300-400 C. During the welding process, the burner, and with it, the filler bar is carried out along the joint. The stream of hot air softens the surface of linoleum and two canvases under the influence of the clamping roller are reliably welded. After the seam has cooled slightly with a arcuate knife or flat chisel, a part of the paid cord protruding above the coating is carefully cut off and the seam is polished until a flat surface is obtained.

If you did not have a welding burner at hand, then you can use an ordinary soldering iron, which, for sure, can be found on a workbench. However, the result may not upset you you will not be able to get an uniform, beautiful seam along the entire length of the coating. Therefore, if you need a high -quality, perfectly even seam and you do not have special equipment, then it is better to use cold welding.

Cold welding

So, what does the expression mean a cold welding for linoleum - a combination of seemingly two opposite concepts? The answer lies in the technology of the connection of two paintings special glue, being a solvent, in a short time segment turns the edges of the material into a liquid state. The canvases are connected, and after evaporation of the solvent, aesthetic connection of increased strength is formed. The technological process of cold welding completely eliminates the processing of linoleum with hot air.

The final result is a strong and even quality in quality is at all inferior to the result of the connection based on temperature melting, while the need for buying an expensive soldering iron disappears. Therefore, to combine the paintings of the household coating, as well as obtaining an intricate or complex (in shape and configuration) seam, experts recommend using the cold welding method of linoleum, the price of which is available for any category of customers. The main drawback of the method is the content of volatile solvents harmful to human health. Therefore, when performing cold welding, provide the room with fresh air.

Cold welding linoleum with glue: varieties

Depending on the glue used, cold welding can be of two types:

- Cold welding a-cell,

- Cold welding s-kley.

You acquired linoleum and, barely having time to spread it, want to connect several of its parts in a whole canvas? Then use it the first type (a) designed specifically for welding the joints of freshly laid coating.But if your floor covering managed to lay down for some time in the apartment, and you began to notice slightly dispersed seams, then it is better to apply the second method (C). The main difference between glue A and glue C is in consistency, in other words in density.

The C -blanket is much thicker, since its task is to connect the joints of two paintings, which is several millimeters. Pouring glue with the coatings between the canvases, you fill the empty space, which after drying forms extremely strong fastening. Cold welding can be performed without adhesive tape, since thick glue will not spread, which means that the probability of undesirable melting of the coating is zero.

How to glue linoleum with cold welding a-cell?

A-blanket works in a completely different way: new parts of linoleum are subject to fastening, tightly laid on each other. Glue actually melts the edges of the coating, forming a whole and perfectly flat panel. The unique properties of the glue provide a high -quality and strong welded seam on the flooring, especially if it is securely glued to the base of the floor.

Technological features of cold welding

Creating a weld

If the flooring is purchased, but not yet laid, then the priority of canvases for obtaining a minimum seam will be the paramount task. For this, two parts of linoleum overlap (at least 5 cm) should be applied. The cut line will be located in the middle of the overlap. With the help of a pencil and line, markings are applied, according to which the material is later cut with a special wallpaper knife. The edges obtained in this way will joke perfectly.

The reliability and durability of the weld, and linoleum as a whole, are determined by the strength of the consolidation and immobility of its edges. It should be remembered that the glued linoleum is not deformed during operation, it is not terrible moist cleaning in the room and even rearrangement of furniture. The coating to the floor can be glued with glue or bilateral tape.

If your room has an area of \u200b\u200bmore than 20 sq.m., then gluing the coating is a mandatory stage in the design of the floor space.

Cleaning the future seam

Since glue contains harmful volatile solvents, gloves become an obligatory attribute of the welding process. Using a vacuum cleaner, carefully clean the joint of particles of dust and dirt. If you wipe the water dry in the seam.

Since cold welding, entering into direct contact with the front surface of the flooring, can make it less attractive and ruin the overall impression of the interior, you should think about protecting the edges of linoleum panels, especially if linoleum has a glossy surface. To avoid unpleasant surprises in the form of a spoiled, molten coating, it is necessary to use a wide unilateral painting tape. It can be glued with two stripes on each panel along the edge or glued one strip to the future weld. Then gently cut the tape on the joint, avoiding possible damage to the coating.

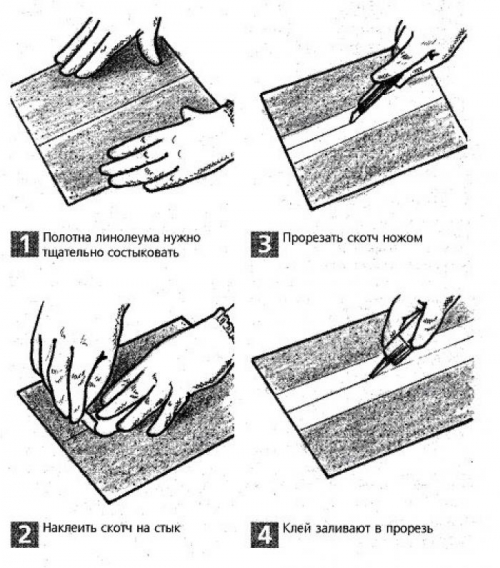

The photo shows a soft linoleum, for welding of which two strips of painting tape are used.

Cold welding

To perform cold welding, it is necessary to carefully cut out the tape over the joint of the panels, and when applying the adhesive composition, the presence of a needle on the tip of the tube should be taken into account, along which the glue will drain. Therefore, in order to avoid excess glue to get on the surface of the coating, keep a cotton swab ready. Without rushing, apply glue to the joint between fastened canvases. To do this, it is enough to draw a tube along the seam, evenly dosing the composition along the entire length of the processed surface. In the process, withstand the height of the glue strip of 4 mm and follow the needle movement strictly along the cut.

You can apply glue in two ways:

The first glue method is applied at once on two canvases, as in our example. The glue that has fallen into the seam enters the coating and polymerizes.

The second glue method is applied only to one panel, which is processed separately, and then attached to the floor surface. Next, the adhesive is applied to the second canvas. The most tightly as possible is laid next to the first and thoroughly leveled, thereby ensuring the high -quality docking of glued pieces.

The method you have chosen is determined by the convenience, consistency of the glue, the current state of flooring and other factors.

After the glue dries (1-2 hours), you can safely walk on the floor.

Removing excess glue

After the glue dries, you can remove the painting tape.

When performing cold welding, part of the glue can come out. No need to rush to remove excess during welding, since the adhesive of the coating may occur from the coating, and this is fraught with a decrease in the quality of the weld. In addition, there is a possibility, using dirty instruments, a non -chilled layer of glue gets dirty. And finally, the last argument is that the dried glue is more convenient to cut off.

Note! Fresh cold welding is a little spring, and at the moment of tension, a recess may appear when cutting, so it is recommended to remove excess in two approaches.

As you can see, the cold welding of linoleum is a simple job, which absolutely anyone can successfully cope with!

You can learn about how at a high quality level and in a short time to perform cold welding of linoleum from the video on YouTube.

Invite a specialist. He

Invite a specialist. He will talk about hot and cold welding. Do not confuse the people. You talk about cold welding, a picture with cutting a welded welding cord with hot air. Decide something ...