The basement insulation is of great importance. This allows you to reduce heat loss at home ...

|

|

Roller shutters Modern solution in the field of security of commercial ... |

Many different solutions are used to design the ceiling. Each option has how ... |

Laying porcelain tiles: step -by -step instructions

Among the variety of tiles used for external and domestic cladding and presented as products in the construction market, porcelain tiles occupy a special place, and its mass production is a new promising direction in the production of finishing materials. Today, new and modern types of decoration are in demand, while the durability, quality and decorativeness, as before, remains in demand by the consumer. All this goes well in porcelain tiles. This excellent material, due to its attractive characteristics and appearance, deservedly has the glory of one of the best finishing materials. The article will talk about laying porcelain tiles on the floor.

Content:

More recently, porcelain tile was used only in industrial construction and was intended for external cladding of buildings. It was also used as a floor covering for public objects with increased cross -country ability and high load on the surface, such as airports, metro, stations, industrial premises, for the interior design of restaurants and cafes. That is, where its excellent operational qualities could be confirmed in practice.

Porcelain tile photo

- But the fact is that then the porcelain tile had an unattractive design of the same type, was distinguished by a high price, large dimensions, and therefore was not available to the simple consumer.

- Now modern technologies have made it possible to expand the range of these products. After that, designers also turned their attention to this material, releasing new spectacular and unsurpassed in beauty collections specially designed for household use. So porcelain tile has become available for wide consumption.

- Most often, porcelain tiles in private construction are used as a floor or wall coating in rooms with high humidity, for example, in kitchens and bathrooms, and high abrasion requirements, such as corridors, living rooms, etc.

Types of porcelain tiles

Porcelain tiles - a quality product of modern production in the field of finishing materials. Due to its natural composition, it is environmentally friendly, which is considered a very important indicator when the dominance of artificial cladding in the construction market today is rather the norm. And such characteristics as the beauty and durability of the material put it in the ranks of leaders in use as a decoration.

A wide variety of design options, a wide palette of colors, a variety of textures that not only repeat natural granite, but also imitate other natural materials, make it possible to use porcelain tiles to implement the most incredible in the courage and attractiveness of design ideas. In order not to be mistaken in choosing a specific type of material and select it for the required tasks, you should pay attention to the following classification:

- Glazed and unglazed tiles. The difference between them is that a vitreous layer is applied to the surface of the first product in the production process, which is then burned. The result is a transparent or matte layer on the surface of the material. Unglazed porcelain tile is usually used as a cladding of external walls, and a non -effective structured surface allows you to lay it on the outer steps of the building, in vestibules and corridors. The glazed surface also makes it possible to reproduce various natural materials with maximum accuracy: material, stone, expensive wood. These imitations can be so professionally made that at first glance they cannot be distinguished from real ones. For example, a porcelain parquet can not only look like a wooden one, but unlike it, is not afraid of moisture, does not deform over time and does not need constant care. Imitation for natural stone - the main feature of the glazed product - successfully conveys its structure and appearance, allowing the use of tiles as an excellent substitute for this natural building material.

- Matte porcelain tiles. It is intended for the interior design of the room and for its external decoration. It can be decorated with walls and facades of buildings, mount on the floor as a floor covering. Such a finish can no doubt decorate any, even the most luxurious elite house. At the same time, it is capable of perfectly combined with almost any internal design, as it has attractive aesthetic qualities, it is convenient and practical in operation.

- Polished porcelain stoneware. This type of tile is obtained by grinding standard blanks with a diamond disk. Such processing gives the finished product a unique shine and exceptional smoothness. It is this type of tile that excellently imitates natural marble or travertine and therefore finds use in luxurious interiors.

All types of porcelain tiles can be ordinary and rectified. The difference is in different design of the edge of the product. In the latter case, porcelain tile has a edge strictly cut by the machine. Various types of tiles are used for different types of styling - from or without seams.

Extraordinary and original variations of the decoration of rooms with porcelain tiles open up new opportunities to give expressiveness and uniqueness to the interior, allowing you to create an indescribable atmosphere of beauty and comfort in the dwelling.

Porcelain tile characteristics

Porcelain tile has a number of positive characteristics.

- Low level of water absorption. This indicator is only about 0.05 %. In the case of installation on the street, this allows the material to tolerate the temperature differences from positive to negative and vice versa. This is a guarantee that porcelain tiles for the facade are not deformed and not cracked. If it is supposed to be used for internal cladding, then this quality will be useful if you place the tiles in baths, bathrooms, saunas - where there is high humidity.

- Resistance to chemical reagents. There are a lot of aggressive substances in many detergents intended to maintain order. Modern coating should have increased resistance to all kinds of negative influences. Porcelain stoneware is just that. Thanks to its excellent qualities in caring for it, you can use any, even the most aggressive detergent.

- High degree of wear resistance. This indicator among porcelain tiles surpasses the same in natural stone. Even with the most enhanced operation, it is difficult to bring into unusable in a short time, the coating from it will serve almost forever. The question of its replacement may arise rather because of the change of interior, and not due to the fact that the cladding could not withstand the test of time.

- Resistance to physical and mechanical damage. Porcelain tile can withstand significant loads. Moreover, it does not matter where the tile is located, inside or outside the building, the material will show itself equally well in any situation. Even in the most stringent operating conditions, the cladding will remain unchanged and will not lose its appearance.

- And finally, decorative qualities. This is not quite a characteristic, but this detail matters when it comes to cladding. Porcelain stoneware are very beautiful, have a pronounced structure and a rich color, which remain unchanged for a long period of time.

Porcelain tile sizes

Porcelain stoneware is sold mainly in the form of tiles, the dimensions of which, as well as the ratio of the parties vary, which determines its format. The most common is a square, but there is also a rectangular shape. In addition to the size, the thickness of the product is also important, since this indicator affects the strength of building materials, as well as ultimately on its cost.

The dimensional row of tiles manufactured today is quite diverse and includes different variations that have become widespread in practice.

- Porcelain mosaic - The smallest format of tiles, their size is 5 by 5 cm. The mosaic is incredibly beautiful, but requires a certain skill when laying. It is used to create both the floor and wall canvas.

- The most common and economical format 30 by 30 cm. The thickness of such porcelain tiles is from 7 to 9 mm. It is intended for floors with an average degree of patency. She is also issued an area in shopping centers, industrial premises and offices.

- The next most popular format 60 by 60 cm special. Plates of this size usually decorate the facades and interior in buildings of large dimensions.

- Non -standard format 30 by 60 cm. The release of such porcelain tiles is dictated, most likely, designer considerations. She looks nevertheless very interesting.

- Industrial format. Tiles with sides 20 by 20 cm. The scope of its application is highly loaded flooring. It is characterized by increased strength and immunity to chemical effects.

- Large sizes of tiles. Used as facade panels, wall covering. The size of the tiles can reach 3 m. It differs highly by the cost, which is dictated by the individuality and exclusivity of manufacture, as well as a larger thickness of the canvas of the tiles.

The price of porcelain tile is determined in each case individually and can directly depend on the size, conditions of use, manufacturer, design. The allocated budget for finishing work remains important.

Laying porcelain tiles

Porcelain tile belongs to materials that are simple in installation. You can perform it yourself. This process is simple and resembles laying ordinary tiles, with the only difference being that there are nuances that are characteristic of this material. Before starting laying porcelain tiles, you need to make a small digression and start with preparatory and additional work that are necessary to achieve the appropriate result.

Stages of work

- First, you should properly prepare the surface on which porcelain tile will be mounted. To do this, carefully check the entire area for the presence of contaminants and remove them. Then align the old uneven surface with the appropriate solutions until the base is equally even in the plane. Such preparation actions will not only facilitate the styling, save glue, but in the future they will exclude the formation of cracks in the porcelain cover.

- Since porcelain tile is a very dense material and does not absorb moisture, the use of the fastening layer in this case is a mandatory moment. It is better to take the type of primer, which is recommended by the manufacturer. It is easiest to apply it to the base of all kinds with brushes or roller until complete and thorough absorption of the solution over the entire surface.

- Almost always, the walls in the rooms are uneven and in some places the corner and curvature may vary. The estimated area does not always correspond to a geometrically correct square or rectangle and the sides may differ among themselves. In order for the tiles to lie evenly, it will be necessary to first correctly mark the place for them. Why first you need to determine whether the walls are located symmetrically, if necessary, to retreat the desired distance and only then begin to lay the material. For the convenience of performing work, you can use the stretched thread and lay the tile in accordance with it.

- Using porcelain tiles, usually used compounds are not suitable, since they are simply not able to hold heavy tiles with a dense structure that has no time and for this reason that does not hold water. Therefore, here you can not do without special glue. He must have high adhesion and elasticity. Only such a composition can reliably hold the tile in place. Before the direct use of the adhesive, you need to prepare it according to the instructions.

- It rarely happens that piece cladding is used by a whole format, but most often it has to be cut by walls, communications and in other places. If there is a question about how to cut porcelain tiles at home, then to cut it, you will need a tile cutter, a grinder or a tile. Or this can be done on a special machine with a wet method. This applies to linear cuts, but if round holes are required for communication, then they can be cut out using a diamond crown.

- In addition, you will definitely need a container for breeding glue, a mixer with a nozzle for stream -abnation, a ruler, a roulette and a level for performing the necessary measurements, a trowel, a gear stapel or cells for working with a solution, a hammer with a rubber tip and the same spatulas for grouting of the seams. It's all. Now you can start work on laying porcelain tiles.

Laying porcelain tiles on the floor with your own hands

The process of laying porcelain tiles is easiest to illustrate on the example of flooring as the easiest option, giving a visual concept of the sequence of work. You can proceed after the proper preparation of the draft floor. The stages of work include the following.

- There are many different ways to arrange tiles. With a rather complicated configuration of the picture, the easiest way to first make the marking, taking into account all the gaps. This will facilitate further installation and will allow you to have a clear idea of \u200b\u200bthe result.

- As a rule, the amount of tiles purchased should be more than 10%calculated. This is necessary in order to compensate for possible waste arising in the process.

- Installation of porcelain tile begins from the far, opposite to the entrance of the wall. This is not only aesthetically true, but also correctly in a practical sense.

- After priming and kneading the glue, you can proceed to its application. First, the contact layer is applied to the base and leveled with a smooth spatula. Then, a gear edge of another tool creates a relief surface, which will provide the best contact of porcelain tile with the base.

- Glue is applied to both surfaces, on the base and on the tile. The area of \u200b\u200bthe applied adhesive should not exceed the size of 3-4 lines.

- After the first row of tiles is laid, the subsequent fragments are applied to the near edge of the first row laid from the performer by the edge and lowered to the solution.

- The horizontal arrangement of the tiles in the plane is constantly checked by the level. It is convenient to adjust just lightly tapping it with a hammer.

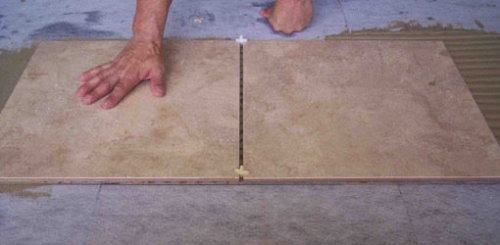

- You can observe the same gap in the seams between fragments of tiles using special plastic crosses, the thickness of which determines the thickness of the joints.

- The adhesive solution, which performed in the seams between the tiles, necessarily removes until it froze. The seams should be empty.

- Such new systems for aligning tiles as SVP have also proven themselves. This is a fairly simple and effective system that even a layman can cope with.

- If necessary, give the tile the required shape, a particular tool is used.

- When connecting porcelain tiles with a different coating, in order to exclude cracks, an elastic compound is used. On compounds with floating structures, the use of rocks of different configurations is possible.

- According to this scheme, the whole tile is laid out in a row, until the entire estimated area is busy.

- Porcelain tiles are left until the glue composition is completely dry. Usually it takes 1-2 days and depends on the thickness of the applied working composition, temperature indicators and the composition and brand of glue.

- After the glue dries, the next step is the grout. To do this, there are special grouting compositions, the characteristic feature of which is rapid captivity and light removal of excess with a wet rag.

- Before applying grout, crosses are removed from the seams, which have already fulfilled their destiny and are no longer needed.

- The grout must be carried out carefully and carefully, not missing a millimeter, so that there are no voids and irregularities, as this spoils not only the appearance, but also reduces operational indicators.

- The grout solution is sealed into the seams with a rubber spatula, the solution is applied, well touched behind the edges of the tiles and to the level with them. The dried surpluses are carefully removed with a cloth or sponge so as not to wash the solution from the seams. A week later, it becomes so strong that you can no longer worry about its preservation and feel free to wash the porcelain tile.

- The space between the tiles and the pipes is filled with a silicone sealant.

- You can proceed with the operation of the flooring of porcelain tiles no earlier than a week later. Then you can put heavy furniture, walk on it. The finished flooring, subject to the laying instructions, will be strong and durable.

Modern porcelain tiles are aesthetic, safe and largely promising material. The cladding from it looks excellent in any interiors in complexity, giving them fabulous beauty and luxury. The remarkable operational qualities of the coating, along with durability and accessibility in the price category, make it attractive for more and more consumers. The installation of porcelain tile is not at all complicated, which allows, if necessary, facing work or reconstruction of any objects in the shortest possible time.