The bathroom is a room with a high level of humidity, so it needs ...

|

|

The process of installing the toilet is quite simple. The main condition for its successful ... |

At the beginning of the development of the technology of casting reinforced concrete structures, builders measured with ... |

Warm water floor in a private house

The arrangement of a warm floor allows you to save well on heating. In addition, it perfectly replaces all heating devices, while freeing the useful area of \u200b\u200bthe room. We consider the technology of the warm floor of water and how to make a water warm floor further.

Table of contents:

- Warm water floor in a private house - the principle of operation

- Water warm floor: advantages and disadvantages

- Warm floors Water mounting circuits and varieties

- Calculation of a warm water floor: process features

- Installation of a warm floor: a collector and its features

- Laying a warm water floor on a concrete base

Warm water floor in a private house - the principle of operation

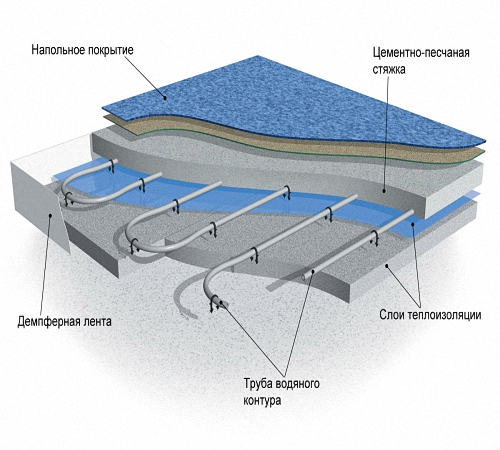

The water floor is a new independent heating system, which in some way replaces radiators and convectors. This system consists of mounted pipelines, inside of which there is hot water. They are laid on the base made of concrete or wood, and are covered on top with the help of floor finishing material.

The pipes that consist of systems are polymer, which is the circulation of hot fluid, most often water. Its feed is carried out using central heating or boiler system. Warm air begins to warm in the underground space and gradually rises up the room. Thus, heat is distributed throughout the room. The lower part of the room is more warm than the upper one, so it is very comfortable in the room.

The scope of use of a warm water floor applies to private houses, since in multi -storey buildings, there is a risk of flooding neighbors with hot water, due to the breakdown of the system.

The warm water floor system consists of the pipeline and the mixing unit of the heat carrier. For the pipeline, preference should be given to pipes having a high level of thermal conductivity, in addition, they should differ in flexibility and have a slight resistance. To fill the pipeline, a cement screed is used - a pump, armostatic mixer and a collector are included in the system of mixing the heat carrier.

Water warm floor: advantages and disadvantages

If we compare the arrangement of a warm floor using another kind of heaters, then the first option has the following advantages:

1. Reducing heating costs.

When arranging a warm water floor, cash costs for the use of electricity are reduced by 25-30 %. If the area of \u200b\u200bthe room is large enough and the ceilings are too high, then the warm water floor is the best option. Since in this case, it helps to save 50%.

2. Comfortable living conditions.

The room, with a warm water floor, warms up evenly, thus created optimal and comfortable conditions for people's lives. When using radiators, the warm air that comes from them immediately rises upstairs, thus, the lower part of the room remains unheated. On the floor with a water floor, you do not have to walk shown, and children can calmly play on it without overcooling.

3. High level of security.

The coolant is under the flooring, thus, the risk of burning about it or injured is excluded.

4. The attractiveness of the appearance of the room.

The warm water floor is hidden in the underground space, so all pipes and other elements of the system remain invisible.

5. Successful compatibility.

Water warm floor is well combined with most finishing materials, in the form of tiles, linoleum, laminate.

6. Available cost.

Installing the entire system requires small monetary investments compared to the result.

7. Various connection options.

It is possible to connect a warm water floor to an autonomous or centralized heating system.

8. Independence from power supply.

This advantage allows the warm floor to heat the house, even at a time when for some reason the light was turned off.

Among the shortcomings of the use of water warm floor at home, we highlight:

- time and labor costs for the installation of equipment and the entire system are quite high, since there are several different materials laid on the surface on the surface;

- When malfunctions appear in the form of leaks, the entire flooring should be dismantled to eliminate them;

- The need for additional sources of heating, since extremely warm floor is not able to cope with the heating of the room.

Warm floors Water mounting circuits and varieties

Depending on the main material, three main types of installation of a warm floor are distinguished:

- concrete;

- polystyrene;

- wood.

The first option is the most popular, as it differs in the highest reliability. In order to equip the distribution layer in the concrete version of the construction of the warm floor, a cement-sand solution is used.

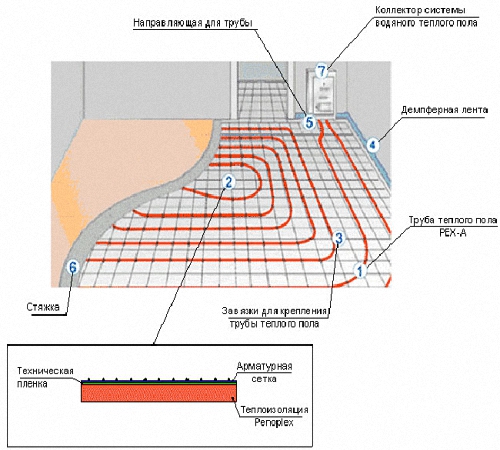

On a pre -leveled surface, a waterproofing layer is laid, and then thermal insulation, then the pipes are laid and fixed. To equip a warm floor with a warm floor in the area of \u200b\u200bthe room, you should take care of laying a reinforcing grid.

When arranging a small room, plastic brackets, fasteners or dowel-tricks are used to fix pipes.

The previously installed system is poured using a solution of cement, sand and special plasticizers that help strengthen the screed and protect it from exposure to high temperature.

In this case, the best decoration options are the use of tiles, decorative stone or laminated parquet board.

The second option is the arrangement of a polystyrene system. This option represents a simplified installation of a warm floor system, during which polystyrene plates are used. Plates are pressed in a special form, they have the form of a convex circle, inside which pipes are installed. To create a monolithic base, there are key areas that are combined with each other. When installing this heating system, it is not required to use additional fasteners to fix the pipes. After installing the pipeline, metal heat distribution plates are installed, then the final finishing material is laid on the floor.

The third option is a warm floor system built on a wooden basis. This system involves the use of a trimmingboard, plywood or other wood -based materials, as a coating for the installation of a system.

Small stripes are built from wooden plates, each length of not more than 18 cm. They are laid on the floor made of wood. The pipeline is mounted between the stripes, and then heat distributors are fixed using screws. After mounting the pipes, the floor surface is covered with a plastic film, then a floor of gypsum fiber sheets is installed, which distribute the temperature in the underground space. It is on them that the main finish is attached.

To ensure the high -quality distribution of the coolant through the entire system, it is recommended to use the collector. It is to him that the outgoing and outgoing pipes are connected.

Considering the question of how to make a water warm floor in the house, you should familiarize yourself with the layout of the pipeline system, there are several of them:

- pipes are laid in the form of a snake;

- Snails;

- Combinations of different ways.

Laying a pipe in the form of a snake implies the installation of pipes parallel to each other.

According to the scheme of the snail, the pipe is located first around the perimeter of the room, with a gradual narrowing to the center. The last option involves a combination of these two methods.

Calculation of a warm water floor: process features

The procedure for calculating for the arrangement of a warm floor on a water basis should be taken into account by some points, namely:

- the use of gender as a basic or additional heating option;

- type of building;

- further type of finish;

- total area and purpose of the premises;

- Heat loss and their meaning.

To determine the last factor, namely heat loss, you should take into account the following nuances:

- type of materials from which the house was erected;

- Type of windows: standard, single or double windows;

- the number of windows and doors;

- climatic features of the region;

- The presence of additional heating devices.

Each type of room has a certain temperature to which the floor should heat up, namely:

- In the residential area, it is 29 degrees;

- in a zone with high heating - 35 degrees;

- with a high humidity of 32 degrees;

- When finishing using parquet - 26.

Keep in mind that before arranging a warm floor, you should foresee the type of coating, which will act as decoration.

Installation of a warm floor: a collector and its features

The collector cabinet is the location of such a device as a collector. To install this cabinet, you need a place of about 500x500 or 400x600 mm.

In addition, some owners of the warm floor intend to mount the cabinet directly into the wall, while others leave it in a hinged position.

After the installation of the cabinet in which the collector is located, the supply and return pipes is installed, along which hot and cold water flows. The collector that is responsible for the distribution of hot water is connected to the supply pipe, and the return pipe is connected to the collector, which joins the final sections of the pipes.

At the site of connection of water pipes with the collector, a locking crane is installed, which will allow repairing the entire system, if necessary. On the other side of the collector, the presence of a drain crane is required.

In order to qualitatively and quickly adjust the temperature in the room, you should take care of the presence of the mixer and regulatory screws. There are special types of collectors, which include all the parts necessary for adjustment and work, but their cost is much higher than that of ordinary collectors.

Laying a warm water floor on a concrete base

The procedure for laying warm feed on a concrete basis involves the implementation of such processes:

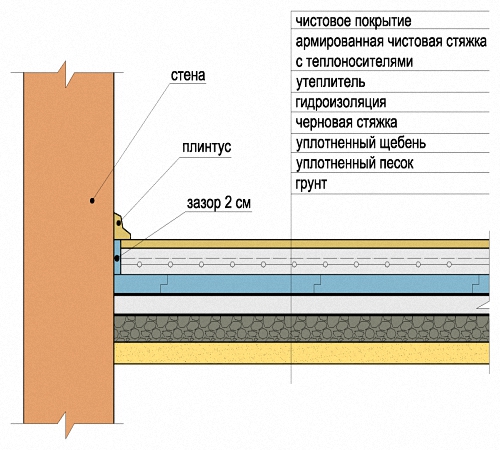

1. Cleaning and alignment of the base.

For starters, dirt, dust and any garbage are removed from the surface. Further, it is checked for the absence of differences and evenness. If the size of the difference is not more than 10 mm, then proceed to the next stage of work. In the presence of more serious differences, the surface is first aligned. For this purpose, the arrangement of bulk black floor should be provided.

2. Ensuring waterproofing.

Using this stage, the ingress and contact of moisture with a warm floor is prevented.

3. Installation of brown insulation.

The use of a damper tape installed around the perimeter of the room will help to carry out this process.

4. Installation of vapor barrier materials.

In order to save on materials, instead of a separate waterproofing and vapor barrier, a waterproofing membrane is used, one side of which is distinguished by a waterproof film, and the second easily passes steam.

5. Strengthening.

For these purposes, a reinforcing mesh is suitable, the section of which is about 150-200 mm. It is such material that will ensure the ease of laying the pipeline system. It is possible to install the reinforcement before laying pipes or after performing this process. It is better to give preference to the second option, since with the help of reinforcement it will be possible to evenly distribute the entire load on the floor.

6. Installation of a warm floor.

First, the pipe is connected to the collector. If the warm floor is used as a single heating element, then its installation is carried out with an interval of 150-200 mm. Otherwise, it is allowed to lay pipes in steps of a maximum of 300 mm. The pipe is connected to the net using special clips. Do not fix the clips too hard, as there is a risk of damage during the heating of the system.

7. The performance of the system and its verification.

Warm floors of water installation, after installing them, require a mandatory check for serviceability. To do this, the system turns on for a certain time, for example for three hours. During this process, the system should warm up, and water - evenly distributed on the surface.

8. The filling procedure.

The screed should exceed the pipeline system by 20-30 mm, the type of screed should be wet.

After drying out the screed, after about a month, install soundproofing materials and make a finish. It is forbidden to turn on the warm floor until the screed is completely dry, since there is a risk of cracking it. On this, the warm water of the water with your own hands is considered ready for operation.

Water warm floor video: