Any repair ends with the installation of a skirting board, without which the room will have ...

|

|

Setting the floor Mandatory stage in the course of repair -... |

By finishing the basement of the building with a brick, it is possible to give him grace and ... |

DIY warm floor repairs

Imagine such a situation - cold days have come, you turned on the system of warm floor, but it does not warm at all ... What should be done in this case? Of course, you can purchase a new electric floor, but then you will have to start dismantling the tiles, then with a screed, and then laying a new warm floor. But this will cause a significant blow to your wallet. But the repair of the warm floor will cost much cheaper, and you can save your funds for more pleasant costs, and with them the warmth in your house.

Table of contents:

- The principle of work of the warm floor

- The causes of the malfunction

- Errors when installing a warm floor system

The principle of work of the warm floor

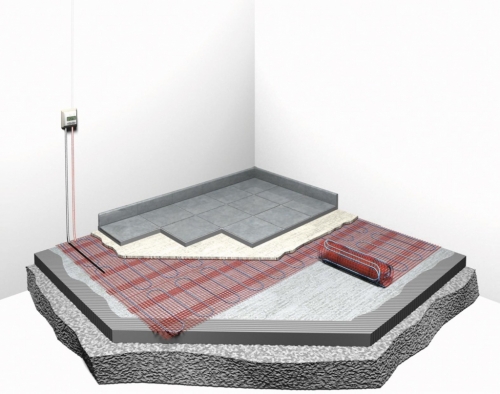

Modern warm floors are a built -in heating system that is mounted in the floor structure. Therefore, the surface turns into a kind of large panel, evenly radiating heat. An electric warm floor is represented by wires, which are located under the tile or screed.

Electricity is supplied to the cable, and it heats up and heats the floor. Before direct supply to the heating element, electricity passes through the thermostat, which allows you to turn on and off the warm floor, as well as adjust the temperature of the warm floors. In addition, when heated, thermoregulator turns off the warm floor automatically, helping to prevent the breakdown of the heating element itself.

A warm floor is called the most convenient type of heating of the room with a uniform distribution of heat around the perimeter and heating of the air. Many owners have already appreciated this method of heating, saving space, a comfortable temperature at the floor level and the absence of unsightly radiators.

The causes of the malfunction

However, there are times when such a good of civilization as a system of warm floors brings a lot of trouble. Before making direct repair of a warm electric floor, you need to find out the reasons for its malfunction. Experts distinguish 3 main problem areas in such a housing heating: thermoregulator, heating element and temperature sensor.

Damage to the heating element

Usually it is not difficult to determine which structural element is the cause of the malfunction. The heating cable most often burns out for a fairly simple reason, it was damaged initially during installation, and during the operation of the defect was not noticed. Sometimes the owners cause damage to the wire.

If some repair work was carried out before the breakdown in the house using a saw or drill, then the heating element can easily be damaged. For example, when installing a door stop, the cable was accidentally drilled. After you find the places of a defective wire, you must start repairing a warm floor with your own hands by replacing it.

It is customary to dismantle the coating on the repair area, opening the screed. Scared or ragged veins are cleaned and connected using sleeves of suitable diameter, squeezing press roles. At the junction, you need to fix the heat -mustard coupling, which should be heated with a construction hairdryer and let cool. Cooling, it is able to contract and firmly seal the connection. The repair site of the warm floor cable is poured with cement from above.

Damage to the temperature sensor

If the temperature sensor has failed, then the base will work, but not at all power. In this case, upon reaching a certain temperature, it will not turn off on its own, and as a result, electricity consumption will increase significantly. Attempted attempts to reduce the temperature of the base will become unsuccessful.

In the event of a malfunction, it is worth repairing a warm floor sensor by replacing it. In this case, there is no need to open the walls or base, because the sensor is laid during installation in a special corrugated tube. In this case, having removed the old equipment from a corrugated tube, it should be noted to establish a new apparatus.

There are disorders of the technology when the sensor is installed in the screed without using the tube. If the old device is walled directly into the base itself, then it is recommended to install an additional sensor under the thermostat. In this situation, the response of the sensor is determined by the movement of air in the room, and not the internal conditions of the system. The thermostat that has become unusable should be replaced by a new one.

Water water repair

The service life of a warm water floor with proper installation and use is half a century. The guarantor of this outcome of events is the installation of high -quality whole pipes. If during the repair the pipe was damaged by a grinder or perforator, you need to immediately repair a waterproof water. Without removing the nozzle of a grinder or perforator, the water should be turned off.

For work, you will need two fitting, press and a piece of pipe. Clean the place around the gust, freeing access to the pipe. Wash with insulation the ends of the hose to avoid getting into the pipe of dirt. You can wear rubber gloves on them. The end of the prepared pipe must be inserted into the fitting at the end of the repair site.

From the inserted piece of the pipe, it is worth cutting off the excess, connect it to the second end of the pipeline and press it. To check, start the water. If everything is fine, then you can pour the repaired area with a screed.

It is not possible to determine the breakdown

When the causes of the malfunction are unclear, it is recommended to measure the supply voltage. The technical documents indicate the operating voltage. The result should not deviate from the above parameter in the instructions by more than 5%. Pay attention to the inclusion indication.

If the light does not burn, check the voltage on the conclusions. The absence of voltage indicates a malfunction of the sensor or thermostat, as well as weakened contacts on the thermostat. You need to check the remote temperature sensor. Disconnect it from the thermostat and measure the resistance, which should be within 5-30 kOhm. Exact indications are indicated in the instructions.

When checking the thermostat, you need to turn off the warming cable from it. If a malfunction is not detected in the thermostat and sensor, it is recommended to look for the cause of the lack of heat in the heating element. To do this, it is necessary to measure the resistance of the insulation and cable, and then verify with the indicators that are indicated in the equipment of the equipment. The reduced indicator of insulation resistance indicates a break in the heating cable and the need to repair the warm floor of Teplolux. You can find out where the exact place of the defect is with special equipment.

Errors when installing a warm floor system

To prevent various breakdowns in the system of warm floor, it is recommended to carry out qualified installation. When installing a warm floor, you need to know several nuances:

- When calculating the length of the heating element, it is worth considering the area that is not busy with furniture, because the heating cable is not laid under the interior items due to the possible failure and overheating.

- The heating element should be bought a strictly necessary size. During installation, cutting the cable leads to a breakdown of the system, as its strength is reduced.

- You can not lay a heating cable on a dirty surface. Before performing the work, the surface is exhausted and cleaned.

- During laying on the cable, it is not recommended to walk. A hard sole will hurt him.

- The temperature sensor must be installed in such a way that in the case of repairing the heat regulator of the warm floor, there is access to it. It must be placed in a corrugated tube.

- You can not leave around the heating element of voids. This can provoke overheating of the cable and its breakdown.

- It is advisable to develop a scheme for installation of heating elements and indicate dimensions. It will be required during the repair so as not to accidentally hurt the pipe or cable.

- Checking the wire after laying is carried out by measuring the resistance. It is not recommended to turn on the system until the screed is completely dried.

- Spurge resistance before and after installing the system warm floor. It must correspond to the value indicated in the technical passport.

Know, it is better to prevent the occurrence of a problem in advance than then to eliminate the results of your negligence in the future. Correct and high -quality installation of the system warm floors will avoid the transient repair of the warm floor of DEVI. And the use of laying scheme during the repair of the laying scheme will protect the system from breakdown with construction tools and a perforator.